Blanking vs. Piercing: The Automotive Engineer's Guide to Stamping

TL;DR

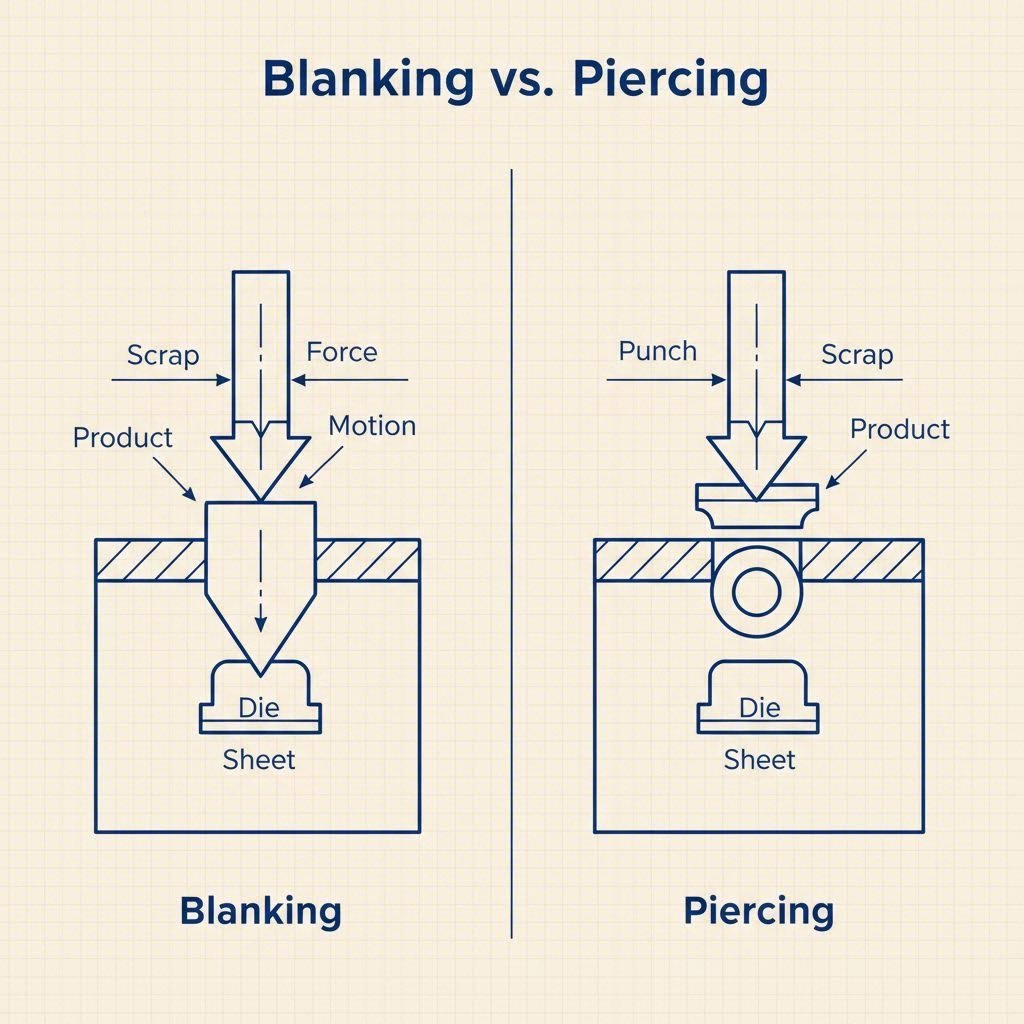

The fundamental difference between blanking and piercing lies in what happens to the cut-out piece of metal (the "slug"). In blanking, the piece punched out is the finished product (the "blank"), while the remaining metal sheet is scrap. In piercing, the sheet containing the hole is the product, and the punched-out slug is scrap.

For automotive engineers, this distinction dictates tooling tolerances: blanking dies are sized to the specific part dimensions, whereas piercing punches are sized to the required hole diameter. In a typical vehicle assembly line, blanking creates the initial shape of a body panel or chassis component from a coil, while piercing adds the necessary holes for fasteners, ventilation, or trim later in the stamping process.

The Core Difference: Scrap vs. Product Strategy

At first glance, blanking and piercing appear identical. Both processes use a punch and die set to shear through sheet metal. However, the engineering intent is diametrically opposed, leading to the "Inversion Rule" of metal stamping. Understanding this rule is critical for process design, cost estimation, and quality control in automotive manufacturing.

Blanking is an operation where the goal is to save the "cookie" and discard the dough. When the punch strikes the sheet, the piece that falls through the die is the valuable part. This process is typically the first step in the manufacturing chain, converting raw coil stock into manageable flat shapes ready for further forming. If you are manufacturing a car hood, the first hit that cuts the large hood shape from the steel roll is a blanking operation.

Piercing (often used interchangeably with punching, though technically distinct in some contexts) is the operation where the goal is to keep the dough and discard the "cookie." The piece that falls through the die is scrap metal. Piercing is almost always a secondary operation performed on a part that has already been blanked. For that same car hood, the subsequent operations that create holes for the windshield washer nozzles or the hood ornament are piercing operations.

The Tooling Logic: Who Rules the Size?

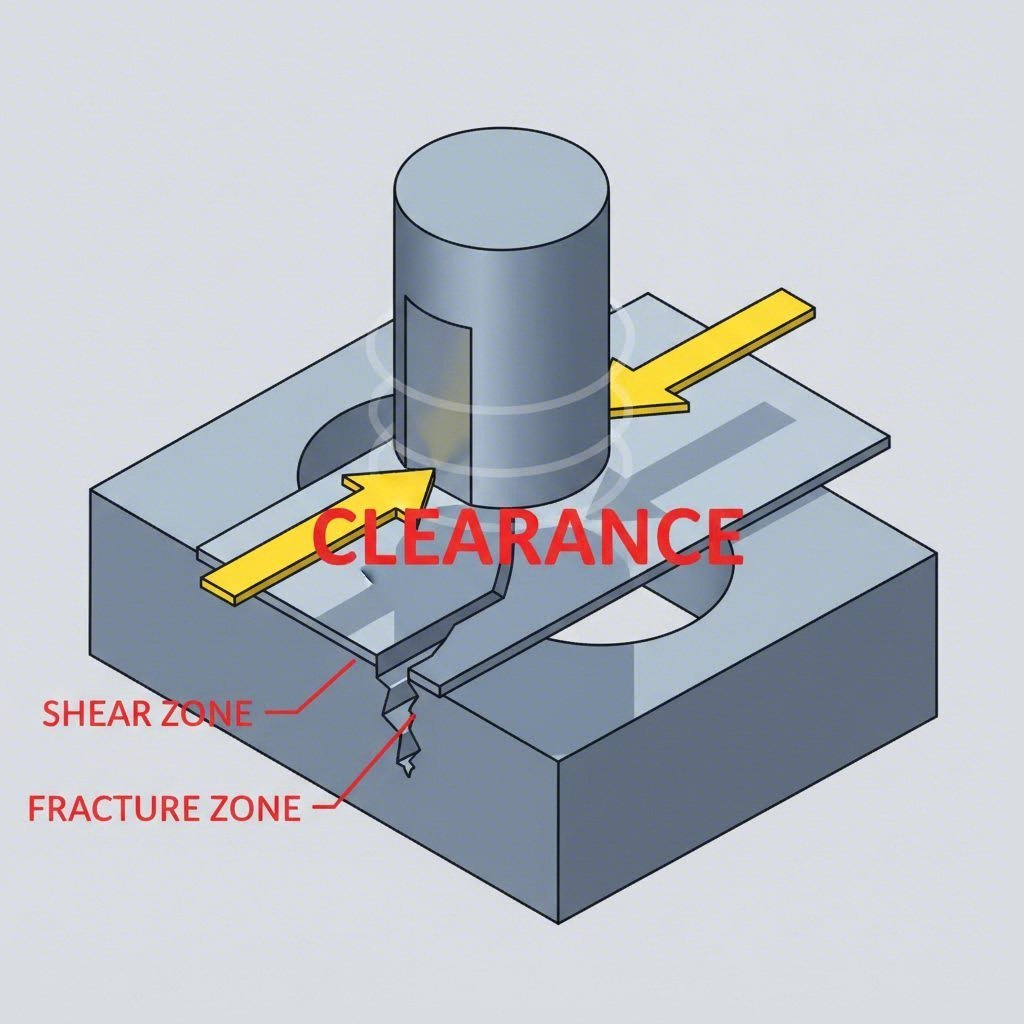

This difference in intent radically changes how tool and die makers calculate clearance and tolerance:

- In Blanking: The die determines the size of the part. Because the part passes through the die, the die cavity is machined to the exact print dimensions. The punch is made smaller by the required clearance amount.

- In Piercing: The punch determines the size of the hole. Because the hole is the feature being measured on the product, the punch is machined to the exact print dimensions. The die opening is made larger by the required clearance amount.

Automotive Workflow: Where Each Fits in the Assembly Line

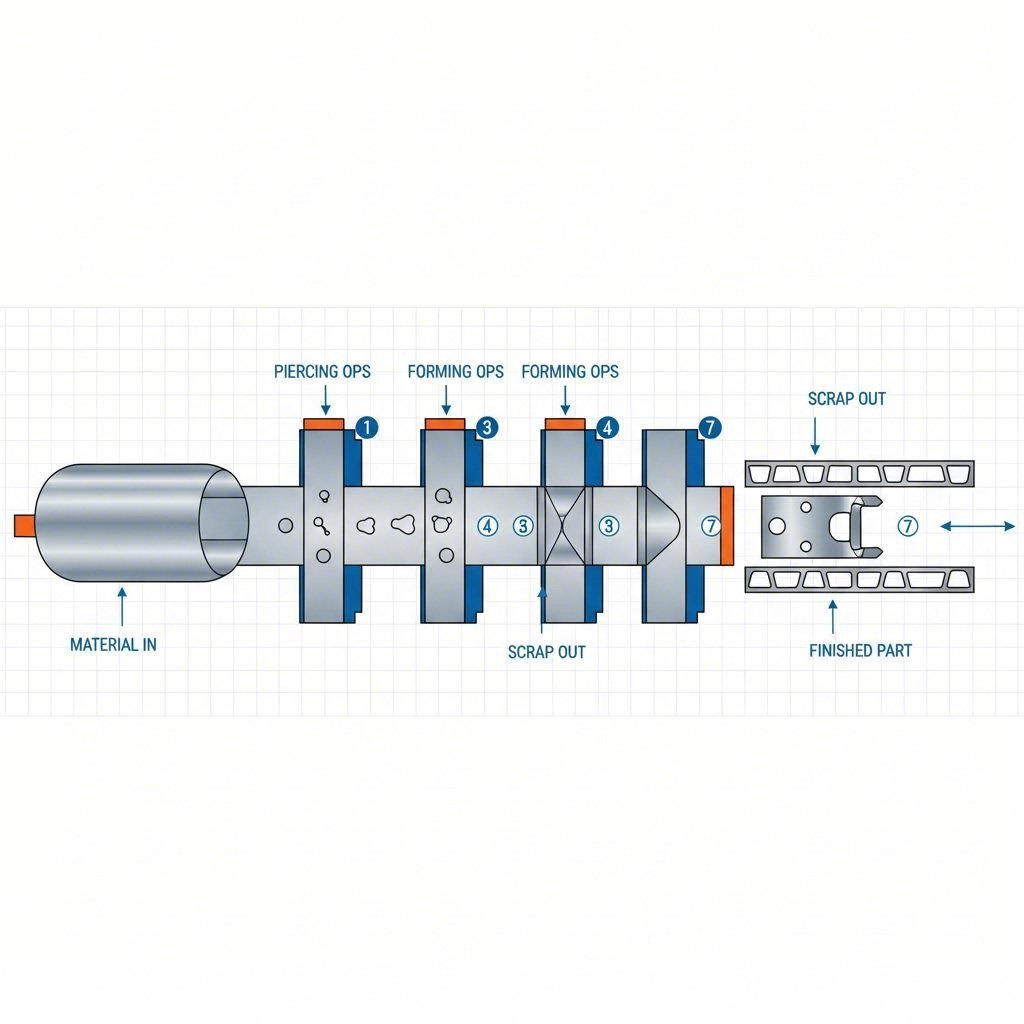

In the high-speed world of automotive stamping, blanking and piercing are choreographed steps in a larger dance. A typical vehicle body panel undergoes a specific sequence known as the "Line Die" or "Transfer Die" process, where these two operations serve different masters.

The process almost invariably begins with a Blanking Line. Here, massive coils of steel or aluminum are fed into a press that "blanks" the initial 2D shape. For a door panel, this blank looks like a flat, rough silhouette of a door. This stage focuses on maximizing material utilization to reduce web scrap—a critical cost factor given that raw material often accounts for 60-70% of the part cost.

Once the blank is formed (drawn) into a 3D shape, Piercing takes over. Automotive dies often combine piercing with trimming operations. As the fender or door moves through the press line, piercing stations strike precisely to create mounting points for side mirrors, door handles, and wiring harnesses. Modern progressive dies may perform piercing simultaneously with bending or flanging, requiring complex cam-operated punches that can pierce holes from side angles rather than just vertically.

For manufacturers scaling from prototyping to mass production, partnering with a capable stamping provider is essential. Shaoyi Metal Technology offers comprehensive automotive stamping solutions that bridge this gap, delivering IATF 16949-certified precision for components ranging from control arms to complex subframes.

Engineering Deep Dive: Tolerances and Edge Quality

Beyond the basic definitions, the physics of the cut—specifically the "shear zone" and "fracture zone"—plays a major role in part quality. When metal is cut, it doesn't just slice cleanly like paper. It undergoes plastic deformation (rollover), then shears (cuts smooth), and finally fractures (breaks away).

Standard vs. Fine Blanking

In standard automotive blanking, the edge will have a rough fracture zone. For body panels, this is acceptable because the edges are often hemmed (folded over) or hidden. However, for precision powertrain components like transmission gears, seat recliners, or brake plates, this rough edge is a failure point.

This is where Fine Blanking enters the equation. Fine blanking is a specialized high-precision variation that uses a three-force system: a V-ring impingement to hold the material, the main blanking force, and a counter-force to support the part. This eliminates the fracture zone, creating a 100% smooth, sheared edge. While significantly more expensive due to press and tooling costs, fine blanking removes the need for secondary machining (shaving or grinding) on critical functional surfaces.

Piercing vs. Punching: The Nuance

While often synonyms, some automotive engineers distinguish "piercing" as a process that may involve forming metal rather than just removing it. For example, a "pierced and extruded" hole creates a collar (flange) around the hole to provide more thread engagement for a screw. A simple "punched" hole just removes the slug. In contrast, "lancing" is a piercing-adjacent process used to create ventilation louvers on heat shields where no material is removed, but the metal is sliced and formed simultaneously.

Comparison Table: Blanking vs. Piercing vs. Punching

To summarize the technical distinctions, use this matrix to determine which process applies to your manufacturing requirement.

| Feature | Blanking | Piercing | Punching |

|---|---|---|---|

| Primary Goal | Create a specific part shape. | Create a hole or opening. | Create a hole or shape. |

| Product | The cut-out piece (Blank). | The remaining sheet. | The remaining sheet. |

| Scrap | The remaining web/skeleton. | The cut-out piece (Slug). | The cut-out piece (Slug). |

| Tooling Rule | Die size = Part size. | Punch size = Hole size. | Punch size = Hole size. |

| Auto Example | Cutting a fender silhouette from coil. | Making holes for a door handle. | Creating ventilation patterns. |

Why Precision Matters in Die Design

Understanding the distinction between blanking and piercing is not merely a semantic exercise; it is the foundation of die design and scrap management. A misidentification on a blueprint can lead to tooling that produces parts with the wrong tolerances—a blanking die built with piercing clearances will result in parts that are undersized by twice the clearance amount. In the automotive industry, where "fit and finish" defines brand quality, such errors are costly.

Whether you are designing a progressive die for a complex bracket or a transfer die for a class-A surface panel, clarity on "what is the product" and "what is the scrap" ensures that the tooling strategy aligns with the final assembly requirements.

Frequently Asked Questions

1. What is the difference between blanking and punching clearance?

The difference lies in which tool component dictates the final dimension. In blanking, the clearance is applied to the punch (making it smaller) because the die opening dictates the finished part size. In punching or piercing, the clearance is applied to the die (making it larger) because the punch size dictates the finished hole diameter.

2. Can blanking and piercing be done in the same machine?

Yes. In a "progressive die" setup, a metal strip moves through multiple stations within a single press. It is common for the strip to be pierced (holes added) in early stations and then blanked (cut out from the strip) in the final station. This integration ensures high speed and consistent relative tolerances between the holes and the part edges.

3. What creates the burr in blanking vs. piercing?

In both processes, the burr (a sharp, raised edge) forms on the side of the metal that exits the tool. In blanking, the burr is found on the punch side of the blank. In piercing, the burr is found on the die side of the sheet. Managing burr height is critical for safety and assembly, often requiring regular tool sharpening or secondary deburring operations.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —