Key Automotive Die Standards and Specifications Explained

TL;DR

Automotive die standards and specifications are a critical framework of technical guidelines that dictate the design, materials, and manufacturing of dies used throughout the automotive industry. Established by industry bodies like the North American Die Casting Association (NADCA) and major Original Equipment Manufacturers (OEMs), these standards are essential for ensuring the quality, safety, interoperability, and consistency of every stamped and cast component in a vehicle.

The Landscape of Automotive Die Standards

In automotive manufacturing, precision is paramount. Automotive die standards and specifications form the bedrock of this precision, providing a unified language and set of rules for engineers, toolmakers, and suppliers. These standards are not merely suggestions; they are comprehensive technical documents that ensure every component, from a small bracket to a large body panel, meets stringent requirements for quality, safety, and performance. The primary purpose of these standards is to create consistency and interoperability across a vast and complex supply chain, minimizing defects and ensuring that parts from different suppliers fit and function together seamlessly.

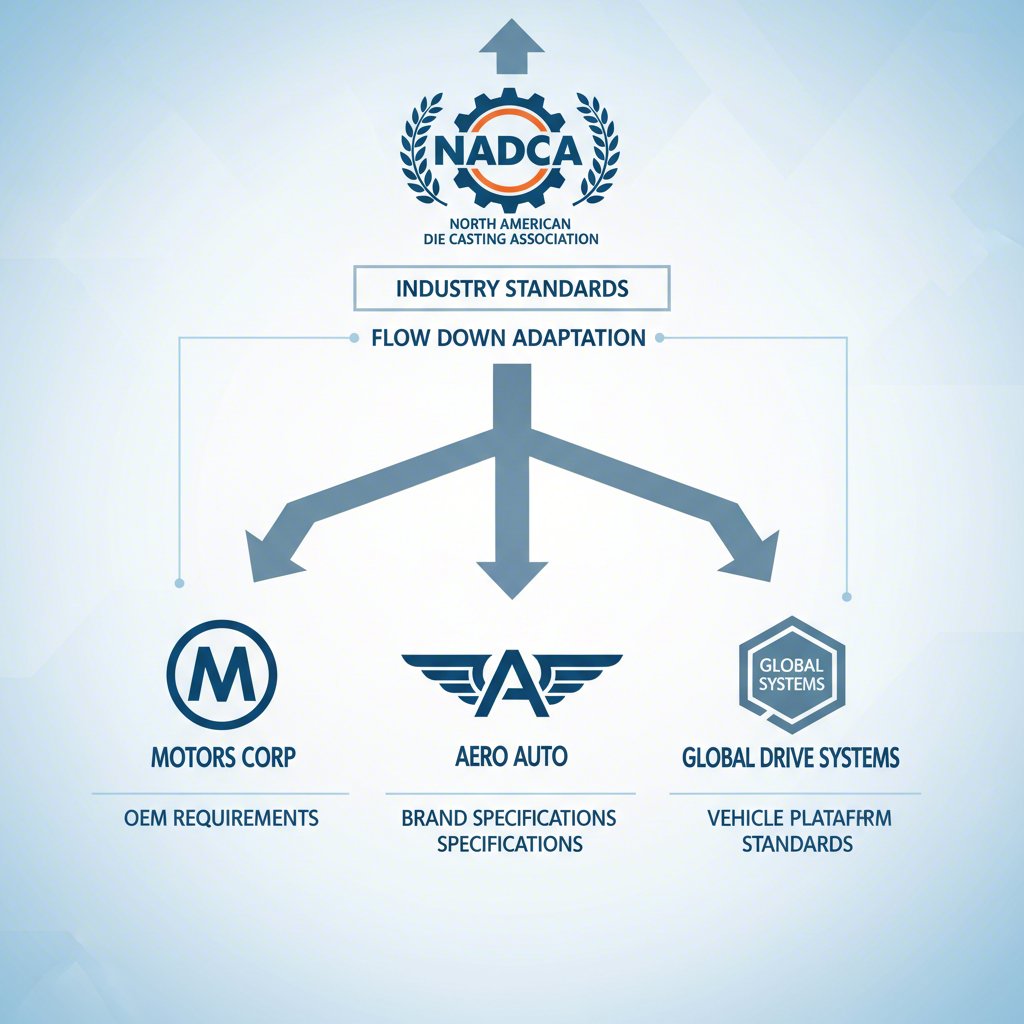

The standards landscape is broadly divided into two major categories: industry-wide standards and manufacturer-specific (OEM) standards. Industry-wide standards are developed by professional organizations that represent a consensus of best practices across the sector. The most prominent of these is the North American Die Casting Association (NADCA), which publishes extensive guidelines covering everything from die materials to safety protocols. These standards serve as a baseline for quality and are adopted by a wide range of companies.

On the other hand, OEMs like General Motors and Ford often develop their own proprietary standards, as do major Tier 1 suppliers like Adient. These documents build upon industry standards but add layers of specific requirements tailored to the company's unique manufacturing processes, materials, and quality targets. For a supplier, adherence to these OEM-specific standards is mandatory to win and maintain contracts. This dual system means that engineers and suppliers must be fluent in both the general industry guidelines and the specific, often more demanding, requirements of each client they serve.

A Deep Dive into NADCA Industry Standards

As a leading authority, the North American Die Casting Association (NADCA) provides the die casting industry with a trusted source of technical standards that form the foundation of quality manufacturing. These standards are meticulously developed to cover the entire lifecycle of the die casting process, ensuring that both users and manufacturers have a common framework for specification, design, and production. Adherence to NADCA standards helps die casters and their suppliers mitigate risks, improve part quality, and enhance the longevity of expensive tooling.

The scope of NADCA's publications is extensive, addressing the diverse needs of the industry. The manuals are regularly updated to reflect the latest advancements in technology and materials. Key areas covered by NADCA standards include:

- Product Specification Standards: These comprehensive guides cover tooling, process information, alloy properties, standard and precision tolerances, and quality assurance provisions for conventional high-pressure die castings.

- High Integrity and Structural Die Casting: For components requiring enhanced mechanical properties, NADCA provides specific standards that address advanced processes like squeeze casting and semi-solid molding.

- Die Steel and Heat Treatment: To maximize the life of a die, NADCA publishes detailed criteria for the procurement and heat treatment of high-quality tool steels like H-13, especially for high-volume or critical performance applications.

- Machine Safety: The NADCA B152.1 standard outlines safety requirements for the design, manufacture, and operation of die casting machines and their associated equipment, protecting workers and ensuring operational consistency.

For die casters and suppliers, leveraging NADCA standards is a strategic advantage. Following these guidelines helps ensure that dies are built to last, castings meet expected mechanical properties, and production processes are safe and efficient. For designers and engineers specifying die-cast parts, referencing NADCA standards in their documentation ensures clarity and sets a clear benchmark for quality. These standards provide a robust framework that reduces ambiguity, streamlines communication between OEMs and suppliers, and ultimately leads to higher-quality, more reliable automotive components.

Navigating OEM-Specific Die Standards

While NADCA provides a crucial foundation, suppliers in the automotive sector must also master the proprietary standards set by each Original Equipment Manufacturer (OEM). Companies like Adient, a global leader in automotive seating, publish their own detailed die specifications that suppliers must follow to the letter. These documents, such as Adient's "North American Die Standards," go beyond general principles and dictate highly specific requirements for die construction, materials, and performance metrics. The purpose is to ensure that every tool built for an Adient facility or its stamping suppliers performs consistently and meets the company’s stringent goals for quality, efficiency, and safety.

OEM standards are developed to address unique production environments and part requirements. They often contain specifics not found in broader industry guidelines. For example, an OEM standard might mandate the use of particular steel types for cutting and forming sections (e.g., A2 vs. D2 tool steel), specify required coatings for high-wear components, or define the exact design of scrap removal chutes and die protection sensors. The table below highlights some key differences in focus between general NADCA standards and a typical OEM-specific document.

| Aspect | General NADCA Standards | Typical OEM-Specific Standards (e.g., Adient) |

|---|---|---|

| Scope | Broad industry best practices for alloys, tolerances, and general design. | Mandatory, detailed requirements for dies running in specific facilities, including tooling components, build processes, and buy-off procedures. |

| Material Specification | Provides data on a wide range of alloys and tool steels (e.g., H-13). | Mandates specific grades of tool steel (e.g., A2, D2, S7) for different applications and requires specific coatings. |

| Buy-Off Process | Offers general quality assurance guidelines. | Defines a rigorous buy-off checklist, including continuous run-off times (e.g., 300 strokes), CMM layouts, and part capability studies (Cpk ≥ 1.67). |

| Supplier Responsibility | General guidance on best practices. | Holds the tooling integrator directly responsible for ensuring all specifications are met, with written approval required for any deviation. |

For suppliers, navigating these complex and varied requirements can be a significant challenge. The need to comply with multiple, distinct OEM standards requires deep technical expertise and meticulous project management. This is where specialized partners become invaluable. Companies such as Shaoyi (Ningbo) Metal Technology Co., Ltd. excel in manufacturing custom automotive stamping dies that meet the rigorous standards of various OEMs and Tier 1 suppliers. Their experience with IATF 16949 certification and advanced simulations allows them to deliver high-quality tooling solutions while managing the intricate compliance demands of the automotive industry, helping suppliers reduce lead times and ensure part quality.

Core Technical Specifications and Design Principles

Beyond the overarching standards from bodies like NADCA and specific OEMs, the success of an automotive die hinges on a collection of core technical specifications. These details govern everything from how the molten metal behaves in the die to the final dimensions and finish of the part. Adhering to these principles is critical for producing defect-free components that meet performance criteria. Key areas of focus include material selection, tooling specifications, and performance metrics that directly impact the quality of the final stamped or cast part.

One of the most critical aspects is managing the physical properties of the casting alloy. For example, designers must account for material shrinkage as the part cools. Failure to do so results in dimensional inaccuracies. Another key parameter is the draft angle—the slight taper applied to die surfaces. Without adequate draft, a part cannot be ejected cleanly from the die, leading to surface defects or damage. The following are some specific technical values that engineers must incorporate:

- Shrinkage Compensation Factors: This value dictates how much larger the die cavity must be to account for the metal shrinking as it solidifies. For common aluminum alloys, this is typically between 0.5% and 0.7%.

- Draft Angle Specifications: To ensure clean part ejection, a minimum draft angle is required. For standard, smooth surfaces, a minimum of 1° is common, while textured surfaces may require 3° or more to prevent dragging.

- Wall Thickness: Uniform wall thickness is crucial for consistent metal flow and cooling, minimizing porosity and warpage. Abrupt changes in thickness should be avoided.

- Fillets and Radii: Sharp internal corners create stress concentrations in both the part and the die itself. Generous fillets and radii improve metal flow, increase part strength, and extend the life of the tool.

Tooling quality is another non-negotiable aspect. For instance, achieving a flawless exterior surface requires what is known as "Class A" tooling, which must produce cast parts that are entirely smooth and free of defects. This level of quality necessitates using premium tool steels, precision machining, and meticulous die maintenance. Furthermore, the construction of the die itself must follow strict guidelines for materials and wear resistance to withstand the immense pressures and thermal cycling of production. These granular details collectively ensure that the die can withstand the immense pressures and thermal cycling of production while consistently delivering parts that meet the automotive industry's exacting demands.

Frequently Asked Questions

1. What is the difference between NADCA and OEM standards?

NADCA standards provide general, industry-wide best practices and guidelines for die casting. OEM standards are proprietary, mandatory requirements set by individual automakers (like Ford or Adient) that are often more specific and stringent, tailored to their unique production processes and quality targets. Suppliers must comply with the specific OEM standards of their clients.

2. Why are draft angles so important in die casting?

Draft angles are a slight taper applied to the walls of the die cavity. They are critical because as the molten metal cools and solidifies, it shrinks and grips onto the die. A draft angle allows the part to be ejected smoothly without being damaged or causing excessive wear on the tool. Without proper draft, parts can have surface defects, get stuck in the die, or even break during ejection.

3. Where can I find official NADCA standards documents?

Official NADCA standards, including those for product specification, safety, and die materials, can be accessed through the North American Die Casting Association's official website. Many of these documents are available for free to NADCA members and can be purchased by non-members.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —