Stamping Automotive Roof Panels: Class A Surface & Defect Control

TL;DR

Stamping automotive roof panels is a precision-critical manufacturing process that transforms flat sheet metal into large, aerodynamic, and defect-free "Class A" surfaces. This process demands specialized large-bed presses and advanced engineering to manage material flow, preventing common defects like "oil canning" (surface waviness) and springback, particularly in modern lightweight aluminum designs. For engineers and procurement teams, success relies on selecting partners with capabilities in both simulation (FEA) and high-tonnage production to ensure structural rigidity and perfect surface finish.

The Automotive Roof Stamping Process: From Blank to Class A Surface

Manufacturing a roof panel is fundamentally different from stamping internal structural parts. As a "Class A" surface—the highest quality standard in automotive manufacturing—a roof panel must be visually flawless. Even microscopic imperfections or uneven strains are unacceptable because they become glaringly obvious once the vehicle is painted and placed under showroom lights. The process involves a specific lifecycle designed to maintain tension and surface integrity.

1. The Drawing Operation

The critical first step after blanking (cutting the raw coil) is the "draw." Unlike smaller parts, a roof panel requires a massive deep-draw process where the metal is stretched over a die to establish its shape. Automotive stamping experts emphasize the importance of "drawbeads"—ridges in the binder area of the die—to control the flow of material. If the metal flows too freely, the panel will be loose and floppy; if it flows too restrictively, the metal will split. Achieving the correct "plastic strain" across the vast flat center of a roof is the primary challenge.

2. Trimming and Flanging

Once the shape is set, subsequent operations trim the excess metal and flange the edges. These flanges are crucial as they form the attachment points for the "ditch molding" or laser brazing channels that connect the roof to the body side frames. Precision here is non-negotiable; a deviation of even 0.5mm can cause water leaks or wind noise in the final assembly.

3. Class A Inspection Criteria

Throughout this line, the focus remains on surface quality. Manufacturers use "highlight rooms"—tunnels bathed in high-intensity fluorescent strip lighting—to visually inspect panels. These lights reflect off the panel's surface, revealing even the faintest ripples or dings that would otherwise be invisible. This level of scrutiny dictates that the stamping facility must maintain clinical levels of cleanliness to prevent dust or lint from entering the dies.

Material Selection: Steel vs. Aluminum Roof Panels

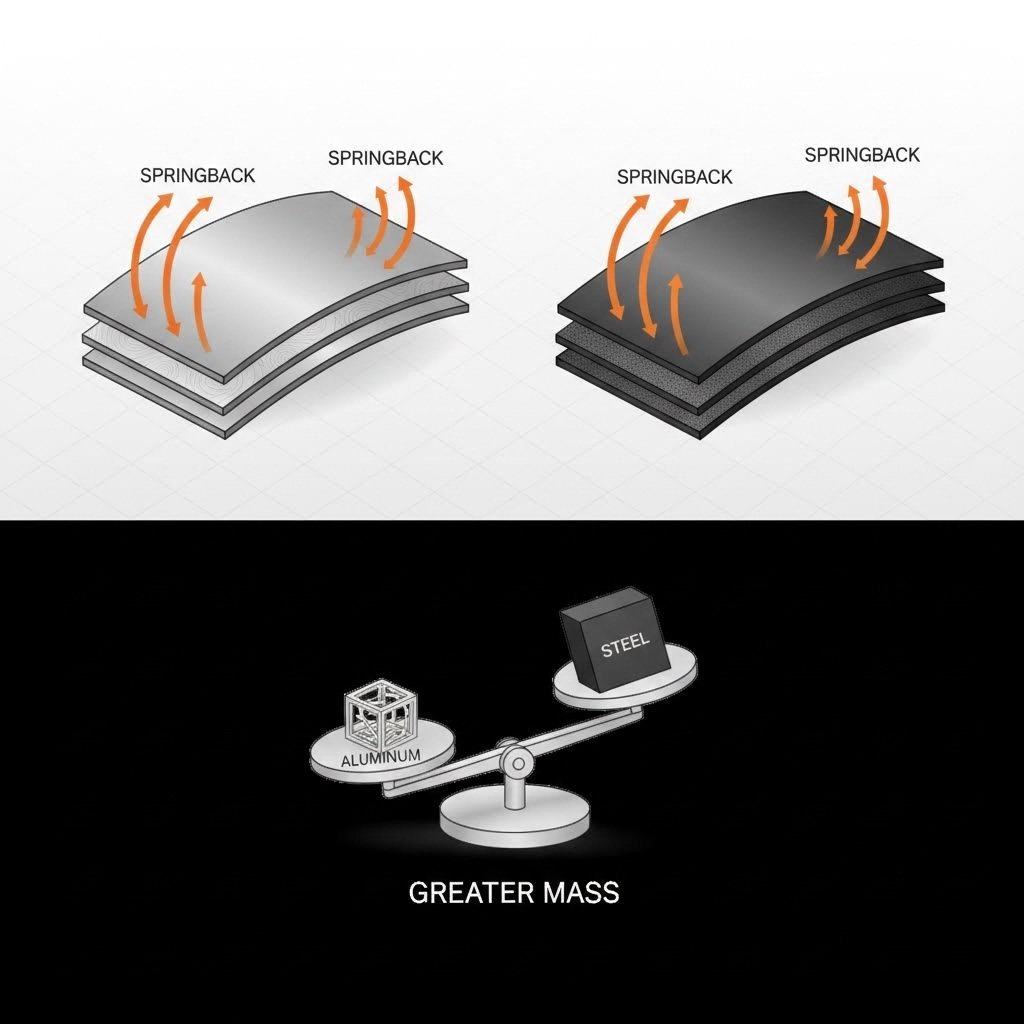

The industry is aggressively shifting from mild steel to aluminum alloys (typically 5000 and 6000 series) to lower the vehicle's center of gravity and improve fuel efficiency. However, this switch introduces significant manufacturing hurdles.

- Springback Challenges: Aluminum has greater elastic recovery than steel. After the press opens, the panel wants to return to its original flat shape. To counteract this, engineers must design dies with "springback compensation," effectively over-bending the part so it relaxes into the correct geometry.

- Formability Limits: Aluminum tears more easily than steel. This limits the depth of styling lines and requires larger radii on corners, influencing the vehicle's aesthetic design.

- Joining Implications: While steel roofs are typically spot-welded, aluminum roofs often require self-piercing rivets (SPRs) or structural adhesives, affecting downstream assembly processes.

Critical Defects & Mitigation: Oil Canning and Surface Distortions

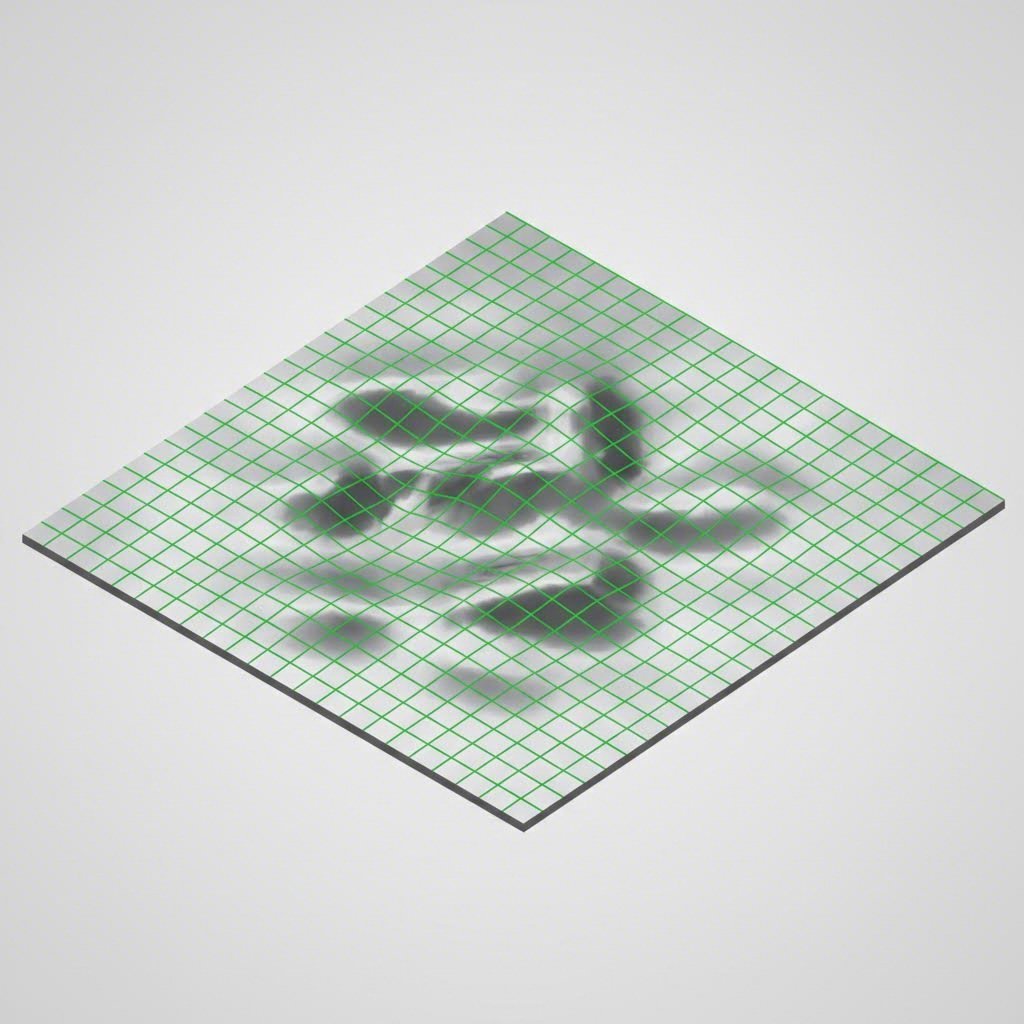

The most persistent enemy of large, flat panels is "oil canning"—a phenomenon where the sheet metal buckles or pops in and out like an old oil can when pressed. This surface waviness is a structural instability caused by uneven internal stresses.

Causes of Oil Canning

Oil canning typically occurs when there is insufficient stretching of the metal in the center of the panel during the draw phase. Without enough tension, the material remains "loose" and unstable. Thermal expansion during the paint shop's bake cycle can also trigger these buckles if the panel expands against a rigid frame.

Engineering Solutions

To mitigate this, engineers employ two main strategies. First, they may introduce subtle "stiffening ribs" or styling creases into the design to break up large flat areas, adding inherent rigidity. Second, they optimize the strain distribution during stamping, aiming for a minimum of 2% plastic strain across the entire surface to work-harden the material sufficiently. Advanced predictive modeling and FEA are essential to identify low-strain areas before the first die is ever machined.

Advanced Engineering: Simulation (FEA) and Prototyping

Before hard tools are cut from steel, the stamping process exists entirely in a virtual environment. Finite Element Analysis (FEA) software, such as AutoForm, simulates the metal flow to predict thinning, wrinkling, and springback. This digital twin allows engineers to validate the feasibility of a design without wasting material.

For physical verification, manufacturers often use "soft tooling" made from Kirksite (a zinc-based alloy) for prototypes. Case studies in prototyping show that Kirksite dies can produce low volumes of parts that mimic production intent, allowing for physical fit-up trials on the Body-in-White (BIW) structure. This step is crucial for validating the "Class A" surface quality before committing to the expensive, hardened steel dies required for mass production.

Selecting a Stamping Partner: Key Capabilities Checklist

Choosing the right manufacturer for roof panels is a strategic decision that impacts the vehicle's final perceived quality. Procurement teams should evaluate potential partners against specific capability criteria.

Essential Infrastructure

The sheer size of a roof panel—often exceeding 4 feet by 8 feet for panoramic designs—requires press beds of substantial dimensions and tonnage (often 2000+ tons). The facility must be equipped with robotic transfer systems to handle these large, floppy parts without inducing handling damage.

Bridging Prototype to Production

The ideal partner can navigate the entire lifecycle. For instance, manufacturers like Shaoyi Metal Technology utilize IATF 16949-certified precision capabilities to bridge the gap between rapid prototyping and high-volume manufacturing. Their ability to manage press forces up to 600 tons allows for the seamless transition of complex components from engineering validation to full-scale production, ensuring consistency in critical dimensions.

Secondary Value-Add

Look for suppliers who offer more than just stamping. Roof production often involves applying sound-deadening mastic (patches) or welding reinforcement brackets (for sunroofs and grab handles) directly at the press line. Integrated secondary operations reduce logistics costs and handling risks.

Conclusion

Stamping automotive roof panels is a discipline where heavy industrial force meets aesthetic perfection. The transition from steel to aluminum and the demand for panoramic glass integration continue to push the boundaries of what is physically possible in a press line. For automakers, the key to success lies in early collaboration with stamping partners who possess not just the machinery, but the engineering foresight to predict and prevent defects like oil canning long before the metal hits the die.

Frequently Asked Questions

1. What are the main steps in the roof stamping process?

The process typically follows a Transfer or Tandem line sequence: Blanking (cutting the shape), Drawing (forming the 3D curvature), Trimming (removing excess metal), Flanging (bending edges for assembly), and finally, Restriking or Piercing (refining shape and adding holes). Each step is automated to ensure precision.

2. Why is "Class A" surface quality so difficult to achieve?

Class A surfaces are the highly visible outer skins of the car. They must be mathematically smooth. Achieving this is difficult because large flat areas magnify even microscopic deviations. Any dust in the die, uneven material flow, or slight springback creates visual distortions that are unacceptable to consumers.

3. Is stamping aluminum roof panels more expensive than steel?

Yes, typically. The aluminum raw material is more expensive than mild steel, and the manufacturing process is more complex due to springback issues and the need for specialized trimming tools. However, the investment is often justified by the significant weight reduction, which improves vehicle range and handling.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —