Automotive Stamping Die Coatings: Technical Guide & Material Selection

TL;DR

Selecting the optimal automotive stamping die coating is a critical engineering decision that balances hardness, lubricity, and processing temperature to prevent tool failure. While PVD (Physical Vapor Deposition)—specifically AlTiN and TiAlN—has become the modern standard for Advanced High-Strength Steel (AHSS) due to its low processing temperature (<500°C) and high toughness, older technologies like TD (Thermal Diffusion) remain the gold standard for extreme galling resistance in stainless steel applications. For the most demanding high-load scenarios, Duplex coatings (plasma nitriding followed by PVD) offer superior support to prevent the “eggshell effect.” Use this guide to match coating specifications to your workpiece material and production volume.

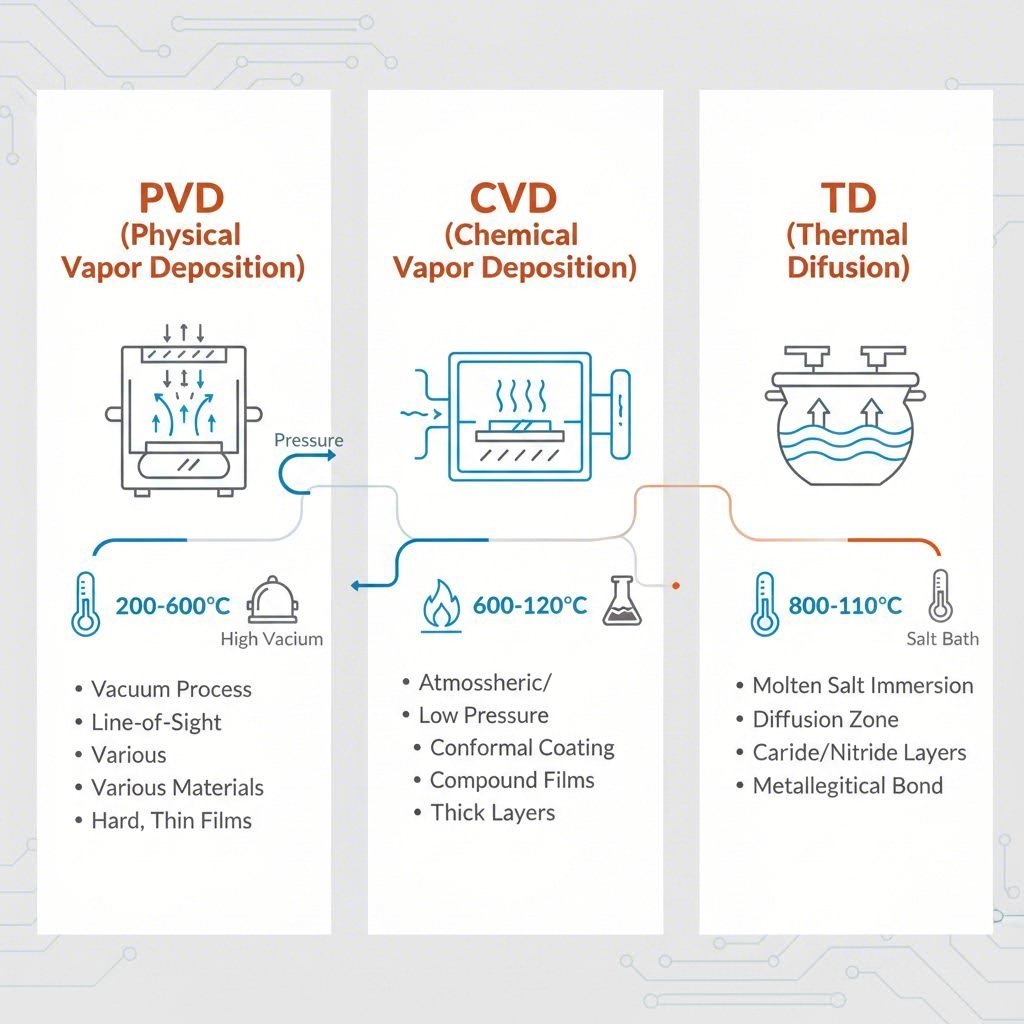

Primary Coating Technologies: PVD vs. CVD vs. TD

In the automotive stamping industry, three dominant surface treatment technologies compete for specification. Understanding the thermodynamic and mechanical differences between them is essential for predicting tool life and dimensional stability.

1. PVD (Physical Vapor Deposition)

PVD is currently the most versatile technology for precision automotive tooling. It involves the condensation of a metallic vapor (titanium, chromium, aluminum) onto the tool surface in a vacuum at relatively low temperatures (typically 800°F–900°F / 425°C–480°C). Because this processing temperature is below the tempering point of most tool steels (like D2 or M2), PVD maintains the substrate's hardness and dimensional accuracy.

According to Eifeler, advanced PVD variants like AlTiN (Aluminum Titanium Nitride) offer hardness values exceeding 3,000 HV and oxidation resistance up to 900°C, making them ideal for the high heat generated when stamping AHSS.

2. CVD (Chemical Vapor Deposition)

CVD creates a coating through a chemical reaction at the surface, typically requiring much higher temperatures (~1,900°F / 1,040°C). This high heat necessitates a vacuum heat treatment cycle after coating to restore the tool's core hardness, which introduces a significant risk of dimensional distortion. However, CVD provides superior adhesion and can uniformly coat complex geometries, including blind holes, which PVD's line-of-sight process may miss.

3. TD (Thermal Diffusion)

Often referred to as the "Toyota Diffusion" process, TD (or TRD) creates a vanadium carbide layer via a salt bath diffusion process. As noted by The Fabricator, TD coatings achieve extreme hardness (~3,000–4,000 HV) and are chemically inert, making them practically immune to adhesive wear (galling) when forming stainless steel or heavy-gauge high-strength low-alloy (HSLA) steels. Like CVD, the high processing temperature requires post-coating heat treatment.

| Feature | PVD (e.g., AlTiN, TiCN) | CVD (e.g., TiC/TiN) | TD (Vanadium Carbide) |

|---|---|---|---|

| Process Temp | Low (<500°C) | High (~1000°C) | High (~1000°C) |

| Hardness (HV) | 2,500 – 3,500 HV | 3,000 – 3,500 HV | 3,200 – 4,000+ HV |

| Distortion Risk | Minimal | High | High |

| Best Application | Precision dies, AHSS, close tolerances | Blind holes, heavy forming | Stainless steel, severe galling |

Matching Coatings to Workpiece Materials

The success of a stamping operation often hinges on the tribological compatibility between the coating and the sheet metal. Mismatching these can lead to rapid catastrophic failure.

Advanced High-Strength Steel (AHSS)

Stamping AHSS (tensile strengths >980 MPa) creates immense localized pressure and heat. Standard TiN coatings often fail here. The industry preference is PVD AlTiN or TiAlN. The addition of aluminum forms a hard aluminum oxide layer on the surface during use, which actually boosts heat resistance. AHSS Guidelines data indicates that while chrome plating might last 50,000 hits, properly selected PVD or Duplex coatings can extend tool life to over 1.2 million hits.

Aluminum Alloys (5xxx/6xxx Series)

Aluminum is notorious for "adhesive wear," where the soft aluminum sticks to the tool surface (a phenomenon known as cold welding). AlTiN is a poor choice here because the aluminum in the coating has an affinity for the aluminum sheet. Instead, specify DLC (Diamond-Like Carbon) or CrN (Chromium Nitride). DLC offers an exceptionally low coefficient of friction (0.1–0.15), allowing the aluminum to slide freely without sticking.

Galvanized Steel

Zinc pickup is a primary failure mode when stamping galvanized sheet. Standard PVD coatings can sometimes exacerbate this if their surface roughness is too high. Ion Nitriding or specific polished CrN coatings are recommended to resist chemical reaction with the zinc layer.

Navigating these material pairings requires not just the right coating, but a manufacturing partner capable of executing the entire production cycle with precision. For automotive programs requiring strict adherence to global standards, companies like Shaoyi Metal Technology leverage IATF 16949-certified processes to manage everything from rapid prototyping to high-volume stamping, ensuring that the theoretical benefits of these advanced coatings are realized in actual production.

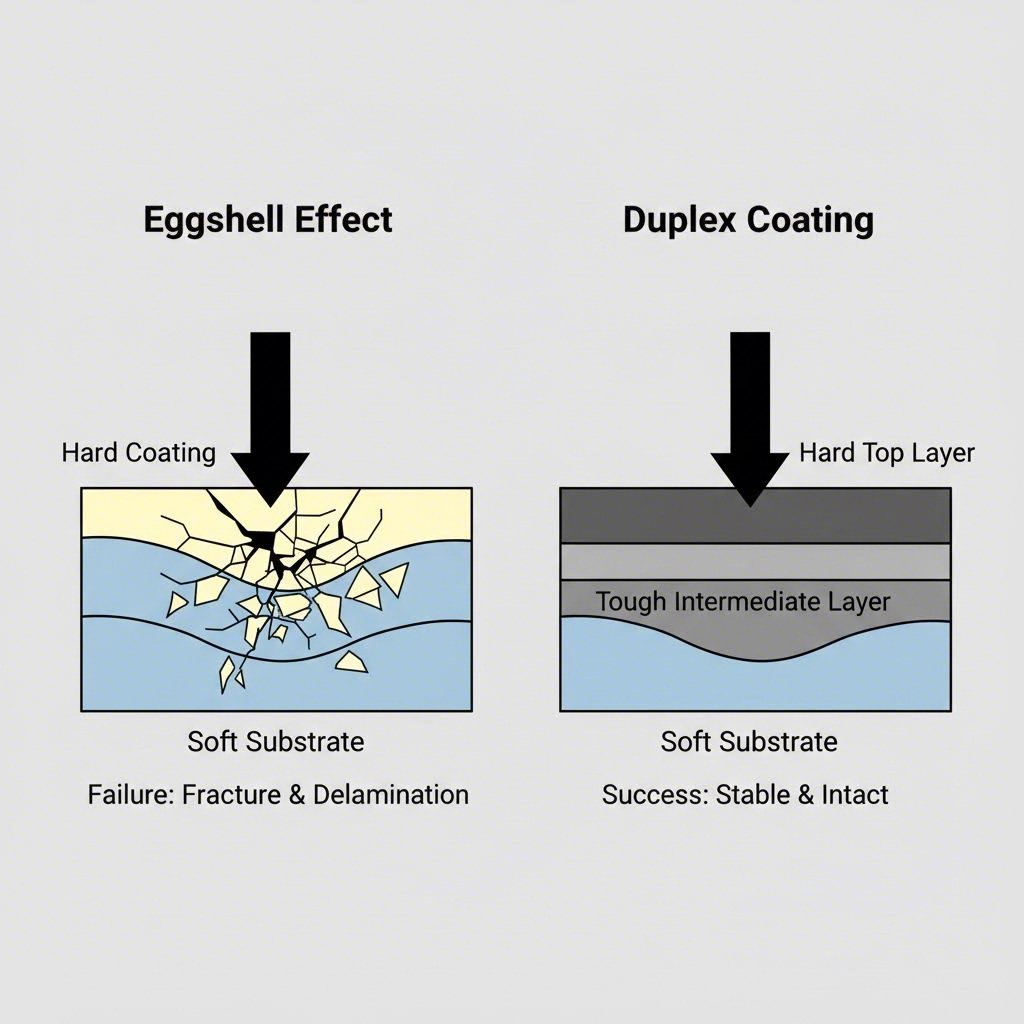

The "Eggshell Effect" & Substrate Selection

A common misconception is that a harder coating fixes a soft tool. In reality, applying a super-hard coating (3000 HV) to a standard soft tool steel (like untreated D2) results in the "Eggshell Effect." Under the high contact loads of automotive stamping, the soft substrate deforms elastically, causing the brittle, hard coating on top to crack and collapse—much like an eggshell cracking when the egg inside is squeezed.

The Solution: Duplex Coatings.

To prevent this, engineers specify a "Duplex" treatment. This process begins with plasma ion nitriding to harden the surface of the tool steel substrate to a depth of ~0.1–0.2mm, creating a supportive gradient. The PVD coating is then applied on top. This hardened sub-layer supports the coating, allowing it to withstand the extreme impact shocks typical of high-speed stamping.

Furthermore, standard D2 tool steel contains large carbide structures that can serve as fracture points. For coated tools, MetalForming Magazine recommends upgrading to Powder Metallurgy (PM) steels (such as CPM M4 or Vanadis). The finer, uniform carbide distribution in PM steels provides a superior anchor for coatings and significantly improved toughness.

Performance Metrics & Failure Analysis

Identifying how a tool is failing is the first step to selecting the right coating correction. Misumi engineering studies highlight three distinct failure modes:

- Abrasive Wear: The tool surface is physically scratched or worn away. Fix: Increase coating hardness (switch from TiN to AlTiN or TD).

- Adhesive Wear (Galling): Workpiece material welds to the tool. Fix: Increase lubricity/reduce friction (switch to DLC or add a WS2 dry lubricant topcoat).

- Chipping/Cracking: The coating or tool edge fractures. Fix: The coating may be too thick or the substrate too brittle. Switch to a tougher coating (lower aluminum content) or a duplex treatment on a tougher PM steel substrate.

Optimizing for Tool Longevity

There is no single "best" coating for all automotive dies. The optimal choice is always a function of the failure mode you are trying to prevent and the material you are forming. For general AHSS stamping, PVD AlTiN on a PM steel substrate is the industry baseline. For extreme galling issues on stainless, TD remains unbeaten. By systematically matching the coating properties—hardness, friction coefficient, and thermal stability—to your specific manufacturing variables, you can transform tool life from a maintenance headache into a competitive advantage.

Frequently Asked Questions

1. What is the best coating for stamping AHSS?

For most Advanced High-Strength Steel (AHSS) applications, AlTiN (Aluminum Titanium Nitride) or TiAlN PVD coatings are preferred. They offer high hardness (~3400 HV) and excellent thermal stability. For the most severe applications (1180 MPa+ steels), a Duplex coating (nitriding + PVD) on a PM tool steel substrate is recommended to prevent substrate collapse.

2. How thick should a PVD coating be for stamping dies?

Standard PVD coatings for stamping are typically applied at a thickness of 3 to 5 microns (0.0001–0.0002 inches). Coatings thicker than this risk delamination due to high internal compressive stresses, while thinner coatings may wear through prematurely. Multi-layer coatings can sometimes be applied slightly thicker without sacrificing adhesion.

3. Can you recoat a stamping die without stripping it?

Generally, no. The old coating must be chemically stripped before a new layer is applied to ensure proper adhesion and dimensional accuracy. Applying PVD over an old, worn coating often leads to flaking and poor performance. However, most PVD coatings can be stripped chemically without damaging the tool steel substrate, allowing for multiple lifecycles.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —