Automotive Die Lifecycle Management: Essential Strategies

TL;DR

Automotive die lifecycle management is the comprehensive process of overseeing a die's entire lifespan, from design and manufacturing through usage, maintenance, storage, and disposal. This systematic approach aims to maximize the tool's productive life, improve part quality, boost production efficiency, and significantly reduce the total cost of ownership. Effective management hinges on proactive maintenance protocols and leveraging specialized technologies like Warehouse Management Systems (WMS) and tool tracking software.

Defining Automotive Die Lifecycle Management

Automotive die lifecycle management is a strategic and systematic approach to overseeing every phase of a stamping die's existence. It extends far beyond simple storage and repair, encompassing a holistic process that includes initial design, procurement, active production use, scheduled maintenance, technological tracking, and eventual disposal. The core purpose is to transform the die from a simple piece of equipment into a highly managed asset, ensuring it delivers maximum value throughout its operational life.

This management discipline is critical in the high-stakes automotive industry, where precision, reliability, and efficiency are paramount. Poorly managed dies are a direct cause of significant financial loss. As detailed in a guide by the Phoenix Group, inadequate die maintenance can lead to quality defects during production, which in turn drives up sorting costs, increases scrap rates, and elevates the risk of shipping defective parts to customers—potentially resulting in expensive recalls and damage to brand reputation.

A well-structured lifecycle plan, much like a general equipment lifecycle plan, is built on four key stages: planning, procurement, maintenance, and disposal. In the context of automotive dies, this means planning for optimal tool design, procuring from expert manufacturers, implementing a rigorous maintenance schedule, and having a clear end-of-life strategy. The benefits are tangible and directly impact the bottom line, including improved equipment reliability, a sharp reduction in unexpected breakdowns, and an extended operational lifespan for these costly assets.

Contrast a managed lifecycle with an unmanaged one. Without a formal system, die repair often becomes reactive, addressing problems only after they cause production stoppages. This leads to lost press time, costly emergency repairs, and the introduction of part variations that can disrupt downstream assembly processes. A proactive lifecycle strategy, supported by expert partners, ensures that every die performs optimally, run after run. For instance, companies like Shaoyi (Ningbo) Metal Technology Co., Ltd. specialize in manufacturing high-precision custom stamping dies, providing a foundation of quality that is essential for a long and productive tool life.

Key Systems & Technologies in Modern Die Management

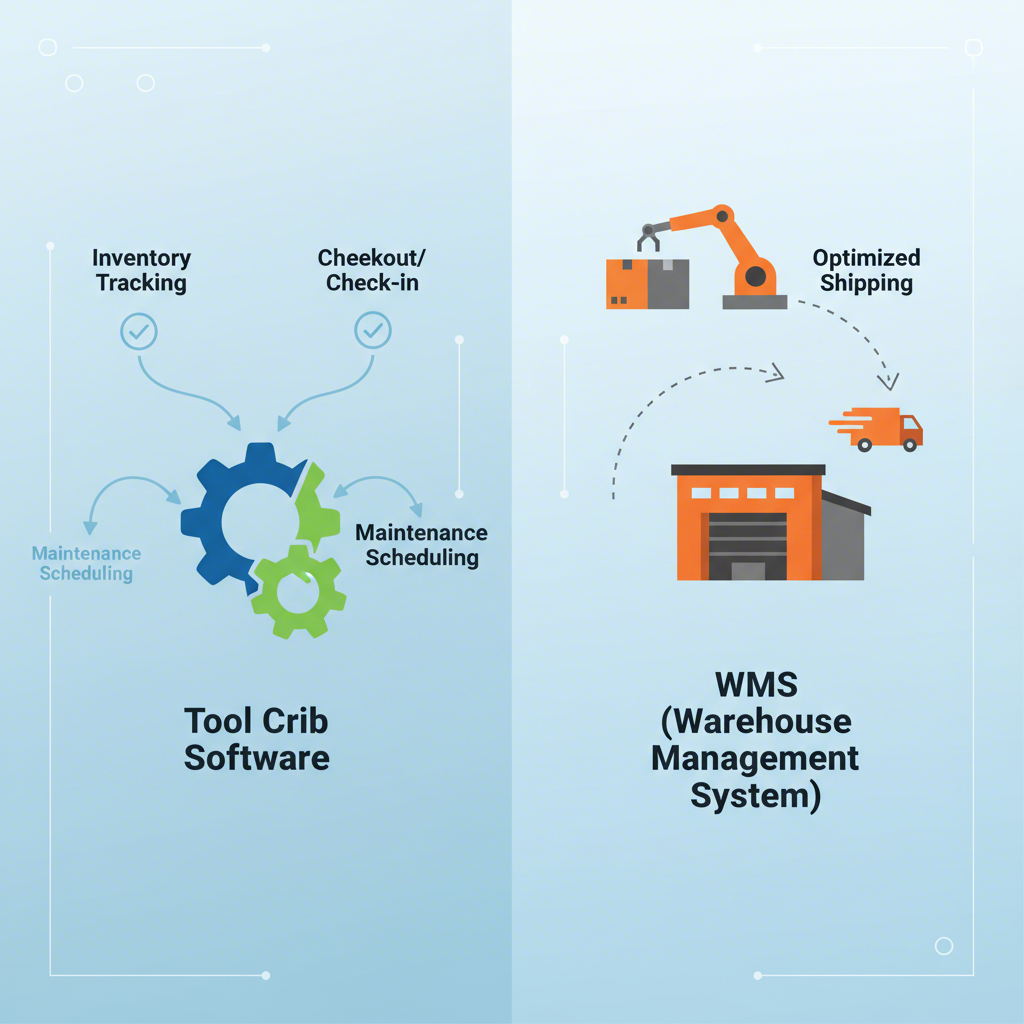

Modern automotive die lifecycle management relies heavily on sophisticated software and hardware to achieve the necessary levels of control and efficiency. Manual tracking and paper-based systems are no longer sufficient for the complexity of today's manufacturing environments. Instead, facilities are turning to specialized technologies like Tool Crib Management Software and Warehouse Management Systems (WMS) to automate tracking, storage, and maintenance scheduling, thereby minimizing human error and providing invaluable data insights.

Tool crib management software serves as the central nervous system for tracking the location, status, and usage history of every die. As explained by Advanced Technology Services (ATS), these systems provide real-time inventory tracking, often using RFID or barcode scanning to automate check-in and check-out processes. This ensures technicians can find the right tool quickly and confirm it's in a ready-to-use state. The software generates automated alerts for scheduled maintenance and provides historical usage reports, which help in forecasting tool demand and optimizing inventory levels.

Warehouse Management Systems (WMS) are specifically designed to automate the physical storage and retrieval of heavy, cumbersome dies. A WMS from a provider like Konecranes manages a press die warehouse by controlling automated gripper cranes. It uses optimization algorithms to determine the most efficient storage locations and sequences for die exchanges, drastically reducing changeover times. These systems can be integrated with Automated Guided Vehicles (AGVs) and conveyors to create a seamless, fully automated flow of dies from the storage area to the press, enhancing both safety and productivity.

These technologies, while distinct, work together to form a cohesive management ecosystem. The tool crib software manages the data and identity of the die, while the WMS manages its physical location and movement. This integration provides a complete picture of the asset's lifecycle, enabling data-driven decisions that reduce costs and improve output.

| Technology | Primary Function | Key Features |

|---|---|---|

| Tool Crib Management Software | Data and status tracking of individual dies and tools. |

|

| Warehouse Management System (WMS) | Automated physical storage, retrieval, and transport of dies. |

|

A Deep Dive into Proactive Die Maintenance and Repair

Proactive maintenance is the most critical phase of automotive die lifecycle management, directly influencing tool longevity, part quality, and press line productivity. It is a systematic process of inspection, repair, and optimization designed to address potential issues before they escalate into production-halting failures. Shifting from a reactive repair model to a proactive maintenance culture is essential for any modern stamping operation seeking to control costs and improve reliability.

A core challenge in a busy die shop is prioritizing work effectively. The Phoenix Group advocates for a data-based "decision tree" to systematically determine which dies get worked on and when. This model prioritizes work orders based on factors like production needs, customer satisfaction, and return on investment. The highest priority is assigned to dies causing a "No Build" condition—where production has stopped due to die failure or severe quality rejections. Subsequent priority levels address dies needing quality improvements, followed by continuous improvement tasks like enhancing formability or incorporating engineering changes.

To manage this process, a robust work order system is indispensable. This system documents, tracks, and schedules all maintenance activities, serving as a vital communication tool. It captures requests from various sources—quality complaints, preventive maintenance checks, or engineering changes—and details the root problem and the corrective steps taken. A well-maintained work order history becomes a valuable database, allowing teams to identify recurring issues, track the effectiveness of previous repairs, and refine preventive maintenance plans for similar tools.

Implementing a streamlined maintenance workflow requires applying manufacturing principles directly to the die shop. While a die shop's work is more variable than a production line, principles of single-piece flow can be adapted to improve the movement of dies through the repair area, reducing turnaround time. The goal is to perform the right work, on the right die, at the right time.

- Implement a Data-Based Decision Tree: Prioritize all maintenance and repair work based on its direct impact on production, quality, and customer satisfaction, not on convenience.

- Utilize a Robust Work Order System: Document every repair request, track its progress, and record the solution. Use this data to identify trends and prevent future failures.

- Apply Lean Manufacturing Principles: Adapt concepts like single-piece flow to optimize the die repair process, minimizing wait times and ensuring value-added work begins as quickly as possible.

Strategies for Maximizing Tool Life and Total Cost of Ownership

The ultimate business objective of automotive die lifecycle management is to maximize the productive life of each tool and reduce its Total Cost of Ownership (TCO). This requires a strategic, long-term perspective that views the die not as a consumable but as a valuable, long-term asset. Every decision, from initial design to the final re-grind, should be aimed at extracting the maximum number of quality parts from the die before its retirement.

A successful strategy often involves what experts at Tru-Edge call "full circle tooling life management." This comprehensive program covers a tool from its first use, through multiple qualified re-grinds, and finally to its disposal and recycling. A key element of this approach is precision re-grinding, a technique that restores a worn tool's cutting edges to their original specifications. Maximizing the number of possible re-grinds through expert techniques significantly extends the tool's life and delivers substantial cost savings compared to purchasing new tools.

The process begins with the initial tool design. A die engineered with future maintenance in mind can be built to allow for a greater number of re-grinds over its life. Partnering with a tool management specialist can help manufacturers implement effective programs to manage this entire cycle. These partners can handle the complex logistics of sorting worn tools, quoting re-grinds, performing the work to exacting standards, and returning them ready for production, often using a Kanban system to ensure a steady supply of refurbished tools.

By focusing on TCO, manufacturers shift their focus from the initial purchase price to the overall value delivered by the asset over its entire lifecycle. This approach accounts for maintenance costs, downtime, scrap rates, and the value of extended life through refurbishment. The result is a more cost-effective and sustainable manufacturing operation.

- Partner with a Tool Management Specialist: Leverage external expertise to manage the complexities of tool sorting, re-grinding, and logistics.

- Design for Maintenance: Work with die manufacturers to ensure new tools are designed in a way that allows for the maximum number of re-grinds.

- Track Performance Metrics: Continuously monitor tool performance, maintenance history, and re-grind cycles to ensure quality standards are met and TCO is being reduced.

- Implement a Kanban System: Establish a tool rotation and stocking program to minimize inventory while ensuring refurbished tools are always available when needed.

Frequently Asked Questions

1. What is the purpose of a die in automotive?

In the automotive industry, a die is a specialized tool used in stamping presses to cut and form sheet metal into specific shapes. This process, known as automotive die stamping, is essential for manufacturing a wide range of components with high precision and consistency, including body panels like fenders, hoods, and doors.

2. What is the equipment lifecycle management plan?

An equipment lifecycle management plan is a strategic framework for managing a piece of equipment through its entire life. It typically consists of four main stages: planning (design and selection), procurement (acquisition), maintenance (operation and repair), and disposal (decommissioning and replacement). The goal is to maximize the equipment's value and efficiency while minimizing total ownership costs.

3. What is the tool and die making process?

The tool and die making process involves the highly skilled work of creating the dies, molds, jigs, and fixtures used in mass production. This process includes precisely cutting, forming, and shaping hard metals to create the tools that will then be used to stamp, forge, or mold materials like metal or plastic into final parts.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —