Stamped Steel Control Arm Failure: A Technical Analysis

TL;DR

Stamped steel control arm failure is primarily caused by metal fatigue, a process where cracks initiate and grow under repeated cyclic loading. These failures often originate in high-stress areas, such as weld seams, which are inherent to their manufacturing process. Environmental factors like corrosion and physical damage can significantly accelerate this degradation, compromising the component's structural integrity and leading to eventual fracture.

The Metallurgy and Manufacturing of Stamped Steel Control Arms

A stamped steel control arm is a critical suspension component manufactured by stamping layers of high-strength steel sheets into a desired shape and then welding them together. This method is widely adopted in the automotive industry due to its cost-effectiveness and efficiency in mass production, allowing for strong yet relatively lightweight parts. The process enables the creation of complex geometries that can be optimized for both strength and vehicle packaging requirements.

The material properties of the steel used are a balancing act between strength, plasticity, and toughness. Steels with higher tensile strength provide excellent rigidity but may exhibit reduced plasticity, making them more susceptible to brittle failure under certain conditions. For instance, some high-strength steels can become prone to fatigue failure when their tensile strength exceeds 1400 MPa. The selection of a specific steel grade, such as a high-strength low-alloy (HSLA) steel, depends on the performance requirements and expected load cases for the vehicle.

For automotive manufacturers seeking unparalleled precision in metal stamping, specialized partners are essential. For example, Shaoyi (Ningbo) Metal Technology Co., Ltd. provides comprehensive solutions, from rapid prototyping to mass production, backed by IATF 16949 certification and advanced automated facilities that ensure high-quality, cost-effective components.

Despite their widespread use, stamped steel control arms have inherent advantages and disadvantages:

- Pros: They offer a good strength-to-weight ratio, are inexpensive to produce, and often exhibit predictable failure modes, such as bending before a complete fracture, which can provide a warning to the operator.

- Cons: The welded seams, while necessary for construction, can become points of stress concentration. Furthermore, the steel material is highly susceptible to corrosion (rust), especially in wet or salted-road environments, which can severely weaken the structure over time.

Identifying whether a vehicle is equipped with stamped steel control arms is straightforward. A simple test involves placing a magnet on the arm; if it sticks, the component is made of either stamped steel or cast iron. To differentiate between the two, tapping the arm with a hammer will produce a ringing sound from stamped steel, whereas cast iron will produce a dull thud.

Root Cause Analysis: Fatigue Failure in Welded Components

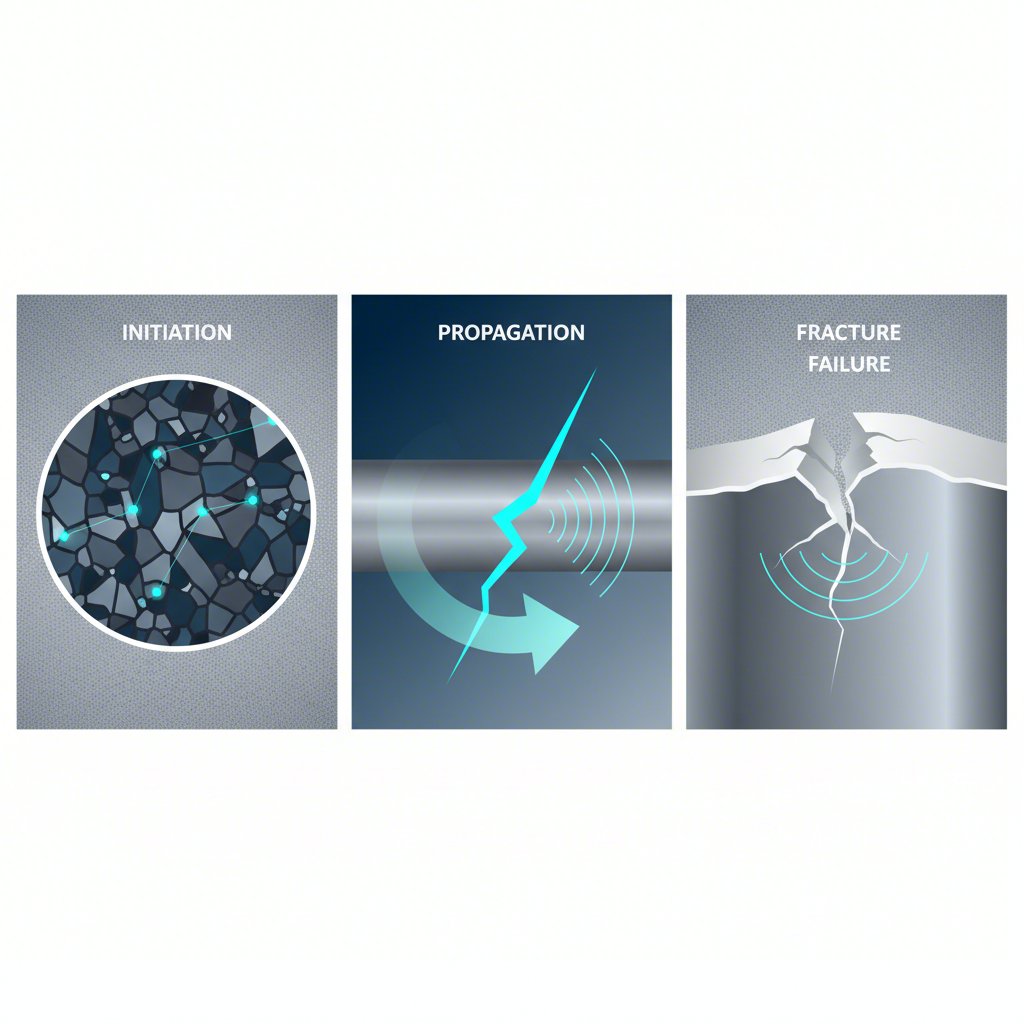

The predominant cause of failure in stamped steel control arms is metal fatigue. This phenomenon occurs when a material is subjected to repeated, cyclic loads—such as those experienced during driving—that are significantly below its ultimate tensile strength. Over time, these cyclic stresses cause microscopic imperfections within the material, especially near welds, to nucleate and grow into macroscopic cracks. The entire process can be broken down into distinct stages.

- Crack Initiation: Microscopic cracks form at points of high stress concentration. In stamped steel control arms, these are most commonly found at the start or end of a weld bead, where the heat from welding alters the steel's microstructure and can introduce residual stresses.

- Crack Propagation: With each load cycle, the initiated crack slowly grows. The rate of propagation depends on the magnitude of the cyclic stress, the geometry of the component, and the material's inherent resistance to fatigue. Some materials exhibit an initial period of cyclic hardening, followed by prolonged cyclic softening until failure.

- Final Fracture: Eventually, the crack grows to a critical size where the remaining cross-section of the material can no longer support the applied load. This results in a sudden, rapid fracture of the component, which can lead to a loss of vehicle control.

Welded joints are particularly vulnerable because the welding process itself can introduce defects like porosity and create a heat-affected zone (HAZ) where the material properties are different from the base metal. Research, such as the failure analysis of a welded automotive component detailed in a ScienceDirect publication, often concludes that fatigue cracks initiate near the weld bead due to these factors. Engineers utilize advanced software like CATIA for design and Hyperworks for stress analysis to predict fatigue life and optimize component topology, aiming to mitigate these risks from the initial design phase.

Environmental and External Factors Accelerating Failure

While fatigue is the underlying mechanism, external factors can drastically accelerate the failure of a stamped steel control arm. The most significant of these is corrosion. Stamped steel, unless properly coated and maintained, is highly susceptible to rust, particularly in environments with high humidity or exposure to road salt. As one study notes, when these components are in a wet environment, they are nearly guaranteed to deteriorate. Rust degrades the material, reduces its effective thickness, and creates surface pits that act as stress risers, providing ideal initiation points for fatigue cracks.

Physical damage from road debris, potholes, or improper servicing can also severely compromise a control arm's integrity. A cut, deep scratch, or dent creates a localized area of high stress. Much of the strength in a stamped steel design lies in its formed edges and corners; damage in these critical areas can disrupt the intended load distribution and create a weak point. This damage essentially provides a pre-existing flaw from which a fatigue crack can propagate much more quickly than it would otherwise.

Regular inspection is crucial for identifying these risks before they lead to failure. A thorough visual check should be performed to look for the following warning signs:

- Corrosion: Check for any signs of rust, especially bubbling paint, flaking metal, or deep pitting near welds and edges.

- Physical Damage: Look for dents, bends, deep gouges, or cracks, paying close attention to the areas around bushings and ball joints.

- Weld Integrity: Inspect weld seams for any visible cracks or signs of separation from the base metal.

Diagnosing Control Arm Failure: Symptoms and Analysis

Identifying a failing control arm often begins with recognizing its symptoms during vehicle operation. These signs indicate that a component within the suspension system is worn or damaged and can no longer maintain proper wheel alignment and stability. Worn bushings are a common culprit, leading to excessive movement that manifests as distinct handling problems. For instance, deteriorated bushings can contribute to steering instability, and are one of several factors that can lead to issues like the infamous "death wobble," a violent shaking of the front wheels that is often caused by a combination of worn steering and suspension components.

Another critical failure point is the ball joint. Leaking seals can allow contaminants to enter the joint, leading to wear and eventual failure. A compromised ball joint can separate completely, causing a catastrophic loss of control over the wheel. Understanding the link between a symptom and its mechanical cause is key to accurate diagnosis.

Here is a breakdown of common symptoms and their likely causes:

| Symptom | Likely Cause |

|---|---|

| Vibrations or shaking in the steering wheel | Worn control arm bushings allowing excessive play. |

| Clunking or popping noises over bumps | Worn ball joints or loose/damaged bushings. |

| Steering wander or pulling to one side | Bent control arm or severely worn bushings affecting alignment. |

| Uneven tire wear | Chronic misalignment caused by a damaged or worn control arm. |

A systematic diagnostic process can help pinpoint the issue. Start with a visual inspection as outlined previously. Follow this with a physical check by safely raising the vehicle and attempting to move the wheel horizontally and vertically. Any significant play or clunking noise likely indicates wear in the ball joints or bushings. This hands-on approach, combined with attention to audible and tactile symptoms during driving, provides a comprehensive method for diagnosing control arm failure.

A Proactive Approach to Component Integrity

Ultimately, understanding the failure analysis of stamped steel control arms is about more than just reacting to a break; it's about proactive assessment and recognizing the interplay between design, material science, and operating conditions. For engineers, this involves continuous improvement in manufacturing processes, such as refining welding techniques to minimize residual stress and microstructural changes. For mechanics and vehicle owners, it underscores the importance of regular, detailed inspections to identify early warning signs like corrosion or physical damage before they escalate to critical failure.

The insights gained from analyzing fatigue cracks, stress concentrations, and environmental degradation provide a clear roadmap for enhancing vehicle safety and component longevity. By acknowledging the inherent vulnerabilities of stamped and welded steel, particularly in harsh environments, preventative maintenance can be targeted effectively. This technical understanding empowers professionals to make informed decisions, whether in the design phase or during routine service, ensuring the continued reliability of these essential suspension components.

Frequently Asked Questions

1. How to tell if you have stamped steel control arms?

A simple method is to use a magnet. If the magnet adheres to the control arm, it is made of steel or cast iron. To distinguish further, gently tap the arm with a hammer. A stamped steel arm will typically produce a higher-pitched, ringing sound, while a cast iron arm will result in a dull thud.

2. What is the primary cause of fatigue failure in welded joints?

The primary cause of fatigue failure in welded joints is the cyclic application of loads, even those below the material's yield strength. These repeated stresses cause microscopic flaws, often located in areas of high stress concentration like the weld toe, to grow into larger cracks over time, eventually leading to component failure.

3. Can bad control arm bushings cause death wobble?

While bad control arm bushings can be a contributing factor to death wobble, they are rarely the sole cause. Death wobble is typically caused by a combination of worn or loose steering and suspension parts, such as the track bar, ball joints, or tie-rod ends. Worn bushings can add to the overall instability that triggers the issue, but the problem is usually more complex.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —