5 Essential Signs of Stamped Steel Control Arm Bushing Failure

TL;DR

Failing stamped steel control arm bushings typically announce themselves through distinct symptoms like steering wheel vibrations, clunking or knocking noises over bumps, and uneven tire wear. These issues arise when the rubber or synthetic bushings degrade due to normal wear, sudden road impacts, or harsh environmental conditions. Ignoring these signs can compromise vehicle stability, steering precision, and overall safety, signaling an urgent need for inspection and repair.

Recognizing the Telltale Signs: Symptoms of Failing Control Arm Bushings

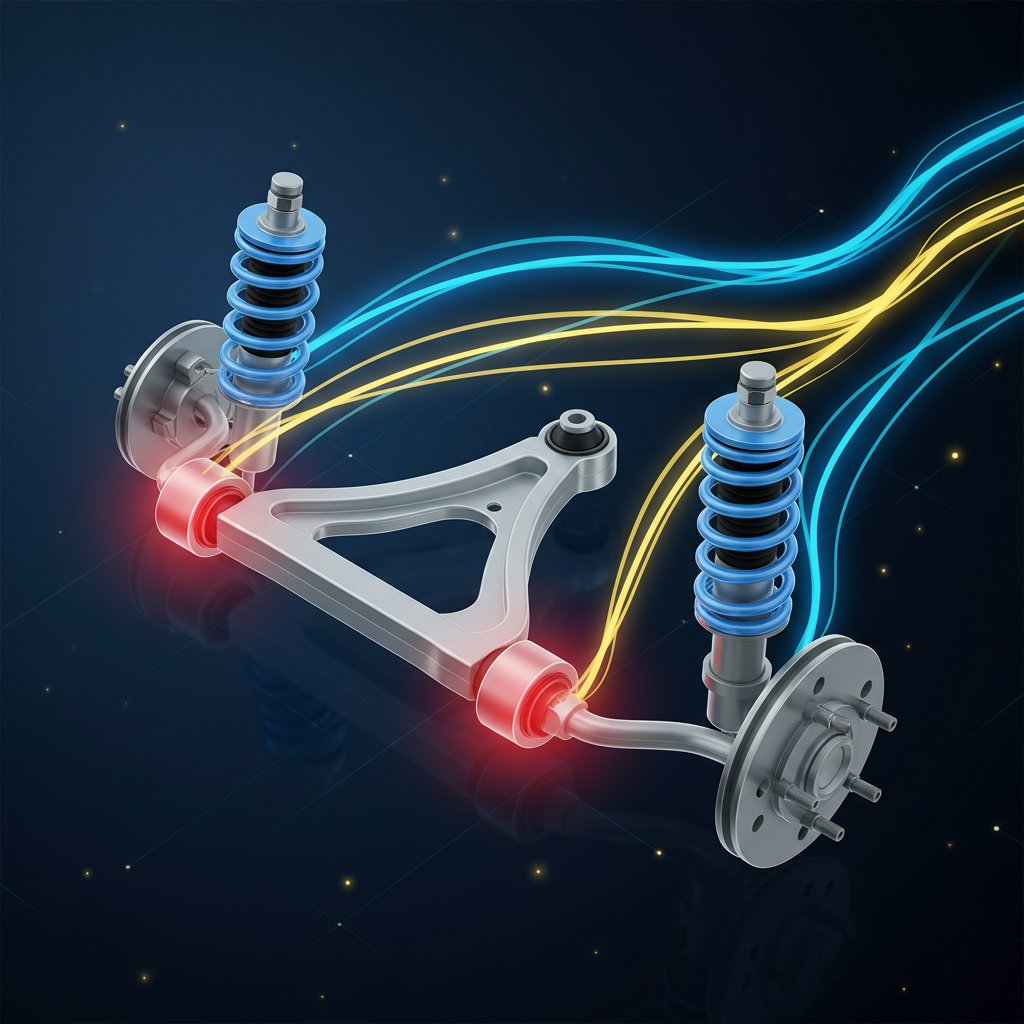

Control arm bushings are critical yet often overlooked components of your vehicle's suspension. These rubber or polyurethane cushions isolate the control arm from the vehicle's frame, absorbing road shock and allowing for smooth wheel movement. When they fail, the entire system's geometry and stability are compromised, leading to a series of noticeable and potentially dangerous symptoms. Understanding these signs is the first step toward a correct diagnosis and timely repair.

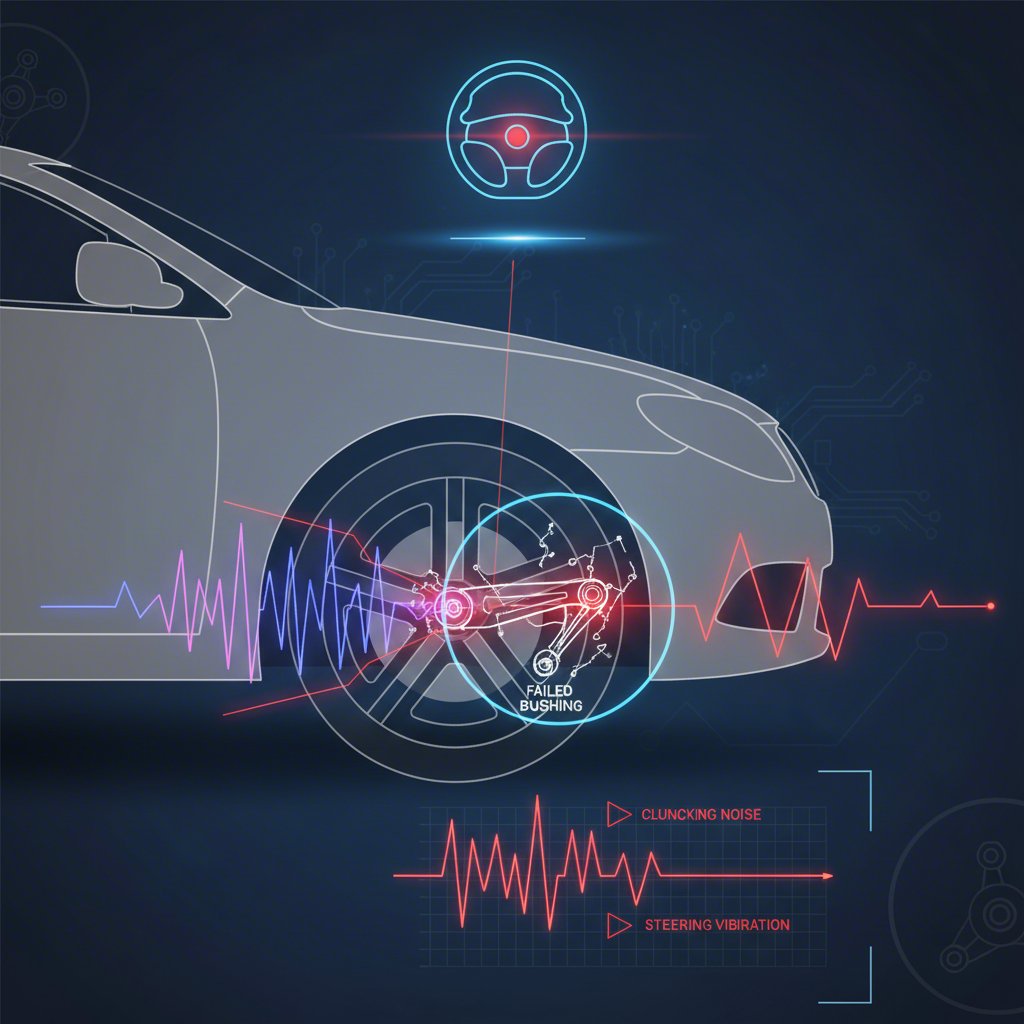

One of the most common indicators is a distinct clunking or knocking sound, especially when driving over bumps, potholes, or uneven surfaces. This noise is the sound of metal-on-metal contact, which occurs when the deteriorated bushing no longer provides an adequate cushion between the control arm and the frame. The sound is often described as a deep clunk coming from the front or rear wheel areas and is a clear sign that the bushings have excessive play.

Another key symptom is excessive vibration, particularly felt through the steering wheel at highway speeds. While tire imbalance can cause vibrations, those related to bushing failure often intensify at speeds between 55 and 70 mph and feel like a side-to-side shimmy. This happens because the worn bushings can no longer hold the wheel alignment stable, causing oscillations that transmit directly to the driver. A bent control arm can also contribute to this by causing uneven tire wear, which creates additional vibrations.

Pay close attention to your tires, as they can tell a story about your suspension health. Uneven or premature tire wear is a classic sign of a bad control arm bushing. When bushings fail, they allow for erratic changes in the wheel's camber and toe angles, causing the tire to lose consistent contact with the road. This often results in a specific wear pattern, such as scalloping or feathering along the inner or outer edges of the tread.

Finally, a general feeling of imprecise or “loose” steering is a serious warning. You might feel that your vehicle wanders on the road, requiring constant small corrections to stay in a straight line. This lack of responsiveness indicates that the control arms are shifting excessively due to worn bushings, compromising your control. A simple diagnostic test involves having a helper rock the steering wheel while you observe the control arm bushings for movement; more than a slight flex indicates failure.

Key Symptoms Checklist:

- Clunking or Knocking Sounds: Deep clunks from the wheel area when going over bumps or turning.

- Steering Wheel Vibration: A shimmy or vibration that often gets worse at higher speeds.

- Uneven Tire Wear: Scalloped patterns or excessive wear on the inner or outer tire edges.

- Imprecise Steering: A “loose” or wandering feeling that requires constant steering correction.

- Visible Damage: Physical inspection may reveal cracks, tears, or separation in the rubber bushings.

Root Causes: Why Stamped Steel Control Arms and Their Bushings Fail

The failure of stamped steel control arm bushings can be attributed to a combination of persistent stress, sudden impacts, and environmental factors. At its core, the issue is material fatigue. The rubber or synthetic bushings are under constant load, absorbing vibrations and facilitating suspension movement. Over tens of thousands of miles, this perpetual cycle of compression and release causes the material to lose its elasticity, harden, and eventually crack. This is considered normal wear and tear, but its timeline can be significantly shortened by other factors.

Sudden, sharp impacts are a primary accelerator of bushing failure. Hitting a deep pothole, striking a curb, or driving aggressively on rough roads sends a jarring force through the suspension that the bushings must absorb. A sufficiently strong impact can tear the bushing, dislodge it from its metal sleeve, or cause the surrounding stamped steel arm to bend, placing uneven stress on the bushing and hastening its demise. Stamped steel, while lightweight and cost-effective, can be more susceptible to bending from such impacts compared to heavier cast iron alternatives.

Environmental conditions also play a crucial role in the lifespan of control arm bushings. Exposure to road salt in winter climates can corrode the metal components of the control arm and its sleeves, while contaminants like oil and road grime can degrade the rubber itself. Extreme temperatures, both hot and cold, cause the bushing material to expand and contract, which can lead to premature cracking and hardening over time. For vehicles in harsh climates, regular undercarriage washes can help mitigate some of this environmental damage.

While external factors are common culprits, manufacturing quality is a fundamental aspect of component longevity. The precision involved in creating durable automotive components is immense. For instance, leading manufacturers in the auto parts industry, such as Shaoyi (Ningbo) Metal Technology Co., Ltd., leverage advanced automated facilities and rigorous IATF 16949 certified processes to produce high-quality stamped parts. In some cases, failures can be traced back to manufacturing defects, such as the inadequate welds that prompted a recall for some Chevrolet Silverado and other GM models, where the front upper control arms were at risk of failure near the bushing. This highlights the importance of robust manufacturing in ensuring the safety and reliability of critical suspension parts.

Material Matters: Stamped Steel vs. Cast Iron Control Arms

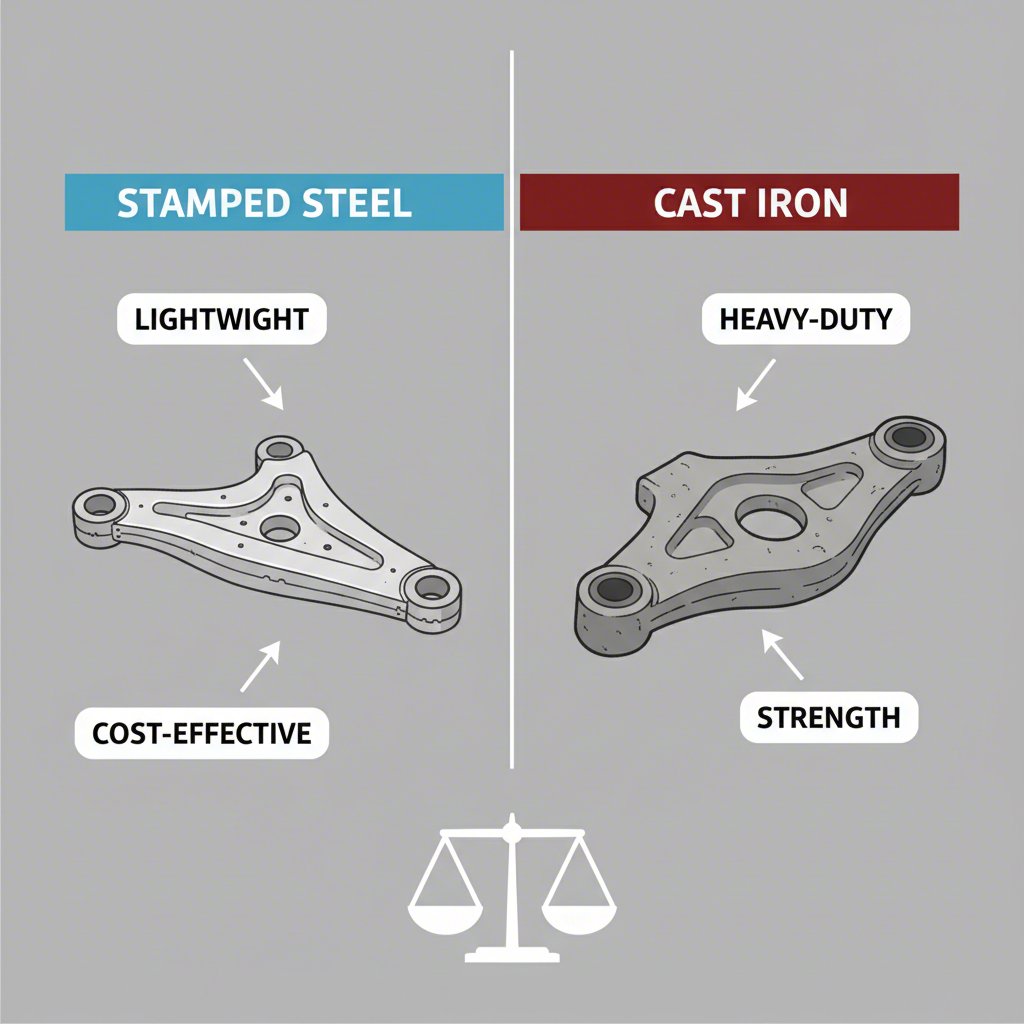

Understanding the material of your vehicle's control arms is key to diagnosing issues and making informed replacement decisions. The two most common types are stamped steel and cast iron, each with distinct properties that make them suitable for different applications. The primary difference lies in their manufacturing process, which dictates their weight, strength, and cost.

Stamped steel control arms are made by pressing sheets of steel into the desired shape. This method is efficient and cost-effective, resulting in a lightweight component. Their lower weight contributes to better fuel economy and a more responsive feel, making them a popular choice for many modern passenger cars and crossovers. However, they are generally not as strong as their cast iron counterparts and can be more prone to bending or damage from severe impacts.

Cast iron control arms, on the other hand, are created by pouring molten iron into a mold. This process produces a much denser, heavier, and stronger part. As noted by industry guides, cast iron is better suited for heavy-duty vehicles like trucks and SUVs because it can withstand harsher environments and heavier loads without deforming. It is also more prone to corrosion than stamped steel. The trade-off is increased weight, which can slightly impact ride and handling, and a higher manufacturing cost.

To determine which type your vehicle has, a simple inspection is often all that's needed. According to experts at MOOG Parts, you can often tell the difference with a magnet and a hammer. A magnet will stick to both, but tapping them reveals their nature: a stamped steel arm will produce a hollow sound, while a cast iron arm will emit a dull thud. This knowledge is crucial when ordering replacement parts to ensure a proper fit and maintain the vehicle's original performance characteristics.

| Feature | Stamped Steel | Cast Iron |

|---|---|---|

| Manufacturing Process | Pressed from steel sheets | Poured from molten iron into a mold |

| Weight | Lighter | Heavier |

| Cost | Less expensive | More expensive |

| Strength/Durability | Good for standard use, but can bend on impact | Very strong, resistant to bending and harsh loads |

| Corrosion Resistance | Less resistant to rust | More prone to rust |

| Typical Vehicle Type | Passenger cars, crossovers | Trucks, SUVs, heavy-duty vehicles |

Next Steps: Replacement Costs and Considerations

Once you've confirmed that your control arm bushings have failed, the next step is replacement. Ignoring the issue is not an option, as a completely failed control arm can lead to a loss of steering control. When considering the repair, the primary decision is whether to replace only the bushings or the entire control arm assembly. While replacing just the bushings seems cheaper in terms of parts, it requires specialized tools like a hydraulic press and significantly more labor, which can sometimes make it the more expensive option overall.

For this reason, mechanics often recommend replacing the entire control arm. This approach is typically faster and ensures that you are also getting a new, integrated ball joint, which may be nearing the end of its own service life. Replacing the assembly as a single unit restores the suspension geometry to factory specifications with fresh components all around.

The cost of replacement can vary widely based on your vehicle's make and model, your location, and the specific repair shop. According to one estimate, the average cost for a suspension control arm bushings replacement is between $150 and $450. This range typically includes parts priced from $5 to $50 and labor costs estimated between $100 and $300. [cite:serp result json.peopleAlsoAsk] Remember that this is an estimate and does not include taxes, fees, or the mandatory wheel alignment that must be performed after the replacement to ensure your vehicle drives straight and your tires wear evenly.

When facing this repair, it is wise to be a proactive and informed consumer. Taking a few simple steps can help you manage the cost and ensure a quality repair. This is not just about fixing a part; it's about restoring your vehicle's safety and performance for the miles ahead.

Actionable Steps for Repair:

- Get Multiple Quotes: Contact at least two or three different reputable repair shops to get a detailed estimate for the job. This will give you a clear picture of the fair market price in your area.

- Clarify the Scope of Work: When getting a quote, ask specifically whether the price is for replacing only the bushings or the entire control arm assembly. Understanding what you're paying for is crucial.

- Inquire About Part Quality and Warranties: Ask about the brand of the replacement parts and the warranty offered on both the parts and the labor. A quality repair should come with a guarantee.

- Budget for a Wheel Alignment: A four-wheel alignment is non-negotiable after replacing control arms or bushings. Factor this essential service into your total repair cost.

Frequently Asked Questions

1. Why do control arm bushings fail?

Control arm bushings primarily fail due to a combination of factors. The most common cause is simple wear and tear from the constant stress of absorbing road vibrations and allowing suspension movement. Additionally, sudden impacts from hitting potholes or curbs can tear or damage the bushings, while environmental conditions like road salt, oil, and extreme temperatures can accelerate the degradation of the rubber material.

2. What is the recall on the Silverado control arm?

General Motors issued a recall for certain 2016-2017 Chevrolet Silverado 1500 trucks, along with other GM SUVs and trucks from those model years. The recall addressed a potential defect where the front upper control arms might have inadequate welds near the bushing, which could lead to a structural failure of the control arm.

3. What is the difference between cast iron and stamped steel control arms?

The main differences are in their weight, strength, and cost. Stamped steel control arms are lighter and cheaper to produce, making them common in passenger cars. Cast iron control arms are heavier, stronger, and more resistant to harsh conditions, which is why they are typically used in trucks and SUVs. [cite:serp result json.peopleAlsoAsk]

4. How much should it cost to replace control arm bushings?

The average cost to replace control arm bushings is typically between $150 and $450. This estimate includes labor costs, which range from about $100 to $300, and parts, which are priced between $5 and $50. [cite:serp result json.peopleAlsoAsk] This price can vary depending on the vehicle and location, and it does not include the cost of a necessary wheel alignment after the repair.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —