Stamped Steel vs Cast Aluminum Control Arms: Which to Choose?

TL;DR

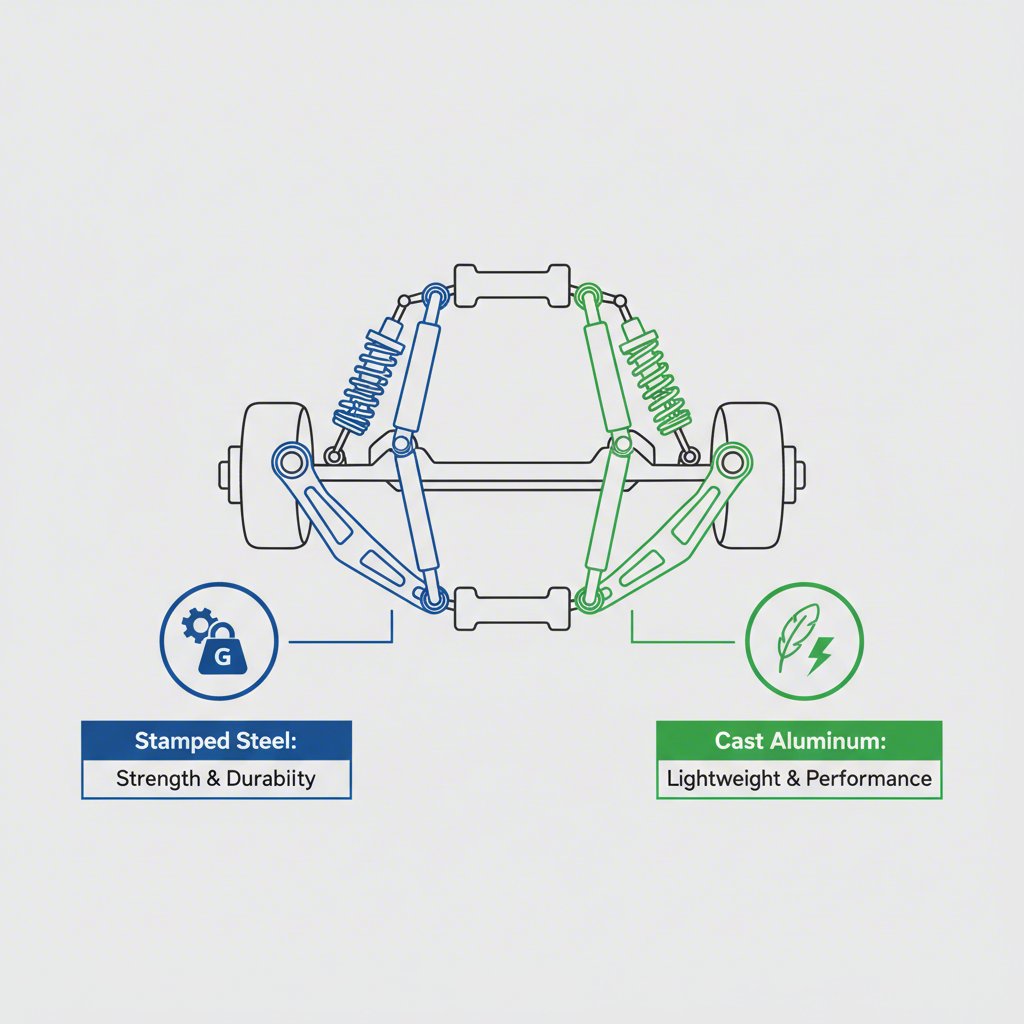

Choosing between a stamped steel control arm and a cast aluminum one involves a trade-off between strength and performance. Stamped steel is a strong, cost-effective OEM choice ideal for heavy-duty use but is heavier and prone to rust. Cast aluminum is significantly lighter, improving handling and ride quality, and offers natural corrosion resistance, making it a premium choice for performance applications, though it comes at a higher cost and may be less durable under extreme impact.

Visual Identification Guide: How to Tell Stamped Steel vs. Cast Aluminum Apart

Before you can decide on a replacement or upgrade, you first need to identify what type of control arms are currently on your vehicle. The differences are rooted in their manufacturing processes, which create distinct visual cues. Stamped steel, cast aluminum, and even cast steel arms each have a unique appearance that makes them relatively easy to tell apart with a quick inspection.

Stamped steel control arms are formed from sheets of steel that are pressed into shape and then welded together. This process results in a component that often looks like two halves joined at a seam. According to Switch Suspension, the most obvious tell is this welded seam. The surface is also typically smooth and is often painted, usually in a glossy black, to prevent corrosion. For automotive manufacturers seeking precision and reliability in such components, specialized metal stamping is crucial. For instance, companies like Shaoyi (Ningbo) Metal Technology Co., Ltd. provide comprehensive solutions that ensure high-quality, cost-effective production for complex automotive parts, reflecting the industrial scale behind these common components.

Cast aluminum control arms, by contrast, are made by pouring molten aluminum into a mold. This creates a single, solid piece without any welded seams. The surface finish is generally rougher and more textured than stamped steel, often with visible marks from the casting process. Because aluminum is naturally resistant to rust, these arms are frequently left unpainted, showing their raw metallic finish. This one-piece construction gives them a more robust, molded appearance compared to the fabricated look of stamped steel.

To simplify identification, here is a quick comparison:

| Visual Cue | Stamped Steel | Cast Aluminum |

|---|---|---|

| Surface Finish | Smooth, often painted (e.g., glossy black) | Rough, textured, typically unpainted |

| Seams | A clear welded seam where two pieces are joined | No seams; appears as a single molded piece |

| Overall Shape | Fabricated look, like two halves joined together | Solid, one-piece, molded appearance |

| Material Feel | Magnetic, feels like sheet metal | Non-magnetic, lightweight feel |

Knowing which type you have is more than just a matter of curiosity; it's critical for ordering the correct replacement parts. As highlighted by experts, different control arm materials can be paired with different knuckles and ball joints, making them non-interchangeable on certain models. Taking a moment to visually inspect your vehicle's suspension can save you from purchasing incompatible parts and ensure a safe, proper fit.

Core Comparison: Strength, Durability, Weight, and Cost

The debate between stamped steel and cast aluminum control arms comes down to a few key performance metrics. Your ideal choice depends entirely on your priorities, whether they are raw strength for heavy-duty applications, weight savings for better handling, or simply the most budget-friendly option. Each material brings a distinct set of advantages and disadvantages to the table.

Strength and durability are the primary selling points for steel. As noted in a comparison by Metrix Premium Parts, steel is generally stronger and better at withstanding heavy loads and impacts. This makes stamped steel control arms the preferred option for trucks, off-road vehicles, and heavy-duty applications where the suspension is subjected to significant stress. While strong, they are not invincible; their welded construction can be a point of failure, and they are highly susceptible to rust in wet or salty climates if the protective coating is compromised.

Weight is where aluminum shines. Aluminum is significantly lighter than steel, and reducing this "unsprung weight" (the mass of the suspension, wheels, and other components not supported by the springs) has profound benefits. Lighter control arms allow the suspension to react more quickly to bumps and road imperfections, which improves tire contact with the ground, enhances handling, and provides a smoother ride. This performance advantage is why aluminum is often the material of choice for luxury and performance vehicles.

Corrosion resistance is another major benefit of aluminum. It naturally forms a protective oxide layer that prevents rust, making it an excellent choice for vehicles in regions with harsh winters or coastal areas. Stamped steel, on the other hand, must rely on paint or other coatings for protection, which can chip or wear away over time, leading to corrosion that can weaken the part.

Finally, cost is often the deciding factor. Stamped steel is less expensive to produce and is therefore the more economical choice. This is why it's commonly used as the original equipment manufacturer (OEM) part on many standard vehicles. Cast aluminum is more costly due to higher material and manufacturing expenses, positioning it as a premium or aftermarket upgrade.

| Attribute | Stamped Steel | Cast Aluminum |

|---|---|---|

| Strength & Impact Resistance | Higher; better for heavy-duty and off-road use. | Lower; can be more prone to bending or breaking under extreme stress. |

| Weight | Heavier; increases unsprung weight, can hinder handling. | Lighter; reduces unsprung weight for improved handling and ride quality. |

| Corrosion Resistance | Low; requires protective coatings to prevent rust. | High; naturally resistant to corrosion. |

| Ride Quality & Handling | Adequate for daily driving but can feel less responsive. | Superior; enhances suspension responsiveness and cornering. |

| Typical Cost | Lower; more budget-friendly for repairs. | Higher; considered a premium or performance upgrade. |

Ultimately, the best material is the one that aligns with your needs. For a daily driver or a work truck where durability and cost are paramount, stamped steel is a practical and reliable choice. If you prioritize enhanced handling, a smoother ride, and superior corrosion resistance for a performance or luxury vehicle, the higher cost of cast aluminum is a worthwhile investment.

The GM Truck Dilemma: A Special Case for Silverado & Sierra Owners

While the stamped steel versus aluminum debate is relevant for many vehicles, it takes on critical importance for owners of 2014 and newer Chevrolet Silverado and GMC Sierra 1500 trucks. On these models, the type of factory-installed upper control arm is not just a matter of performance—it's a significant safety and reliability concern, especially for those looking to install a leveling or lift kit.

The core of the issue lies in the design of the OEM stamped steel upper control arms. According to a detailed analysis by ReadyLIFT, these arms feature a ball joint that is essentially sandwiched between the two metal halves of the arm. This design provides a very small surface area for retaining the ball joint and, crucially, lacks the retaining clips found on the cast aluminum and cast steel versions. When the suspension angle is increased by a leveling or lift kit, the stress on this weak point rises dramatically, leading to a high risk of the ball joint cup distorting and the entire joint failing or pulling out of the arm.

This potential for catastrophic failure makes upgrading the control arms a near necessity for modified trucks. The widely accepted recommendation for owners of GM trucks with factory stamped steel arms is clear: if you plan to level or lift your truck, you must replace the stock arms. The safest options are to install a high-quality aftermarket upper control arm designed for lifted applications or to purchase the factory cast aluminum arms, which do not suffer from the same design flaw.

Complicating matters further is the issue of interchangeability. From 2014-2016, GM used different steering knuckles (aluminum and steel) paired with different control arm materials. These knuckles have different sized holes for the ball joints, meaning a simple swap is not always possible. Stamped steel and aluminum arms were typically paired with one knuckle size, while cast steel arms used another. This makes it essential for owners to verify not only their control arm type but also their knuckle material before ordering any replacement parts to ensure compatibility.

For any Silverado or Sierra owner, the practical advice is straightforward. Before ordering a lift kit, leveling kit, or any replacement suspension components, you must physically inspect your truck to determine which upper control arms it has. If you find stamped steel arms, you should factor the cost of upgrading them into your budget. Ignoring this issue can lead to premature part failure, unsafe driving conditions, and potentially costly damage to your vehicle. This specific case underscores how a simple material choice can have significant real-world consequences for vehicle safety and modification.

Frequently Asked Questions

1. Are steel or aluminum control arms better?

Neither is universally "better"; the best choice depends on your priorities. Steel control arms are stronger, more durable against heavy impacts, and less expensive, making them ideal for heavy-duty trucks, off-roading, and budget-conscious repairs. Aluminum control arms are lighter, which improves handling, ride comfort, and fuel efficiency, and they are naturally corrosion-resistant, making them superior for performance and luxury vehicles, especially in harsh climates.

2. What is the difference between cast and stamped steel control arms?

The main difference is the manufacturing process, which affects their appearance and properties. Stamped steel arms are made from two pieces of sheet steel pressed into shape and welded together, resulting in a visible seam and a smooth, painted surface. Cast steel arms are made by pouring molten steel into a single mold, giving them a rougher, textured, one-piece appearance with no welded seams. Stamped steel is common on many stock vehicles, while cast steel is often found on heavy-duty applications.

3. Which is better, cast aluminum or steel?

Cast aluminum is better for applications where weight reduction and performance handling are key goals. Its lower weight reduces unsprung mass, allowing the suspension to perform more efficiently. Steel is better for applications that demand maximum strength and impact resistance at a lower cost. For industrial or heavy-duty needs, steel's superior strength often makes it the more suitable choice.

4. What is the best material for control arms?

The best material depends on the vehicle's purpose and environment. For performance and luxury cars, especially in wet or salty climates, aluminum is often considered best due to its light weight and corrosion resistance, which enhance handling and longevity. For work trucks, off-road vehicles, or situations where cost and raw strength are the primary concerns, steel is typically the most practical and effective material.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —