Exposing the Top Problems with Stamped Steel Upper Control Arms

TL;DR

Stamped steel upper control arms are a common source of problems for many truck owners due to their lightweight, cost-effective design. Key issues include a high potential for ball joint failure, poor weld quality, and a tendency to bend or crack under stress. These problems are often magnified on leveled or lifted vehicles. Compared to stronger alternatives like cast iron or forged aluminum, stamped steel arms offer less durability, making replacement a common consideration for safety and performance.

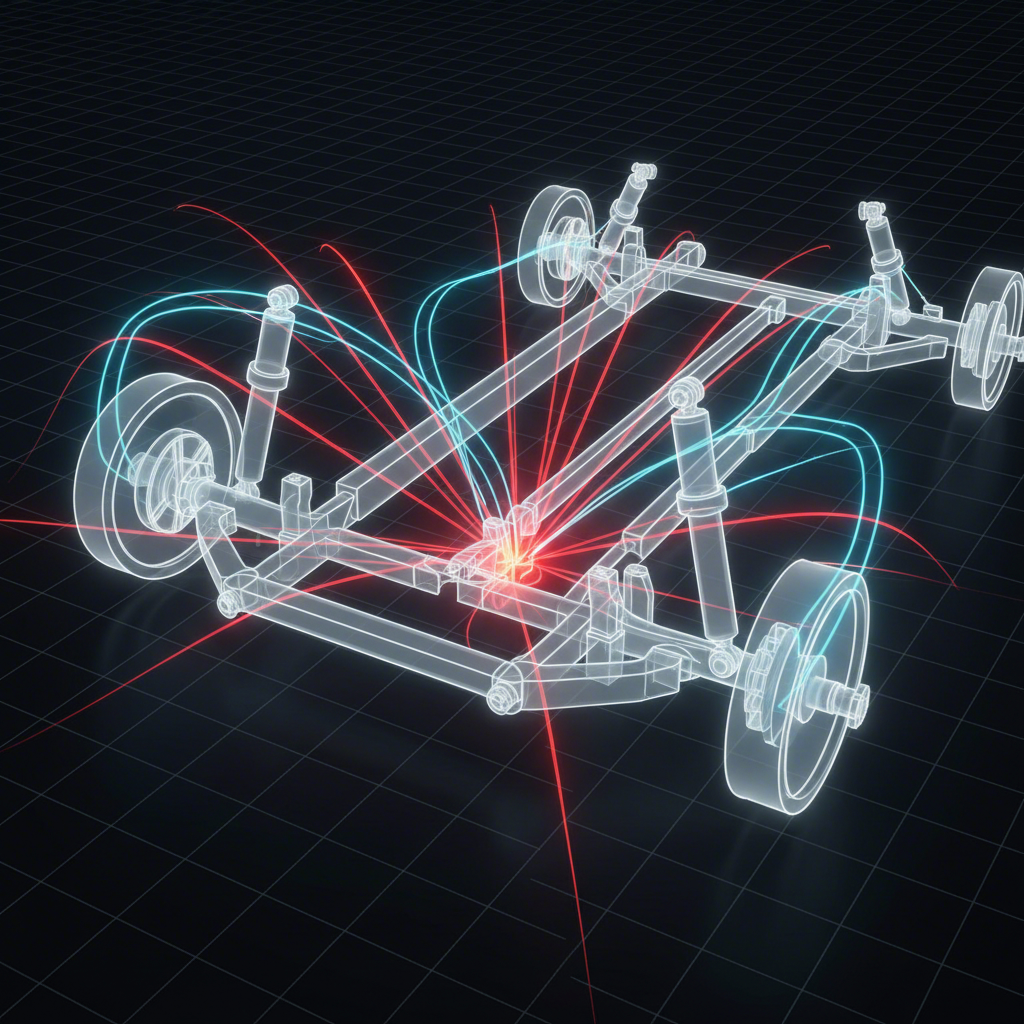

Understanding Stamped Steel Control Arms

A control arm is a critical suspension component that connects your vehicle's frame to the steering knuckle, which holds the wheel. Its job is to allow the wheel to move up and down with the terrain while maintaining stability and steering control. Stamped steel upper control arms are manufactured by cutting steel plates, pressing them into a specific shape, and then welding the pieces together. This process results in a hollow, lightweight component that helps manufacturers reduce vehicle weight and production costs.

While effective for standard road use, this manufacturing method creates inherent trade-offs. The hollow structure and reliance on welds make stamped steel arms less robust than solid, single-piece cast or forged arms. The process of automotive stamping requires significant expertise to ensure consistency and strength. For automotive manufacturers seeking reliable metal stamping, specialized providers such as Shaoyi (Ningbo) Metal Technology Co., Ltd. offer comprehensive solutions from prototyping to mass production, ensuring components meet strict industry standards like IATF 16949.

These components are prevalent in many modern trucks and SUVs, including various Chevrolet Silverado and GMC Sierra models. For many drivers, they perform adequately under normal conditions. However, when subjected to heavy loads, off-road driving, or suspension modifications, their design limitations can become apparent, leading to the problems many owners report.

Common Problems and Failure Symptoms

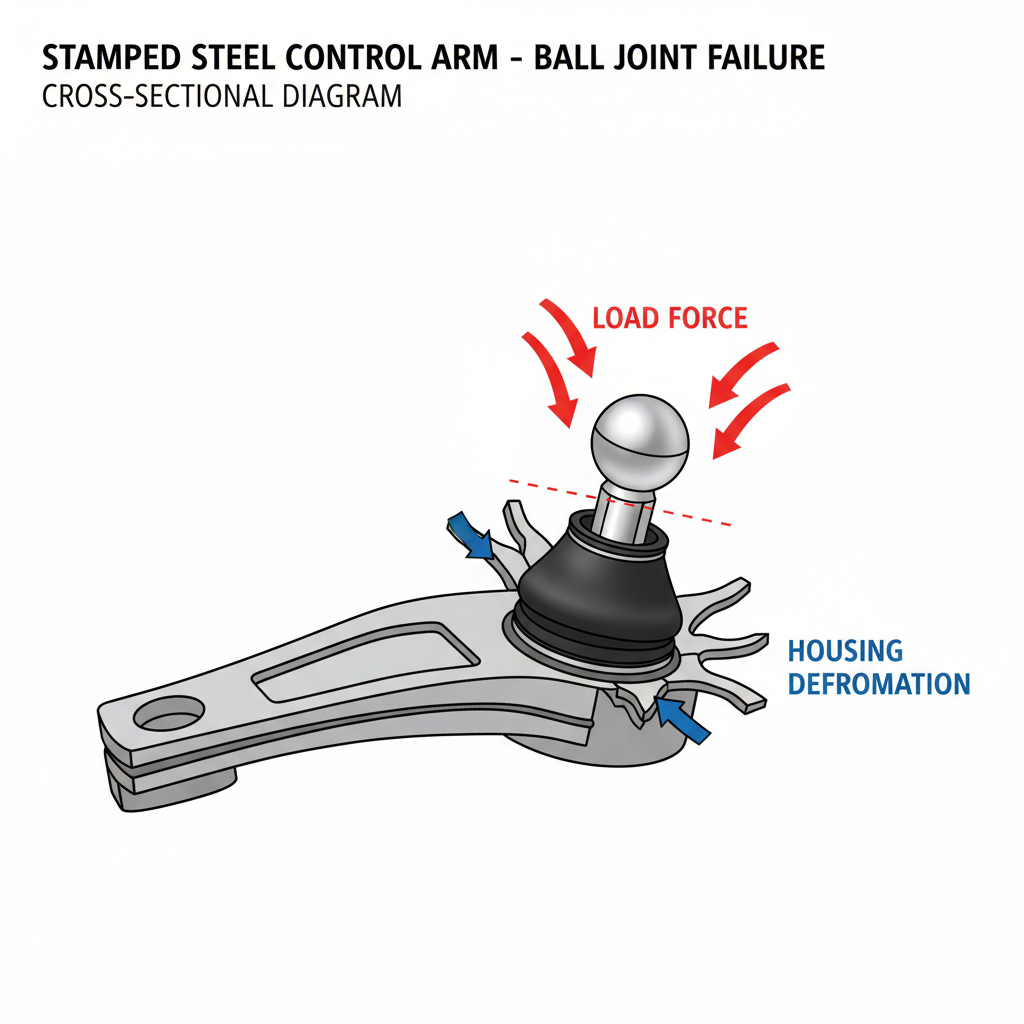

The most significant concern with stamped steel upper control arms is the risk of catastrophic ball joint failure. Unlike cast designs that often feature retention clips for safety, the ball joint in a stamped steel arm is sandwiched between the upper and lower metal plates. According to an analysis by ReadyLIFT, if the metal cup holding the ball joint distorts from stress, the ball stud can pull completely through the arm, causing the suspension to disengage from the wheel. This can lead to a sudden loss of vehicle control.

Poor weld quality has also been a documented issue. Forum discussions on platforms like GM-Trucks.com have highlighted recalls and owner complaints related to bad welds near the bushings, which can lead to cracks and eventual failure. These vulnerabilities are often exposed when the suspension geometry is altered, such as with a leveling or lift kit, which places additional stress on the factory components at steeper angles.

A recent recall of aftermarket ball joints made by Cognito Motorsports for GM HD trucks underscores this weak point. As reported by autoevolution, the issue involved the ball stud pulling through the housing, a failure mode identical to the primary concern with OEM stamped steel arms. This highlights the ball joint assembly as a critical stress point. Vehicle owners should be vigilant for symptoms that indicate a problem. Pay close attention to the following warning signs:

- Clunking or popping noises: These sounds are often most noticeable when driving over bumps or making sharp turns.

- Vibrating steering wheel: A loose or failing ball joint can cause vibrations that are felt through the steering wheel.

- Uneven tire wear: When a control arm fails, it can throw off the vehicle's alignment, causing tires to wear down prematurely or unevenly.

- Wandering steering: The vehicle may feel unstable or difficult to keep in a straight line, requiring constant steering correction.

Stamped Steel vs. Cast Iron vs. Aluminum Control Arms: A Detailed Comparison

Choosing the right control arm material depends heavily on your vehicle and how you use it. Stamped steel, cast iron, and cast aluminum each offer a distinct balance of strength, weight, and cost. Understanding these differences is crucial for making an informed decision, whether you are replacing a worn part or upgrading your suspension.

Stamped steel is the budget-friendly, lightweight option favored by manufacturers for mass-market vehicles. Cast iron, as explained by GMT Rubber, is the heavyweight champion, prized for its immense strength and durability, making it ideal for heavy-duty trucks and SUVs. Cast aluminum offers a modern compromise, providing strength that is superior to stamped steel while being significantly lighter than cast iron. To help you decide, here is a detailed breakdown of their key attributes:

| Attribute | Stamped Steel | Cast Iron | Cast Aluminum |

|---|---|---|---|

| Manufacturing Process | Steel plates are stamped into shape and welded together. | Molten iron is poured into a single-piece mold. | Molten aluminum is poured into a single-piece mold. |

| Strength/Durability | Lowest; prone to bending, cracking at welds, and ball joint failure. | Highest; extremely strong and resistant to deformation. | High; stronger than stamped steel but can crack on severe impact. |

| Weight | Lightest, as it is hollow. | Heaviest, due to its dense, solid construction. | Lightweight, offering a good strength-to-weight ratio. |

| Cost | Lowest to manufacture and replace. | More expensive than stamped steel. | More expensive than stamped steel; often the costliest option. |

| Common Applications | Standard cars, light-duty trucks, and SUVs. | Heavy-duty trucks, commercial vehicles, and SUVs. | Performance cars, light trucks, and modern SUVs. |

For a daily driver that stays on paved roads, stamped steel arms are generally sufficient. However, for anyone who tows, goes off-road, or has installed a lift kit, upgrading to cast iron or cast aluminum is a wise investment in safety and long-term durability.

Solutions: Upgrades and Recalls

If you've identified issues with your stamped steel control arms or plan to modify your truck's suspension, the most effective solution is replacement. Upgrading to a more robust aftermarket or OEM alternative not only resolves the inherent weaknesses but also improves suspension geometry and overall performance, especially on lifted vehicles. Experts strongly advise that any truck with stamped steel arms receiving a leveling kit or lift should have the upper control arms replaced to prevent premature ball joint failure.

Your main options are stronger OEM parts or specialized aftermarket arms. For many GM trucks, this means swapping the stamped steel units for factory cast aluminum or cast steel arms from a different trim level or model year. Aftermarket solutions, such as tubular or forged steel control arms, are specifically engineered to correct ball joint angles on lifted trucks, providing better alignment, more suspension travel, and superior strength.

Regarding recalls, the situation can be complex. While there have been specific GM recalls related to poor weld quality from certain vendors, many widely discussed issues pertain to the fundamental design limitations rather than a specific manufacturing defect. To determine if your vehicle is affected by a known issue, it is always best to check your VIN with a dealership or on the manufacturer's official recall site. If you are experiencing problems, here is a practical path forward:

- Identify your current control arms. As recommended by MOOG Parts, an easy way to check is with a magnet. A magnet will stick to stamped steel and cast iron but not to aluminum. Tapping a steel arm will produce a hollow sound, while cast iron will make a dull thud.

- Assess your driving needs. Consider whether you primarily drive on the highway, tow heavy loads, go off-roading, or have a lifted or leveled suspension. Your usage will determine the best replacement material.

- Research appropriate replacements. Explore options from both OEM catalogs and reputable aftermarket brands that specialize in suspension components for your specific truck model.

- Consult a certified mechanic. Proper installation is critical for safety and performance. A professional technician can ensure the new control arms are installed correctly and the vehicle is properly aligned afterward.

Frequently Asked Questions

1. What is the difference between cast iron and stamped steel control arms?

The primary difference lies in their manufacturing, strength, and weight. Stamped steel control arms are made from welded steel plates, making them lightweight and inexpensive but less durable. Cast iron control arms are made from a single piece of molded iron, making them much heavier, stronger, and more resistant to harsh conditions, which is why they are typically used in heavy-duty vehicles.

2. Are stamped steel control arms magnetic?

Yes, stamped steel control arms are magnetic. A simple way to identify your control arm material is to use a magnet. If the magnet sticks, the arm is either stamped steel or cast iron. If it does not stick, it is aluminum.

3. What is the GM upper control arm recall?

There have been several issues related to GM upper control arms. Some official recalls have targeted specific production runs of stamped steel arms due to poor weld quality from a supplier. Additionally, there have been recalls for aftermarket ball joints designed for GM trucks that were found to be defective, highlighting the vulnerability of this component. If you are concerned, it is best to check your vehicle's VIN for any open recalls with an authorized dealer.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —