Stamped Suspension Components: Manufacturing Tech & Benefits

TL;DR

Stamped suspension components are critical structural parts—such as control arms, subframes, and wishbones—manufactured by forming high-tensile sheet metal under high-tonnage presses. This process offers superior strength-to-weight ratios and cost-efficiency for high-volume automotive production compared to casting or forging. Key advantages include precise repeatability, the ability to utilize advanced high-strength steels (AHSS) for lightweighting, and scalability for Tier 1 supply chains.

For procurement officers and engineers, the selection of a stamping partner hinges on capabilities in progressive die technology, adherence to IATF 16949 standards, and expertise in handling modern materials like SPFH590 to meet strict EV range and emissions targets.

What Are Stamped Suspension Components?

Stamped suspension components represent the backbone of modern automotive chassis design, bridging the gap between static structural integrity and dynamic vehicle handling. Unlike casting, which pours molten metal into a mold, stamping involves the cold forming of flat sheet metal—typically high-strength steel or aluminum—into complex geometries using precision dies and mechanical presses.

The primary components produced through this method include:

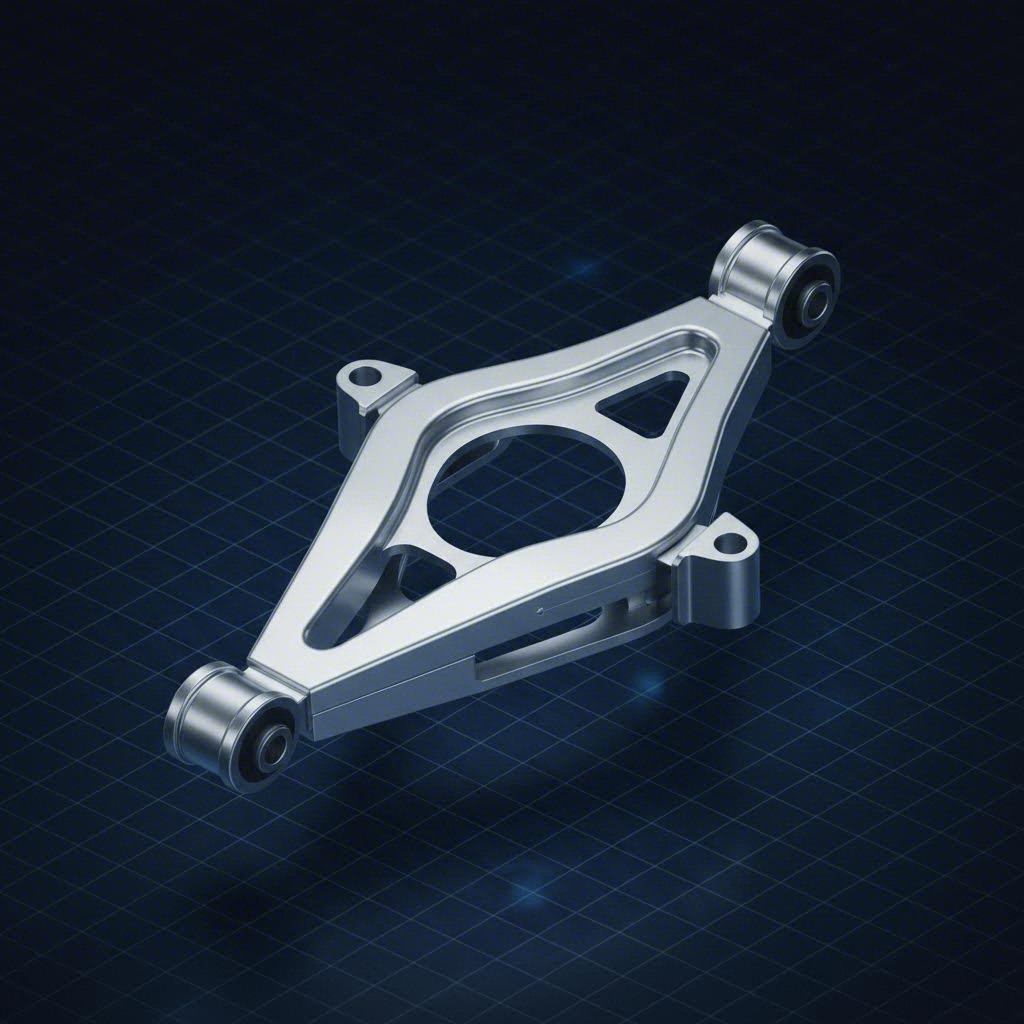

- Control Arms (A-Arms): The critical links connecting the wheel hub to the vehicle frame, managing wheel motion. Stamped control arms are favored for their ability to balance high durability with reduced mass.

- Subframes and Cross-members: Large structural foundations that support the engine and suspension geometry. Stamping allows these to be produced in halves (shells) and welded, creating rigid box sections.

- Suspension Links and Wishbones: Connectors that maintain wheel alignment during travel, often requiring complex bending to clear other chassis parts.

- Spring Seats and Brackets: High-volume mounting points that require extreme consistency for safe assembly.

The shift toward stamped suspension parts is driven largely by the automotive industry's urgent need for lightweighting. As manufacturers race to extend electric vehicle (EV) range and meet tighter emissions standards for internal combustion engines, replacing heavy cast iron parts with stamped high-tensile steel significantly reduces unsprung mass. This reduction not only improves fuel efficiency but also enhances steering response and ride comfort.

The Manufacturing Process: From Coil to Component

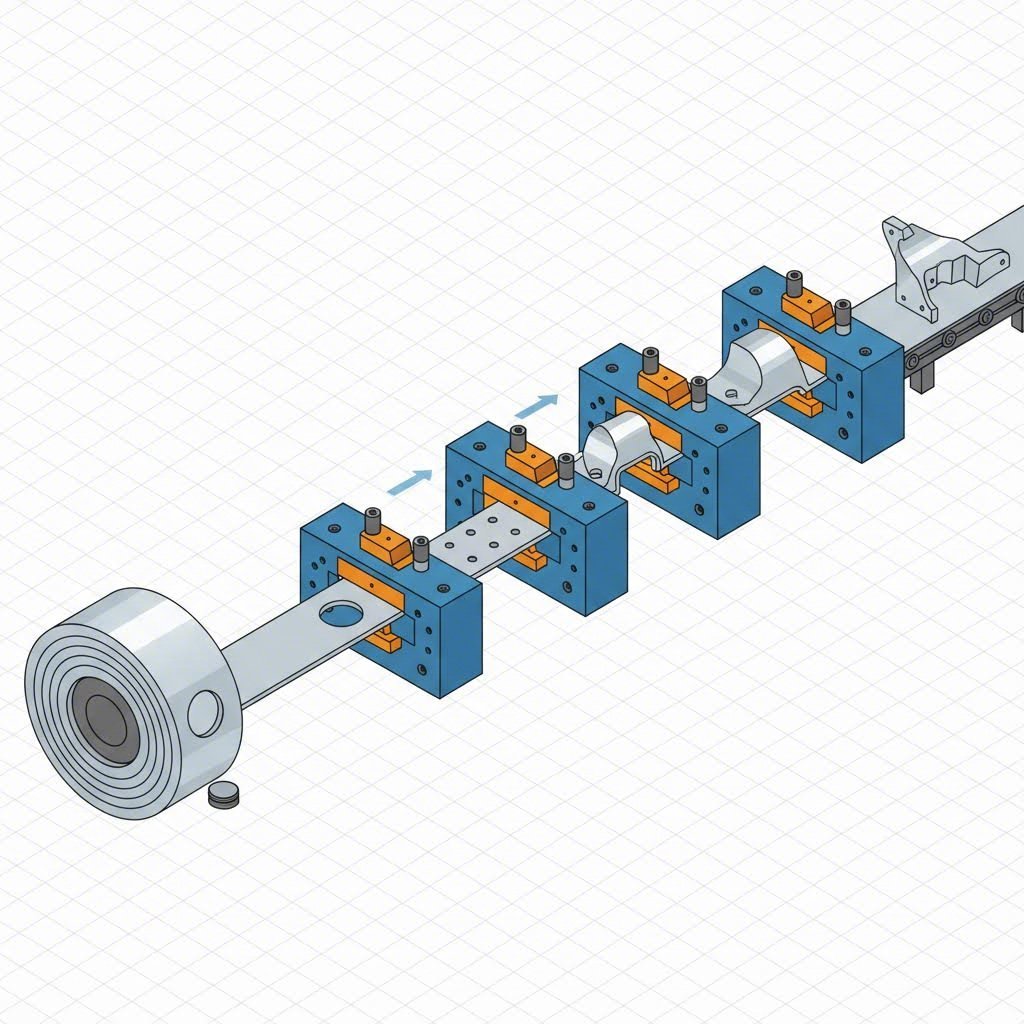

Manufacturing stamped suspension parts is a sophisticated workflow that demands rigorous process control to ensure every micron of the final geometry meets OEM specifications. The process typically follows a linear path from raw material to finished assembly.

1. Design and Die Creation

Production begins in the engineering department, where CAD/CAM software simulates metal flow to predict potential failure points like thinning or springback. Tool and die makers then craft the negative and positive molds (dies) from hardened tool steel. For complex suspension parts, progressive dies are often used, where a metal strip moves through multiple stations within a single press, performing cutting, bending, and forming operations sequentially.

2. Blanking and Piercing

The raw coil is fed into the press. The first physical step is blanking and piercing, where the approximate outline of the part is cut (blanked) from the strip, and necessary holes for bushings or mounting bolts are punched (pierced). Precision here is vital; a misalignment of even a millimeter can lead to assembly failures down the line.

3. Forming and Bending

This is the core transformation. The blank is forced into the die cavity to take its three-dimensional shape. For deep components like subframe shells, this may involve deep drawing, where the metal is stretched. For control arms, the process typically involves bending flanges to create structural rigidity. Advanced transfer die systems may be used for larger parts, mechanically moving the component between separate presses for different forming operations.

4. Embossing and Coining

To further enhance structural stiffness without adding weight, manufacturers employ embossing (raising a section of the metal) and coining (squeezing the metal to refine edges or create precise mounting surfaces). These features act like ribs, preventing the component from buckling under heavy suspension loads.

5. Assembly and Finishing

Stamped suspension parts rarely leave the factory as single sheets. They are often welded (e.g., two stamped shells welded together to form a hollow control arm), assembled with bushings and ball joints, and finally treated. Surface finishing such as E-coating (electro-coating) is standard to provide the heavy-duty corrosion resistance required for under-carriage exposure.

Materials & Technology: The High-Tensile Shift

The material landscape for suspension stamping has evolved dramatically. While mild carbon steel was once the standard, modern requirements have pushed the industry toward Advanced High-Strength Steels (AHSS).

Grades such as SPFH590 and other high-tensile steels (often exceeding 590 MPa tensile strength) allow engineers to use thinner gauges of metal without compromising structural safety. This "thin-wall, high-strength" approach is the gold standard for automotive suspension components manufacturing in the EV era.

However, stamping AHSS presents unique challenges. The material's high strength results in significant "springback"—the tendency of the metal to return to its original shape after forming. Manufacturers must use advanced simulation software to over-bend parts precisely so they spring back to the correct tolerance. Additionally, tooling wear is accelerated, requiring frequent maintenance and the use of carbide-coated dies.

Aluminum is also widely used for premium and performance vehicles due to its superior weight savings, though it requires specialized handling to prevent cracking during the forming process and typically incurs higher material costs than steel.

Stamping vs. Forging & Casting: A Comparative Analysis

Selecting the right manufacturing method is a trade-off between volume, cost, and performance. While forging provides exceptional strength and casting offers geometric freedom, stamping reigns supreme for high-volume efficiency.

| Feature | Metal Stamping | Casting (Iron/Aluminum) | Forging |

|---|---|---|---|

| Production Volume | Best for High Volume (>10k units) | Low to Medium Volume | Medium Volume |

| Material Efficiency | High (Minimal scrap with nested designs) | Medium (Sprues/gates waste) | Low to Medium |

| Wall Thickness | Thin, Uniform (Lightweight) | Variable, Thicker (Heavier) | Thick, Solid |

| Tooling Cost | High Initial Investment | Lower Initial Investment | High Initial Investment |

| Unit Cost | Lowest (at scale) | Moderate | Highest |

| Structural Application | Control arms, links, subframes | Knuckles, engine blocks | Heavy-duty knuckles, hubs |

Stamping is the clear winner for components that require a shell-like structure to maximize the strength-to-weight ratio. A stamped control arm, formed from two welded sheets, provides the torsional rigidity needed for cornering while remaining significantly lighter than a solid cast equivalent.

Quality Standards & Supplier Selection

In the automotive Tier 1 supply chain, quality is not optional. Suspension parts are safety-critical; a failure at highway speeds can be catastrophic. Therefore, sourcing managers must enforce strict vetting criteria.

IATF 16949 Certification is the baseline requirement. Unlike general ISO 9001 standards, IATF 16949 focuses specifically on defect prevention, reduction of variation, and waste reduction in the automotive supply chain. A capable manufacturer must demonstrate:

- Traceability: The ability to track a specific batch of steel coil to a finished lot number.

- Fatigue Testing: In-house capabilities to cycle-test components to failure, ensuring they meet the millions of load cycles a vehicle endures.

- Process Repeatability: The use of automated inspection systems to ensure the millionth part is identical to the first.

Finding a partner who can manage the full lifecycle—from engineering validation to mass production—is often the biggest challenge. Some specialized manufacturers bridge this gap effectively. For example, Shaoyi Metal Technology offers comprehensive stamping solutions that span from rapid prototyping to high-volume manufacturing, leveraging IATF 16949 precision for critical components like control arms and subframes. Partnering with a supplier that offers this continuity reduces the risk of errors when scaling up from a prototype design to a production-ready die.

Conclusion

Stamped suspension components remain a cornerstone of automotive engineering, offering an unmatched balance of cost, weight, and performance. As the industry pivots toward electric mobility, the demand for high-tensile, lightweight stamped parts will only intensify. For buyers and engineers, success lies in selecting manufacturing partners who not only possess the requisite press tonnage but also the metallurgical expertise and quality systems to deliver zero-defect components at global scale.

Frequently Asked Questions

1. What is the difference between progressive die and transfer die stamping?

Progressive die stamping uses a single continuous strip of metal that moves through multiple stations within one press, making it ideal for smaller, faster-to-produce parts like brackets. Transfer die stamping involves moving individual parts between separate die stations (or presses), which allows for larger, more complex components like subframes that need more freedom of movement during forming.

2. Why is high-tensile steel preferred for suspension parts?

High-tensile steel allows manufacturers to use thinner sheets of metal to achieve the same or better strength compared to thicker mild steel. This reduces the overall weight of the vehicle (unsprung mass), which improves fuel economy, EV range, and suspension responsiveness.

3. Can aluminum be stamped for suspension components?

Yes, aluminum is frequently stamped for suspension parts to achieve maximum weight reduction. However, it requires different tooling considerations than steel due to its lower formability and higher tendency to crack. It is typically found in premium or performance vehicle applications where the higher material cost is justified.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —