Steel vs. Aluminum Control Arms: Making the Right Choice

TL;DR

Choosing the right control arms comes down to a trade-off between strength, weight, and cost. Stamped steel control arms are the industry standard for a reason: they offer excellent durability and are highly cost-effective, making them ideal for heavy vehicles and high-stress applications. Forged aluminum control arms, however, provide a significant performance advantage with up to 50% less weight and natural corrosion resistance, perfect for improving handling and ride quality on street-performance cars.

Understanding the Materials: Stamped Steel vs. Forged Aluminum

Before weighing the pros and cons, it’s essential to understand what makes these two types of control arms fundamentally different. Their manufacturing processes directly influence their performance, appearance, and durability. Knowing how to identify them is also crucial, especially when ordering replacement parts like ball joints, as fitment can vary even on the same vehicle model.

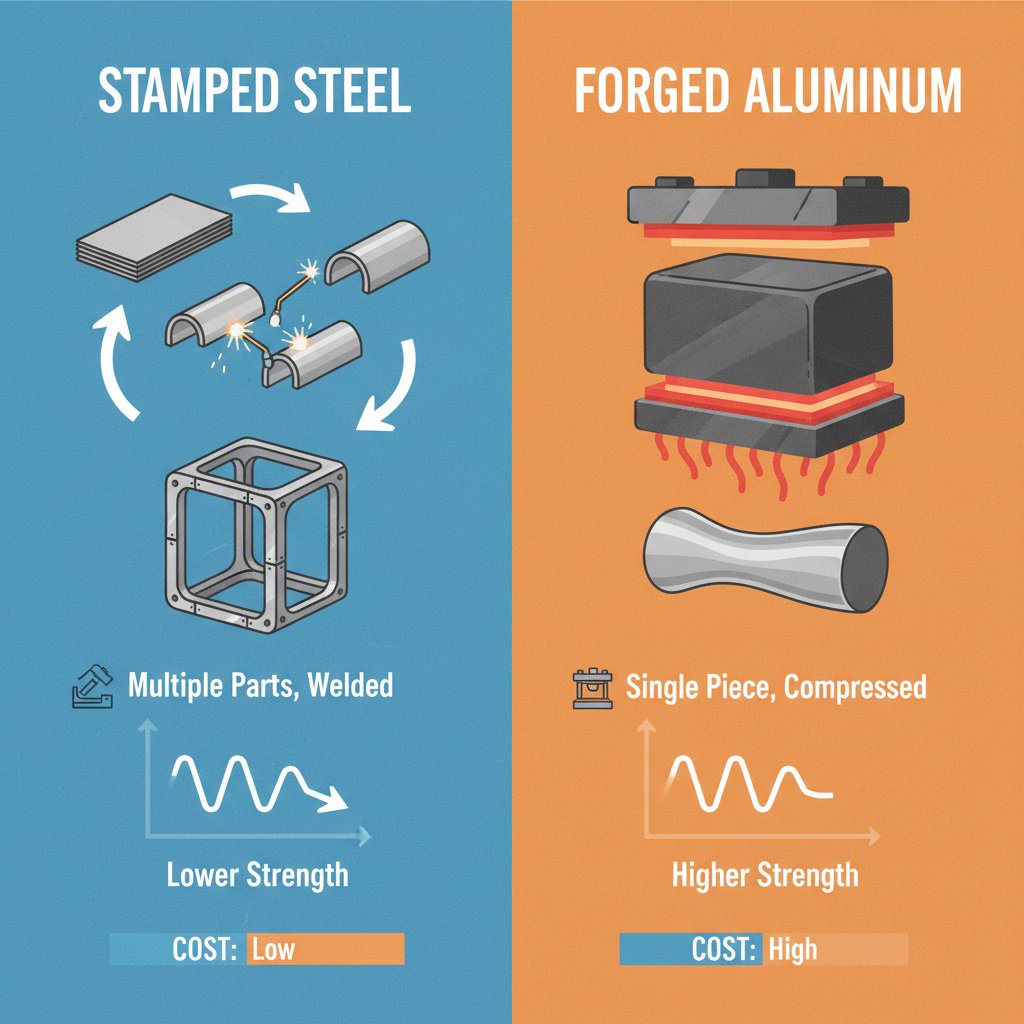

Stamped steel control arms are the most common type found in production vehicles. The process involves taking large sheets of steel, cutting them to a pattern, and then stamping or bending them into the desired shape. Multiple pieces are then welded together to create the final component. This method is efficient and cost-effective, producing a strong and reliable part. For automotive manufacturers who rely on precision and consistency in this process, specialized suppliers are key. For instance, companies like Shaoyi (Ningbo) Metal Technology Co., Ltd. provide comprehensive metal stamping solutions that meet the rigorous IATF 16949 automotive quality standard, ensuring every component is built to spec.

Forged aluminum control arms are crafted from a single, solid piece of aluminum alloy. This billet is heated to a malleable state and then pressed into shape under immense pressure. This forging process aligns the metal's internal grain structure, resulting in a component that is exceptionally strong for its weight. There are no welds or seams, which eliminates potential failure points and creates a dense, robust part that offers superior performance characteristics.

Visually identifying the two is straightforward:

- Stamped Steel: Look for visible welds or seams where pieces of metal have been joined. The surface is typically smooth and painted (often black) to prevent rust.

- Forged Aluminum: These appear as a single, solid piece of metal. They often have a rougher, cast-like texture or a smooth, machined finish and are typically left unpainted due to aluminum's natural corrosion resistance.

Head-to-Head Comparison: Strength, Durability, and Weight

When you place stamped steel and forged aluminum side-by-side, their distinct advantages become clear. The best choice for your vehicle depends entirely on its intended use, from daily driving to competitive racing. Steel generally has excellent toughness and impact resistance, making it better suited to withstand the heavy loads and harsh impacts common in off-road or heavy-duty applications. Its inherent durability makes it a reliable choice for trucks and classic muscle cars with heavy front ends.

While steel is strong, forged aluminum boasts a superior strength-to-weight ratio. Modern forged aluminum parts are more than capable of handling the stresses of aggressive street driving and even track days. However, the most significant advantage of aluminum is its dramatic weight reduction. Aluminum control arms can be 40-50% lighter than their steel counterparts. This reduction in "unsprung weight"—the mass of the suspension, wheels, and other components not supported by the springs—allows the suspension to react more quickly to changes in the road surface. The result is improved handling, sharper steering response, and a better overall ride quality.

The following table breaks down the key performance differences:

| Feature | Stamped Steel | Forged Aluminum |

|---|---|---|

| Strength | Excellent toughness and impact resistance. | Excellent strength-to-weight ratio. |

| Durability | Highly resistant to impact and stress. Ideal for heavy loads. | Very durable for its weight, but can be more prone to bending under extreme impact compared to steel. |

| Weight | Heavy, which can negatively impact suspension responsiveness. | Significantly lighter, reducing unsprung weight for improved handling. |

| Best Use Case | Heavy vehicles, trucks, off-roading, drag racing, and budget-conscious builds. | Street performance, autocross, road racing, and vehicles in corrosive climates. |

Long-Term Factors: Cost, Corrosion, and Lifespan

Beyond pure performance, practical considerations like cost and long-term durability play a major role in the decision. Stamped steel is the undisputed winner when it comes to upfront cost. Both the raw material and the manufacturing process are less expensive, which is why it's the go-to choice for most original equipment manufacturers (OEMs). This makes steel control arms an economical option for repairs and replacements.

However, the long-term value proposition can shift depending on your climate. Steel is susceptible to rust, and while protective coatings are applied, they can chip or wear away over time. In regions with heavy rainfall, snow, and road salt—often called the "Salt Belt"—corrosion can become a significant issue, potentially shortening the component's lifespan.

This is where forged aluminum has a distinct advantage. Aluminum naturally forms a layer of aluminum oxide on its surface when exposed to air, which acts as a powerful barrier against corrosion. This inherent resistance means aluminum control arms require less maintenance and have a longer lifespan in harsh, wet environments, potentially justifying their higher initial cost over time.

Stamped Steel

Pros

- Excellent toughness and impact resistance

- Less expensive upfront cost

- Widely available for most vehicles

Cons

- Heavy, increasing unsprung weight

- Prone to rust and corrosion over time

Forged Aluminum

Pros

- Significant weight savings for better handling

- Excellent natural corrosion resistance

- Superior strength-to-weight ratio

Cons

- Higher initial purchase price

- May be less forgiving under extreme impact than steel

Frequently Asked Questions

1. What is the best material for control arms?

There is no single "best" material; the ideal choice depends on your goals. Forged aluminum is often considered superior for performance applications due to its light weight, high strength, and corrosion resistance, which enhances handling. Stamped steel remains the most common and practical choice for daily drivers and heavy-duty vehicles because of its durability and cost-effectiveness.

2. Are forged aluminum upper control arms good?

Yes, forged aluminum upper control arms are an excellent upgrade for many vehicles. They provide a significant reduction in unsprung weight, which allows the suspension to respond more quickly for improved handling and ride comfort. They are also very strong and resist rust, making them a durable, high-performance option for street and track use.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —