Powder Coating OEM Control Arms: What You Must Know First

TL;DR

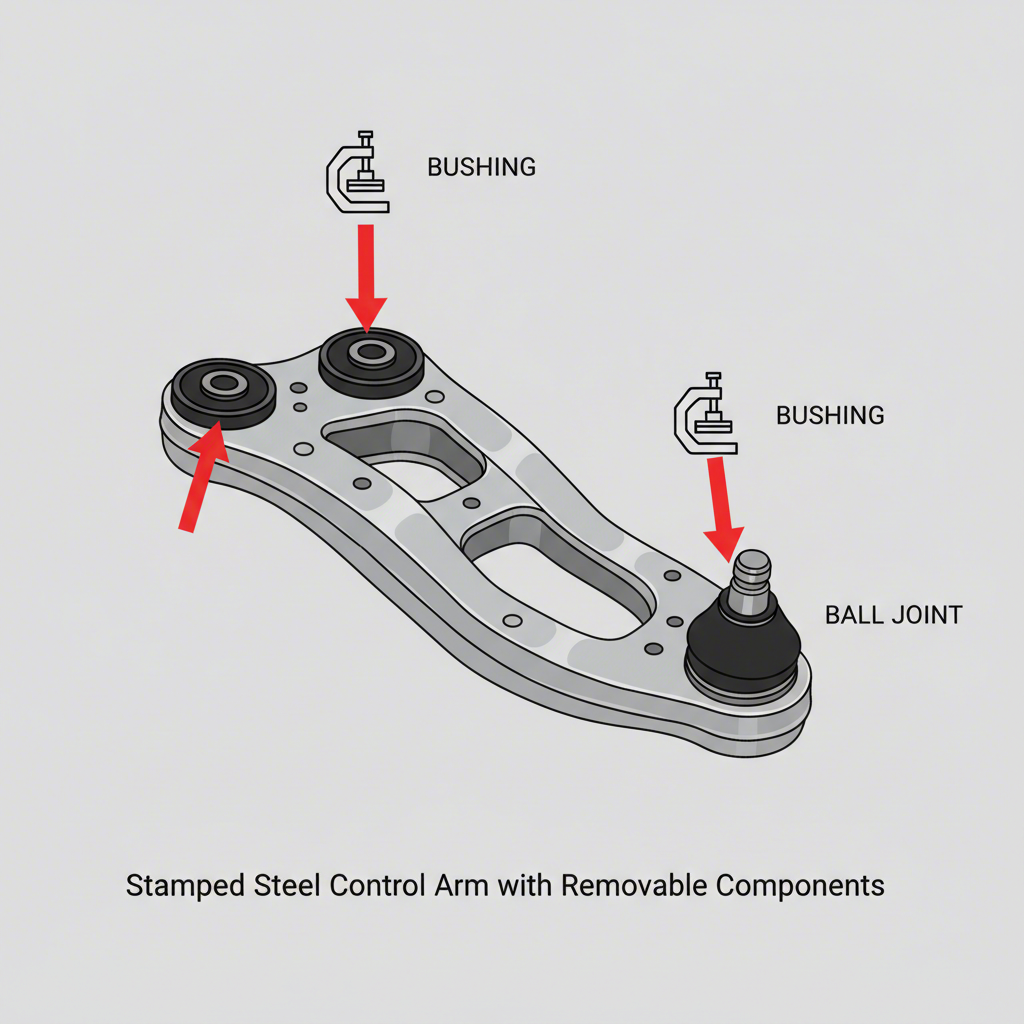

Yes, you can absolutely powder coat OEM stamped steel control arms for a durable, professional finish. However, it's critical that you first remove all rubber or polyurethane bushings and ball joints. The high-temperature curing process required for powder coating will melt and destroy these components, making complete disassembly the most important step for a successful outcome.

The Core Question: Is Powder Coating OEM Control Arms a Good Idea?

When restoring a vehicle's suspension, the question of refinishing parts like control arms always comes up. While a quick coat of paint is one option, powder coating offers a far more durable, chip-resistant, and professional-looking finish. Stamped steel, the material used for most OEM control arms, is an excellent candidate for this process. The metal itself handles the procedure perfectly, resulting in a finish that looks and performs like new.

The challenge isn't with the steel, but with the process itself. Powder coating involves electrostatically applying a dry powder to the metal part, which is then cured in an oven at temperatures typically reaching 400°F (about 200°C). As several automotive forum discussions confirm, these temperatures are far too high for the rubber or polyurethane bushings and the grease-filled ball joints that are pressed into the arms. Leaving them in will result in a melted, useless mess, ruining both the components and the fresh coating.

Therefore, the feasibility of the project hinges entirely on your ability to strip the control arm down to its bare metal state. The quality of the final product also depends on the initial component. OEM stamped steel arms are designed for strength, and specialist manufacturers in the automotive industry produce these precise, high-quality auto stamping parts. For instance, companies like Shaoyi (Ningbo) Metal Technology Co., Ltd. focus on creating reliable components that provide a solid foundation for any restoration or refinishing project.

Critical Preparation: Stripping Your Control Arms to Bare Metal

Successfully powder coating your control arms is 90% preparation. Failing to properly remove all non-metal components is not an option. This is the most labor-intensive part of the job, but it is absolutely essential. Here’s what you need to do to get the arms ready for the coater.

The process generally involves these key steps:

- Press Out Old Bushings: The original rubber bushings are pressed in tightly. You will typically need a hydraulic shop press or a specialized bushing removal tool to force them out without damaging the control arm. Soaking the surrounding area with a penetrating lubricant can help, but expect to use significant force.

- Remove Ball Joints: Most ball joints are either pressed in or bolted on. Bolted joints are easy to remove, but pressed-in versions require a ball joint press or separator tool. Since you're going this far, it's the perfect time to replace these common wear items with new ones anyway.

- Address Welded Components: Some vehicles have ball joints that are welded to the control arm from the factory. This presents a significant challenge. You cannot simply press them out. In this case, the old joint must be professionally cut out and a new one welded in, a job best left to an experienced fabrication or machine shop.

- Final Cleaning and Blasting: Once the hardware is removed, the arms need to be thoroughly degreased and media blasted (like sandblasting) to remove all rust, old paint, and grime. This ensures the powder has a perfectly clean surface to adhere to. Most powder coating shops include this blasting as part of their service.

If you don't have the tools, like a hydraulic press, don't worry. As users on Reddit have pointed out, most machine shops or even some wheel and tire shops can press out old bushings and ball joints for a reasonable labor charge. Taking them to a professional is often safer than risking damage to the control arm by using improper methods.

Cost vs. Benefit Analysis: Is It Worth The Expense?

Before you commit, it's wise to weigh the total investment against the benefits. While powder coating offers superior durability, it's significantly more complex and expensive than painting. The decision often comes down to your budget, goals, and how much work you're willing to do yourself.

Let's break down the potential costs. The powder coating service itself is just one piece of the puzzle. You must also account for new parts and potential labor for disassembly and reassembly.

| Item or Service | Estimated Cost (per arm) |

|---|---|

| Powder Coating Service | $40 - $60 |

| New Bushings (Set) | $30 - $100+ |

| New Ball Joint | $25 - $80+ |

| Machine Shop Labor (Pressing) | $20 - $50 |

| Estimated Total | $115 - $290+ |

Note: Costs are estimates based on available data and can vary widely by location and vehicle model. The price for the coating service is based on figures from automotive powder coating price lists.

When you add it all up, the total cost can easily exceed $100-$200 per control arm. In contrast, a high-quality chassis paint like POR-15 might cost around $50 for a can that can cover multiple components. Painting is a much simpler job that doesn't require removing bushings if they are in good shape (you just have to mask them carefully). So, which is right for you? If you're building a show car or doing a full, nut-and-bolt restoration where appearance and longevity are paramount, the high cost of powder coating is often justified. For a daily driver or a budget-conscious repair, a thorough cleaning followed by a durable rust-inhibiting paint is a much more practical and cost-effective solution.

Frequently Asked Questions About Powder Coating

1. How much does it cost to powder coat control arms?

The cost for the powder coating service alone typically ranges from $40 to $60 per control arm. However, the total project cost is much higher, as you must also budget for new bushings, new ball joints, and potentially machine shop labor to press the old components out and new ones in. The all-in cost can easily be between $115 and $290 per arm.

2. What metal cannot be powder coated?

While most metals like steel and aluminum are ideal for powder coating, some materials are unsuitable. The primary limitation is heat sensitivity. Materials with low melting points, like certain plastics, wax, or wood, cannot withstand the high curing temperatures. Additionally, very porous materials that can trap moisture may result in a poor finish, and galvanized steel can sometimes have issues with bubbling or poor adhesion if not pre-treated properly.

3. Can you powder coat OEM rims?

Yes, absolutely. OEM rims, which are typically made of steel or aluminum, are perfect candidates for powder coating. The process is very popular for wheel refurbishment as it provides a very durable, long-lasting, and uniform finish that stands up well to brake dust, road debris, and cleaning chemicals.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —