Stamped Steel Control Arms: The Essential Pros and Cons

TL;DR

Stamped steel control arms are the standard, budget-friendly suspension component found on most factory vehicles, making them a cost-effective choice for daily driving. Their primary drawbacks are significant weight, a tendency to flex under pressure which can affect handling, and a high susceptibility to rust and damage. While perfectly adequate for standard use, performance-oriented drivers or those in harsh climates often upgrade to stronger, lighter tubular or aluminum alternatives for improved durability and responsiveness.

What Are Stamped Steel Control Arms?

A control arm is a critical component of your vehicle's suspension system, acting as the crucial link between the chassis (or frame) and the wheel assembly. Its job is to allow the wheels to move up and down in response to bumps and dips in the road while keeping them firmly planted for stable handling. Stamped steel control arms are the most common type found in mass-produced passenger cars and trucks, primarily due to their low manufacturing cost.

The term "stamped" refers directly to their manufacturing process. They are created by taking large sheets of steel and using powerful hydraulic presses to stamp them into a specific shape, often a U-shaped channel. Typically, two of these stamped pieces are then welded together to form the complete arm. This method is highly efficient for large-scale production, which helps keep vehicle manufacturing costs down. You can often visually identify a stamped steel arm by its welded seams and relatively simple, functional appearance compared to more complex cast or tubular designs.

The entire assembly pivots on bushings where it connects to the vehicle's frame and utilizes a ball joint at the wheel end, allowing for the multi-axis movement required for steering and suspension travel. For automotive manufacturers, achieving precision in this process is paramount. For instance, companies specializing in high-volume production, such as Shaoyi (Ningbo) Metal Technology Co., Ltd., leverage advanced automated facilities and rigorous quality control like IATF 16949 certification to produce these critical components with the consistency and reliability required for the automotive industry.

The Pros: Why Stamped Steel Is So Common

The single greatest advantage of stamped steel control arms is their cost-effectiveness. The manufacturing process is streamlined for mass production, making them significantly cheaper to produce than any other type. This low cost is passed on to the consumer, both in the initial price of the vehicle and in the cost of replacement parts. For a typical daily driver needing a repair, choosing an OEM-style stamped steel replacement is often the most economical and sensible option.

Beyond price, stamped steel arms are designed to meet the demands of ordinary driving conditions. For the average commuter or family car that isn't subjected to the stresses of a racetrack or rugged off-road trails, these arms provide sufficient strength and durability. They are engineered to handle the loads and impacts of paved roads and are considered perfectly adequate for what enthusiasts might call a "cruiser"—a vehicle built for comfortable, standard driving rather than high performance.

This combination of low cost and adequate performance for their intended purpose is precisely why manufacturers have used them for decades. They fulfill the necessary function without adding unnecessary expense to the vehicle's final price tag, representing a practical balance of economy and engineering for the vast majority of cars on the road.

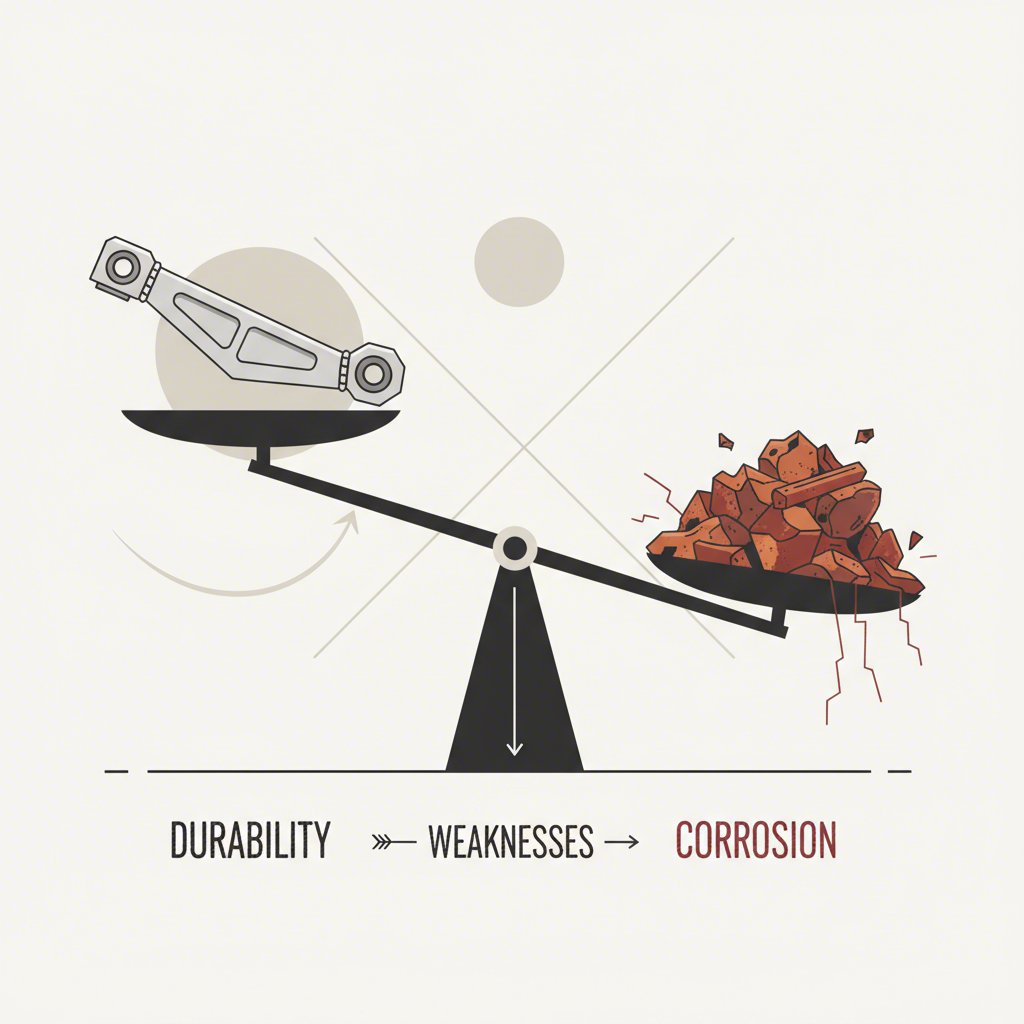

The Cons: Key Weaknesses and Limitations

Despite their affordability, stamped steel control arms come with several notable disadvantages that often lead vehicle owners to seek upgrades. One of the most significant issues is their susceptibility to rust and corrosion. The stamped and welded construction can create areas where moisture collects, and in damp climates or regions where road salt is used in winter, they can rust through much quicker than other materials. This corrosion can weaken the arm, potentially leading to structural failure.

Weight is another major drawback. Steel is a dense material, and stamped arms are relatively heavy compared to aluminum or tubular steel alternatives. This added weight is part of the vehicle's "unsprung mass"—the mass of the suspension, wheels, and other components not supported by the springs. High unsprung mass can make the suspension less responsive, leading to a harsher ride and less effective tire contact with the road over bumps.

Finally, performance is a key limitation. Stamped steel arms are prone to flexing under high-stress conditions like hard cornering or heavy braking. This flex can subtly alter the suspension geometry, leading to less precise handling, unpredictable steering feel, and uneven tire wear. For any application beyond standard daily driving, such as performance driving, towing, or off-roading, these weaknesses become much more apparent.

- High Weight: Increases unsprung mass, which can negatively impact ride quality and handling.

- Susceptibility to Rust: The steel material and welded seams are prone to corrosion, especially in wet or salty environments.

- Flex and Rigidity Issues: Can bend or flex under load, compromising suspension geometry and reducing steering precision.

- Prone to Damage: Can be more easily bent or damaged from impacts with potholes or road debris compared to stronger designs.

Stamped Steel vs. The Alternatives: A Head-to-Head Comparison

When considering a replacement or upgrade, the main alternatives to stamped steel are tubular steel and cast aluminum control arms. Each material offers a different balance of strength, weight, performance, and cost, catering to different needs and priorities. Understanding these differences is key to making the right choice for your vehicle and driving style.

Tubular steel arms are a popular performance upgrade. Constructed from welded steel tubing, they are significantly stronger and more rigid than their stamped counterparts. This rigidity prevents flex, maintaining proper suspension geometry for improved handling and stability. They often feature improved designs with corrected ball joint angles for lifted or lowered vehicles and can add positive caster for better steering feel. While heavier than aluminum, they are often lighter than stock stamped arms and offer a massive leap in durability.

Cast aluminum control arms are the lightweight champions. As noted in a guide from Metrix Premium Parts, aluminum's lower density reduces unsprung weight, which enhances suspension responsiveness and can improve both ride comfort and traction. Aluminum is also highly resistant to corrosion, making it an excellent choice for vehicles in wet climates. However, it is generally not as strong as steel in withstanding heavy impacts and is typically the most expensive option, often found on luxury or performance vehicles from the factory.

| Attribute | Stamped Steel | Tubular Steel | Cast Aluminum |

|---|---|---|---|

| Cost | Lowest | Moderate to High | Highest |

| Strength & Durability | Adequate for OEM use; prone to bending | Very High; excellent rigidity | Good; less resistant to major impacts than steel |

| Weight | High | Varies; often lighter than stamped | Lightest |

| Performance | Basic; prone to flex | Excellent; improved geometry and handling | Excellent; best for reducing unsprung weight |

| Corrosion Resistance | Poor; highly susceptible to rust | Good (when properly coated) | Excellent |

Which Should You Choose?

Your decision should be based on your specific needs. For a budget-conscious repair on a standard daily driver, stamped steel is a perfectly logical choice. If you're looking for a significant strength and handling upgrade for a classic car, muscle car, or off-road truck, tubular steel offers the best durability and performance for the price. If your priority is minimizing weight for the best possible ride quality and suspension response, and budget is less of a concern, cast aluminum is the premium option.

Frequently Asked Questions

1. What is the best material for control arms?

There isn't a single "best" material for all situations; the ideal choice depends on your vehicle, budget, and how you drive. For standard daily driving and budget-friendly repairs, stamped steel is sufficient. For strength, durability, and performance handling, especially in heavy-duty or classic car applications, tubular steel is often the preferred upgrade. For lightweight performance, superior ride quality, and excellent corrosion resistance, cast aluminum is the premium choice, commonly used in luxury and modern performance cars.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —