Metal Stamping Body Panels Manufacturing: A Technical Guide

TL;DR

Metal stamping body panels manufacturing involves high-tonnage precision processes to transform sheet metal into aerodynamic, structural automotive components. Unlike standard bracketry, body panels require specialized "Class A" tooling to ensure flawless, defect-free exterior surfaces. The industry is increasingly shifting from traditional steel to high-strength aluminum alloys to reduce vehicle weight, necessitating advanced tribology and spring-back compensation in die design.

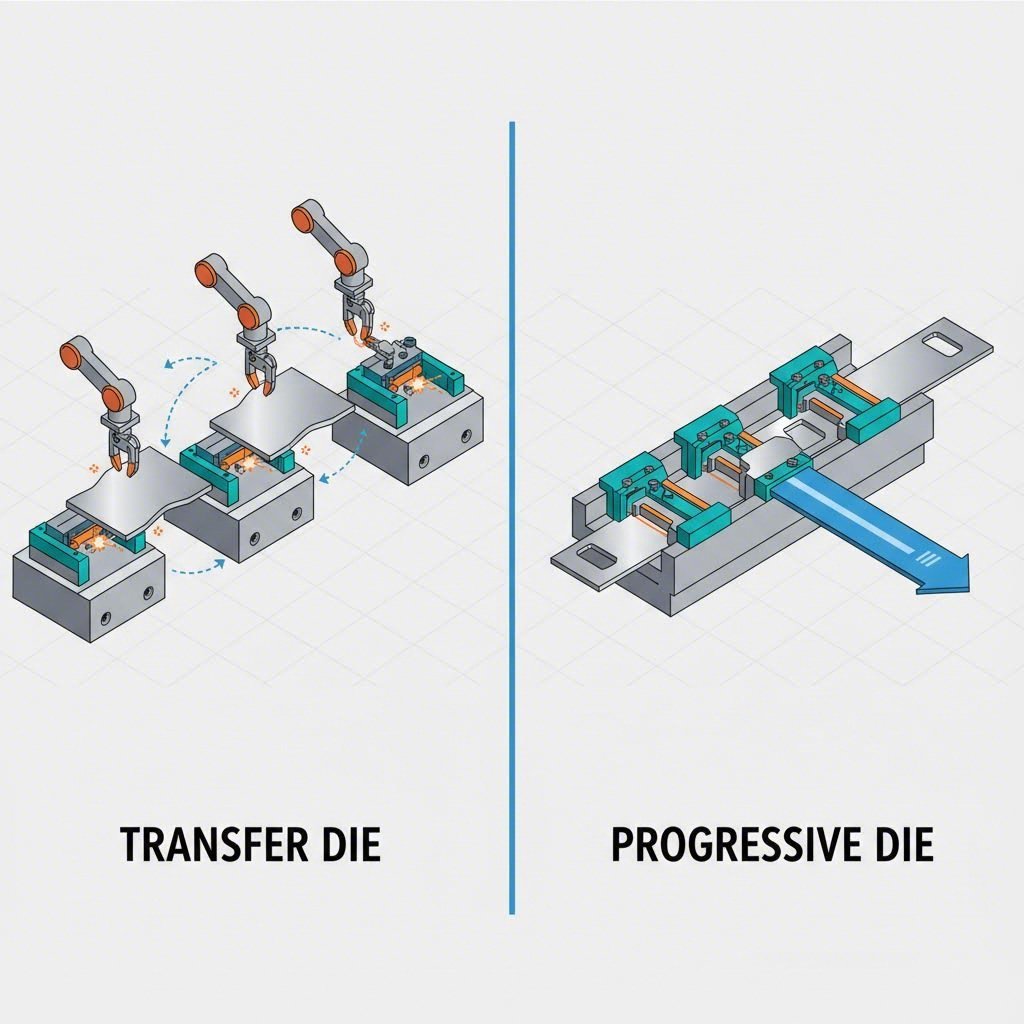

For automotive engineers and procurement officers, the critical decision points lie in selecting the right die technology—typically transfer dies for large panels versus progressive dies for smaller structural parts—and vetting suppliers based on their ability to maintain strict surface quality standards under high-volume production pressure.

Process Selection: Transfer vs. Progressive Dies

The manufacturing of automotive body panels is dictated by part geometry, size, and volume. While standard stamping might utilize simple blanking, body panels demand complex multi-stage forming. The two dominant technologies are Transfer Die Stamping and Progressive Die Stamping, each serving distinct engineering needs.

Transfer Die Stamping: The Standard for Large Panels

For large surface-critical components like hoods, doors, roofs, and fenders, transfer die stamping is the industry standard. In this process, the part is separated from the metal strip early in the cycle and mechanically transferred between stations by automated fingers or rails. This allows for free manipulation of the part at every angle, which is essential for deep drawing and complex contouring without the restriction of a carrier strip.

Progressive Die Stamping: Speed for Structural Parts

Progressive die stamping feeds a continuous strip of metal through multiple stations, with the part remaining attached to the strip until the final cutoff. This method is faster and more cost-effective for smaller, high-volume structural components like pillars, reinforcements, and brackets. However, the connection to the strip limits the ability to rotate the part for complex geometries, making it less suitable for large outer skin panels.

| Feature | Transfer Die Stamping | Progressive Die Stamping |

|---|---|---|

| Primary Application | Large panels (Hoods, Roofs, Doors) | Structural parts, Brackets, Hinge plates |

| Part Handling | Independent transfer (fingers/rails) | Connected to carrier strip |

| Material Efficiency | High (less scrap skeleton) | Lower (requires carrier strip width) |

| Tooling Cost | Higher initially (complex automation) | Moderate to High |

| Production Speed | Moderate (10–30 strokes/min) | High (40–800+ strokes/min) |

Material Selection: Steel vs. Aluminum

Material selection in metal stamping body panels manufacturing is a balancing act between formability, cost, and weight reduction. The push for fuel efficiency and range extension in electric vehicles (EVs) has accelerated the adoption of lightweight materials, fundamentally changing stamping parameters.

The Shift to Aluminum

Aluminum alloys (5000 and 6000 series) are increasingly favored for closures (hoods, tailgates) because they offer up to 40% weight savings compared to steel. However, aluminum presents significant manufacturing challenges. It has a higher tendency for "spring-back"—the metal's elasticity causing it to return to its original shape after forming—requiring over-crowning in the die design. Additionally, aluminum is more prone to galling (adhesion to the tool), necessitating specialized lubricants and PVD-coated dies to prevent tearing.

Advanced High-Strength Steel (AHSS)

Despite the rise of aluminum, steel remains dominant for safety cage components due to its superior tensile strength. Modern "Gen 3" steels offer a compromise, providing high strength with improved formability. Manufacturers often employ cold-rolled steel techniques to harden these materials further, though this increases the tonnage required from the press line.

Achieving "Class A" Surface Quality

The defining characteristic of body panel manufacturing is the requirement for "Class A" surface quality. A Class A surface refers to the visible outer skin of the vehicle, which must be mathematically perfect and free from any aesthetic defects. Unlike internal structural parts (Class B) or hidden brackets (Class C), Class A panels must reflect light uniformly without ripples or distortion.

Defect Prevention and Detection

Achieving this level of quality requires a near-cleanroom environment on the stamping floor. Even a microscopic dust particle trapped in the die can cause a "pimple" or dent on the panel, rendering it scrap. Common defects that engineers fight against include:

- Orange Peel: A rough surface texture caused by incorrect grain size in the raw material or excessive stretching.

- Ludering (Stretcher Strains): Visible flow lines that appear when the metal yield point is exceeded unevenly.

- Sink Marks: Depressions caused by material shrinking over internal ribs or bosses.

Top-tier manufacturers utilize automated optical inspection systems and "stoning"—a manual process where skilled toolmakers rub an abrasive stone over the panel to highlight high and low spots invisible to the naked eye. This attention to detail is what separates a general automotive stamping shop from a specialized body panel manufacturer.

Cost Factors and Supplier Qualification

The economics of stamping are driven by tooling amortization and cycle time. The initial capital investment for a set of Class A transfer dies can reach millions of dollars. Therefore, supplier selection is not just about piece price; it is about lifecycle capability.

Bridging Prototype to Production

A major bottleneck for OEMs is the transition from soft-tool prototypes to hard-tool mass production. Suppliers that can manage both phases reduce risk significantly. For example, manufacturers like Shaoyi Metal Technology streamline this progression by offering capabilities that scale from rapid prototyping to high-volume production. Their facility supports press capacities up to 600 tons and adheres to IATF 16949 standards, ensuring that the rigorous quality controls developed during the prototype phase are maintained when production ramps up to millions of units.

Key Vetting Criteria

When auditing a potential partner for body panels, procurement teams should verify:

- Press Tonnage & Bed Size: Do they have the 1000+ ton presses required for a single-piece body side or hood?

- Simulation Software: Do they use AutoForm or Dynaform to predict spring-back and thinning before steel is cut?

- Secondary Operations: Can they handle hem-rolling (folding the edge of the outer panel over the inner panel) and robotic assembly?

Conclusion

Mastering metal stamping body panels manufacturing requires a convergence of metallurgical science, precision engineering, and rigorous quality control. As vehicle designs become more aerodynamic and lightweight, the reliance on advanced aluminum forming and Class A surface perfection will only increase. Success in this field depends on partnering with manufacturers who not only possess the necessary high-tonnage infrastructure but also demonstrate a deep understanding of die tribology and defect mitigation.

Frequently Asked Questions

1. What is the difference between Class A and Class B stamping surfaces?

Class A surfaces are the visible exterior parts of a vehicle (hoods, fenders, doors) that require a flawless, mirror-like finish suitable for painting. Class B surfaces are internal or structural components (floor pans, inner door frames) where minor aesthetic imperfections like tool marks or ripples are acceptable as long as structural integrity is maintained.

2. Why is aluminum used more frequently in modern body panels?

Aluminum is approximately one-third the weight of steel, which significantly improves fuel economy in combustion vehicles and extends the range of electric vehicles. While more expensive and difficult to stamp due to spring-back, the weight savings justify the cost for premium and EV models.

3. What press tonnage is required for stamping body panels?

Stamping large body panels typically requires massive hydraulic or mechanical presses, often ranging from 1,000 to 3,000 tons or more. This high force is necessary to flow the metal into complex shapes without tearing, especially when working with high-strength alloys.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —