Steel vs. Aluminum Control Arms: A Cost & Performance Analysis

TL;DR

Choosing between stamped steel and aluminum control arms involves a clear trade-off between cost and performance. Stamped steel control arms are significantly cheaper to replace, offering durability and strength ideal for heavy-duty use. In contrast, aluminum control arms, while more expensive, provide a substantial weight reduction that improves handling, responsiveness, and ride quality, along with superior corrosion resistance. Your decision should balance your budget with your vehicle type and driving needs.

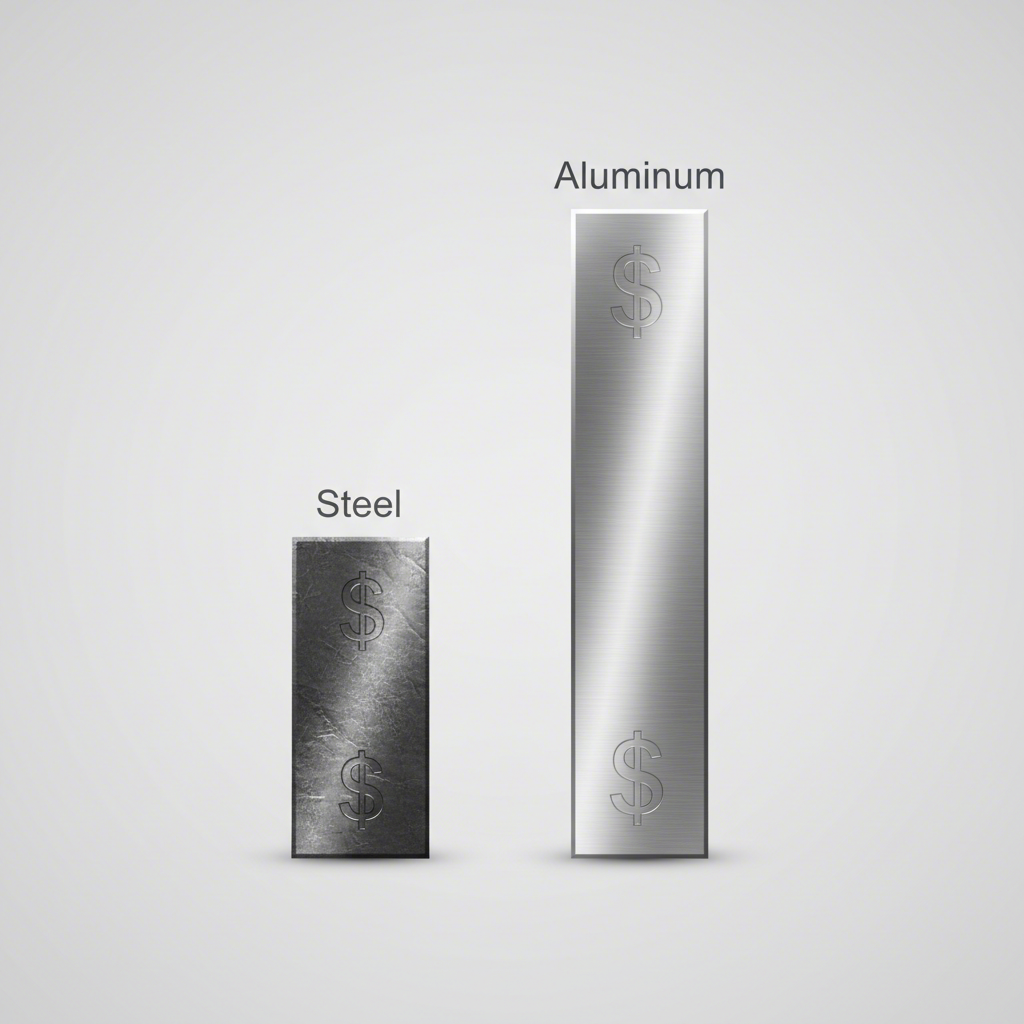

Cost Analysis: Stamped Steel vs. Aluminum Replacement

When facing a control arm replacement, the most immediate factor for most drivers is the cost. The material choice—stamped steel or aluminum—is the primary driver of the final price tag. Stamped steel is consistently the more budget-friendly option. This is due to both lower raw material costs and more established, less complex manufacturing processes. For vehicle owners prioritizing a cost-effective repair, steel is the default choice for both original equipment (OEM) and aftermarket parts.

The manufacturing of these components requires significant expertise to ensure they meet stringent automotive safety standards. For instance, specialized firms in auto stamping parts, such as Shaoyi (Ningbo) Metal Technology Co., Ltd., leverage advanced, automated processes to produce high-quality stamped steel components for the automotive industry, helping to manage costs while maintaining precision and reliability.

According to automotive experts, the total cost to replace a single control arm typically ranges from $400 to $1,000. It's important to note that the part itself often only accounts for 25% to 50% of that total bill. The largest expense is almost always labor. Factors like your vehicle's make and model, as well as local mechanic labor rates, will cause the final price to vary. High-end luxury vehicles or complex suspension designs naturally command higher repair costs. Furthermore, mechanics almost always recommend a wheel alignment after the job, which adds around $125 to the total.

To illustrate the difference, here is a general breakdown of the estimated costs:

| Component | Stamped Steel (Estimate) | Aluminum (Estimate) |

|---|---|---|

| Part Cost (Per Arm) | $75 - $200 | $150 - $400+ |

| Labor Cost (Per Arm) | $200 - $500 | $200 - $500 |

| Wheel Alignment | $125 | $125 |

| Total Estimated Cost (Per Arm) | $400 - $825 | $475 - $1,025+ |

Performance & Durability: Which Material Holds Up?

Beyond the initial cost, the choice between steel and aluminum has significant implications for your vehicle's performance, handling, and long-term durability. The decision isn't just about saving money; it's about matching the material's properties to your driving style, vehicle type, and even the climate you live in. Each material offers a distinct set of advantages that cater to different needs.

The primary performance benefit of aluminum is its significant weight savings. Aluminum control arms can be 40-50% lighter than their steel counterparts. This reduction in weight is known as decreasing "unsprung weight"—the mass of the suspension, wheels, and other components not supported by the springs. Less unsprung weight allows the suspension to react more quickly to bumps and imperfections in the road, leading to improved tire contact, better handling, and a smoother ride. Aluminum is also naturally corrosion-resistant, making it an excellent choice for vehicles in regions with heavy rain, snow, or road salt.

On the other hand, steel's main advantage is its raw strength and durability. Steel can withstand higher loads and greater impacts without bending or breaking, making it the preferred material for heavy-duty applications like trucks, SUVs, or classic cars with heavy engines. For drivers who prioritize ruggedness or engage in activities like drag racing where components are under extreme stress, steel's resilience is a major asset.

To help you decide, consider these pros and cons:

Stamped Steel Control Arms

-

Pros:

- Lower cost for both parts and manufacturing.

- Superior strength and durability, ideal for heavy vehicles and high-stress applications.

- High heat tolerance, beneficial in performance scenarios like drag racing.

-

Cons:

- Significantly heavier, which can negatively impact handling and ride quality.

- Prone to rust and corrosion over time, even with protective coatings.

Aluminum Control Arms

-

Pros:

- Substantial weight reduction improves suspension responsiveness and vehicle handling.

- Excellent natural resistance to corrosion, increasing longevity in wet or salty climates.

- Better heat dissipation compared to steel.

-

Cons:

- Higher material and manufacturing costs result in a more expensive part.

- May be more susceptible to damage from extreme impacts compared to steel.

Compatibility and Replacement Considerations

A common question for vehicle owners is whether they can swap from one material to another—for instance, replacing factory aluminum arms with more affordable steel ones, or upgrading from steel to lightweight aluminum. While this is sometimes possible, it is not always a straightforward, direct replacement. Compatibility is a critical factor that requires careful consideration to ensure safety and proper vehicle function.

The primary concern with swapping materials is ensuring the geometry of the suspension remains correct. Different control arms, even for the same vehicle model, can have slight variations in shape or, more importantly, use different components. For example, some sources indicate that cast steel and aluminum control arms on the same truck model might use different ball joints. Attempting to install an incompatible part could lead to improper fitment, accelerated wear on other suspension components, and unsafe driving conditions.

Interestingly, automakers themselves sometimes make this change. In some cases, General Motors has used stamped steel arms as the official service replacement for original aluminum upper control arms on their trucks, indicating that manufacturer-approved swaps are possible. However, this underscores the importance of using parts specifically designed and verified for your vehicle's year, make, and model. Simply choosing an arm that looks similar is a significant risk.

Regardless of whether you stick with the original material or attempt a swap, any control arm replacement is a major suspension job. It is crucial that a full wheel alignment is performed immediately after the work is completed. Failing to do so will result in poor handling, uneven tire wear, and potential steering issues. To ensure a safe and successful repair, it's best to consult with a trusted professional mechanic. They can verify part compatibility and perform the job correctly.

Before proceeding with a replacement, ask your mechanic these key questions:

- Is this part a direct OEM-equivalent fit for my specific vehicle model?

- If swapping materials, are the ball joints and bushings fully compatible?

- Will this change affect my vehicle's suspension geometry or ride height?

- Does the quoted price include a full four-wheel alignment after the installation?

Frequently Asked Questions

1. What's the average cost to replace a control arm?

The average cost to replace a single control arm is typically between $400 and $1,000. This price includes the cost of the part, several hours of labor, and a subsequent wheel alignment. The final cost depends heavily on the vehicle model and local labor rates.

2. What is the best material for control arms?

The "best" material depends on your priorities. Aluminum is ideal for performance and luxury vehicles, offering improved handling and corrosion resistance, especially in wet climates. Steel is better for heavy-duty applications, trucks, or those on a tight budget, as it provides superior strength and durability at a lower cost.

3. What is the difference between cast iron and stamped steel control arms?

Stamped steel control arms are made by stamping sheets of steel into the desired shape. They are lightweight and inexpensive, making them common on many modern passenger cars. Cast iron control arms are heavier and stronger, formed by pouring molten iron into a mold. They are typically used in heavy-duty vehicles like trucks and SUVs that require maximum strength to handle harsh conditions.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —