Automotive Stamping Burr Reduction: Precision Strategies for Zero-Defect Parts

TL;DR

Automotive stamping burr reduction relies on a dual strategy: proactive prevention through precise engineering and reactive precision removal. While post-process deburring is common, the most effective method involves optimizing punch-to-die clearance—typically 8–12% of material thickness for standard steels—to ensure a clean fracture rather than a tear.

For modern automotive applications involving Advanced High-Strength Steels (AHSS), relying on the traditional "10% rule" often fails. Engineers must adopt material-specific clearance formulas, implement rigorous tool maintenance schedules (every 5,000 strokes), and utilize advanced finishing technologies like Electrochemical Machining (ECM) or hybrid CNC processing to meet zero-defect OEM standards.

Automotive Burr Standards & Acceptance Criteria

In the automotive industry, a "burr" is not just a cosmetic defect; it is a potential failure point that can compromise assembly fit, electrical conductivity, and safety. The definition of an acceptable burr is strictly governed by standards such as DIN 9830 and customer-specific OEM requirements. Historically, the general rule of thumb for acceptable burr height was 10% of the material thickness (t). For a 1mm sheet, a 0.1mm burr might have been passable.

However, this linear rule breaks down with the widespread adoption of AHSS and aluminum alloys in modern vehicle manufacturing. For critical mating parts, a burr height exceeding 0.003 inches (approx. 0.076mm) is often visible and problematic, while anything over 0.005 inches creates a safety hazard for handling and assembly. High-precision components often demand tolerances as tight as 25–50 µm to ensure proper function in engines or transmissions.

Meeting these rigorous demands requires a manufacturing partner capable of maintaining consistent precision across high volumes. For instance, Shaoyi Metal Technology utilizes presses up to 600 tons and IATF 16949-certified processes to deliver critical components like control arms that strictly adhere to global OEM standards, bridging the gap from prototype to mass production.

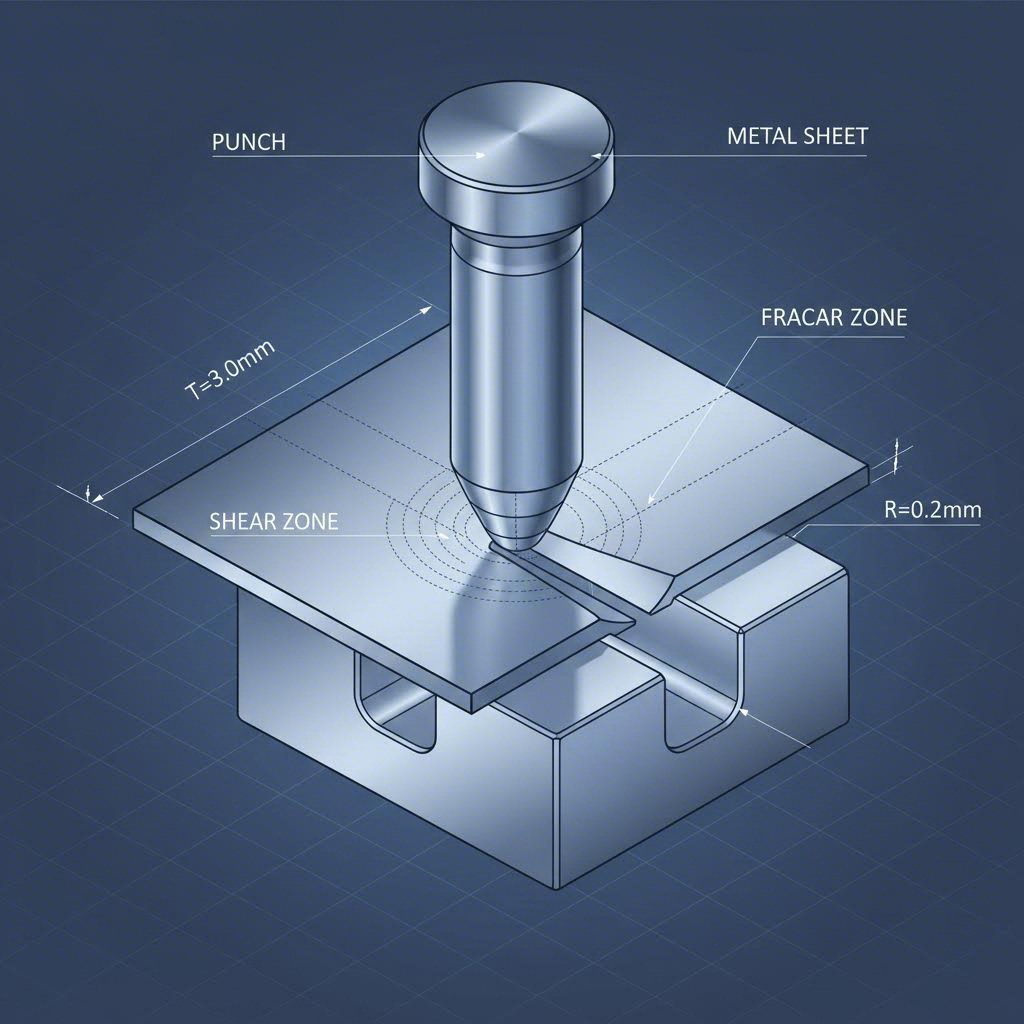

Phase 1: Precision Die Clearance & Engineering

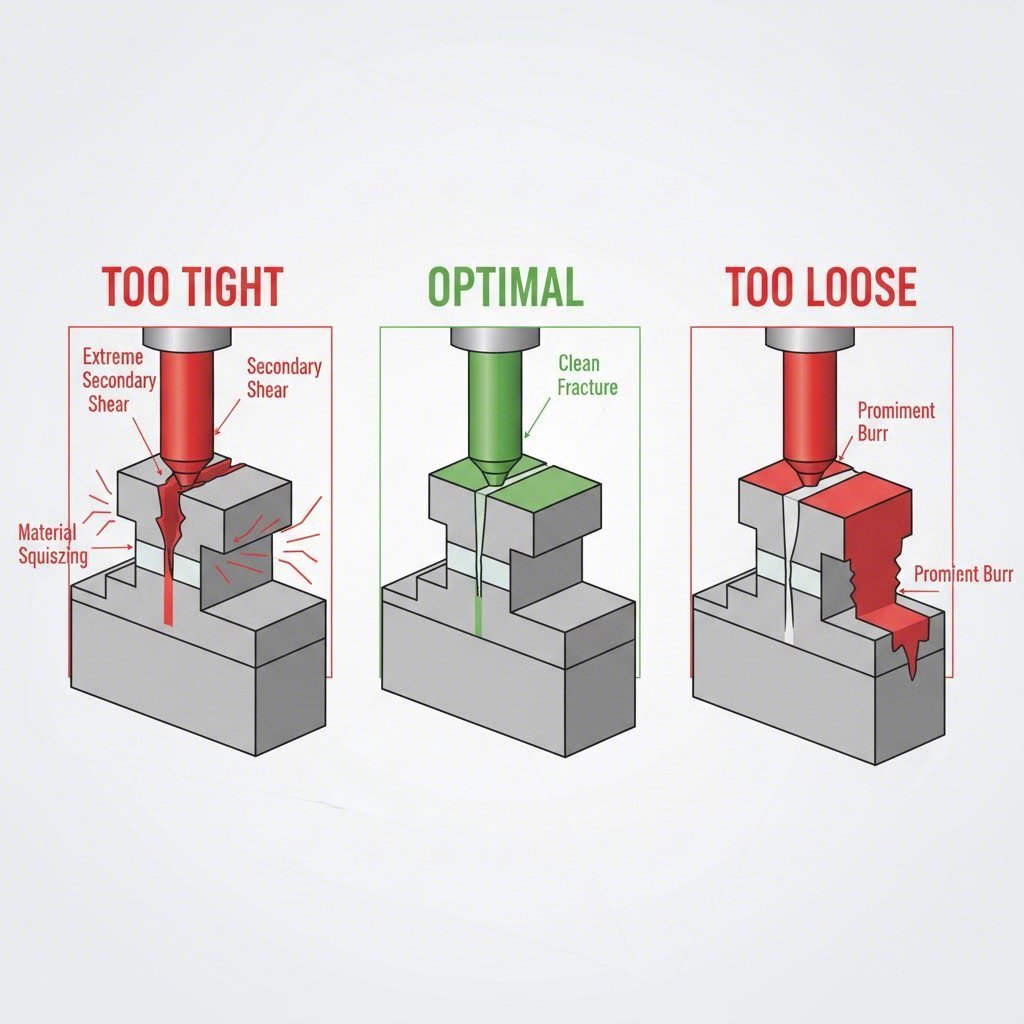

The most effective way to minimize burrs is to prevent them during the engineering phase. The primary lever for prevention is the punch-to-die clearance. If the clearance is too tight, the material undergoes secondary shearing, creating a ragged edge. If the clearance is too loose, the material tears rather than shears, leaving a large roll-over and a heavy burr.

Optimizing clearance is not a "one size fits all" calculation. It depends heavily on the material's tensile strength and thickness. Industry data suggests the following clearance percentages (per side) for common automotive materials:

| Material Type | Recommended Clearance (% of Thickness) | Why? |

|---|---|---|

| Cold-Rolled Steel | 8% – 10% | Balances shear strength and fracture propagation. |

| Stainless Steel | 10% – 12% | Higher work hardening requires slightly larger clearance. |

| Aluminum (5000/6000 Series) | 7% – 9% | Softer material tends to drag; tighter clearance helps snap the fracture. |

| Inconel / High-Alloy | 5% – 8% | Extreme hardness requires very tight control to prevent hardening. |

For high-strength steels, clearances may need to increase significantly—sometimes up to 21% of material thickness—to accommodate the material's resistance to fracture. Engineers must also account for press deflection. Even with perfect tool geometry, a press that lacks parallelism can introduce uneven clearance during the stroke, causing burrs on one side of the part. Regular load balancing and centering of the die are as critical as the tool design itself.

Phase 2: Tool Maintenance & Cutting Edge Management

Even perfectly engineered dies will produce burrs if the cutting edge degrades. A sharp cutting edge concentrates stress effectively to initiate fracture. As the edge rounds over, the force distributes over a larger area, causing the material to flow plastically before breaking, which results in a burr.

A cutting edge is generally considered "dull" when the edge radius exceeds 0.05mm. To prevent this, proactive maintenance is essential. Best practices include:

- Scheduled Regrinding: Do not wait for visible burrs. Implement maintenance intervals based on stroke count—typically inspecting cutting sections every 5,000 to 10,000 strokes depending on the material severity.

- Proper Grinding Protocol: When sharpening, it is standard to remove 0.05–0.1mm of material to restore a pristine edge. Ensure the grinding heat does not anneal (soften) the tool steel.

- Advanced Coatings: Applying surface treatments like PVD (Physical Vapor Deposition) or TD treatment can dramatically extend tool life. For example, a coated punch might last 600,000 strokes compared to 200,000 for an uncoated one, maintaining edge sharpness for longer periods.

Phase 3: Post-Process Deburring Technologies

When prevention alone cannot meet the strict surface finish requirements—such as Ra 0.8µm for fuel system parts—post-process deburring becomes necessary. Manufacturers choose between mass finishing and precision methods based on the part's geometry and volume.

Mass Finishing Methods

For bulk automotive brackets and clips, vibratory tumbling or barrel finishing is the standard. Parts are submerged in a media (ceramic, plastic, or steel) and vibrated. This abrasive action grinds away external burrs. While cost-effective, it lacks selectivity and can slightly alter the part's overall dimensions if not carefully controlled.

Precision Deburring Methods

For complex geometries like hydraulic manifolds or transmission valves, mass finishing is often insufficient. Electrochemical Deburring (ECM) uses electrolysis to dissolve burrs without touching the part, ensuring no mechanical stress is applied. Similarly, the Thermal Energy Method (TEM) utilizes a rapid burst of heat to vaporize thin burrs instantly. These methods are more expensive but guarantee the internal cleanliness required for critical fluid-handling components.

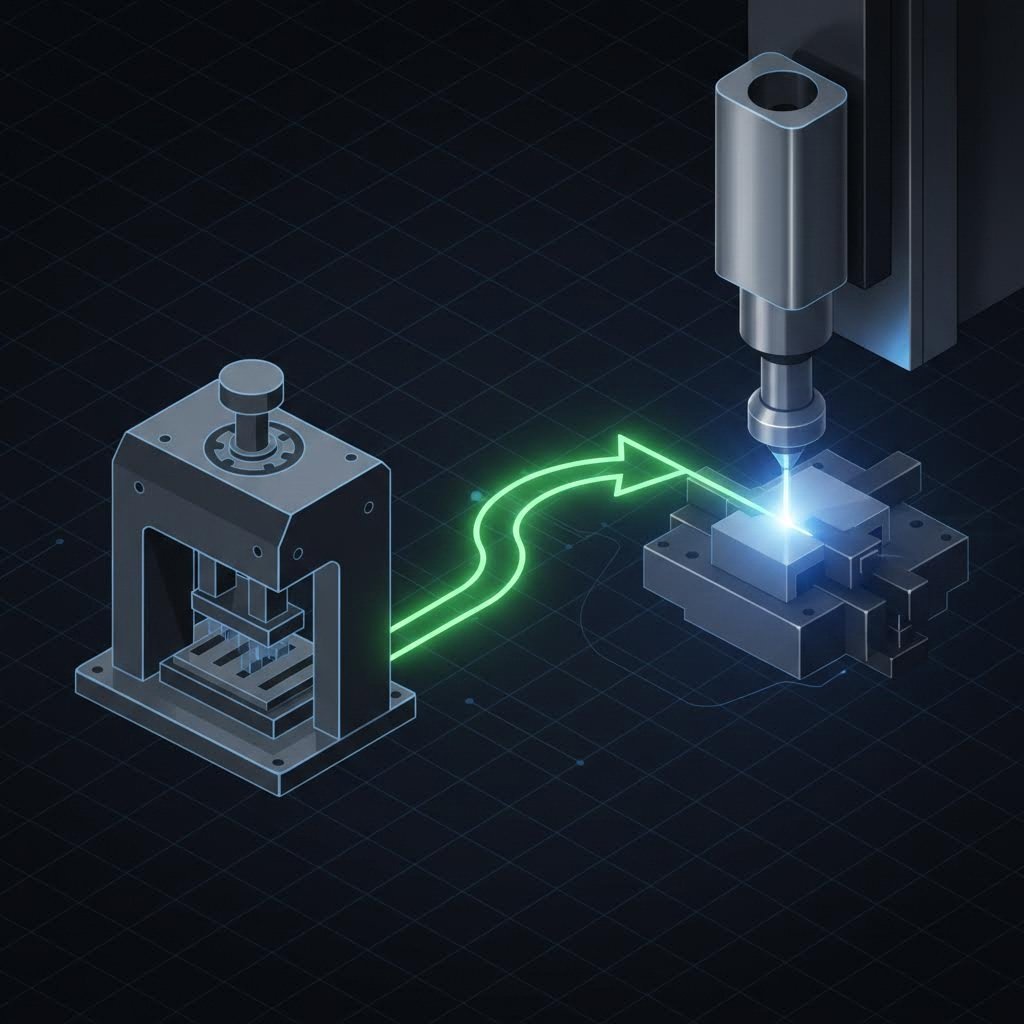

Advanced Innovation: Hybrid Stamping & CNC

The frontier of automotive stamping burr reduction lies in hybrid processing. Traditional stamping allows for speed, but often leaves rough edges. CNC machining offers precision but is slow. Hybrid Stamping-CNC technologies combine these processes into a unified workflow.

In this approach, the part is stamped to near-net shape and then immediately processed by a CNC unit to trim critical edges. This method can reduce burr height from a typical 0.1mm down to an imperceptible 0.02mm. It is particularly valuable for visible interior components (like speaker grilles or dashboard trims) and high-precision EV battery terminals where even microscopic conductive debris could cause a short circuit.

Conclusion

Eliminating burrs in automotive stamping is a function of discipline, not luck. It starts with calculating the correct die clearance for the specific material grade and maintaining tool sharpness through rigorous schedules. However, as material standards evolve, so must the solutions. Integrating advanced post-processing or hybrid technologies ensures that manufacturers can deliver zero-defect parts that survive the scrutiny of modern automotive quality control.

Frequently Asked Questions

1. What is the maximum acceptable burr height for automotive parts?

While the traditional limit was 10% of the material thickness, modern automotive standards often demand much tighter tolerances. For critical mating surfaces or high-precision assemblies, burrs must often be kept under 0.05mm (0.002 inches) to prevent assembly issues and safety hazards.

2. How does die clearance affect burr formation?

Die clearance dictates how the metal fractures. Insufficient clearance (too tight) causes secondary shearing and ragged edges, while excessive clearance (too loose) causes the metal to roll over and tear. The optimal clearance creates a clean fracture zone, typically ranging from 8% to 12% of the material thickness depending on the steel grade.

3. Can chemical etching eliminate burrs completely?

Yes, chemical etching is a burr-free process because it dissolves material rather than cutting it with force. It eliminates mechanical stress and deformation, making it an excellent alternative for intricate, flat automotive components like shims, screens, or fuel cell plates where traditional stamping might cause distortion.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —