Mitigating Springback's Impact on Automotive Die Design

TL;DR

Springback is the elastic shape recovery of sheet metal after forming, a critical issue in automotive die design that causes dimensional inaccuracies and costly production delays. The impact of springback is significantly greater with Advanced High-Strength Steels (AHSS). Effective management requires accurately predicting this behavior and proactively creating a compensated die design, where tooling surfaces are modified to ensure the final part springs back into the precise target shape.

Understanding Springback and Its Critical Impact in Automotive Manufacturing

In sheet metal forming, springback refers to the geometric change a part undergoes after the forming pressure is released and it is removed from the die. This phenomenon occurs because the material experiences both permanent (plastic) and temporary (elastic) deformation during stamping. Once the tooling is removed, the stored elastic energy within the material causes it to partially revert to its original shape. This seemingly minor elastic recovery can have major consequences for the precision-required world of automotive manufacturing.

The impact of uncontrolled springback is severe and cascades through the production process. Inaccurate prediction leads directly to parts that fail to meet geometric tolerances. This dimensional deviation creates significant challenges downstream, compromising the integrity and quality of the final vehicle. The primary negative effects include:

- Dimensional Deviations: The final part does not match the intended CAD geometry, leading to poor fit and finish.

- Assembly Difficulties: Mismatched components can make automated and manual assembly processes difficult or impossible, causing production line stoppages.

- Increased Die Tryout Loops: Engineers are forced into a costly and time-consuming cycle of trial-and-error, where dies are repeatedly modified and tested to achieve the correct part shape.

- Higher Scrap Rates: Parts that cannot be corrected or assembled must be discarded, increasing material waste and production costs.

- Compromised Profitability: The combination of wasted time, labor, and materials directly impacts the financial viability of a project.

The challenge of springback is particularly acute with the use of modern materials like Advanced High-Strength Steels (AHSS). As explained in guidelines from AHSS Insights, these materials have a high ratio of yield strength to Young's Modulus, meaning they store significantly more elastic energy during formation. When this energy is released, the resulting springback is far more pronounced than in conventional mild steels. This phenomenon manifests in several distinct modes, including angular change (deviation from the tool angle), sidewall curl (curvature in a channel wall), and twist (torsional rotation due to unbalanced residual stresses).

Key Factors Influencing Springback Behavior

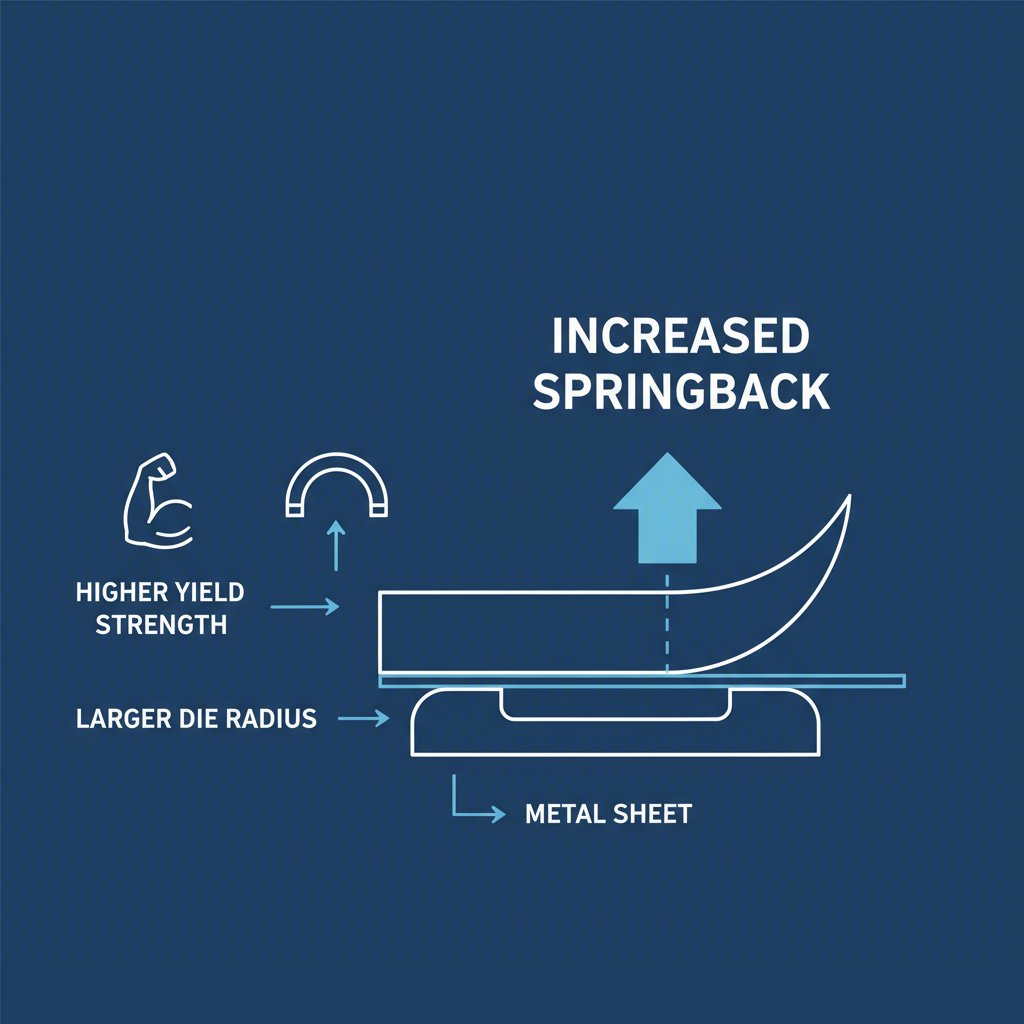

The severity of springback is not random; it is governed by a predictable set of variables related to material properties, tooling geometry, and process parameters. A thorough understanding of these factors is the first step toward effective prediction and compensation. Die designers must analyze these elements to anticipate how a material will behave under forming pressures.

Material properties are a primary driver. Steels with higher yield and tensile strength, such as the TRIP and micro-alloyed steels used extensively in automotive components, exhibit more significant springback. This is because higher-strength materials require more force to deform plastically, which in turn stores more elastic energy that is released upon unloading. Sheet thickness also plays a role; thinner gauges, often used for vehicle lightweighting, have less structural rigidity and are more susceptible to shape deviation.

Tooling geometry is an equally critical factor. A comprehensive study on automotive steel sheets found that tooling choices can have a more significant effect than certain material characteristics. Research published in the journal Materials revealed that the die diameter has a more prominent impact on springback than material anisotropy. Specifically, the study concluded that larger die radii result in higher springback because they induce less plastic deformation, making the elastic recovery more noticeable. This highlights the importance of optimizing tool and die design as a primary method for springback control.

To provide a clear framework for analysis, the key influencing factors and their effects are summarized below:

| Influencing Factor | Effect on Springback |

|---|---|

| Material Yield Strength | Higher strength leads to increased springback. |

| Sheet Thickness | Thinner sheets generally exhibit more springback. |

| Die Bending Radius | Larger radii result in greater springback. |

| Material Anisotropy | Has a less prominent effect compared to tooling geometry. |

| Work Hardening Rate (n-value) | Higher work hardening increases the as-formed flow stress, contributing to more springback. |

Advanced Die Design Strategies for Springback Compensation

Effectively managing springback requires moving from reactive adjustments to proactive design strategies. The most advanced approach is known as springback compensation, where the die itself is intentionally designed to an 'incorrect' shape. This 'compensated' die face forms the sheet metal in such a way that it elastically springs back into the desired, dimensionally accurate geometry. For example, if a 90-degree bend is predicted to spring back by 2 degrees, the die must be designed to bend the part to 92 degrees.

While traditional methods like overbending or coining exist, they often rely on costly physical trial-and-error. Modern compensation is a simulation-driven process that integrates sophisticated software into the design workflow. This approach provides a more precise, efficient, and reliable path to achieving first-time-right tooling. For complex automotive components, partnering with specialists in this area is crucial. Firms like Shaoyi (Ningbo) Metal Technology Co., Ltd. exemplify this modern approach, utilizing advanced CAE simulations to engineer custom automotive stamping dies that proactively account for material behavior, ensuring precision for OEMs and Tier 1 suppliers.

The simulation-driven compensation workflow follows a clear, systematic process:

- Initial Forming Simulation: Using Finite Element Analysis (FEA), engineers simulate the entire stamping process with the nominal die geometry to accurately predict the final part shape, including the magnitude and direction of springback.

- Calculation of Compensation: The software compares the predicted springback shape to the target design geometry. It then calculates the necessary geometric adjustments required for the die surfaces to counteract this deviation.

- CAD Model Modification: The calculated adjustments are automatically applied to the CAD model of the die, creating a new, compensated tool surface geometry.

- Validation Simulation: A final simulation is run using the compensated die design to verify that the part will now spring back to the correct dimensions. This validation step confirms the strategy's effectiveness before any steel is cut for the physical tool.

This proactive method significantly reduces the need for expensive and time-consuming die recuts and adjustments during the physical tryout phase, accelerating time-to-market and reducing overall production costs.

The Role of Simulation and Predictive Analysis in Modern Die Design

Accurate prediction through simulation software is the cornerstone of modern springback compensation. Finite Element Analysis (FEA) allows engineers to virtually model the entire stamping operation—from blank holder force to punch speed—to forecast the final part shape with remarkable detail. As described in a technical guide from ETA, Inc., this predictive power enables the creation of compensated tool faces before manufacturing begins, transforming die design from a reactive art into a predictive science.

However, the effectiveness of simulation is not absolute and faces significant challenges. A primary limitation is that the accuracy of the output is entirely dependent on the quality of the input data. Inaccurate material characterization, especially for complex AHSS grades, can lead to incorrect springback predictions. Research has shown that basic isotropic hardening models are often insufficient for predicting springback in high-strength steels because they fail to account for phenomena like the Bauschinger effect, where a material's yield strength changes under reverse loading conditions (e.g., bending and unbending over a die radius). Achieving reliable results requires advanced material models and precise data from physical testing.

Despite these challenges, the benefits of leveraging simulation are undeniable when implemented correctly. It provides a powerful framework for optimizing die design and mitigating manufacturing risks.

Pros of Simulation

- Reduces the number of costly and time-consuming physical die tryouts.

- Lowers overall costs by minimizing scrap rates and manual die adjustments.

- Accelerates the product development cycle and time-to-market.

- Allows for the testing and validation of complex geometries and new materials in a virtual environment.

Cons of Simulation

- Prediction accuracy is highly dependent on precise material input data.

- Can be computationally intensive, requiring significant processing power and time.

- May require specialized expertise to interpret results and implement advanced material models correctly.

- Inaccurate modeling can lead to incorrect compensation, necessitating expensive die recuts.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —