Checking Fixtures for Stamped Parts: Engineering Guide and Specs

TL;DR

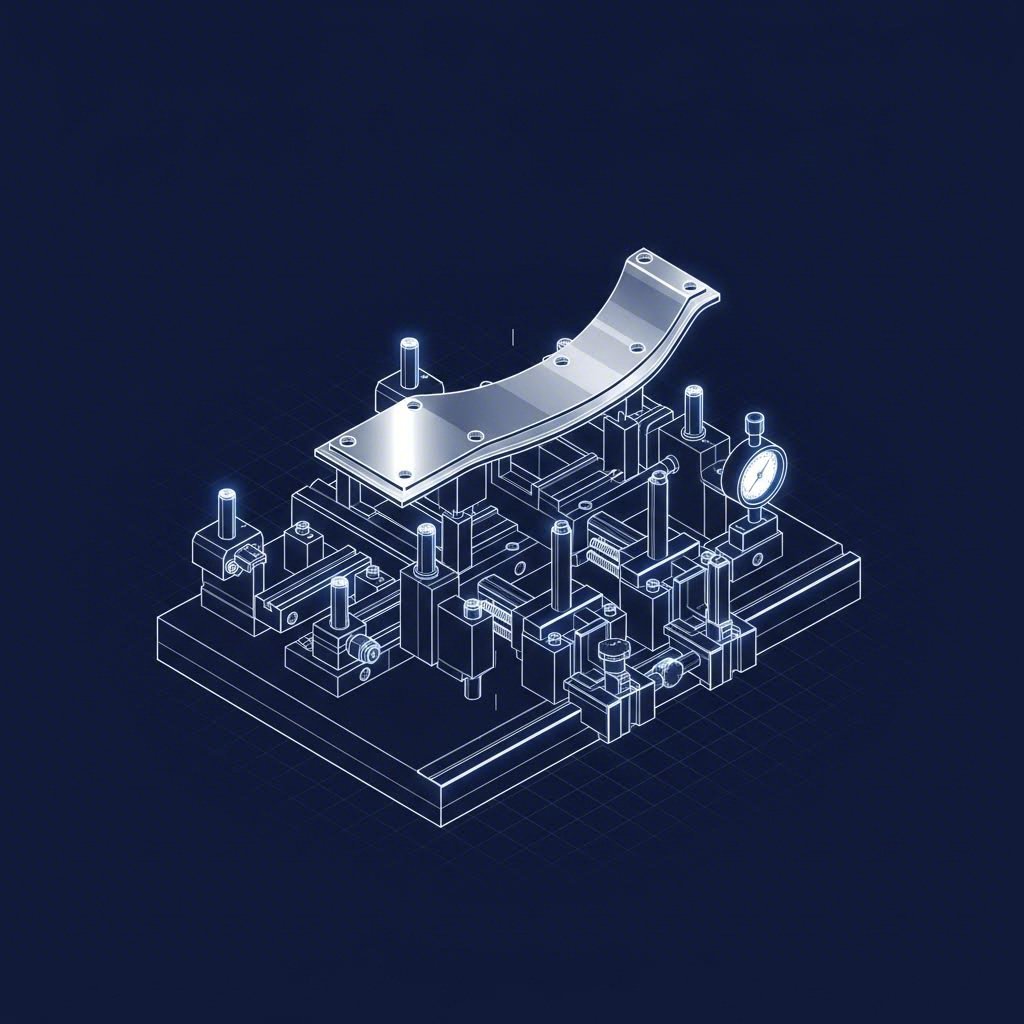

Checking fixtures for stamped parts are precision quality assurance tools designed to securely hold a workpiece in a simulated vehicle position, allowing for the verification of its dimensional accuracy, geometric tolerances (GD&T), and fit. Unlike general-purpose measuring tools, these fixtures provide a physical standard that represents the "perfect body," enabling manufacturers to rapidly detect deviations, ensure process stability, and validate parts against CAD data.

By transforming invisible dimensional errors into visible gaps or interferences, checking fixtures serve as a critical line of defense in process control. They bridge the gap between slow, high-precision CMM inspections and high-speed production needs, offering immediate feedback to stamping lines to reduce scrap and ensure that complex assemblies—like fenders or door panels—align perfectly during final production.

Fundamentals: What Are Checking Fixtures for Stamped Parts?

At its core, a checking fixture for stamped parts is a dedicated inspection tool used to verify that a manufactured sheet metal component meets the engineering design intent. Unlike a Coordinate Measuring Machine (CMM), which is a flexible but slower programmable device, a checking fixture is purpose-built for a specific part number. It physically replicates the mounting points and mating surfaces of the final assembly—such as a vehicle frame—to simulate how the part will behave in reality.

The primary role of these fixtures is process control. In high-volume stamping operations, waiting for a CMM report can take hours, during which thousands of potentially defective parts could be produced. A checking fixture allows operators on the shop floor to load a part, clamp it, and immediately check critical attributes (like hole positions, trim lines, and surface profiles) using simple Go/No-Go pins or feeler gauges. This immediacy allows for real-time adjustments to the stamping press or die, significantly reducing material waste.

It is important to distinguish between a holding fixture and a full checking fixture. A CMM holding fixture is designed solely to secure the part in a stress-free state for a probe to measure, whereas a full checking fixture contains integrated measuring elements—such as dial indicators, scribe lines, and template profiles—that allow for independent verification without an external measuring machine.

Types of Checking Fixtures: From Single Part to Assembly

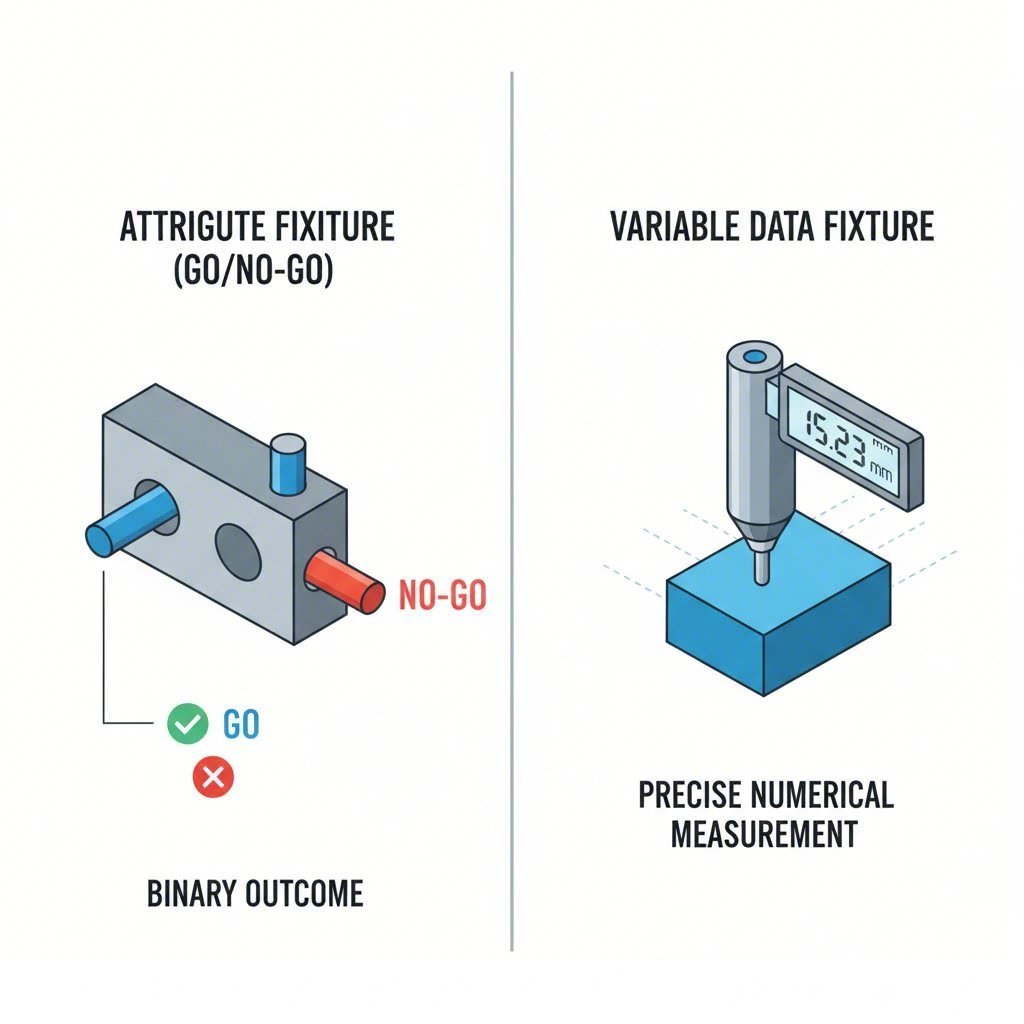

Selecting the correct fixture type depends on the production stage (prototype vs. mass production) and the data required (attribute vs. variable). Engineers must choose between speed and data depth.

1. Single-Part Attribute Fixtures (Go/No-Go)

These are the workhorses of mass production. Attribute fixtures use simple "pass/fail" mechanisms to check features. For example, if a locating pin fits into a hole, the hole is the correct size and location; if it doesn't, the part is rejected. These fixtures are ideal for rapid inline inspection where the goal is to prevent bad parts from moving downstream.

2. Variable Data Fixtures (SPC)

When specific numerical data is needed for Statistical Process Control (SPC), variable data fixtures are used. Instead of a simple pin, these fixtures incorporate dial indicators, LVDT sensors, or digital probes to measure the exact deviation from the nominal value (e.g., "the flange is 0.5mm too long"). This data is crucial for analyzing trend lines and predicting die wear before parts go out of tolerance.

3. Assembly and Sub-Assembly Fixtures

Stamped parts rarely exist in isolation. Assembly fixtures verify the relationship between two or more mated components, such as a door inner and outer panel. These fixtures focus on "flush and gap" analysis, ensuring that when the parts are welded or hemmed, the final assembly fits the vehicle body correctly. They often simulate the mounting points of adjacent parts, like the hood or bumper, to check for interference.

| Fixture Type | Primary Function | Typical Usage |

|---|---|---|

| Attribute (Go/No-Go) | Rapid Pass/Fail check | High-volume production line |

| Variable (SPC) | Detailed numerical measurement | Quality lab, process capability studies |

| CMM Holding | Secure part for CMM probing | First-article inspection, complex profiling |

| PIMM (Match Check) | Simulate mating parts | Prototyping, assembly verification |

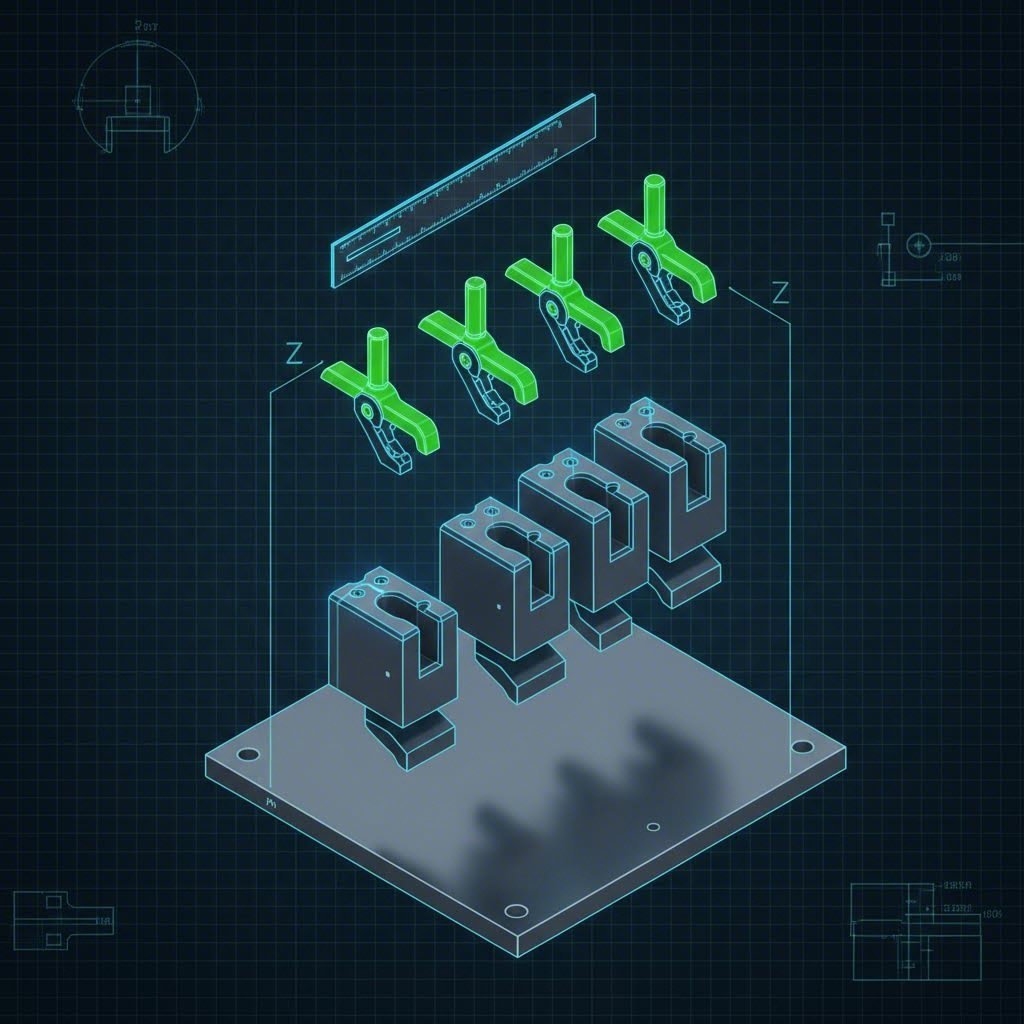

Critical Components & Anatomy of a Fixture

A high-quality checking fixture is an assembly of precision-engineered components, each serving a distinct function in the "Locate, Clamp, Measure" workflow.

- Base Plate: The foundation of the fixture, typically machined from aluminum or steel for rigidity. It must provide a flat, stable reference plane (often marked with grid lines) to ensure repeatability. For large body side fixtures, cast iron or welded steel structures are used to prevent warping over time.

- Locating Elements (RPS): These are the most critical components. Using the Reference Point System (RPS), locating pins and blocks constrain the part's degrees of freedom, positioning it exactly as it will be mounted in the vehicle. Hardened steel (often HRC 55-60) is used to resist wear from repeated loading.

- Clamping Units: Once located, the part must be held securely. Toggle clamps or pneumatic swing clamps are positioned at specific "net pads" to apply pressure without deforming the sheet metal. The clamping sequence is often prescribed to mimic the assembly process.

- Measuring Elements: These include flush and gap blocks (checked with feeler gauges), scribing lines (for visual trim checks), and bushings for checking pins. Modern fixtures may also integrate digital readouts for critical control points.

Design Standards & Technical Specifications

The design of a checking fixture is governed by strict engineering standards to ensure it is more precise than the part it measures. A common rule of thumb is the 10% Rule: the tolerance of the fixture must be 10% of the part's tolerance. If a stamped hole has a tolerance of ±0.5mm, the fixture's locating pin position must be accurate to within ±0.05mm.

Material selection is equally vital. While aluminum (AL6061 or AL7075) is popular for its light weight and ease of machining, high-wear areas like locating blocks and net pads must be made of hardened tool steel or coated with TiN (Titanium Nitride) to prevent degradation. Color coding is also standardized: typically, clamping units are color-coded (e.g., red for "clamp here") and "Go" gauges are green while "No-Go" are red, facilitating intuitive operation for workers.

For manufacturers transitioning from rapid prototyping to mass production—much like the comprehensive stamping solutions offered by Shaoyi Metal Technology—selecting the right fixture specifications is critical. Whether validating a prototype control arm or inspecting a high-volume subframe, the fixture design must align with global standards (such as IATF 16949) to ensure that the rigorous quality demands of automotive OEMs are consistently met.

Operational Guide: How to Use & Maintain

Even the most precise fixture is useless without correct operation. The inspection process typically follows a standard sequence: Load, Locate, Clamp, Inspect. Operators must clean the locating pads before every cycle to ensure no metal shavings or dust compromise the part's position.

Maintenance is critical for long-term accuracy. Fixtures should undergo a certification check (typically annually or biannually) using a CMM to verify that the locating points have not drifted due to wear or impact. Daily checks should include inspecting clamps for looseness and verifying that checking pins are not bent. If a fixture is dropped or damaged, it must be tagged out of service immediately until recalibrated.

Ensuring Production Quality

Checking fixtures for stamped parts are the bridge between design theory and manufacturing reality. They translate complex GD&T data into physical, actionable checks that shop floor teams can perform in seconds. By investing in the right type of fixture—whether a simple attribute gauge for a bracket or a complex assembly rig for a side panel—manufacturers gain the process control necessary to deliver defect-free components.

Ultimately, the value of a checking fixture lies in its ability to predict and prevent issues. By making deviations visible early in the process, these tools protect the integrity of the final assembly, reduce costly rework, and maintain the trust of automotive clients who demand perfection in every curve and contour.

Frequently Asked Questions

1. What is the difference between a jig and a fixture?

While often used interchangeably, they have distinct functions. A fixture is designed to hold and locate a workpiece securely for inspection or manufacturing (like welding or assembly) but does not guide the tool. A jig not only holds the part but also physically guides the cutting or drilling tool (e.g., a drill jig guides the drill bit). In quality control, we almost exclusively use fixtures.

2. How often should a checking fixture be calibrated?

Calibration frequency depends on usage volume and criticality, but a general standard is once per year. High-volume production fixtures may require semi-annual certification. Additionally, calibration should be performed immediately if the fixture is dropped, modified, or shows signs of excessive wear on locating pins.

3. Can a checking fixture replace a CMM?

No, they are complementary. A CMM provides absolute certification and detailed analysis for troubleshooting or initial part approval (PPAP). A checking fixture provides speed and 100% inspection capability on the production line. The CMM is often used to certify the checking fixture itself.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —