Stamping Bumper Reinforcement Bars: Engineering Safety & Strength

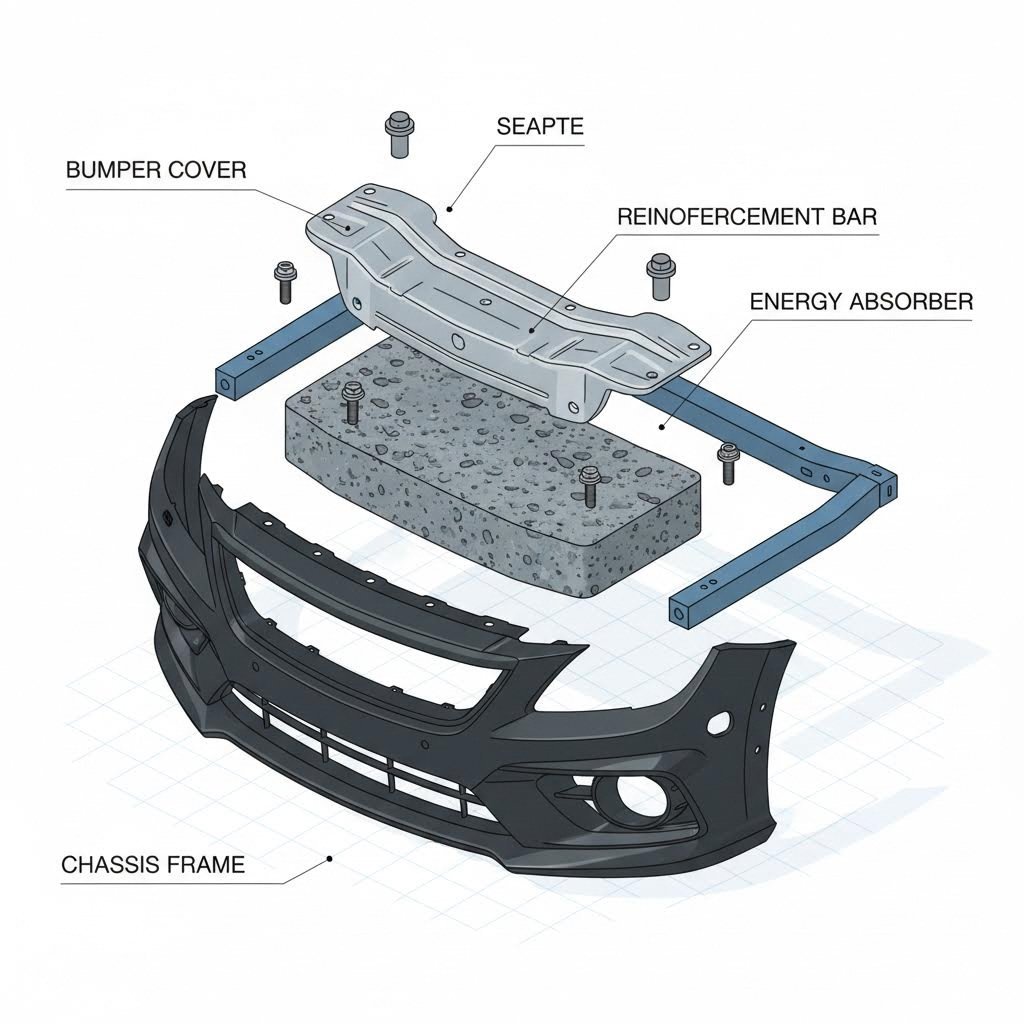

<h2>TL;DR</h2><p>Stamping bumper reinforcement bars is a critical automotive manufacturing process that transforms ultra-high-strength steel (UHSS) or aluminum into the structural impact beams hidden behind a vehicle's cosmetic bumper cover. Unlike welded or tubular aftermarket options, these stamped components are engineered to absorb kinetic energy through controlled deformation, protecting the chassis and passengers during a collision. While cold stamping is common for standard steel, hot stamping (press hardening) is increasingly used to produce lighter, stronger bars that meet modern fuel efficiency and safety standards.</p><h2>What Are Stamped Bumper Reinforcement Bars?</h2><p>A bumper reinforcement bar, often called an impact bar or crash beam, is the rigid structural component located immediately behind the plastic bumper cover and energy-absorbing foam. While the outer cover provides aerodynamics and aesthetics, the reinforcement bar handles the heavy lifting during an impact. It is the primary shield that distributes collision forces across the vehicle’s frame rails, preventing localized damage to the engine bay or passenger cabin.</p><p>The term "stamped" refers to the specific manufacturing method used to create these beams. In mass-production vehicles, Original Equipment Manufacturers (OEMs) almost exclusively use stamped reinforcement bars. A massive die presses a flat sheet of metal into a complex, three-dimensional shape in a single or progressive hit. This process creates a continuous, seam-free structure that is optimized for predictable crumpling—a key requirement for modern crumple zones.</p><p>This distinction is vital for both engineers and vehicle owners. A stamped bar is designed to be a "sacrificial" part. It effectively commits suicide to save the rest of the car, deforming plastically to dissipate energy. This differs significantly from rigid off-road plate bumpers or aftermarket tubular bars, which are often designed to resist deformation, potentially transferring more shock to the vehicle's frame and occupants.</p><h2>The Manufacturing Process: Cold vs. Hot Stamping</h2><p>Understanding the quality of a bumper reinforcement bar requires looking at how it is made. The stamping process determines not just the shape, but the metallurgical properties of the final component. Manufacturers generally employ one of two methods depending on the required strength-to-weight ratio.</p><p><strong>Cold Stamping</strong> is the traditional method where steel sheets are pressed at room temperature. This is cost-effective and suitable for standard high-strength steel grades. However, as steel gets stronger, it becomes harder to form without cracking, limiting the complexity of shapes that can be cold-stamped. For standard replacement parts, cold stamping remains a dominant and reliable method.</p><p><strong>Hot Stamping (Press Hardening)</strong> represents the cutting edge of safety technology. In this process, boron steel sheets are heated to over 900°C (1,650°F) until they become malleable. The red-hot steel is then stamped in a cooled die, which quenches the part simultaneously. This rapid cooling transforms the steel’s microstructure into martensite, boosting tensile strength from around 50 ksi to over 200 ksi (1,500 MPa). This allows OEMs to use thinner, lighter bars that offer superior crash protection—essential for improving fuel economy without compromising safety.</p><p>For companies seeking to bridge the gap between prototype engineering and mass production, specialized partners like <a href="https://www.shao-yi.com/auto-stamping-parts/">Shaoyi Metal Technology</a> provide comprehensive stamping solutions. With press capabilities up to 600 tons and IATF 16949 certification, they can handle the rigorous demands of producing critical safety components like reinforcements and subframes, ensuring that the transition from design to finished part meets global OEM standards.</p><h2>Material Science: Why Steel Grade Matters</h2><p>Not all metal bars are created equal. The material chosen for stamping bumper reinforcement bars dictates how the vehicle behaves in a crash. The industry has moved far beyond basic mild steel.</p><ul><li><strong>Ultra-High-Strength Steel (UHSS):</strong> This is the standard for modern OEM crash beams. UHSS offers an incredible strength-to-weight ratio. During the stamping process, the material often undergoes "work hardening," becoming even stronger as it is deformed. This makes it difficult to repair but excellent for protecting passengers.</li><li><strong>Aluminum Alloys:</strong> Used frequently in luxury and electric vehicles (EVs) to offset battery weight. Aluminum bars must be thicker than their steel counterparts to achieve the same crash rating, but they still offer significant weight savings. Stamping aluminum requires precise control to avoid spring-back, where the metal tries to return to its original shape after pressing.</li><li><strong>Aftermarket Chromoly:</strong> Performance enthusiasts often swap stamped factory bars for tubular chromoly supports. While companies like <a href="http://www.bmrsuspension.com/?page=products&productid=3134">BMR Suspension</a> note that factory stamped steel supports add "unnecessary weight" for a drag racer (saving ~4 lbs with a swap), the stamped OEM design is superior for street safety because it covers a wider surface area for impact absorption.</li></ul><h2>Comparison: Stamped vs. Tubular vs. Plate Bumpers</h2><p>When replacing a bumper reinforcement or upgrading for off-road use, buyers face a choice between three distinct manufacturing styles. Each serves a different purpose.</p><table><thead><tr><th>Feature</th><th>Stamped (OEM Style)</th><th>Tubular (Performance)</th><th>Plate (Off-Road)</th></tr></thead><tbody><tr><td><strong>Primary Material</strong></td><td>UHSS or Aluminum</td><td>Chromoly / Mild Steel Tube</td><td>Heavy Gauge Steel Plate</td></tr><tr><td><strong>Crash Behavior</strong></td><td>Crumples to absorb energy</td><td>Rigid; minimal crumple</td><td>Deflects; transfers shock to frame</td></tr><tr><td><strong>Weight</strong></td><td>Moderate to Light (if Hot Stamped)</td><td>Very Light (Weight saving focus)</td><td>Heavy</td></tr><tr><td><strong>Ideal Use Case</strong></td><td>Daily Driving, Restoration</td><td>Drag Racing, Track Use</td><td>Rock Crawling, Heavy Duty</td></tr></tbody></table><p>For the average driver, the stamped bar is the only safe option. It is engineered to work in harmony with the vehicle's airbags. A rigid plate bumper might look tough, but because it doesn't deform, it transmits the shock pulse almost instantly to the sensors, potentially altering airbag timing. Conversely, specialized manufacturers like <a href="https://southernstamping.com/">Southern Stamping</a> produce heavy-duty stamped bumpers for trucks where external durability is prioritized over the hidden crumple zones of passenger cars.</p><h2>Industry Applications & Replacement Guide</h2><p>Bumper reinforcement bars are designed as single-use items. Once they have been involved in a collision, their structural integrity is compromised. Even if the bar looks straight, the internal grain structure of the stamped metal may have micro-fractures or work-hardening stress that will cause it to fail catastrophically in a second impact.</p><h3>When to Replace</h3><p>Replacement is mandatory if there is any visible kink, bend, or deep rust. According to safety experts at <a href="https://www.carparts.com/blog/what-is-a-bumper-reinforcement-when-should-it-be-replaced-quickref/">CarParts.com</a>, you should never attempt to straighten or weld a damaged reinforcement bar. Welding destroys the heat treatment achieved during the stamping process, weakening the steel significantly. If the bar is bent, the mounting points on the frame (crush boxes) should also be inspected carefully.</p><h3>Sourcing: OEM vs. Aftermarket</h3><p>For repairs, you generally have two choices: OEM (Original Equipment Manufacturer) or Aftermarket. OEM stamped bars are guaranteed to fit and meet the exact crash test standards of the vehicle. Aftermarket stamped bars are often more affordable and can be CAPA-certified to ensure they meet similar quality standards. However, ensure the aftermarket part uses the same grade of steel; a cheaper mild steel stamp will not offer the same protection as an OEM hot-stamped boron steel bar.</p><h2>Final Thoughts on Structural Safety</h2><p>The engineering behind stamping bumper reinforcement bars is a balance of physics, metallurgy, and manufacturing precision. These components are the unsung heroes of vehicle safety, transforming raw kinetic energy into controlled deformation to keep passengers safe. Whether you are sourcing parts for a collision repair or evaluating manufacturing partners for a new automotive line, prioritizing the quality of the stamping process and material grade is non-negotiable. For daily driven vehicles, sticking to factory-spec stamped bars ensures that the complex safety systems, from crumple zones to airbag sensors, function exactly as designed.</p><section><h2>Frequently Asked Questions</h2><h3>1. What is the difference between a bumper cover and a reinforcement bar?</h3><p>The bumper cover is the visible plastic or fiberglass shell on the exterior of the car, designed for aerodynamics and styling. The reinforcement bar is the heavy-duty metal beam hidden behind the cover that actually absorbs the impact energy during a crash and protects the frame.</p><h3>2. Can I repair a bent stamped bumper reinforcement bar?</h3><p>No. Stamped reinforcement bars are designed as sacrificial, one-time-use components. Attempting to heat, straighten, or weld the bar alters the metal's temper and structural properties, rendering it unsafe for future impacts. It must always be replaced.</p><h3>3. Why are some reinforcement bars made of aluminum instead of steel?</h3><p>Manufacturers use aluminum to reduce the vehicle's overall weight, which improves fuel economy and handling. While aluminum is lighter, the bars are typically stamped from thicker gauge sheets to achieve impact resistance comparable to ultra-high-strength steel.</p></section>

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —