Flawless Powder Coating on Die Cast Aluminum Explained

TL;DR

Yes, powder coating on die-cast aluminum is not only possible but also a highly recommended finishing method. It provides a durable, protective, and cosmetic finish that significantly outperforms conventional paint. Success hinges on meticulous surface preparation, including thorough cleaning and a critical pre-baking step called outgassing, before the electrostatic application and heat curing of the powder.

The Advantages of Powder Coating Die-Cast Aluminum

Choosing the right finish for die-cast aluminum parts is crucial for performance and longevity. Powder coating has emerged as a superior choice for many applications due to its unique combination of durability, aesthetic flexibility, and environmental benefits. Unlike liquid paint, which relies on solvents, powder coating is a dry finishing process where a polymer resin powder is applied electrostatically and then cured with heat, creating a hard, resilient skin over the metal.

This process results in a finish that is significantly tougher and more resistant to physical and environmental stresses. It provides excellent protection against chipping, scratching, and abrasion, making it ideal for parts that will see heavy use or be exposed to rough conditions. The thermal bonding process creates a coating that is much thicker than liquid paint without the risk of running or sagging, ensuring uniform protection even on complex shapes.

Furthermore, the chemical makeup of powder coatings offers robust defense against corrosion, UV rays, and various chemicals. This makes it a perfect fit for components used in demanding environments, such as automotive or marine applications. For instance, in the manufacturing of high-performance components, such as those for the automotive industry, a resilient finish is non-negotiable. For precision-engineered solutions like automotive forging parts, a quality finish ensures both performance and longevity. Many applications in sectors from aerospace to telecommunications rely on this enhanced protection to extend the service life of their products and reduce maintenance costs.

The key benefits of powder coating aluminum die-castings include:

- Superior Durability: The cured coating forms a tough, abrasion-resistant layer that withstands impact and minimizes damage from scratches and chips.

- Corrosion Resistance: It creates a seamless barrier that protects the aluminum substrate from moisture, chemicals, and salt, effectively preventing corrosion.

- Aesthetic Versatility: Powder coating is available in a vast array of colors, textures, and gloss levels, allowing for extensive customization to meet specific design requirements.

- Eco-Friendly Process: The application process releases negligible volatile organic compounds (VOCs), making it a more environmentally responsible choice compared to solvent-based paints. Oversprayed powder can also be collected and reused, minimizing waste.

- Uniform Coverage: The electrostatic application method ensures that the powder wraps around the part, providing consistent coverage even on intricate designs and hard-to-reach areas.

Preparing Cast Aluminum for a Flawless Finish

The single most critical factor in achieving a durable, long-lasting powder coat on die-cast aluminum is surface preparation. The porous nature of cast aluminum can trap air and contaminants, which, if not addressed, will lead to defects like bubbles, pinholes, and poor adhesion. A meticulous multi-step preparation process is essential to ensure the powder bonds correctly and the final finish is smooth and resilient.

Skipping any of these steps can compromise the integrity of the entire coating. For example, failing to properly outgas the part is a common cause of surface defects. As the part heats up in the curing oven, any trapped gases will expand and push their way through the melting powder, leaving behind blisters or pinholes in the final finish. Similarly, inadequate cleaning will leave behind a film of oil or residue that prevents the powder from adhering to the metal surface, leading to flaking or peeling down the line.

Follow these essential steps for optimal preparation:

- Cleaning and Degreasing: The first step is to remove all surface contaminants. This involves using alkaline cleaners, solvents, or ultrasonic cleaning to thoroughly wash away any oils, grease, dirt, or processing residues from the casting surface. A completely clean surface is the foundation for a successful coating.

- Mechanical Treatment: To create a surface profile that promotes strong adhesion, mechanical treatment like sandblasting or shot blasting is used. This process removes any existing oxidation and slightly roughens the surface of the aluminum. According to experts at Diecasting-mould.com, this step is vital for helping the powder coating grip the metal.

- Pre-Baking (Outgassing): This is a crucial step unique to cast metals. The part is heated in an oven (typically at 180–200°C) before the powder is applied. As noted in an article by CEX Casting, this process, known as outgassing, forces any trapped air or residual moisture out of the metal's pores, preventing them from causing defects during the final curing stage.

- Chemical Conversion Coating: For maximum corrosion resistance and adhesion, a chemical conversion coating is applied. This treatment, often using chromate or non-chromate solutions, modifies the aluminum surface to make it more receptive to the powder coat and provides an additional layer of protection against rust.

The Powder Coating Application and Curing Process

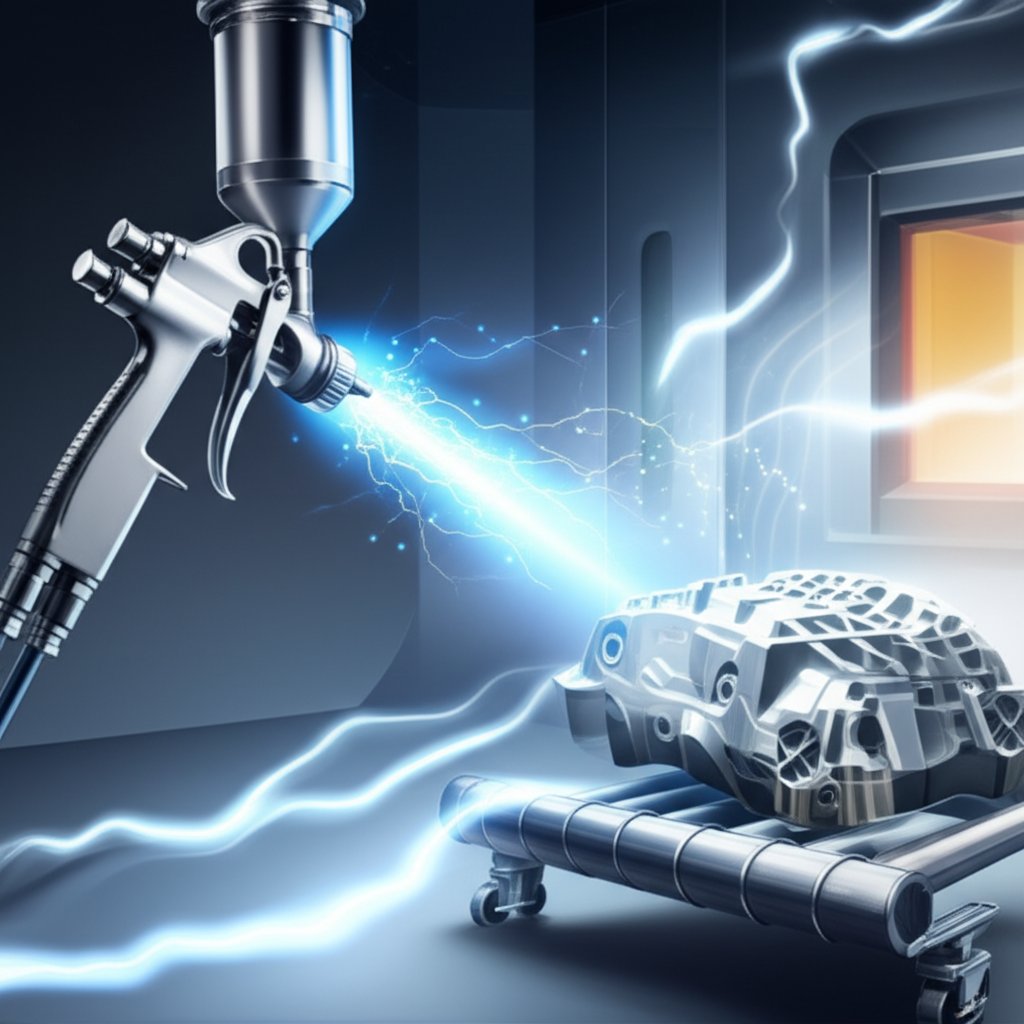

Once the aluminum part is properly prepared, it moves to the application and curing stages, where the dry powder is transformed into a solid, protective skin. This two-part process relies on the principles of electrostatics and thermal chemistry to create a finish that is both uniform and incredibly durable. The entire operation is performed in a controlled environment to prevent contamination from dust or other airborne particles.

The application begins with the electrostatic spray process. The dry powder is fed into a specialized spray gun that imparts a positive electrical charge to the particles. The die-cast aluminum part is grounded, creating an electrical potential difference. When the charged powder is sprayed towards the part, it is naturally attracted to the grounded surface, wrapping around it evenly. This electrostatic attraction ensures that the powder clings to the part in a uniform layer, reaching into corners and complex geometries that would be difficult to cover with liquid paint.

After the powder is applied, the part is carefully transferred to a curing oven. The heat inside the oven, typically set around 200°C (400°F) for 10 to 20 minutes, initiates a chemical transformation. First, the powder melts and flows together, forming a continuous liquid film over the entire surface. Then, as it remains at temperature, a cross-linking chemical reaction occurs, creating a dense, interconnected polymer network. Once this curing process is complete, the part is removed from the oven and allowed to cool, hardening into the final, tough finish.

Powder Coating vs. Other Finishes (Anodizing & Paint)

While powder coating offers a compelling balance of features, it's important to understand how it compares to other common aluminum finishes like anodizing and liquid paint. Each method has distinct advantages and is suited for different applications, so the best choice depends on your specific requirements for durability, appearance, cost, and environmental impact.

Anodizing is an electrochemical process that creates a very hard, durable, and corrosion-resistant oxide layer on the aluminum's surface. It's not a coating that sits on top of the metal but rather an integral part of it. Liquid paint, the most traditional option, involves applying a solvent-based pigment in thin layers. It is often the lowest-cost option but typically offers the least durability.

A detailed comparison from Gabrian.com highlights that powder coating often presents a middle ground, providing better durability than paint and more color options than anodizing, often at a lower cost than anodizing. The choice ultimately depends on the product's intended use and design goals.

| Finish Type | Durability | Corrosion Resistance | Cost | Color Options | Environmental Impact |

|---|---|---|---|---|---|

| Powder Coating | High (Resists chipping & scratching) | Excellent | Moderate | Vast | Low (No VOCs) |

| Anodizing | Very High (Extremely hard surface) | Excellent | High | Limited (Often metallic) | Moderate (Involves acids) |

| Liquid Paint | Low (Prone to chipping & scratching) | Good | Low | Vast | High (Contains VOCs) |

For applications requiring maximum hardness and wear resistance, anodizing may be the better choice. For low-cost projects where durability is not the primary concern, liquid paint can suffice. However, for a majority of die-cast aluminum applications, powder coating provides the ideal combination of performance, aesthetics, and value.

Frequently Asked Questions

1. Can you powder coat die-cast?

Yes, absolutely. Powder coating is an excellent choice for finishing die-cast aluminum and zinc components. It is widely used to provide both a protective and a cosmetic coating, valued for its durability and high-quality appearance. The key to a successful outcome is thorough surface preparation to account for the material's porosity.

2. What is the best coating for cast aluminum?

The "best" coating depends on the specific application's needs. For a balance of excellent durability, corrosion resistance, cost-effectiveness, and a wide range of color options, powder coating is often considered the best all-around choice. For extreme wear resistance, anodizing might be superior. For applications where cost is the primary driver and durability is less critical, liquid paint could be suitable.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —