Stamped Steel Control Arms: The Impact on Suspension Geometry

TL;DR

Stamped steel control arms are common, cost-effective suspension components that connect a vehicle's chassis to the wheel assembly. While economical, their construction from two welded pieces of steel makes them susceptible to flexing under heavy loads from cornering or acceleration. This flex can temporarily alter your vehicle's suspension geometry, negatively impacting handling, tire grip, and overall performance. Understanding this trade-off between cost and rigidity is crucial for any vehicle owner or enthusiast.

What Is a Control Arm and Its Role in Suspension Geometry?

A control arm is a critical link in a vehicle's suspension system, connecting the chassis or frame to the suspension hub that holds the wheel. Often referred to as an A-arm, its primary job is to allow the wheels to move vertically—up and down over bumps—while keeping them stable and correctly aligned with the vehicle's body. As detailed in a guide by GMT Rubber, this controlled movement ensures the tires remain in contact with the ground, which is essential for stability, steering control, and a smooth ride.

The effectiveness of a control arm hinges on its core components working in unison. Each assembly is a combination of parts that facilitate its pivoting motion while absorbing vibrations from the road.

- Body: The main structure of the arm, typically made of stamped steel, cast iron, or aluminum, which provides the necessary strength to handle suspension forces.

- Bushings: Usually made of rubber or polyurethane, these are cylindrical sleeves that connect the control arm to the vehicle's frame. They act as pivot points and dampen vibrations, preventing harshness from reaching the cabin.

- Ball Joint: This is a spherical bearing that connects the other end of the control arm to the steering knuckle or wheel hub. It allows the wheel to pivot for steering and move up and down with the suspension.

Control arms are fundamental to maintaining proper suspension geometry—the precise angles of the wheels relative to the car and the road. Key alignment angles like camber (the inward or outward tilt of the top of the tire), caster (the angle of the steering pivot), and toe (the direction the tires point relative to each other) are all managed by the fixed points of the control arms. When these components are functioning correctly, the vehicle handles predictably. However, worn bushings or a damaged ball joint can lead to poor steering response, clunking noises, and uneven tire wear.

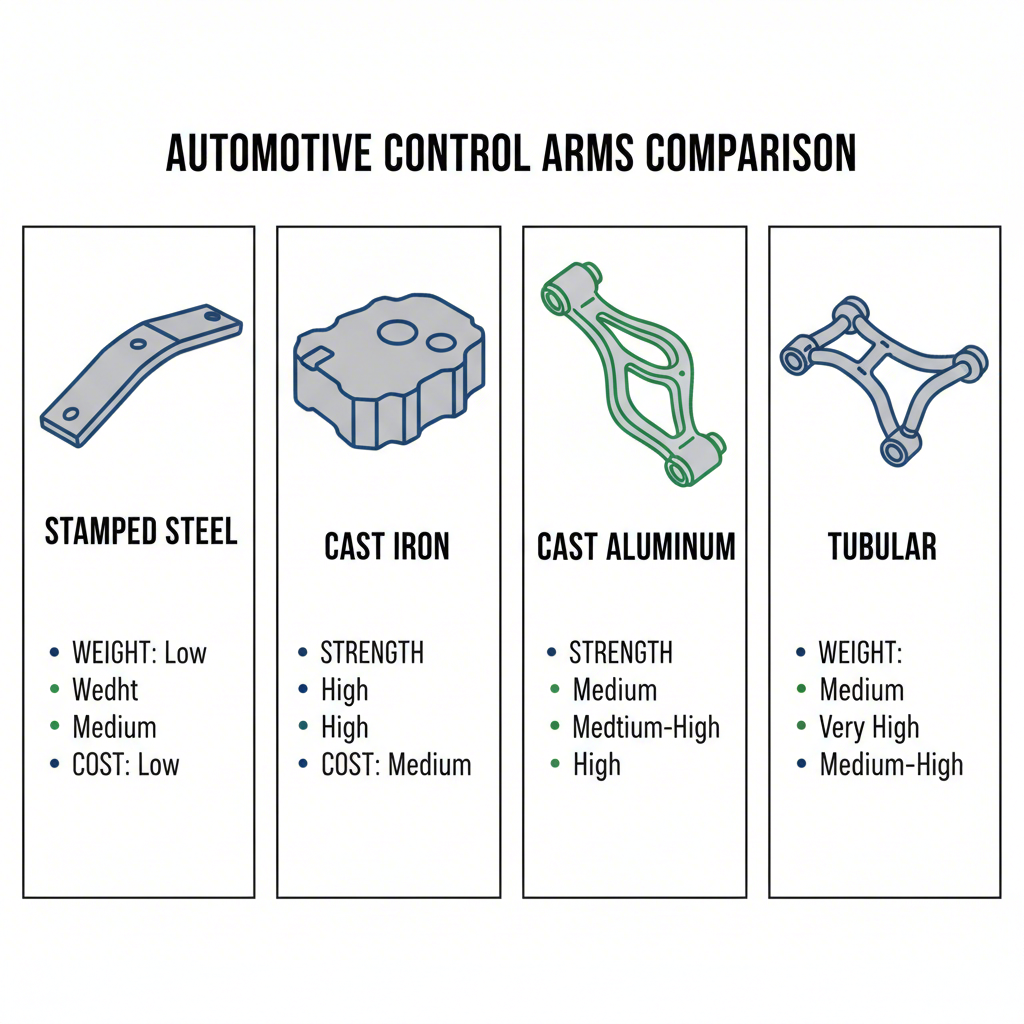

Stamped Steel vs. Alternatives: A Material and Design Comparison

Control arms are manufactured from several different materials, each offering a unique balance of strength, weight, and cost. Stamped steel is one of the most common options, particularly in mass-produced passenger cars, due to its low production cost. This process involves stamping two halves from a sheet of steel and welding them together. For automotive manufacturers focused on efficiency and scale, this method is ideal, and specialists in this field, such as Shaoyi (Ningbo) Metal Technology Co., Ltd., provide the high-precision metal stamping required for these and other complex automotive components.

However, stamped steel is not the only option available. Cast iron, cast aluminum, and tubular steel each present distinct advantages and disadvantages that make them suitable for different applications, from heavy-duty trucks to high-performance sports cars. As explained in a guide by Maxtrac Suspension, identifying which type you have is key for maintenance and upgrades. Stamped steel arms typically have a smooth, glossy black painted finish with a visible welded seam, whereas cast versions have a rougher texture.

To help clarify the differences, here is a detailed comparison of the most common control arm materials:

| Material Type | Pros | Cons | Commonly Used In |

|---|---|---|---|

| Stamped Steel | Inexpensive to manufacture. | Prone to flexing under load; susceptible to rust and damage. | Economy cars, sedans, and some light trucks. |

| Cast Iron | Extremely strong and durable; resistant to bending. | Very heavy, which adds to unsprung weight; can be brittle. | Heavy-duty trucks, SUVs, and older muscle cars. |

| Cast Aluminum | Lightweight and strong; corrosion-resistant. | More expensive than steel; can crack upon severe impact. | Performance cars, luxury vehicles, and some modern trucks. |

| Tubular Steel | Very high strength-to-weight ratio; often designed for specific performance goals. | Most expensive option; fabrication is complex. | Racing applications, custom builds, and high-performance aftermarket upgrades. |

How Stamped Steel Control Arms Affect Suspension Geometry and Performance

The core issue with stamped steel control arms lies in their inherent design. Being constructed from two pieces of metal welded together creates a U-shaped cross-section that is not fully enclosed. While this is sufficient for daily driving, it presents a significant weakness under high-stress conditions. During hard cornering, aggressive acceleration, or braking, the forces exerted on the suspension can cause these arms to physically flex and deform. This temporary change, though slight, directly alters the vehicle's suspension geometry when it matters most.

This flex can lead to undesirable changes in alignment angles like camber and toe. For example, during a sharp turn, the outer wheel's control arm is under immense load. If it flexes, it can allow the top of the tire to tilt outward (positive camber), which reduces the size of the tire's contact patch on the road. A smaller contact patch means less grip, leading to understeer and less predictable handling. This instability compromises both performance and safety.

To combat this weakness, a common modification for enthusiasts and racers is "boxing" the control arms. This process involves fabricating a steel plate and welding it over the open side of the arm, effectively creating a fully enclosed, box-like structure. This modification dramatically increases the arm's rigidity and prevents it from flexing under load. By keeping the suspension geometry stable, boxing a control arm ensures that alignment angles remain consistent, maximizing tire grip and restoring predictable handling during high-performance driving. The process, while requiring fabrication skills, is a cost-effective way to achieve the strength of more expensive aftermarket components.

For those considering this modification, the general steps are as follows:

- Create a Template: Use cardboard to create a template that fits the open underside of the control arm, ensuring holes are marked for any necessary access points like sway bar links.

- Cut the Plate: Transfer the template onto a piece of 16-gauge mild steel and cut it to shape.

- Prepare for Welding: Clean the control arm and the new plate to ensure a strong, clean weld.

- Tack and Weld: Tack the plate into position, then use a stitch welding technique to secure it permanently while managing heat to prevent warping the arm.

- Finish and Paint: Once cooled, clean the welds and paint the finished control arm to prevent rust.

Frequently Asked Questions

1. How do I tell if I have stamped steel control arms?

You can typically identify stamped steel control arms by their appearance. They are made from two pieces of steel welded together, creating a visible seam along the edges. They are often painted a glossy black and feel relatively lightweight. A simple test is to use a magnet; if it sticks, the arm is made of a steel-based material like stamped steel or cast iron. In contrast, cast aluminum arms will not be magnetic and usually have a rougher, unpainted silver finish.

2. What car has the best suspension geometry?

There is no single car with the "best" suspension geometry, as the ideal setup depends entirely on the vehicle's intended purpose. A luxury sedan like a Mercedes-Benz S-Class is engineered for maximum comfort and stability, while a sports car like a Porsche 911 has geometry optimized for sharp handling and high-speed cornering. Heavy-duty trucks require robust systems for towing and hauling. Ultimately, the "best" geometry is a carefully engineered compromise between handling, comfort, and load-carrying capacity tailored to a specific vehicle's goals.

3. What is the shape of the control arm?

Control arms come in various shapes, but the most common designs are the 'A-arm' or 'wishbone' shape. This triangular design provides two mounting points on the vehicle's frame and a single point at the wheel, offering a stable and robust connection. Some suspension designs may use different shapes, such as an 'L-shape' or a simple straight link, depending on the specific geometry and space constraints of the vehicle's suspension system.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —