Stamped Steel Control Arms: A Major Risk for Your Truck?

TL;DR

Stamped steel control arms are generally not the best choice for trucks, especially for modified or heavy-duty applications. While they are a common and inexpensive factory option, their design makes them highly susceptible to rust and premature ball joint failure. For stock, daily-driven trucks under normal conditions, they can be adequate, but for lifted, leveled, or off-road vehicles, upgrading to more robust cast steel or forged aluminum arms is strongly recommended for safety and durability.

Understanding Control Arms: Stamped Steel vs. The Alternatives

A control arm is a critical suspension component that connects the vehicle's frame to the steering knuckle or wheel hub. Its job is to manage the wheel's movement, ensuring stability and proper alignment. When it comes to trucks, the material and construction of these arms are paramount due to the higher loads and stresses involved. Stamped steel control arms are manufactured by stamping and welding together pieces of sheet steel, creating a hollow, box-like structure. This method is cost-effective, which is why it's a popular choice for original equipment manufacturers (OEMs).

The manufacturing process is a key differentiator. For companies specializing in high-volume automotive parts, precision is key. For example, expert manufacturers in the field like Shaoyi (Ningbo) Metal Technology Co., Ltd. utilize advanced automated processes to create complex stamped components that meet strict industry standards like IATF 16949. This ensures consistency in mass production, but the inherent design of a welded, multi-piece arm has different performance characteristics than a single-piece component.

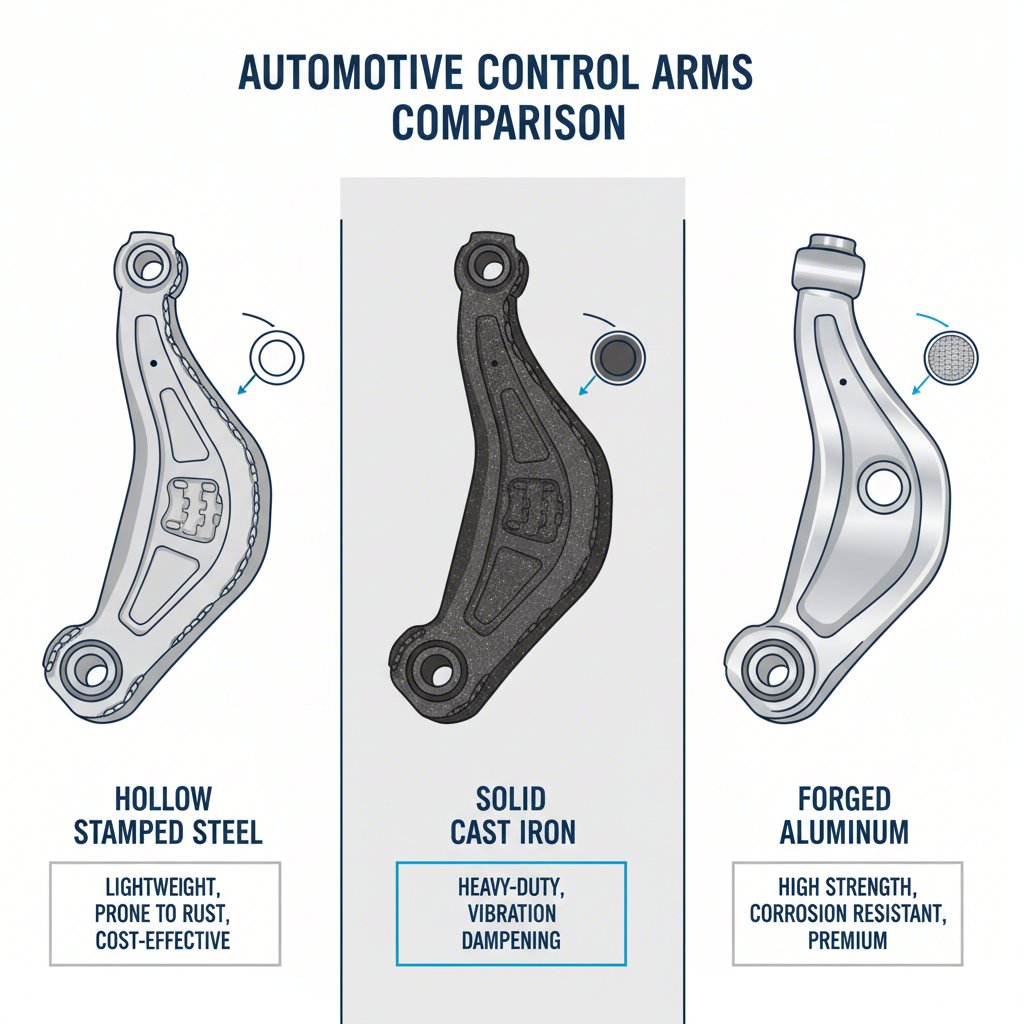

In contrast, cast steel or cast iron arms are made by pouring molten metal into a mold, resulting in a solid, single-piece part. Forged arms, often made from aluminum, are created by shaping a solid piece of metal under extreme pressure, which aligns the grain structure and creates exceptional strength. To identify what's on your truck, you can perform a simple magnet test. A magnet will stick to both stamped and cast steel but not to aluminum. To tell stamped steel from cast, look closely: stamped arms have visible seams and welds where the pieces are joined, while cast arms have a rough, one-piece appearance with no seams.

To clarify the differences, here is a breakdown of the most common control arm types:

| Feature | Stamped Steel | Cast Steel / Iron | Forged / Cast Aluminum |

|---|---|---|---|

| Manufacturing | Sheets of steel are cut, bent, and welded together. | Molten metal is poured into a single-piece mold. | A solid billet is heated and pressed into shape under high pressure. |

| Appearance | Hollow, with visible seams and welds. | Solid, thick, with a rough, grainy surface texture. | Solid, often smoother than cast steel, and much lighter. |

| Key Weakness | Prone to rust at welds and ball joint failure. | Heavy and can be brittle under extreme impact. | Higher cost. |

| Common Use | Standard on many factory cars and light-duty trucks. | OEM on heavy-duty trucks and performance vehicles. | Performance, luxury, and off-road applications. |

The Pros and Cons of Stamped Steel Arms on Trucks

Choosing the right components for your truck involves weighing the trade-offs between cost, performance, and durability. Stamped steel control arms are a perfect example of this balance. Their primary advantage is their low manufacturing cost, which makes them an affordable option for both automakers and consumers seeking replacement parts. They are widely available and serve as the standard equipment on millions of vehicles, meaning they are generally sufficient for unmodified, on-road use.

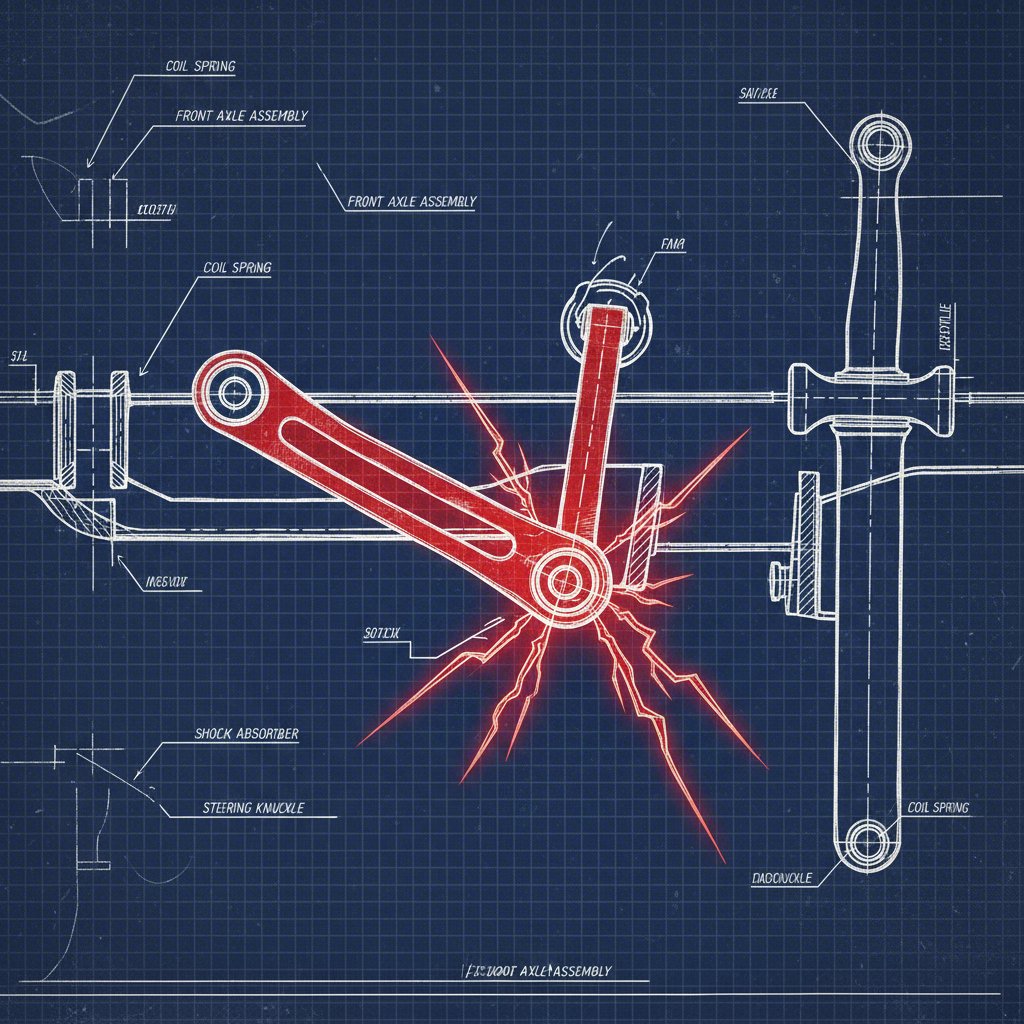

However, the disadvantages become apparent when these arms are used on trucks, which demand more from their suspension. The hollow, welded construction is a major point of weakness. Moisture can get trapped inside or accumulate at the seams, leading to rust from the inside out. As noted in multiple automotive forums and guides, this corrosion significantly compromises the arm's structural integrity over time. One of the most frequently cited and dangerous issues is the high rate of ball joint failure. Some stamped steel designs lack proper support or retention for the ball joint, meaning that when it fails, it can potentially separate from the arm entirely, leading to a catastrophic loss of steering control.

Here’s a clear summary of the trade-offs:

-

Pros:

- Low Cost: Significantly cheaper to produce and purchase than cast or forged alternatives.

- Availability: As a common OEM part, they are easy to find for most truck models.

- Adequate for Stock Use: For a standard truck used for daily commuting, they perform their function as intended by the manufacturer.

-

Cons:

- Susceptible to Rust: The welded seams are notorious for trapping moisture and rusting through, weakening the entire component.

- Ball Joint Failure: They are associated with a higher incidence of ball joint failure, sometimes without a proper retention design to prevent separation.

- Limited Strength: The construction is less robust than solid cast or forged arms, making them unsuitable for the increased stress of heavy loads, towing, or off-roading.

When inspecting your truck, be vigilant for signs of wear on stamped steel arms. Look for rust perforation, especially around the welds and ball joint housing. Check for any cracks in the metal or welds, and test the ball joints for any play or looseness, as this is a primary indicator of impending failure.

When to Upgrade: Stamped Steel in Lifted and Heavy-Duty Trucks

While factory stamped steel control arms may suffice for a truck at its stock height and weight, they become a significant liability once you modify your vehicle. The moment you install a leveling kit or a suspension lift, the geometry of your truck's front end changes dramatically. This alteration increases the angle of the control arms, placing the factory ball joints under extreme stress and pushing them beyond their intended range of motion. This is the primary reason why ball joint failure is so common on leveled and lifted trucks with stock stamped steel arms.

This issue is prevalent across popular truck models like the Chevy Silverado, GMC Sierra, and Ford F-150. Truck owners in online communities frequently report that the upper ball joints on stamped steel arms are the first to fail after installing even a modest 2-inch leveling kit. The stock arms are simply not designed to accommodate these new angles, leading to accelerated wear, binding, and eventual failure. This isn't just a durability issue; it's a critical safety concern.

Aftermarket control arms are engineered specifically to solve this problem. Reputable options from brands featured on sites like Jack-It are typically made from stronger tubular or forged steel and are designed to correct the suspension geometry on a lifted truck. They feature improved ball joints with a greater range of motion and often allow for custom camber and caster adjustments, which are essential for restoring proper alignment and drivability after a lift. These upgrades ensure the suspension can cycle freely without binding, providing better performance and, most importantly, preventing premature component failure.

Consider upgrading your control arms if you meet any of the following criteria:

- Your truck is lifted or leveled: If you have installed any suspension lift or leveling kit, especially one over 2 inches, upgrading your upper control arms is essential for correcting ball joint angles and ensuring safety.

- You frequently drive off-road: Off-roading subjects suspension components to repeated high stress and impacts that can quickly overwhelm stock stamped steel arms.

- You use your truck for heavy towing or hauling: The additional weight puts extra strain on all suspension parts, and stronger control arms provide a much-needed margin of safety and durability.

- You are replacing a failed ball joint: If a ball joint has already failed on your stamped steel arm, it's a strong indicator that the design is inadequate for your use case. Upgrading the entire arm is a smarter long-term solution than simply pressing in a new joint.

Frequently Asked Questions

1. What is the best material for control arms?

The best material depends on the application. For heavy-duty use, off-roading, and maximum strength, cast iron or forged steel are superior due to their solid construction. For performance and luxury vehicles where weight reduction and corrosion resistance are priorities, aluminum is an excellent choice. Stamped steel serves as a cost-effective option for standard, light-duty passenger vehicles but is generally the least durable of the common materials.

2. How to tell if you have stamped steel control arms?

You can identify them with a quick visual and physical test. First, use a magnet; if it sticks, the arm is steel (either stamped or cast). If it doesn't, it's aluminum. Next, look for physical characteristics. A stamped steel arm will have visible seams and welds where multiple pieces of metal have been joined together to form its shape. In contrast, a cast iron or cast steel arm is made from a single piece and will have a solid, rougher texture with a casting seam.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —