Deep Draw Stamping Oil Pans: Process, Specs & Engineering Guide

TL;DR

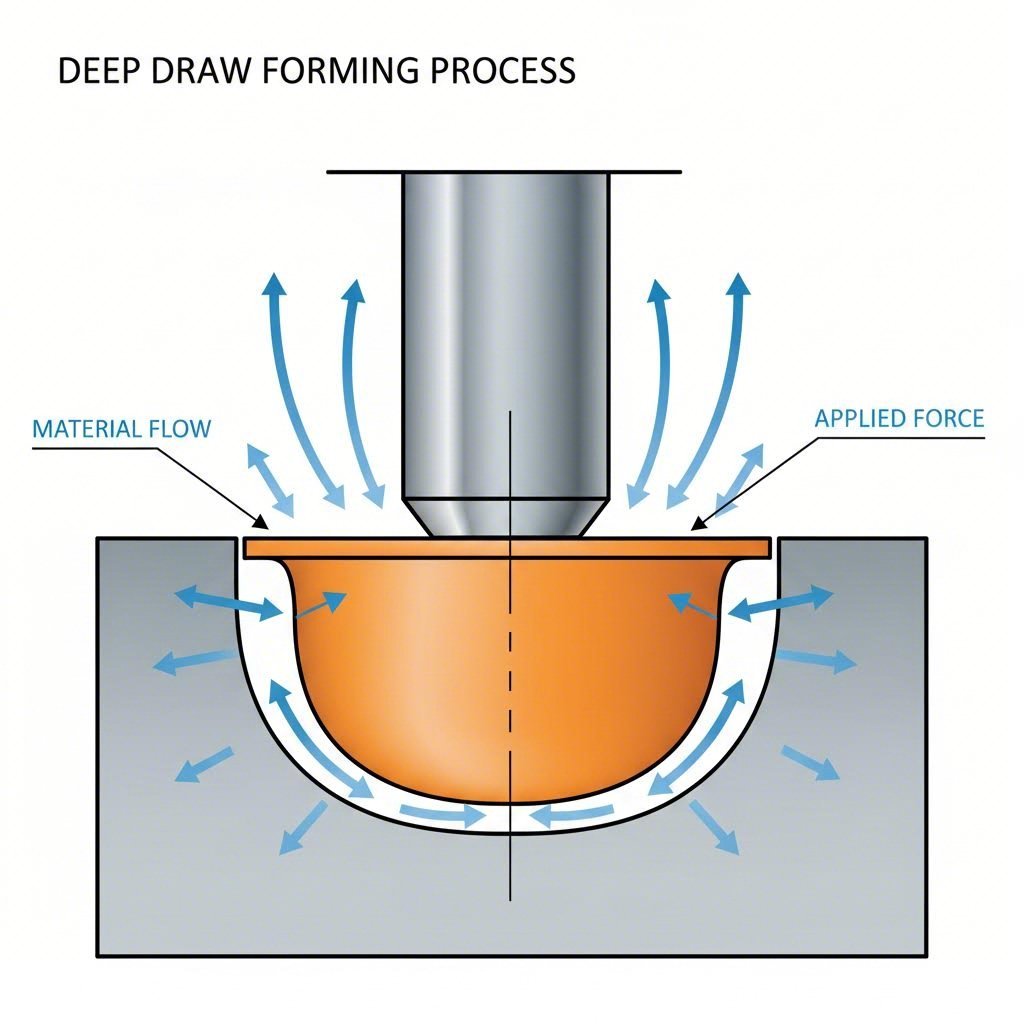

Deep draw stamping oil pans is a precision metal forming process that creates seamless, leak-proof reservoirs by stretching flat sheet metal—typically Interstitial Free (IF) or Extra Deep Drawing Steel (EDDS)—into complex shapes where the depth exceeds the diameter. Unlike cast aluminum alternatives, stamped pans offer superior ductility, lighter weight, and lower costs in high-volume production.

Key manufacturing metrics include achieving draw depths of up to 13 inches while maintaining flange flatness tolerances within 0.1mm to ensure perfect sealing. This process requires hydraulic or mechanical presses ranging from 400 to 2000+ tons to control material flow and prevent wrinkling or tearing.

Deep Draw Stamping vs. Casting: The Engineering Case

For automotive engineers and procurement managers, the choice between deep drawn steel and cast aluminum oil pans often comes down to three factors: durability, weight, and sealing integrity. Deep draw stamping transforms a single metal blank into a hollow, axisymmetric shape without seams, fundamentally eliminating the leak paths associated with welded fabrications.

Structural Integrity and Work Hardening

While cast aluminum offers rigidity, it is prone to cracking under impact—a critical failure mode for low-hanging oil pans exposed to road debris. Deep drawn steel, conversely, benefits from work hardening (or strain hardening) during the forming process. As the material is stretched, its crystalline structure realigns, significantly increasing tensile strength. A stamped steel pan will dent rather than shatter upon impact, preserving the engine's lubrication system.

Cost and Volume Efficiency

Deep drawing is the dominant choice for high-volume automotive production. Once the tooling (die and punch) is validated, cycle times are measured in seconds. In contrast, casting requires longer cooling times and more extensive secondary machining. For heavy-duty diesel applications, stamped pans using .071” CR IF (Cold Rolled Interstitial Free) steel provide the necessary robustness without the weight penalty of thick-wall castings.

Step-by-Step Manufacturing Workflow

Producing a defect-free oil pan requires a rigorous, multi-stage process. The transition from a flat coil to a finished 13-inch deep reservoir involves precise control over material flow and tribology.

1. Blanking and Lubrication

The process begins by cutting the initial shape, or "blank," from the master coil. The blank size is calculated by volume, not area, to account for the material flow. specialized high-pressure lubricants are applied to minimize friction between the sheet and the die, which is critical to preventing galling during extreme deformation.

2. The Draw Operation

This is the defining step. The blank is clamped by a blank holder with precise pressure—too little causes wrinkles, too much causes tearing. A mechanical or hydraulic punch forces the metal into the die cavity. For deep pans (e.g., 8-13 inches), this may require multiple draw stations (redrawing) to reach the final depth without exceeding the metal's forming limit diagram (FLD).

3. Ironing and Wall Thickness Control

Deep drawing inherently thins the material at the bottom corners and thickens it at the flange. Precision ironing steps are often integrated to redistribute material, ensuring uniform wall thickness. Manufacturers must maintain walls within tight tolerances (typically ±0.005 inches) to ensure structural performance.

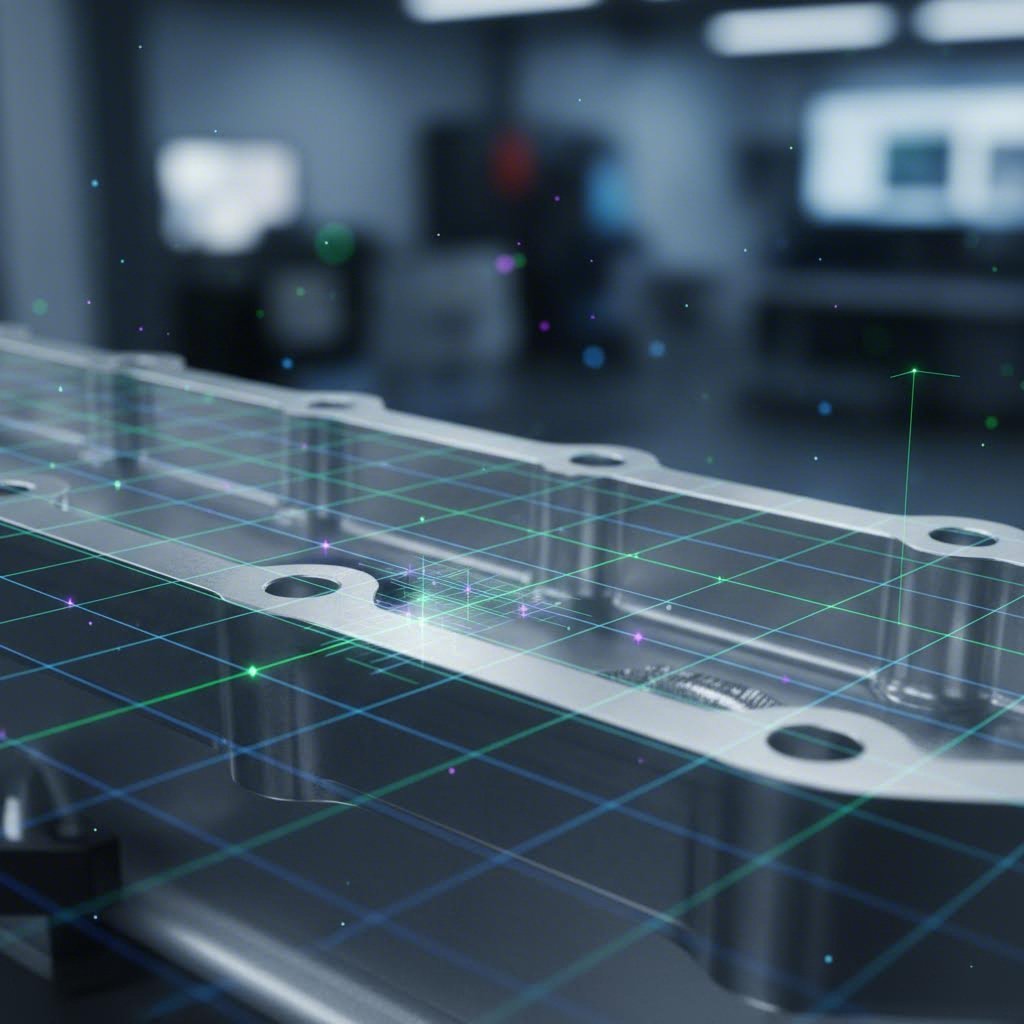

Achieving these complex geometries requires manufacturing partners with robust equipment lists. Suppliers like Shaoyi Metal Technology utilize presses up to 600 tons and adhere to IATF 16949 standards to bridge the gap from rapid prototyping to mass production of critical components like subframes and oil pans.

4. Trimming and Flanging

Once the shape is formed, the excess material is trimmed. The flange—the sealing surface that mates with the engine block—is then flattened. This is the most critical quality feature; a warped flange guarantees oil leaks. Leading manufacturers typically target a flatness tolerance of 0.1mm within 250mm to ensure a perfect seal with the gasket.

Material Specifications for Deep Drawing

Selecting the right steel grade is non-negotiable for oil pans, which undergo severe deformation. Standard carbon steel often lacks the necessary elongation properties.

| Material Grade | Characteristics | Typical Application |

|---|---|---|

| IF Steel (Interstitial Free) | Ultra-low carbon, stabilized with Ti/Nb. Non-aging with extreme ductility. | Complex shapes with draw depths >8 inches. |

| EDDS (Extra Deep Drawing Steel) | Superior formability, similar to IF but optimized for consistency. | Passenger car oil pans, transmission pans. |

| DC04 / DC06 | European standard cold-rolled grades for deep drawing. | General automotive stamping. |

| 5052-O Aluminum | High fatigue strength, excellent corrosion resistance. | Lightweight sports/luxury vehicle pans. |

For most heavy-duty applications, manufacturers specify materials like .071" (1.8mm) CR IF or .055" (1.4mm) EDDS. These grades allow for "stretch" ratios that would tear standard steels.

Critical Design and Quality Considerations

Engineering an oil pan goes beyond just the shape. The assembly must integrate multiple features while passing rigorous validation tests.

Leak Testing and Validation

Zero defects is the standard. Finished pans undergo 100% leak testing, typically involving a 1.5 Bar air decay test or submersion underwater for 30 seconds to identify microscopic pinholes. Salt spray testing (often >480 hours) is also mandatory for steel pans to validate the durability of e-coating or powder coating against road salts.

Feature Integration

Modern oil pans are assemblies, not just shells. They require:

- Baffles: Spot-welded inside the sump to prevent oil starvation during high-G cornering or braking.

- Drain Plug Seats: Reinforced areas that must withstand torque loads exceeding 80 N·m without deforming.

- Dipstick Guides: Precision-stamped tubes integrated into the side wall.

Draft Angles and Radii

To facilitate part removal from the die, vertical walls usually require a draft angle. However, deep drawing allows for straighter walls than casting. Corner radii should be generous—typically 6-8x material thickness—to facilitate material flow and reduce stress concentrations that lead to cracking.

Engineering the Perfect Seal

Deep draw stamping remains the gold standard for manufacturing oil pans that balance cost, weight, and reliability. By leveraging advanced materials like IF steel and precise process controls—from blank holder pressure to flange flattening—manufacturers can deliver components that outlast the engines they protect. For engineers, success lies in defining clear specifications for draw depth, material elongation, and sealing tolerances early in the design phase.

Frequently Asked Questions

1. What is the difference between deep drawing and regular stamping?

The primary difference is the depth-to-diameter ratio. Deep drawing is specifically defined as a process where the depth of the part exceeds half its diameter. It involves significant material flow and stretching, whereas regular stamping (or shallow drawing) focuses more on cutting, bending, and forming surface details with minimal wall thinning.

2. What is the best steel for deep drawing oil pans?

Interstitial Free (IF) steel and Extra Deep Drawing Steel (EDDS) are the top choices. These grades have ultra-low carbon content and are stabilized with titanium or niobium, providing the extreme ductility required to stretch into deep shapes (8–13 inches) without splitting or tearing.

3. Why use stamped steel instead of cast aluminum?

Stamped steel is generally lighter, more ductile, and significantly cheaper to produce in high volumes than cast aluminum. While cast aluminum is more rigid, it can crack upon impact with road debris. Stamped steel tends to dent rather than fracture, offering better failure protection for the engine's oil supply.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —