Embossing vs Debossing Automotive Parts: The Engineering Guide

TL;DR: The Core Difference for Automotive Engineers

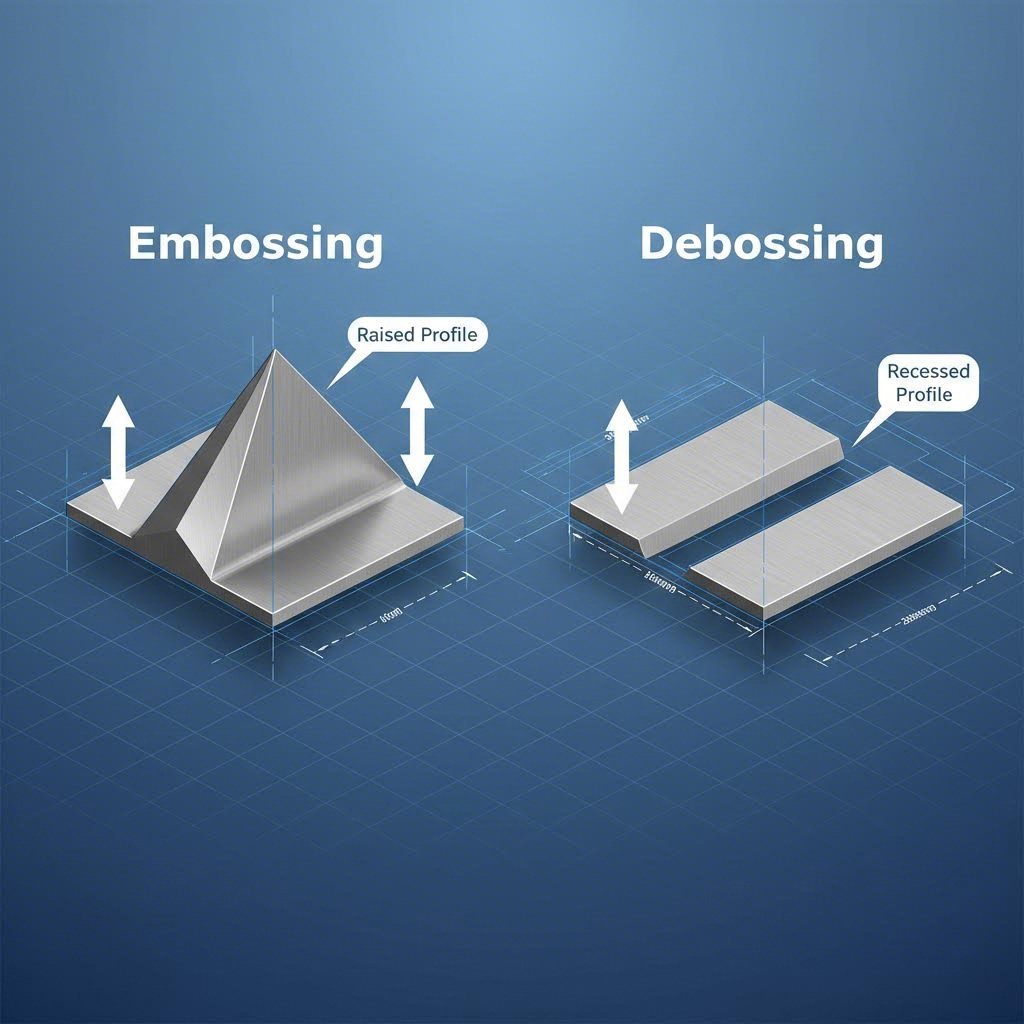

The primary distinction between embossing and debossing lies in the direction of material flow and its subsequent interaction with automotive finishes. Embossing uses matched male and female dies to push material upward, creating raised characters that remain legible even after heavy painting, powder coating, or dirt accumulation. This makes it the standard for static chassis tags and safety components.

Conversely, debossing (often technically referred to as impression stamping or scribing in automotive contexts) pushes material downward into the substrate. While this protects the mark from surface abrasion, it is prone to filling with paint or grease, reducing legibility. However, debossing—specifically via dot peen or scribing—is the industry standard for variable data like unique Vehicle Identification Numbers (VINs) because it does not require expensive fixed die sets for every character change.

The Mechanics of Metal Deflection

Understanding the physics behind these markings is critical for selecting the right tooling. In automotive manufacturing, the choice between embossing and debossing dictates die clearance, press tonnage, and material flow properties.

Die Configurations: Male vs. Female

Embossing is a dual-die process. It requires a mated set: a male die (with raised features) on the bottom and a female die (with recessed features) on top. When the press cycles, the sheet metal or plastic is forced between them, stretching the material upward. This requires precise alignment; if the clearance between dies is too tight, the material will shear or crack; if too loose, the definition is lost.

Debossing, in its purest industrial form, also utilizes a male/female die set but in reverse—pushing the image down. However, in most high-speed automotive stamping lines, what is often called "debossing" is actually Impression Stamping. This uses a single hardened male die to strike the surface against a flat anvil. The key difference is the back of the part: a true debossed part has a raised reverse side (negative), whereas an impression-stamped part remains flat on the back.

Material Flow and Stress

Embossing places the material under significant tensile stress as it stretches to accommodate the raised height. For automotive aluminum (like 5000 or 6000 series) or high-strength steel, engineers must calculate the maximum elongation percentage to prevent micro-fractures. Debossing compresses the material, work-hardening the localized area. This compression can actually strengthen the part at the mark site, whereas embossing can create stress risers if not radiused correctly.

Functional Marking: Chassis, Engine & Metal Parts

For under-the-hood and under-body components, the battle isn't about looks—it's about traceability through processing. Components like heat shields, firewalls, and engine blocks face harsh post-processing environments that dictate the marking method.

Readability Through Paint and Coatings

Embossing is the clear winner for coated parts. In automotive assembly, chassis parts are often e-coated, primed, and painted after marking. If a part is debossed (indented), the paint flows into the recesses, filling them up and making the characters unreadable. Embossed characters, standing proud of the surface, allow the paint to flow off the peaks. The mark remains distinct and legible even under thick layers of undercoating.

This is why you will typically see static data—such as model codes or platform designations on firewalls—embossed directly into the sheet metal. It ensures the data survives the paint shop and 20 years of road grime.

The Variable Data Challenge: VINs

While embossing is superior for legibility, it has a fatal flaw: cost. Embossing requires a fixed die set. To emboss a unique 17-digit VIN for every single car coming off the line, you would need a complex, slow, and expensive rotary numbering head.

Therefore, debossing (via dot peen or scribing) is the standard for unique vehicle identification. Scribing machines use a diamond or carbide stylus to "write" the VIN into the metal frame. While these marks are recessed, they are applied deep enough to survive standard e-coats, or are applied after painting (masking required). This method allows for infinite variability without changing tooling, a necessity for modern mass production.

Aesthetic Applications: Interior Trim & Branding

Inside the cabin, the search intent shifts from durability to "perceived quality." Designers use these techniques to communicate luxury and tactile feedback.

Leather and Soft Touch Surfaces

For leather seats, steering wheels, and dashboard trim, debossing (often called hot stamping in this context) creates a premium, understated look. By pressing a heated die into the leather, the fibers are compressed and darkened, creating a permanent, elegant depression. This is preferred over embossing for logos because raised leather areas are prone to abrasion and wear from passengers sliding in and out of the vehicle.

Tactile Controls and Switchgear

Embossing dominates the design of switchgear and buttons. A raised icon on a window switch or radio button provides crucial haptic feedback, allowing the driver to identify the control without taking their eyes off the road. In modern "In-Mold Labeling" (IML) processes for plastic interiors, embossing is used to give 3D texture to otherwise flat touch surfaces, blending the sleek look of a touchscreen with the physical assurance of a mechanical button.

Critical Comparison Factors (Decision Matrix)

When selecting a marking technology for a new automotive component, use this matrix to evaluate the trade-offs between cost, durability, and manufacturing constraints.

| Feature | Embossing (Raised) | Debossing / Stamping (Recessed) |

|---|---|---|

| Legibility with Paint | Excellent (Paint flows off peaks) | Poor (Paint fills recesses) |

| Tooling Cost | High (Requires matched male/female dies) | Medium/Low (Single die or stylus) |

| Variable Data (VIN) | Difficult (Slow, complex numbering heads) | Excellent (Programmable dot peen/scribe) |

| Abrasion Resistance | Low (Raised surface takes the wear) | High (Mark is protected below surface) |

| Cycle Time | Fast (Single press stroke) | Fast to Slow (Stamping is fast; Scribing is slower) |

For manufacturers looking to bridge the gap between these prototyping decisions and mass production, Shaoyi Metal Technology offers comprehensive stamping solutions. Their capabilities, ranging from rapid prototyping to 600-ton press runs, allow for the seamless integration of both embossing and complex debossing workflows. Whether you need 50 prototypes to validate a design or millions of mass-produced control arms, their IATF 16949-certified precision ensures your marking standards meet global OEM requirements. You can verify their full engineering range at Shaoyi Metal Technology Stamping Solutions.

Summary Recommendation by Part Type

To finalize your manufacturing strategy, categorize your parts by their exposure and data needs:

- Choose Embossing If: The part will be painted, powder-coated, or exposed to heavy grease (e.g., chassis data plates, firewalls, oil pans). The raised characters ensure the information is never lost under coating layers.

- Choose Debossing/Stamping If: The part requires unique serial numbers (VINs), or if the surface will be subjected to heavy friction (e.g., floor pans, mating surfaces). The recessed mark is protected from being scraped off.

- Choose Hot Stamping (Deboss) If: You are designing interior aesthetic parts like leather or vinyl. It provides a high-quality finish that resists wear from occupant contact.

Final Thoughts: Choosing the Right Impression

Ultimately, the decision between embossing and debossing in the automotive sector is rarely a matter of preference—it is an engineering calculation driven by the part's lifecycle. An embossed mark survives the paint booth; a debossed mark survives the assembly line's friction. By aligning your marking method with the component's environmental exposure and data variability, you ensure traceability from the press shop to the salvage yard. The correct choice prevents costly recalls due to illegible safety data and enhances the perceived quality of the vehicle's interior.

Frequently Asked Questions

1. Is embossing or debossing better for painting automotive parts?

Embossing is significantly better for painted parts. Because the characters are raised, paint tends to flow away from the peaks, keeping the edges sharp and legible. With debossing, paint pools in the recesses, often filling them completely and obscuring the mark, especially with thick automotive coatings like e-coat or undercoating.

2. Why are VIN numbers usually debossed or scribed?

VINs require unique, variable data for every single vehicle. Embossing requires a fixed die set for each character, which is mechanically complex and expensive to change for every cycle. Debossing (specifically dot peen or scribing) uses a programmable stylus that can change the characters instantly via software, making it the only viable option for high-volume serialization.

3. Which process is more expensive for metal parts?

Embossing is generally more expensive regarding tooling because it requires a matched set of male and female dies created with precision clearance. Impression stamping (a form of debossing) typically requires only a single male die and a flat anvil, reducing initial tooling costs. However, for variable data, programmable scribing machines eliminate consumable die costs entirely.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —