Cost of Automotive Stamping Dies: Budgeting for Progressive Tooling

TL;DR

Automotive stamping die costs range dramatically based on size and complexity, from approximately $3,000 for simple soft tooling (brackets, clips) to over $1,000,000 for a full Class-A body panel line (fenders, hoods). For mid-sized precision components, a progressive die typically averages around $15,000 to $30,000. The decision heavily depends on production volume: while stamping tooling requires a high upfront investment, it offers the lowest per-unit price for quantities exceeding 10,000–20,000 parts annually.

Breakdown by Die Type: Progressive vs. Line vs. Soft Tooling

The single biggest factor influencing the cost of automotive stamping dies is the technology chosen to manufacture the part. Engineers must balance the upfront tooling budget against the expected production speed and part volume.

Progressive Dies ($15,000 – $60,000+)

Progressive dies are the workhorses of the automotive industry for small-to-medium structural parts like brackets, clips, and connectors. In this setup, a metal strip feeds through a single die with multiple stations—cutting, bending, and forming the part in sequential steps with every stroke of the press.

According to industry data from manufacturers like Bazz Houston, the average progressive die costs approximately $30,000. This cost can dip to $15,000 for simpler geometries or exceed $60,000 for complex parts requiring tight tolerances. While the initial price is significant, progressive dies are highly efficient, often running at 60–100+ strokes per minute, which drives the piece-price down to pennies.

Transfer and Line Dies ($100,000 – $1,000,000+)

For large automotive body panels (Class A surfaces) like doors, hoods, and fenders, progressive dies are usually unsuitable due to the size of the part and the complexity of the forming required. Instead, manufacturers use Line Dies or Transfer Dies.

Real-world sourcing data indicates that a single drawing die (the first step in forming a fender) often costs between $250,000 and $500,000. However, a finished panel requires a full line of dies—Draw, Trim, Flange, and Pierce—pushing the total package cost to between $500,000 and $1,000,000. These dies require massive casting beds, extensive CNC machining, and manual finishing (spotting) to ensure perfect surface quality.

Soft Tooling and Prototyping ($3,000 – $15,000)

For low-volume production (under 5,000 parts) or prototyping, "soft tooling" provides a budget-friendly alternative. These dies often use single-hit tooling or cheaper, pre-hardened steels rather than durable carbide. Costs can be as low as $3,000 for simple blanking tools. While soft tooling wears out faster and requires more manual labor per part, it allows manufacturers to validate designs without committing to a six-figure asset.

Key Cost Drivers: Materials, Complexity, and Volume

Understanding what drives the price of a quote allows procurement managers to value-engineer their requests. The total cost of an automotive stamping die is generally composed of three main buckets: material, machining, and validation.

- Die Material (20–40% of Total Cost): The steel used to build the die itself is a major expense. For high-volume automotive runs (500,000+ hits), toolmakers use premium grades like SKD11 or solid carbide, which are expensive but resistant to wear. For shorter runs, cheaper alloys like Cr12MoV may be used to reduce costs, though they require more frequent sharpening.

- Machining and Complexity (30–50% of Total Cost): Every feature on a part—every hole, tab, and radius—requires a corresponding station in the die. Adding complexity increases the hours required for CNC machining and Wire EDM (Electrical Discharge Machining). A die with 15 stations will cost significantly more than one with 5, simply due to the machining hours involved.

- Tryout and Validation (10–15% of Total Cost): The "Tryout" phase is where the die is tested in a press to ensure it produces parts to spec. This is critical for automotive components requiring high precision. If a die fails to hold tolerance during tryout, it requires expensive manual rework.

Strategic Sourcing and Production Volume

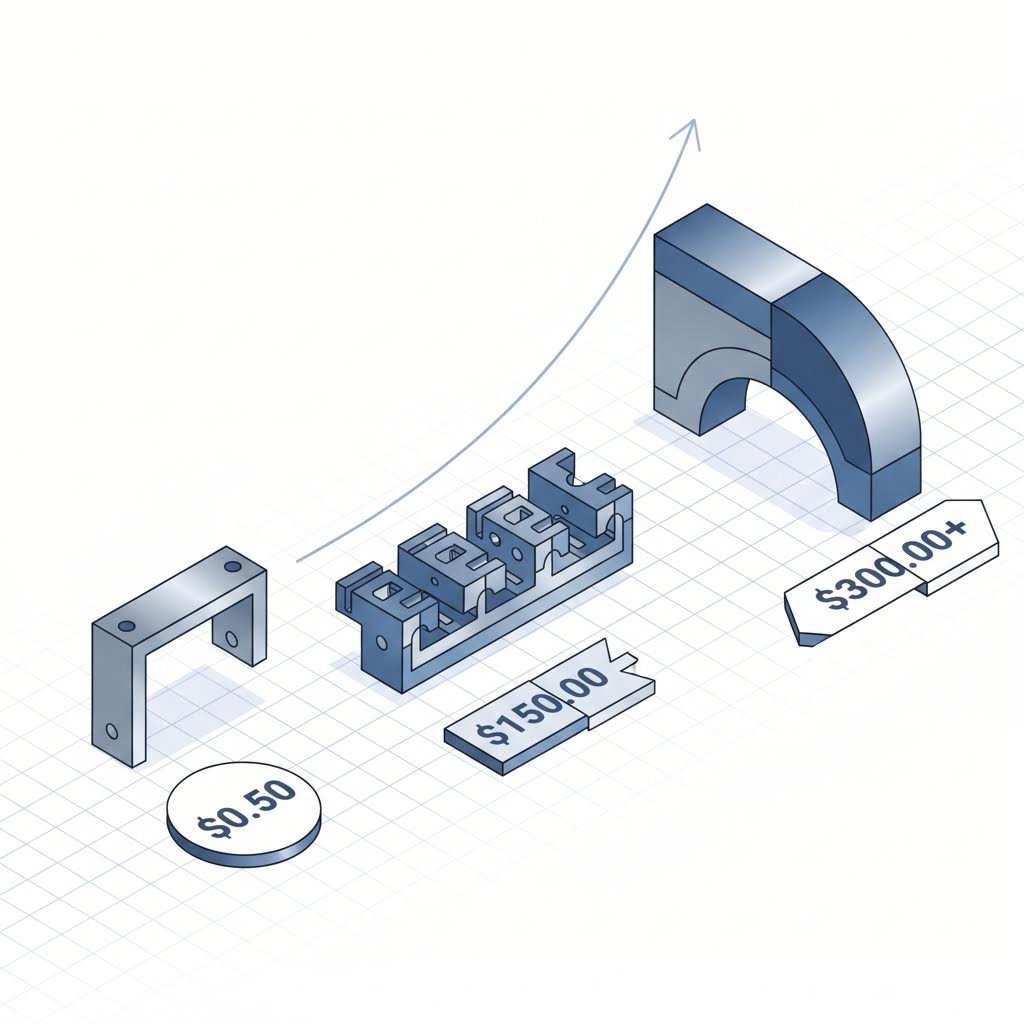

The economics of metal stamping are defined by the "break-even" point. Stamping is rarely cost-effective for quantities under 2,000 units because the amortization of the tooling adds too much to the per-part cost. For these lower volumes, processes like laser cutting or press brake forming are often superior.

However, once volume exceeds 10,000 to 20,000 units annually, the investment in a hard die pays off rapidly. For example, a $30,000 progressive die might reduce the part cost from $5.00 (laser cut) to $0.50 (stamped). Over 20,000 parts, the savings ($90,000) easily cover the initial tooling expense.

For manufacturers seeking a partner capable of managing this transition, Shaoyi Metal Technology offers a strategic advantage. With IATF 16949 certification and press capabilities up to 600 tons, they bridge the gap between rapid prototyping and high-volume mass production. Their ability to engineer cost-effective tooling solutions helps automotive OEMs move from design validation to full-scale manufacturing while maintaining strict adherence to global standards.

Hidden Costs: Maintenance and Logistics

The purchase price of the die is not the final cost. Automotive stamping dies require ongoing maintenance to maintain part quality. Sharpening and shimming are routine expenses, typically estimated at 5–10% of the die's value annually depending on usage intensity. Neglecting this maintenance leads to burrs on parts and potential catastrophic die failure.

Logistics also play a role, particularly for offshore tooling. While Asian markets often provide dies at 30% lower cost than Western counterparts, the shipping of heavy tool steel (often weighing several tons) adds significant expense and lead time. Furthermore, if a die requires modification after delivery, the lack of local support can lead to expensive downtime.

Conclusion: Balancing Budget and Performance

Budgeting for automotive stamping dies requires a clear understanding of the trade-off between upfront capital expenditure (CapEx) and long-term operating expense (OpEx). While a $30,000 progressive die or a $500,000 fender line may seem expensive initially, these tools are the only viable path to achieving the low unit costs required for mass automotive production.

Success lies in accurately forecasting annual volumes and selecting the right class of tooling—Soft, Progressive, or Transfer—to match the product's lifecycle. By accounting for material grades, complexity, and maintenance early in the design phase, engineers and buyers can prevent budget overruns and ensure a smooth launch.

Frequently Asked Questions

1. How much does a metal stamping die cost on average?

A typical progressive die for mid-sized automotive parts ranges from $15,000 to $30,000. However, costs vary widely: simple prototype tooling can be as low as $3,000, while complex Class-A body panel dies often exceed $500,000.

2. What is the difference between die cutting and metal stamping?

Die cutting typically refers to shearing softer materials (like gaskets, fabrics, or thin foils) using a steel rule die, similar to a cookie cutter. Metal stamping is a high-tonnage industrial process that uses hardened steel dies to not only cut but also form, draw, and bend sheet metal into complex 3D shapes.

3. Why is automotive tooling so expensive?

The cost reflects the precision engineering, high-grade tool steels, and extensive machining hours required to build the die. Automotive dies must endure millions of high-impact cycles while maintaining micron-level tolerances, requiring robust construction and expensive materials like carbide or SKD11 steel.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —