Automotive Stamping Scrap Management: Strategies for Maximum ROI

TL;DR

Effective automotive stamping scrap management is not merely a custodial task but a critical financial strategy that transforms waste into a revenue stream. A holistic approach involves three pillars: minimizing waste generation at the source through advanced nesting software, automating physical removal with specialized conveyor systems, and maximizing resale value via strict alloy segregation. By integrating these processes, manufacturers can convert scrap handling from a sunken operational cost into a competitive asset that significantly improves the bottom line.

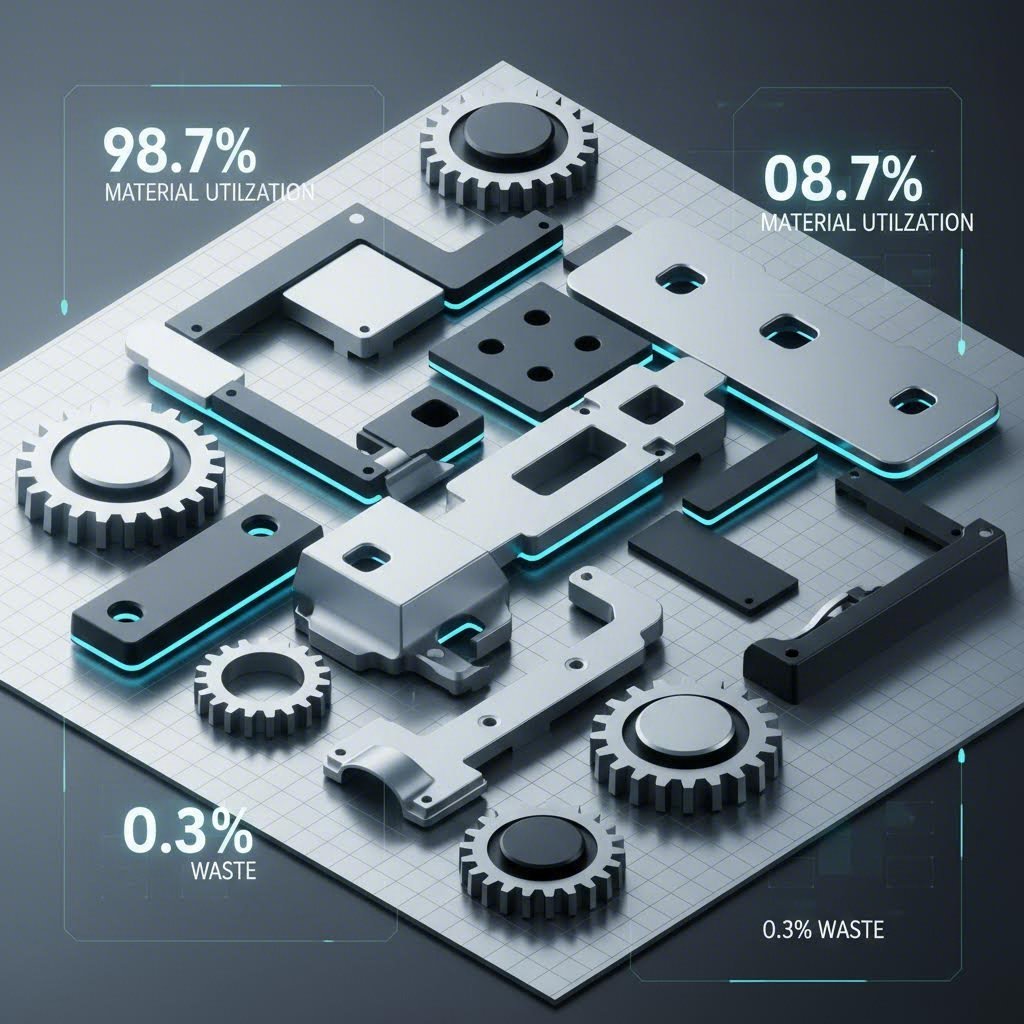

Strategy 1: Minimizing Scrap at the Source (Prevention)

The most profitable scrap is the scrap you never generate. The foundation of efficient automotive stamping scrap management lies in the pre-production phase, specifically in die design and material utilization. Engineers focus heavily on the Material Utilization Ratio (MUR), which measures the percentage of raw sheet metal that ends up in the finished part versus the offal. Increasing this ratio by even a fraction of a percentage point can result in massive annual savings in high-volume automotive production.

Advanced simulation software plays a pivotal role here. Tools like Dynaform allow engineers to simulate the stamping process, optimizing blank shapes and nesting layouts to reduce the web width between parts. This process, known as "nesting," ensures that the strip layout maximizes every square inch of the coil. Additionally, techniques like "common edge cutting," where adjacent parts share a cut line, can eliminate the web entirely in specific applications. Implementing these digital strategies before physical tooling is cut is the most effective way to reduce the volume of scrap that must be managed later.

Furthermore, the choice of manufacturing partner significantly influences scrap rates. Experienced fabricators understand that precision in the prototyping phase predicts efficiency in mass production. Accelerating production with comprehensive partners like Shaoyi Metal Technology helps bridge the gap from rapid prototyping to high-volume manufacturing. By leveraging IATF 16949-certified precision and press capabilities up to 600 tons, manufacturers can ensure that critical components—from control arms to subframes—are produced with optimized tooling that adheres to global OEM standards, minimizing material waste from the outset.

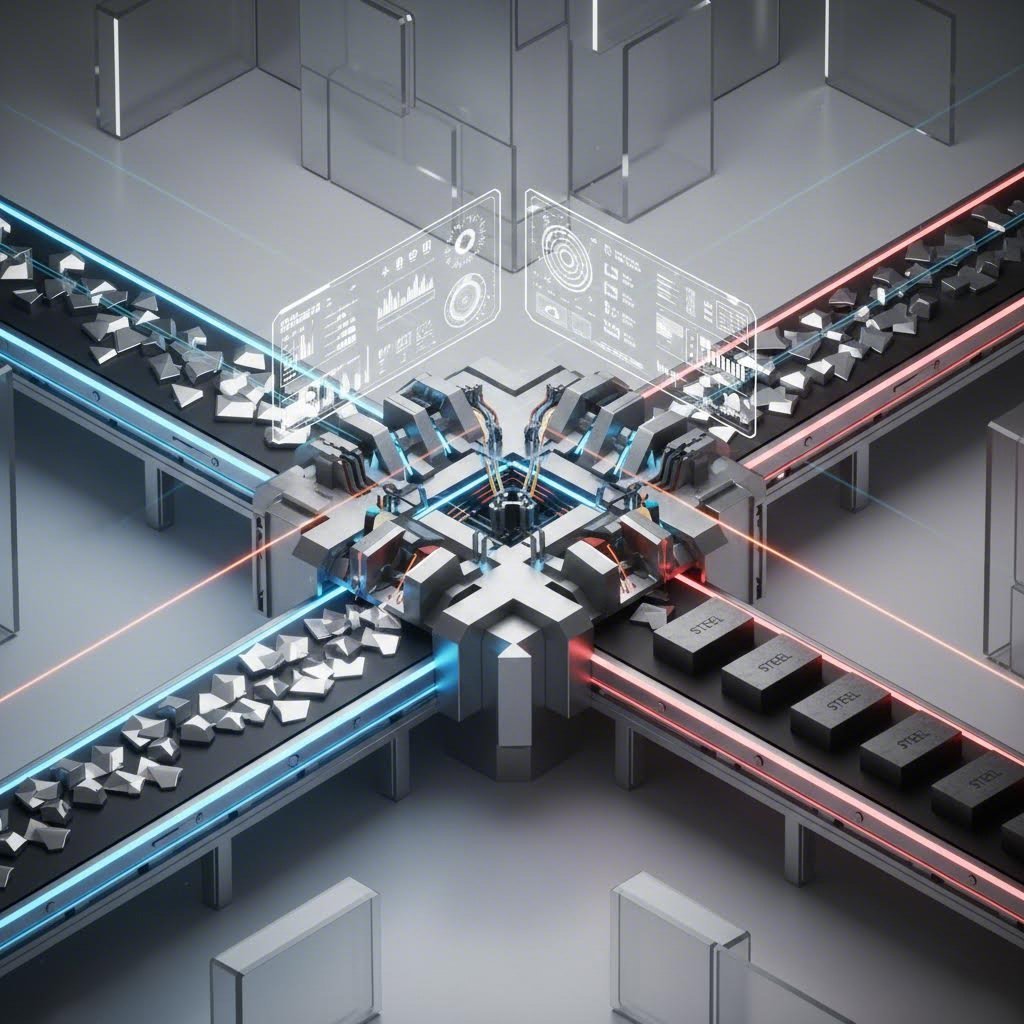

Strategy 2: Automated Removal and Handling Systems

Once scrap is generated, immediate and reliable removal is essential to maintain press uptime. In the high-speed environment of automotive stamping, a backed-up scrap chute can cause catastrophic die damage and halt production lines. The choice of removal system depends largely on the material type and the physical constraints of the facility, often requiring a mix of under-press and overhead solutions.

Steel belt conveyors are the industry workhorse for heavy-duty applications. They are durable and capable of handling sharp, heavy steel off-cuts that would destroy lighter belts. However, they require regular maintenance to prevent jamming. Alternatively, oscillating conveyors (shaker pans) offer a low-maintenance solution for moving scrap out of tight pits. These systems use vibration to slide metal forward, eliminating the need for belts or rotating parts that can wear out or jam, making them ideal for "set-and-forget" operations in difficult-to-access areas.

For lighter materials, particularly in modern automotive manufacturing where aluminum is increasingly used for weight reduction, pneumatic or vacuum systems are superior. Companies like Mayfran International provide specialized systems that use airflow to transport lightweight aluminum chips and off-cuts quickly. This prevents the lightweight scrap from floating or jamming in traditional mechanical conveyors and ensures a cleaner press environment.

Strategy 3: Segregation and Value Recovery

The difference between treating scrap as trash and treating it as a product lies in segregation. Automotive stamping lines often run different alloys—various grades of steel, aluminum, and copper. Mixing these metals degrades their value to the lowest common denominator. To maximize Return on Investment (ROI), facilities must implement systems that keep these streams separate, aiming for high purity levels that command premium prices from recyclers.

Advanced scrap management systems employ diverter chutes and dual-direction conveyors that automatically route scrap to different bins based on the active press recipe. For example, when a line switches from steel to aluminum, the control system adjusts the diverter to send the offal to a dedicated aluminum container. Achieving 95% or higher purity is often the threshold for top-tier pricing. Case studies from Compass Systems demonstrate that engineered systems designed to deliver high-purity aluminum scrap can dramatically shorten the payback period on equipment investment.

Beyond separation, physical processing increases value. Scrap is voluminous and expensive to transport because you are mostly shipping air. Implementing on-site shredders or briquetting machines can compress scrap into dense bricks or chips. This increases the density ratio significantly—sometimes up to 6:1—reducing haulage fees and making the material more attractive to smelters. Recyclers like Interco emphasize that processed, segregated nonferrous metals from stamping operations yield significantly higher returns than loose, mixed loads.

Strategy 4: Smart Systems and Safety Compliance

Modern scrap management has entered the Industry 4.0 era. It is no longer enough to just move metal; the system must provide data. "Smart" scrap systems utilize IoT sensors to monitor bin levels, conveyor load, and equipment health in real-time. These systems can automatically notify haulers when a bin is approaching capacity, preventing overflow and eliminating the downtime associated with waiting for a swap. This data-driven approach transforms scrap logistics from a reactive headache into a predictive workflow.

Safety is the final, non-negotiable component. Stamping scrap is razor-sharp and often coated in slippery lubricants, posing severe risks to workers. Automating the handling process reduces human exposure to these hazards. Furthermore, managing the fluids associated with scrap is critical for environmental compliance. Systems that separate and recover cutting fluids not only reduce disposal costs but also ensure adherence to ISO 14001 standards. As noted by industry experts at ETA, Inc., ignoring the "hidden costs" of scrap—such as fluid disposal and safety liabilities—can silently erode the profitability of a stamping operation.

Engineering Profit from Process

Optimizing the lifecycle of stamping scrap requires a shift in perspective. It is not waste management; it is resource management. By investing in precise die design, robust automated removal systems, and intelligent segregation technologies, automotive manufacturers can uncover significant value. The most successful plants view their scrap output as a secondary product line, managed with the same rigor and attention to quality as the automotive components they produce.

Frequently Asked Questions

1. What are the primary methods for transporting stamping scrap?

The most common methods include steel hinge belt conveyors for heavy-duty applications, oscillating (shaker) conveyors for low-maintenance transport in tight spaces, and pneumatic (vacuum) systems for lightweight materials like aluminum. Magnetic conveyors are also used for ferrous metals to separate steel parts from non-ferrous coolants or waste.

2. Why is scrap segregation important in automotive stamping?

Segregation is vital for financial recovery. Mixed scrap (e.g., steel mixed with aluminum) is sold at the price of the lowest-value metal or as "dirty" scrap. Segregated scrap that meets purity standards (often 95%+) commands a significant premium. For instance, clean aluminum off-cuts sell for a much higher price per ton than mixed ferrous scrap.

3. How does "nesting" reduce scrap costs?

Nesting is a software-driven process used during the design phase to lay out parts on a metal strip in the most efficient pattern possible. By interlocking shapes and minimizing the distance between cuts (the web), manufacturers improve the Material Utilization Ratio (MUR), ensuring more finished parts are produced from the same amount of raw coil, directly reducing the volume of waste generated.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —