Stamping Automotive Pillars: Advanced Technologies & Engineering Solutions

TL;DR

Stamping automotive pillars is a high-precision manufacturing process critical for vehicle safety and structural integrity. It involves forming A, B, and C pillars from Ultra-High-Strength Steels (UHSS) and advanced aluminum alloys using techniques like hot stamping and progressive die forming. Manufacturers must balance conflicting goals: maximizing crash protection—particularly for rollover and side-impact scenarios—while minimizing weight for fuel efficiency and EV range. Advanced solutions now include servo press technology and specialized tooling to overcome challenges like springback and work hardening.

Anatomy of Automotive Pillars: A, B, and C

The structural backbone of any passenger vehicle relies on a series of vertical supports known as pillars, labeled alphabetically from front to rear. While they function collectively to support the roof and manage impact energy, each pillar presents unique stamping challenges due to its specific geometry and safety role.

The A-pillar frames the windshield and secures the front door hinges. According to Group TTM, A-pillars are engineered with intricate 3D curves and varying wall thicknesses to optimize visibility while providing robust rollover protection. The geometric complexity often requires multiple forming operations to create flanges for windshield mounting without compromising the pillar's structural rigidity.

The B-pillar is perhaps the most critical component for occupant safety in side-impact collisions. Located between the front and rear doors, it connects the vehicle floor to the roof, acting as the primary load path during a crash. To prevent intrusion into the passenger cabin, B-pillars must possess exceptionally high yield strength. Manufacturers frequently utilize reinforcement tubes or patchworks of high-strength steel within the pillar assembly to maximize energy absorption.

C and D pillars support the rear of the cabin and the back window. While they endure lower direct impact loads than the B-pillar, they are essential for torsional stiffness and rear-end crash safety. In modern manufacturing, these components are increasingly integrated into larger body-side outer panels to reduce assembly steps and improve vehicle aesthetics.

Material Science: The Shift to UHSS and AHSS

The automotive stamping industry has largely pivoted from mild steels to Ultra-High-Strength Steel (UHSS) and Advanced High-Strength Steel (AHSS) to meet stringent crash regulations. This transition is driven by the need to increase the strength-to-weight ratio, which is particularly vital for electric vehicles (EVs) where battery weight must be offset by a lighter body-in-white.

Material grades such as Boron steel are now standard for safety-critical zones. These materials can achieve tensile strengths exceeding 1,500 MPa after heat treatment. However, working with these hardened materials introduces significant engineering hurdles. Higher tonnage presses are required to deform the material, and the risk of cracking or tearing during the draw process is elevated compared to softer alloys.

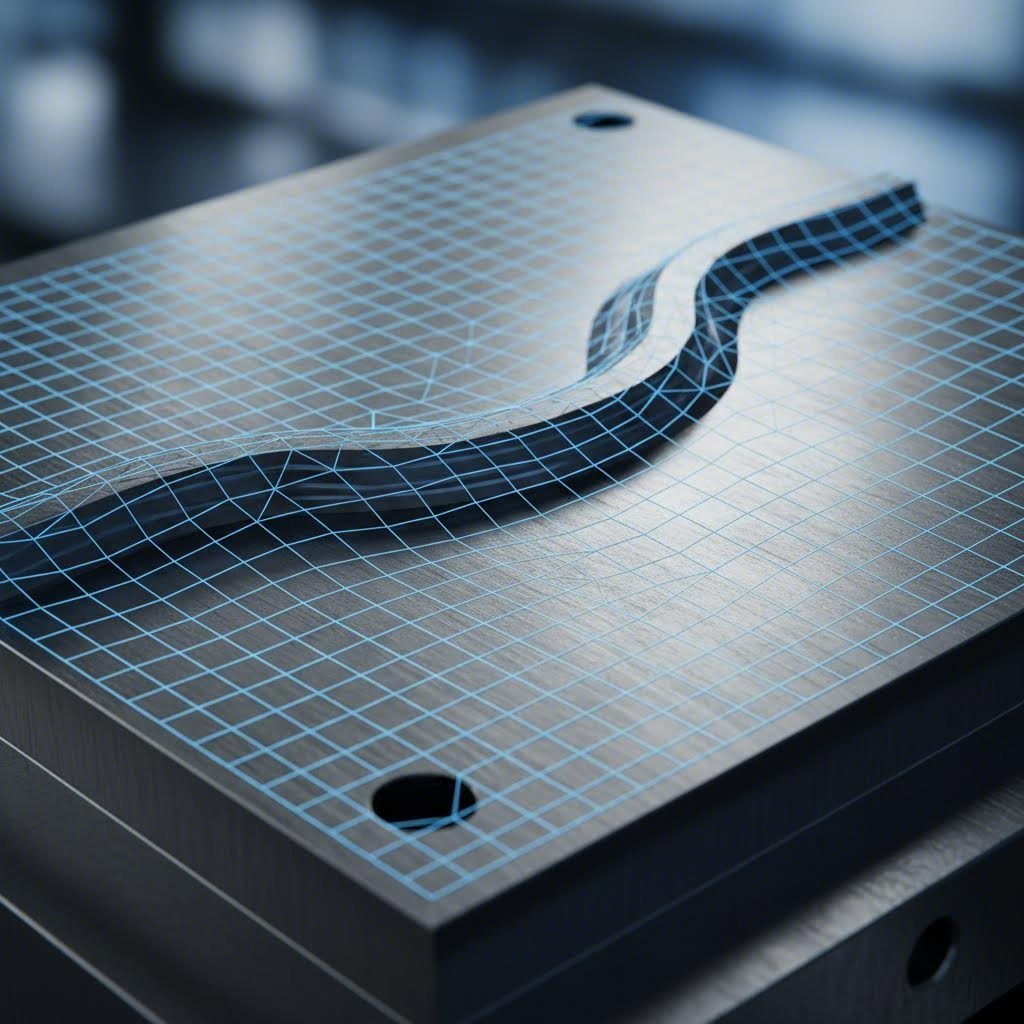

This material evolution also impacts tooling design. To withstand the abrasive nature of UHSS, stamping dies must be equipped with premium tool steel segments and often require specialized surface coatings. Manufacturers must also account for the "springback" effect—where the metal attempts to return to its original shape after forming—by engineering over-bending compensations directly into the die surface.

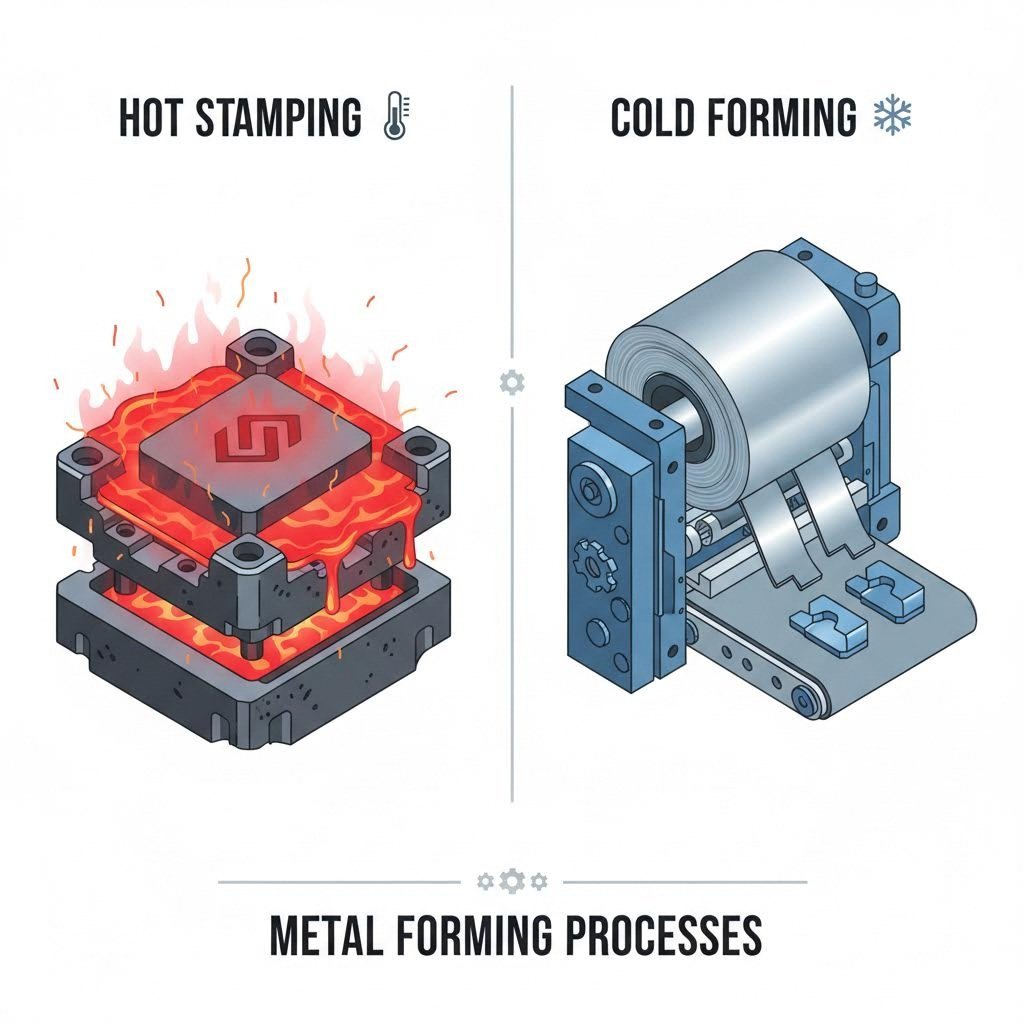

Primary Stamping Technologies: Hot vs. Cold Forming

Two dominant methodologies define the production of automotive pillars: hot stamping (press hardening) and cold forming (often using progressive dies). The choice between them depends largely on the part's complexity and the required strength characteristics.

Hot Stamping is the preferred method for components requiring ultra-high strength, such as B-pillars. In this process, the steel blank is heated to approximately 900°C until it becomes malleable (austenitization). It is then transferred quickly to a cooled die where it is formed and quenched simultaneously. Magna highlights that this technique allows for the creation of complex geometries with ultra-high strength properties that would crack if formed cold. The result is a dimensionally stable part with minimal springback.

Cold Forming and Progressive Dies remain the standard for parts with intricate features like the A-pillar. A progressive die performs a series of operations—piercing, notching, bending, and trimming—in a single continuous pass as the coil feeds through the press. This method is highly efficient for high-volume production. For manufacturers needing to bridge the gap between rapid prototyping and mass production, partners like Shaoyi Metal Technology offer scalable solutions, utilizing press capabilities up to 600 tons to handle complex automotive components with IATF 16949-certified precision.

Innovations like the "TemperBox" technology described by GEDIA allow for tailored tempering within the hot forming process. This enables engineers to create "soft zones" within a hardened B-pillar—areas that can deform to absorb energy while the rest of the pillar remains rigid to protect passengers.

Comparison of Stamping Methodologies

| Feature | Hot Stamping (Press Hardening) | Cold Forming / Progressive Die |

|---|---|---|

| Primary Application | B-Pillars, Door Rings, Safety Reinforcements | A-Pillars, C-Pillars, Structural Brackets |

| Material Strength | Ultra-High (1,500+ MPa) | High (up to 980-1,200 MPa typically) |

| Cycle Time | Slower (due to heating/cooling cycle) | Fast (continuous strokes) |

| Dimensional Accuracy | Excellent (minimal springback) | Good (requires springback compensation) |

| Tooling Cost | High (cooling channels, thermal management) | Moderate to High (complex die stations) |

Engineering Challenges & Solutions in Pillar Production

Manufacturing automotive pillars is a constant battle against physical limitations. Springback is the most pervasive issue in cold stamping UHSS. Because the material retains significant elastic memory, it tends to unbend slightly after the press opens. Advanced simulation software is now used to predict this movement, allowing toolmakers to machine the die surface to a "compensated" shape that yields the correct final geometry.

Lubrication and surface quality are equally critical. High contact pressures can lead to galling (material transfer) and excessive tool wear. Furthermore, residual lubricants can interfere with downstream welding processes. A case study by IRMCO demonstrated that switching to an oil-free, fully synthetic stamping fluid for galvanized steel pillars reduced fluid consumption by 17% and eliminated white corrosion issues that were causing weld defects.

Dimensional precision is non-negotiable, as pillars must align perfectly with doors, windows, and roof panels. Variations of even a millimeter can lead to wind noise, water leaks, or poor closing efforts. To ensure accuracy, many manufacturers employ in-line laser measurement systems or check fixtures that verify the position of every mounting hole and flange immediately after stamping.

Future Trends: Lightweighting and EV Integration

The rise of electric vehicles is reshaping pillar design. The heavy battery pack in EVs necessitates aggressive lightweighting elsewhere in the chassis. This is driving the adoption of Tailor Welded Blanks (TWB), where sheets of different thicknesses or grades are laser-welded together before stamping. This puts the thickest, strongest metal only where it is needed (e.g., the upper B-pillar) and uses thinner metal elsewhere to save weight.

Radical design changes are also on the horizon. Some concepts, such as B-pillarless door systems, completely reimagine the body structure to improve accessibility. These designs shift the structural load typically handled by the B-pillar into reinforced doors and rocker panels, requiring even more advanced stamping and latching mechanisms to maintain side-impact safety standards.

Precision at the Core of Safety

The manufacturing of automotive pillars represents the intersection of advanced metallurgy and precision engineering. As safety standards evolve and vehicle architectures shift toward electrification, the stamping industry continues to innovate with smarter dies, stronger materials, and more efficient processes. Whether through the heat of press hardening or the speed of progressive dies, the goal remains constant: producing a rigid, lightweight safety cell that protects occupants without compromise.

Frequently Asked Questions

1. What is the difference between hot stamping and cold stamping for pillars?

Hot stamping (press hardening) involves heating the steel blank to around 900°C before forming and quenching it in the die. This process is used to create ultra-high-strength components like B-pillars that resist intrusion. Cold stamping forms the metal at room temperature, which is faster and more energy-efficient, but dealing with springback in high-strength materials is more challenging. It is often used for A-pillars and other structural parts.

2. Why are B-pillars made from Ultra-High-Strength Steel (UHSS)?

B-pillars are the primary defense against side-impact collisions. Using UHSS allows the pillar to withstand immense forces and prevent the vehicle cabin from collapsing inward, protecting the occupants. The high strength-to-weight ratio of UHSS also helps reduce the overall vehicle weight compared to using thicker gauges of milder steel.

3. How do manufacturers handle springback in stamped pillars?

Springback occurs when stamped metal tries to return to its original shape. Manufacturers use advanced simulation software (AutoForm, Dynaform) to predict this behavior and design the stamping dies with "over-bend" or compensated surfaces. This ensures that when the part springs back, it settles into the correct final dimensions.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —