Squeeze Casting vs High Pressure Die Casting: Choosing the Right Process

TL;DR

Squeeze casting combines casting and forging principles, applying sustained high pressure during solidification to create dense, strong, and virtually porosity-free parts. In contrast, high-pressure die casting (HPDC) uses rapid injection for faster production of complex parts but is more susceptible to internal porosity. The primary trade-off is performance versus speed: choose squeeze casting for high-integrity, safety-critical components, and opt for high-pressure die casting for high-volume, intricate parts where speed and cost-per-part are paramount.

Fundamental Process Differences: How Each Method Works

Understanding the core mechanics of squeeze casting vs. high-pressure die casting reveals why they produce parts with vastly different properties. Though both involve shaping molten metal in a die, the application of pressure and the flow of metal are fundamentally distinct. This distinction is crucial for determining which process aligns with a project's technical requirements.

High-pressure die casting is defined by speed and force. The process involves injecting molten metal into a hardened steel mold cavity under immense pressure and at high velocity. This rapid, often turbulent, filling ensures that even the most intricate and thin-walled sections of the mold are completely filled before the metal begins to solidify. However, this turbulence can trap air and gases within the metal, leading to porosity in the final component.

The typical steps for HPDC are:

- Mold Preparation: The two halves of the steel die are cleaned and lubricated.

- High-Speed Injection: Molten metal is forced into the closed die cavity at high speed (often over 100 mph) and pressure.

- Rapid Solidification: The metal cools and solidifies quickly within the water-cooled die.

- Ejection: The die opens, and the solidified part, or 'casting,' is ejected.

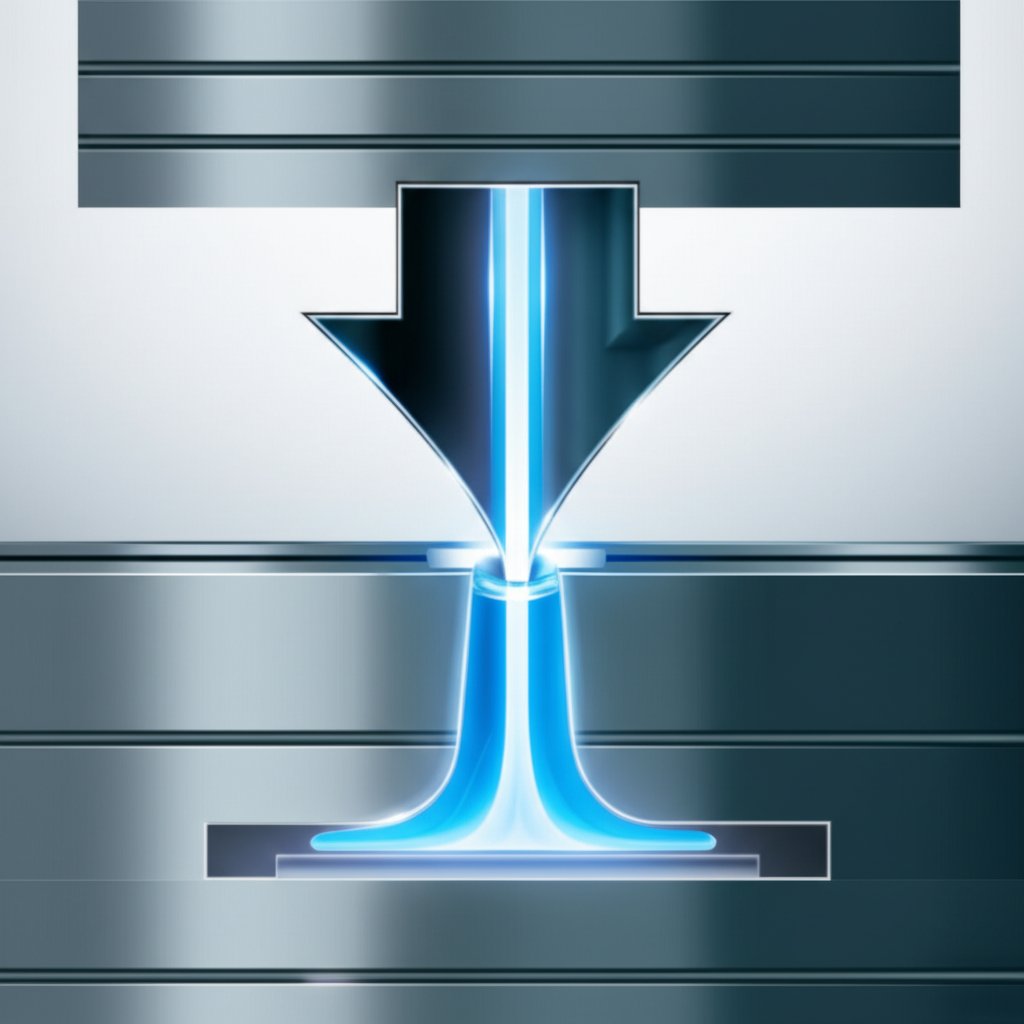

Squeeze casting, also known as liquid metal forging, is a more deliberate hybrid process that prioritizes material integrity. It involves a slower, controlled filling of the die, followed by the application of intense, sustained pressure as the metal solidifies. This approach ensures a laminar (non-turbulent) flow that minimizes the chance of trapping gas. The constant pressure effectively squeezes out any potential voids or shrinkage porosity, creating a dense, highly refined grain structure. This process is detailed in guides from manufacturing experts like CEX Casting.

The steps for squeeze casting generally follow this sequence:

- Metal Pouring: A precise amount of molten metal is poured into the bottom half of a pre-heated die.

- Die Closure and Pressurization: The upper half of the die closes, sealing the cavity and applying immense pressure to the molten metal via a punch.

- Pressurized Solidification: This high pressure is maintained throughout the entire solidification process, forcing the metal into every detail of the die and eliminating porosity.

- Ejection: Once solid, the pressure is released, and the high-integrity part is removed.

The essential difference lies in when and how pressure is used. HPDC uses pressure for injection, while squeeze casting uses it for solidification. This results in HPDC being a process optimized for speed and complexity, whereas squeeze casting is engineered for metallurgical soundness and superior mechanical performance.

Head-to-Head Comparison: Key Technical & Performance Metrics

The choice between squeeze casting and high-pressure die casting ultimately hinges on a trade-off between production speed and the final part's quality and performance. Each process excels in different areas, and understanding these distinctions is critical for engineers and designers. The sustained pressure in squeeze casting produces components that are heat-treatable and weldable, a significant advantage over many HPDC parts where trapped gases can cause blistering during heat treatment. This is a key point highlighted by industry resources like Sunrise Metal.

Porosity is arguably the most significant differentiator. HPDC's high-speed, turbulent injection process often traps air and gas, leading to internal porosity. While manageable for many applications, this can be a critical failure point in components subjected to high stress or pressure. Squeeze casting, by contrast, is designed to eliminate porosity. The slow, laminar fill and sustained pressure during solidification force out gases and prevent shrinkage voids, resulting in a dense, pressure-tight material structure ideal for hydraulic and pneumatic applications.

These process differences directly impact mechanical properties. Squeeze-cast parts exhibit superior strength, ductility, and fatigue resistance due to their fine-grained, non-porous microstructure. This makes them suitable for safety-critical applications where failure is not an option. HPDC parts offer good mechanical properties for their weight but typically cannot match the performance levels of squeeze-cast or forged components without subsequent, and often costly, treatments.

The following table provides a clear, at-a-glance comparison of the key metrics:

| Metric | High-Pressure Die Casting (HPDC) | Squeeze Casting |

|---|---|---|

| Porosity Level | Higher, due to potential gas entrapment | Very low to virtually non-existent |

| Mechanical Strength | Good | Superior (higher tensile strength and ductility) |

| Heat Treatable? | Generally No (risk of blistering) | Yes (T6 and other treatments are common) |

| Cycle Time | Very Fast | Slower |

| Best For | Complex, thin-walled, high-volume parts | High-integrity, safety-critical parts |

| Surface Finish | Excellent, often requires minimal finishing | Excellent, near-net-shape reduces machining |

| Typical Alloys | ADC12, A380, A360 | A356, A357, AlSi10Mg |

Ultimately, the decision rests on the application's demands. If the goal is mass production of a complex part like a laptop chassis where internal porosity is not a structural concern, HPDC is the clear winner. However, for a safety-critical automotive suspension component that must withstand immense forces without failure, the superior, defect-free properties of squeeze casting are essential.

Cost, Tooling, and Complexity Considerations

Beyond performance metrics, the financial and design implications of each process play a crucial role in the decision-making process. The cost structure for squeeze casting vs. high-pressure die casting is nuanced, involving initial investment, operational costs, and tooling longevity. While both methods require significant upfront capital for machinery and dies, their cost-effectiveness varies dramatically with production volume and part requirements.

High-pressure die casting is characterized by very high initial tooling costs. However, its rapid cycle times mean that for high-volume production runs (tens of thousands to millions of parts), the cost per part becomes extremely low. This makes it a highly economical choice for mass-market products. The tooling, however, is subjected to intense thermal shock and high-velocity metal flow, which can lead to wear and a shorter overall lifespan compared to squeeze casting tools.

Squeeze casting tooling costs can be comparable to or slightly less than HPDC, but the process has a longer cycle time, which increases the operational cost per part. This makes it less economical for extremely high-volume production. A key advantage, as noted by some manufacturers, is that squeeze casting tools endure less thermal and erosive stress, potentially leading to a longer service life and reducing long-term tooling replacement costs. The near-net-shape results also minimize expensive post-casting machining, which can offset the higher cycle cost.

Part geometry and complexity are also defining factors. HPDC is unmatched in its ability to produce highly intricate, thin-walled components with complex features. The high-speed injection forces metal into every minute detail of the die. Squeeze casting, while capable of producing complex shapes, is less suited for the extreme thin walls and intricate coring that HPDC can achieve. It is better suited for producing simpler but more robust parts with thicker sections, where its ability to eliminate porosity is a key advantage. This makes it a powerful alternative when forging is too restrictive on geometry, as explained by resources like Yichou.

Ideal Applications: Where Each Process Excels

The technical and cost differences between high-pressure die casting and squeeze casting translate into distinct and well-defined applications across various industries. Matching the process to the part's function is essential for ensuring both performance and commercial viability. The choice often comes down to a simple question: is this part a high-volume, complex-shaped component, or is it a high-performance, safety-critical one?

High-Pressure Die Casting Applications

Thanks to its speed and precision in forming complex geometries, HPDC is a dominant force in mass manufacturing. Its applications are widespread, particularly where lightweight, detailed parts are needed in large quantities.

- Consumer Electronics: The intricate and thin-walled housings for laptops, smartphones, tablets, and cameras are often made using HPDC.

- Automotive: Non-structural components like engine blocks, transmission cases, oil sumps, and decorative elements are ideal for HPDC.

- Lighting: LED light fixtures and heat sinks with complex fin designs are efficiently produced through die casting.

- Household Appliances: Components for kitchen mixers, vacuum cleaners, and power tools benefit from the precision and surface finish of HPDC.

Squeeze Casting Applications

Squeeze casting is the go-to process when mechanical integrity, pressure tightness, and safety are non-negotiable. Its ability to produce porosity-free, high-strength parts makes it essential for high-performance sectors. As noted by foundries like CastAlum, it is the right choice for safety-critical components.

- Automotive: This is a primary sector for squeeze casting. Safety-critical chassis and suspension parts like steering knuckles, control arms, subframes, and high-performance wheels rely on its superior strength and fatigue resistance.

- Aerospace: Structural fittings, landing gear components, and other parts requiring high strength-to-weight ratios are excellent candidates for this process.

- Fluid Control: The dense, pressure-tight nature of squeeze-cast parts makes them ideal for hydraulic and pneumatic components, such as pump housings and valve bodies.

- Defense: Components for military vehicles and weapon systems that demand extreme durability often utilize squeeze casting.

For applications demanding the absolute highest levels of strength, particularly in the automotive sector, engineers also evaluate related manufacturing methods. For instance, precision-engineered automotive forging parts provide exceptional strength and reliability for the most demanding applications. Companies such as Shaoyi (Ningbo) Metal Technology specialize in these high-performance forged components, offering another path for creating robust, safety-critical parts when geometric complexity is less of a constraint.

Frequently Asked Questions

1. What is another name for squeeze casting?

Squeeze casting is also commonly referred to as liquid metal forging. This name highlights its hybrid nature, as it combines the process of pouring liquid metal like in casting with the application of high pressure during solidification, which is characteristic of forging.

2. What are the main disadvantages of squeeze casting?

The primary disadvantages of squeeze casting include a slower production rate compared to high-pressure die casting, which can lead to a higher cost per part. It is also less suitable for producing extremely complex or very thin-walled components. Finally, the initial investment in machinery and tooling is significant, making it best suited for medium- to high-volume production of high-performance parts.

3. When should you use high-pressure die casting?

High-pressure die casting should be used when you need to produce a large volume of parts with complex, intricate geometries and thin walls. It is the ideal choice for applications where production speed and low cost-per-part are critical priorities and where minor internal porosity is not a structural concern, such as in consumer electronics housings or non-structural automotive components.

4. What are the advantages of squeeze casting?

The main advantages of squeeze casting are superior mechanical properties, including high strength and ductility. The process produces parts that are virtually free of porosity, making them pressure-tight and suitable for safety-critical applications. Squeeze-cast components are also heat-treatable and have an excellent surface finish, which can reduce the need for secondary machining operations.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —