Boron Steel Hot Stamping Process: Engineering Parameters & Metallurgy

TL;DR

The boron steel hot stamping process (also known as press hardening) is a thermal forming method that transforms low-alloy boron steel—typically 22MnB5—from a ferritic-pearlitic microstructure (~600 MPa) into a fully martensitic state (~1500 MPa). This transformation is achieved by heating the blank to austenitization temperatures (900–950°C) and subsequently forming and quenching it within a water-cooled die at rates exceeding 27°C/s. The process enables the production of complex, lightweight automotive components with ultra-high strength and zero springback, such as B-pillars and roof rails.

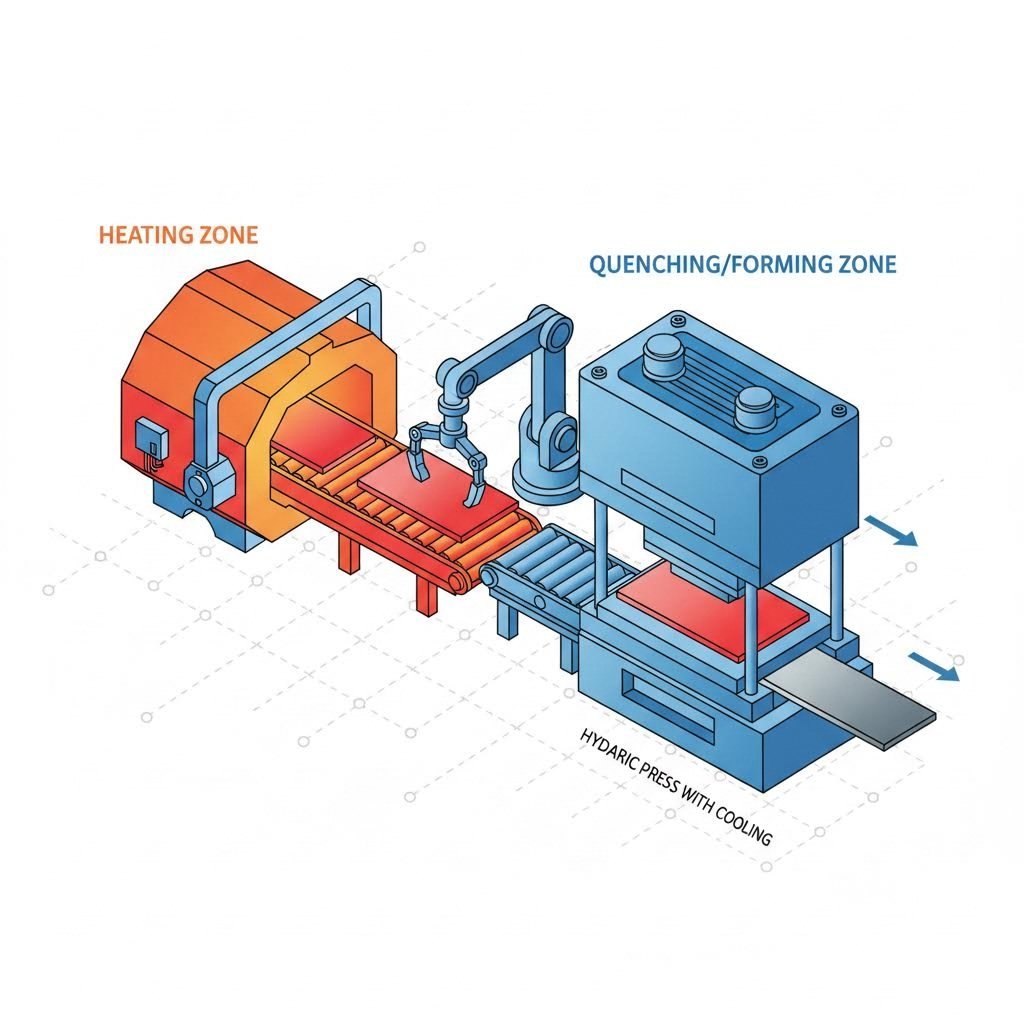

The Physics of Hot Stamping: Direct vs. Indirect Methods

Hot stamping is not a monolithic process; it is categorized into two distinct methodologies—Direct and Indirect—defined by when the forming occurs relative to the thermal cycle. Understanding the distinction is critical for process engineers selecting equipment for specific part geometries.

Direct Hot Stamping

The direct method is the industry standard for the majority of structural components due to its efficiency. In this sequence, a flat blank is first heated in a furnace to approximately 900–950°C to achieve a homogeneous austenitic structure. The hot blank is then transferred rapidly (typically in under 3 seconds) to the press, where it is simultaneously formed and quenched in a cooled tool. This method is cost-effective but is limited by the formability of the material at high temperatures; extreme draw depths can result in thinning or cracking.

Indirect Hot Stamping

For parts with extremely complex geometries that exceed the hot formability limits of the steel, the indirect method is employed. Here, the blank is cold formed to near-net shape (90–95% complete) prior to heating. The pre-formed part is then austenitized in a specialized furnace and transferred to the press for a final calibration and quenching step. While this allows for more intricate shapes, it significantly increases cycle time and capital investment due to the additional cold stamping stage and the need for 3D-shaped furnace handling systems.

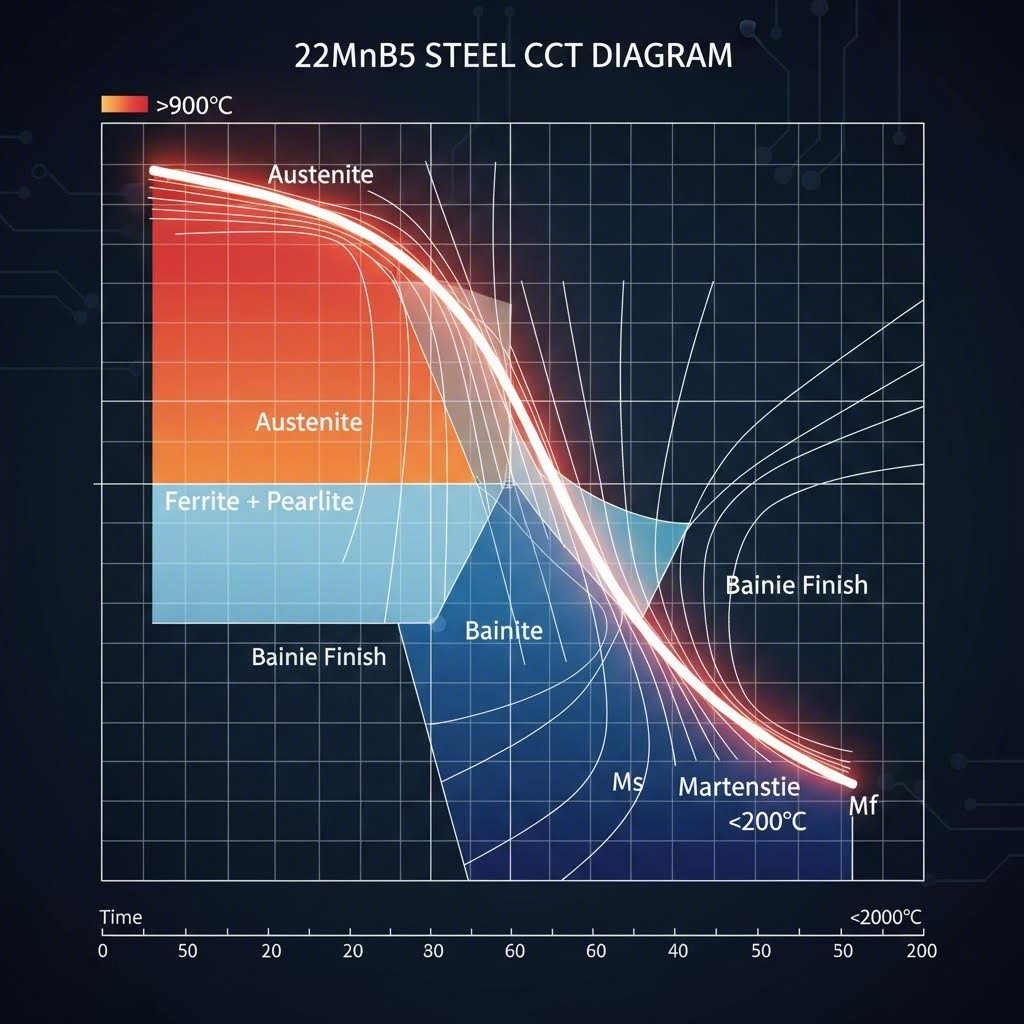

Metallurgical Transformation: Turning 22MnB5 into Martensite

The core value of hot stamping lies in the microstructural phase transformation of 22MnB5 steel. In its as-delivered state, this boron-alloyed steel exhibits a ferritic-pearlitic microstructure with a yield strength of approximately 350–550 MPa and a tensile strength of roughly 600 MPa. The process engineering focuses on manipulating three critical variables to alter this structure.

1. Austenitization

The steel must be heated above its upper critical temperature (Ac3), typically around 850°C, though process setpoints often range from 900°C to 950°C to ensure complete transformation. During the dwell time (usually 4–10 minutes depending on thickness and furnace type), the carbon enters a solid solution, creating austenite. This face-centered cubic (FCC) structure is ductile, allowing for complex forming with lower tonnage compared to cold stamping.

2. The Role of Boron and Cooling Rates

Boron is added to the alloy (0.002–0.005%) specifically to delay the formation of ferrite and pearlite during cooling. This hardenability agent allows the steel to be quenched at a manageable rate—typically >27°C/s (critical cooling rate)—to bypass the nose of the bainite curve and transform directly into martensite. If the cooling rate drops below this threshold, softer phases like bainite form, compromising the final strength.

3. The Al-Si Coating Solution

At temperatures above 700°C, bare steel oxidizes rapidly, forming a hard scale that damages dies and requires post-process shot blasting. To mitigate this, industry-standard materials like Usibor 1500P utilize a pre-applied Aluminum-Silicon (Al-Si) coating. During heating, this coating alloys with the substrate to form an Fe-Al-Si diffusion layer, which prevents scaling and decarburization. This innovation eliminates the need for protective furnace atmospheres and subsequent cleaning steps, streamlining the production line.

The Production Line: Critical Equipment & Parameters

Implementing a hot stamping line requires specialized machinery capable of managing extreme thermal gradients and high tonnage. The capital investment is substantial, often necessitating strategic partnerships for prototyping and overflow production.

- Furnace Technology: Roller hearth furnaces are the standard for high-volume direct hot stamping. They must maintain temperature uniformity within ±5°C to ensure consistent mechanical properties. For indirect processes or lower volumes, chamber furnaces may be used. The total dwell time is a function of blank thickness, typically calculated as t = (thickness × constant) + base time, often resulting in 4–6 minutes for standard gauges.

- Hydraulic and Servo Presses: Unlike cold stamping, the press must dwell at the bottom of the stroke to hold the part against the cooled die surfaces. Hydraulic or servo-hydraulic presses are preferred for their ability to apply and hold maximum tonnage (often 800–1200 tons) for the required quenching time (5–10 seconds). The total cycle time typically ranges from 10 to 30 seconds.

- Tooling and Cooling Channels: The die is a heat exchanger. It must contain intricate internal cooling channels (often drilled or 3D printed) to circulate water at high flow rates. The goal is to extract heat rapidly, maintaining the tool surface temperature below 200°C to ensure efficient quenching.

- Laser Trimming: Because the finished part has a tensile strength of ~1500 MPa, traditional mechanical trimming dies wear out almost instantly. Therefore, laser trimming (typically 5-axis fiber lasers) is the standard method for cutting holes and final perimeters after forming.

For manufacturers navigating the transition from prototype to mass production, the complexity of this equipment chain can be a barrier. Leveraging Shaoyi Metal Technology’s comprehensive stamping solutions can bridge this gap. Their capabilities, which include precision press work up to 600 tons and adherence to IATF 16949 standards, provide the necessary engineering infrastructure to validate process parameters and scale production without immediate heavy capital expenditure.

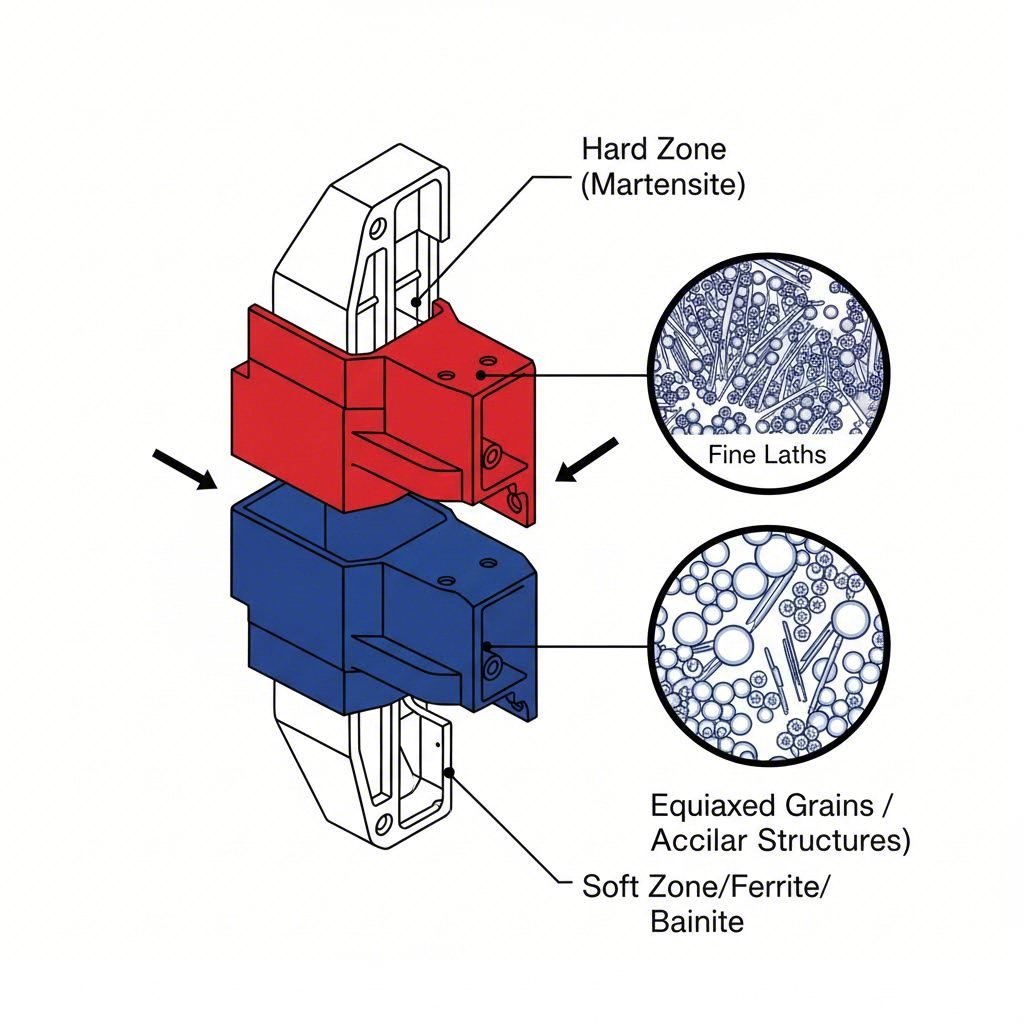

Advanced Applications: Tailored Properties & Soft Zones

Modern vehicle safety design often requires a single component to exhibit dual properties: high intrusion resistance (hard) and high energy absorption (soft). Hot stamping enables this through Tailored Properties.

Soft Zone Technology

By controlling the cooling rate in specific areas of the die, engineers can prevent the martensitic transformation in localized zones. For example, a B-pillar may need a fully martensitic upper section (1500 MPa) to protect the occupant's head, but a softer, ductile lower section (500–700 MPa) to absorb energy during a side impact. This is achieved by insulating specific sections of the tool or using heating elements to keep the die temperature above the martensite start (Ms) temperature, allowing bainite or ferrite to form instead.

Tailor Welded Blanks (TWBs)

Another approach involves laser welding two different steel grades or thicknesses before the hot stamping process. A blank might combine a boron steel sheet with a ductile HSLA steel sheet. When hot stamped, the boron side hardens while the HSLA side retains ductility, creating a part with distinct performance zones without complex die heating systems.

Strategic Analysis: Advantages, Disadvantages & Costs

Deciding to implement hot stamping involves a complex trade-off between performance and cost. The following analysis highlights the key decision factors for automotive engineers.

| Feature | Advantage | Disadvantage |

|---|---|---|

| Strength-to-Weight | Achieves 1500–2000 MPa, allowing for significantly thinner gauges (lightweighting) without compromising safety. | Material costs for Al-Si coated boron steel are higher than standard high-strength steels. |

| Geometric Accuracy | Zero springback due to forming in the austenitic state and stress relief during quenching. | High cycle times (10–30s) compared to cold stamping (2–5s) reduce throughput. |

| Process Complexity | Eliminates the need for multiple forming steps/dies; complex shapes formed in one stroke. | Requires expensive laser trimming and high energy consumption for furnaces. |

| Tooling Maintenance | Lower tonnage required for forming hot steel reduces mechanical stress on press frames. | Thermal fatigue (heat checking) on dies requires expensive tool steels and frequent maintenance. |

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —