Stamping Airbag Housings: Deep Draw Protocols & Servo Control Strategies

TL;DR

Stamping airbag housings represents the pinnacle of automotive metal forming, requiring the transformation of flat sheet metal into seamless, high-pressure canisters through deep draw stamping. Unlike standard brackets, these safety-critical components function as pressure vessels, demanding 1008 Cold-Rolled Steel or HSLA grades to withstand explosive deployment forces without fragmentation. The manufacturing standard has shifted toward servo-driven presses (typically 400–600 tons) which allow for precise ram speed profiling—slowing down during the draw to prevent wall thinning and speeding up during retraction to maximize output.

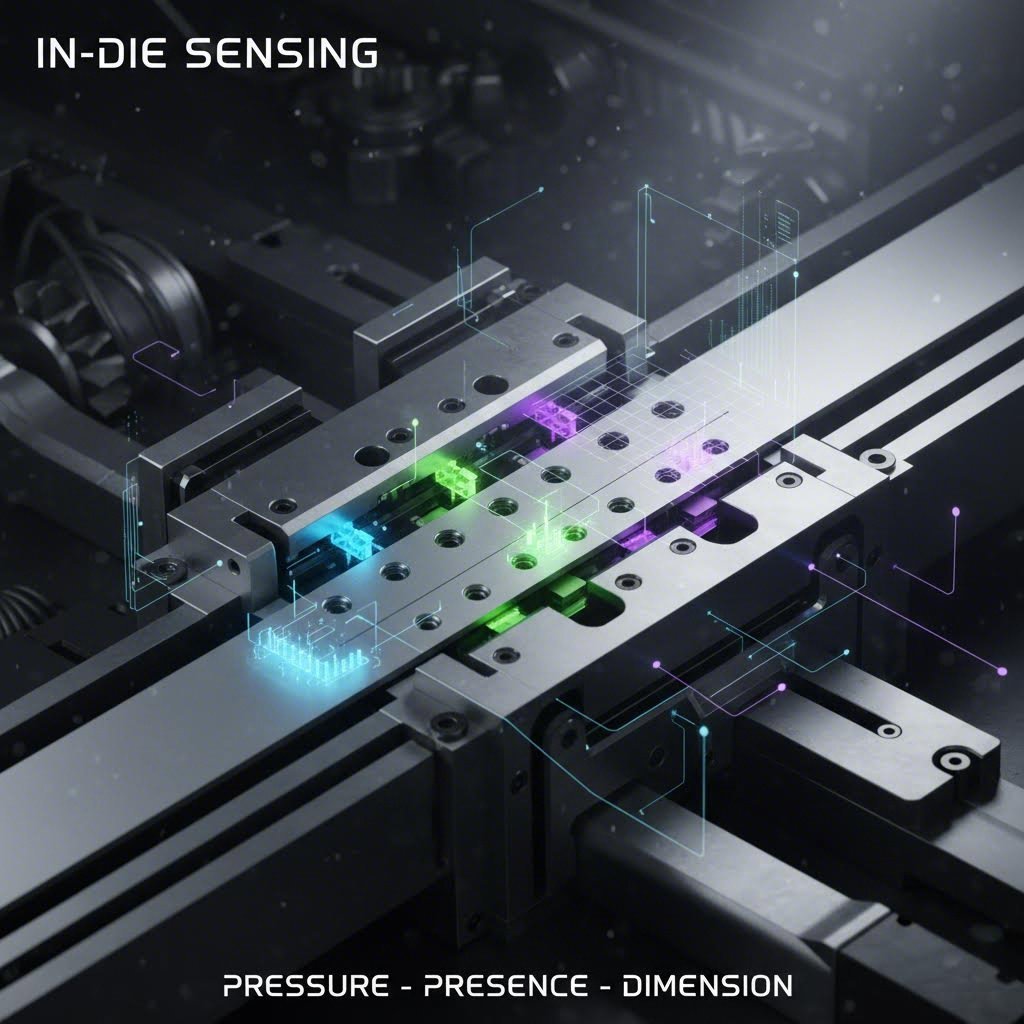

To ensure zero-defect production, top-tier manufacturers integrate in-die sensing technologies, such as leak testing and vision inspection, directly into the stamping line. This approach eliminates the risk of shipping defective units by verifying critical dimensions and pressure integrity before the part ever leaves the press.

Deep Draw Mechanics: The Critical Process for Airbag Housings

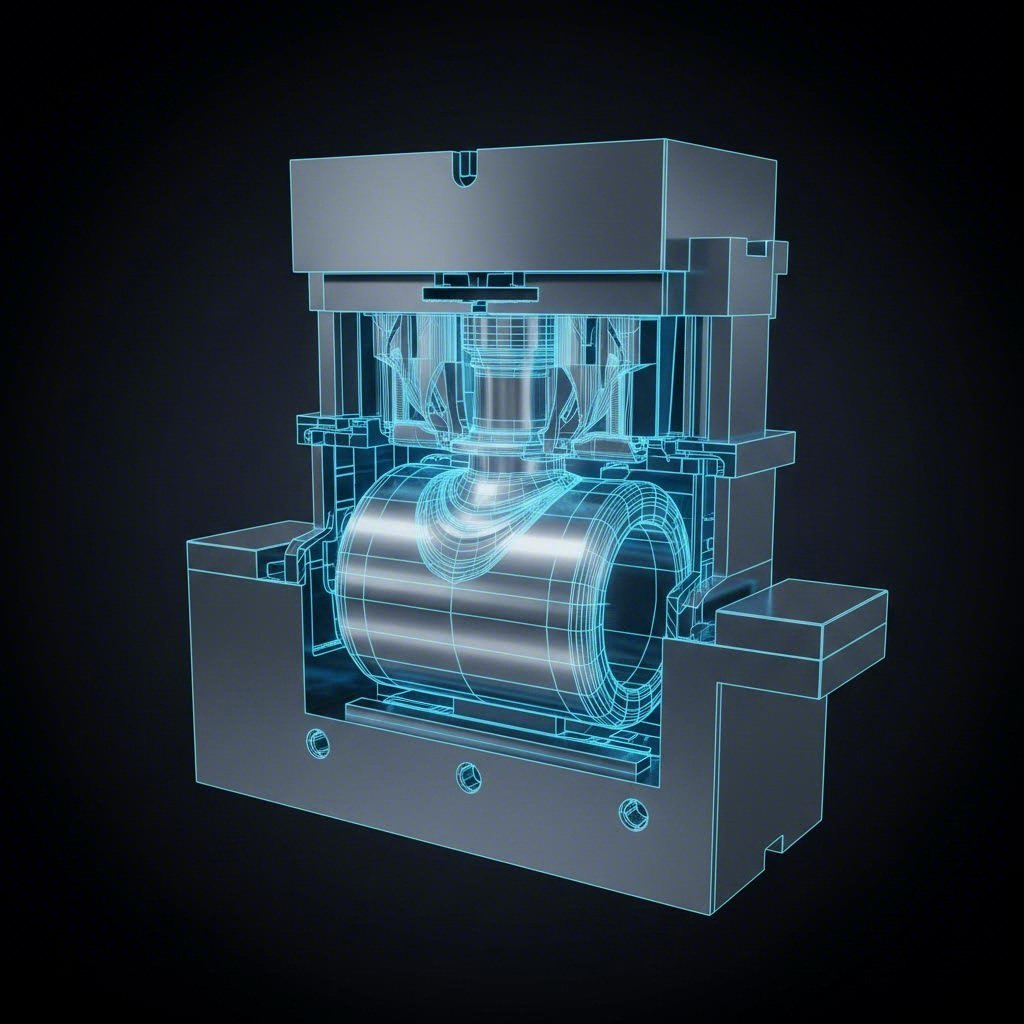

The manufacturing of airbag housings—specifically for driver-side inflators and passenger-side diffusers—is almost exclusively achieved through deep draw metal stamping. This process is distinct from standard progressive stamping because the depth of the component often exceeds its diameter, creating significant material flow challenges. The goal is to produce a "canister" shape that houses the chemical propellant and airbag cushion while maintaining a hermetic seal.

The process typically involves a multi-stage transfer or progressive die sequence: blanking, cupping, redrawing, and ironing. During the initial cupping stage, the material is drawn into the die cavity. Subsequent redrawing stations step down the diameter while increasing the depth. A critical engineering challenge here is managing wall thickness. As the metal flows into the die, it naturally thins at the radius and thickens at the flange. Successful stamping of airbag housings requires precise clearance management to keep wall thickness within strict tolerances (often ±0.05mm), ensuring the housing does not burst unpredictably during deployment.

Advanced manufacturers utilize techniques like zigzag servo feeds to optimize material usage. By nesting circular blanks in a staggered pattern, producers can reduce scrap rates by up to 7%, a significant cost saver in high-volume automotive production. This efficiency is critical given the expensive nature of the deep-draw quality steel required for these applications.

Material Specifications: Steel Grades & Trade-offs

Material selection for airbag housings is a balance between formability (ductility) and tensile strength. The material must be soft enough to undergo severe plastic deformation during the deep draw process without tearing, yet strong enough to act as a pressure vessel during the explosive airbag deployment event.

| Material Grade | Primary Benefit | Typical Application | Formability vs. Strength |

|---|---|---|---|

| 1008 Cold-Rolled Steel (CRS) | Superior Formability | Standard inflator housings | High ductility, Moderate strength |

| HSLA (High-Strength Low-Alloy) | Weight Reduction | Modern lightweight vehicles | Lower ductility, High strength |

| 304 Stainless Steel | Corrosion Resistance | External or exposed housings | Difficult to form, High durability |

While 1008 CRS remains the industry standard for its predictability in deep drawing, there is a marked shift toward High-Strength Low-Alloy (HSLA) steels. Automakers are aggressively pursuing lightweighting strategies, and HSLA allows for thinner walls without compromising containment strength. However, HSLA presents manufacturing challenges; its higher yield strength leads to increased springback and faster die wear. According to Design News, earlier steel designs required complex assemblies of up to five stampings and dozens of rivets, whereas modern material science allows for more integrated, monolithic deep-drawn shapes that reduce assembly points and failure modes.

Advanced Machinery: Servo Presses & Ram Profiling

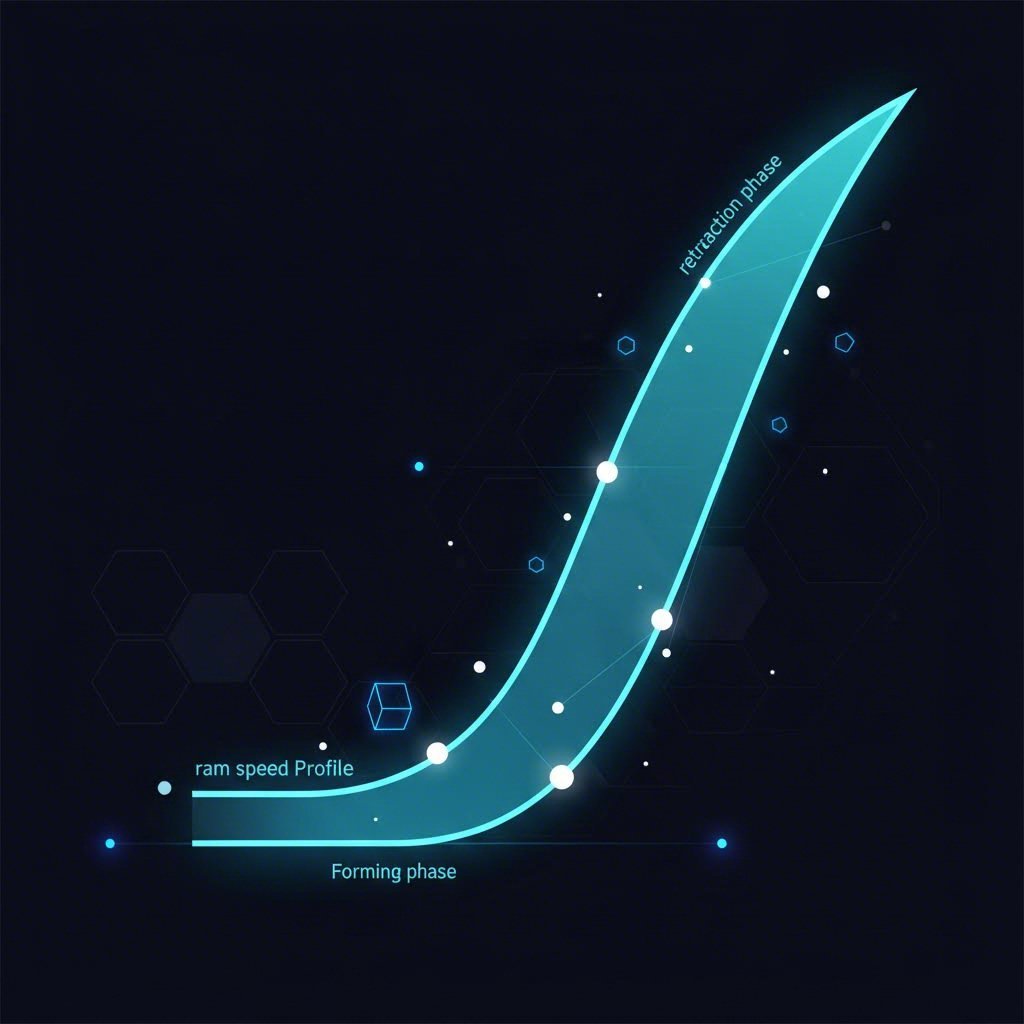

The geometric complexity of airbag housings has rendered standard mechanical flywheel presses obsolete for top-tier production. The industry now relies heavily on servo press technology. Unlike mechanical presses that run at a fixed velocity curve, servo presses utilize high-torque motors to directly drive the ram, allowing engineers to program the slide velocity at any point in the stroke.

This capability is indispensable for stamping airbag housings. For instance, manufacturers can program the press to decelerate rapidly just as the punch contacts the material, maintaining a slow, constant velocity during the deep draw portion of the stroke. This "soft touch" allows the material to flow properly, preventing thinning and fractures. Once the part is formed, the ram accelerates to maximum speed for the return stroke. MetalForming Magazine highlights case studies where servo presses change speed up to seven times per single stroke, optimizing the forming window while maintaining high strokes per minute (SPM).

Furthermore, servo presses facilitate "pendulum" or "half-stroke" modes, where the ram does not return to top-dead-center, significantly reducing cycle time for shallower components. This precision control is what enables the consistent production of safety-critical features like the burst seam—the scored line where the airbag breaks through the housing upon deployment.

Quality Control: The Zero-Defect Mandate

In the realm of automotive safety components, statistical sampling is insufficient; 100% verification is the standard. Defective airbag housings can lead to catastrophic failure—either deploying too slowly or fragmenting into shrapnel. Consequently, modern stamping lines integrate in-die sensing and testing technologies that validate part quality before the die even opens.

- In-Die Pressure Testing: Sensors verify the integrity of the vessel immediately after forming to detect microscopic cracks or thinning that could lead to leaks.

- Hydro Burst Testing: While typically done offline on a sample basis, this test pressurizes the housing to failure to ensure it bursts at the engineered pressure limit and in the correct location.

- Vision Inspection: High-speed cameras integrated into the line measure critical dimensions, such as flange flatness and mounting hole location, ensuring seamless assembly with the airbag module.

- Inside-Out Piercing & Hole Detection: Specialized cam dies pierce side holes for mounting gas generators, with sensors confirming that every slug is removed (slug detection) to prevent rattles or blockages.

Leading manufacturers like Metal Flow emphasize that these technologies are not add-ons but fundamental aspects of the tooling design. By catching defects at the source, manufacturers protect OEM clients from the massive financial and reputational costs of safety recalls.

Strategic Sourcing & Cost Factors

Procuring stamped airbag housings involves evaluating potential partners on more than just piece price. The major cost drivers are tooling (progressive vs. transfer dies), material utilization, and certification. Transfer dies are generally more expensive but necessary for deeper draws, while progressive dies offer higher speed for shallower components.

To manage these complexities, automotive OEMs and Tier 1 suppliers often seek partners who bridge the gap between engineering validation and mass production. For those navigating this landscape, Shaoyi Metal Technology's comprehensive stamping solutions offer a strategic advantage. With press capabilities reaching 600 tons and strict adherence to IATF 16949 standards, they provide the necessary infrastructure to scale from rapid prototyping of 50 units to full-volume manufacturing of millions, ensuring that safety-critical specifications are met from the very first strike.

Buyer’s Checklist for Airbag Housing Manufacturers:

- Tonnage Capacity: Do they have 400-600 ton servo presses to handle HSLA steel?

- In-Die Protection: Is sensor integration part of their standard tooling build?

- Certification: Is the facility IATF 16949 certified (mandatory for automotive)?

- Secondary Ops: Can they handle washing, deburring, and plating in-house to reduce logistics risks?

Engineering Precision for Safety

The manufacturing of airbag housings is a discipline where metallurgy, mechanical engineering, and metrology converge. As vehicle safety standards evolve and automakers push for lighter, stronger materials, the reliance on deep draw expertise and servo-controlled precision will only deepen. Success in this sector is defined not just by the ability to form metal, but by the ability to guarantee the integrity of that form under the most extreme conditions imaginable.

Frequently Asked Questions

1. Who are the primary manufacturers of airbag systems using these housings?

The global market is consolidated among a few major Tier 1 suppliers who integrate stamped housings into complete airbag modules. Key players include Autoliv, which is widely recognized as the industry leader, along with ZF Friedrichshafen AG, Hyundai Mobis, Denso Corporation, and Continental AG. These companies set the rigorous specifications that stamping suppliers must meet.

2. Why is deep draw stamping preferred over casting for airbag housings?

Deep draw stamping is preferred because it produces parts with superior grain structure and structural integrity compared to casting. Stamped steel offers higher tensile strength and ductility, which is essential for a pressure vessel that must expand without shattering. Additionally, stamping is significantly faster and more cost-effective for high-volume automotive production runs compared to die casting or machining.

3. What is the typical production volume for stamped airbag parts?

Airbag housings are high-volume components, often produced in the millions annually. Because almost every modern vehicle requires multiple airbags (driver, passenger, side-curtain, knee), a single stamping line with high-speed servo presses can produce thousands of parts per shift. This volume justifies the high initial investment in complex progressive or transfer tooling.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —