Automotive Die Casting Process: Precision Parts Explained

TL;DR

The automotive die casting process is a high-pressure manufacturing technique where molten non-ferrous metal is injected into a reusable steel mold, known as a die. This method is essential to the modern automotive industry for producing strong, lightweight, and complex components with high precision. By using alloys like aluminum, zinc, and magnesium, die casting is critical for enhancing vehicle performance, improving fuel efficiency, and enabling the mass production of parts with excellent dimensional accuracy.

The Fundamentals of Die Casting: What It Is and Why It Matters in Automotive

Die casting is a metal casting process defined by forcing molten metal into a mold cavity under high pressure. According to Wikipedia, this pressure can range from 10 to 175 megapascals (MPa), ensuring the metal fills every detail of the complex, two-part hardened steel mold. Once the metal cools and solidifies, the die is opened, and the part, known as a casting, is ejected. This process shares similarities with plastic injection molding but is used for non-ferrous metals, making it a cornerstone of modern manufacturing.

In the automotive industry, the significance of die casting cannot be overstated. Manufacturers face constant pressure to improve fuel economy and reduce emissions, which largely depends on reducing vehicle weight. Die casting provides an effective solution by enabling the production of lightweight components without sacrificing strength or durability. As noted by RapidDirect, this technique is a key alternative for metal manufacturing that allows for thinner walls and complex geometries, which are difficult to achieve with other methods. This leads to lighter vehicles, better mileage, and enhanced overall performance.

The process's ability to produce near-net-shape parts with excellent surface finish and dimensional consistency is another major advantage. This reduces the need for extensive secondary machining operations, saving both time and cost in high-volume production environments. While die casting is ideal for creating intricate parts, other high-performance methods like forging are also vital in automotive manufacturing. For instance, some companies specialize in automotive forging parts, a process renowned for producing components with exceptional strength, often used for critical stress-bearing applications like suspension and powertrain components.

The core benefits of automotive die casting include:

- Lightweighting: Using low-density metals like aluminum and magnesium helps reduce overall vehicle weight, directly contributing to better fuel efficiency.

- Complexity and Precision: The high-pressure injection allows for the creation of intricate, thin-walled parts with tight tolerances, enabling more sophisticated and compact vehicle designs.

- High Production Speed: Die casting is a rapid process, with automated machines capable of producing thousands of identical parts in a single session, making it highly cost-effective for mass production.

- Strength and Durability: Die-cast parts exhibit excellent strength-to-weight ratios and good corrosion resistance, ensuring longevity and reliability for critical automotive components.

The Step-by-Step Die Casting Process: From Molten Metal to Finished Part

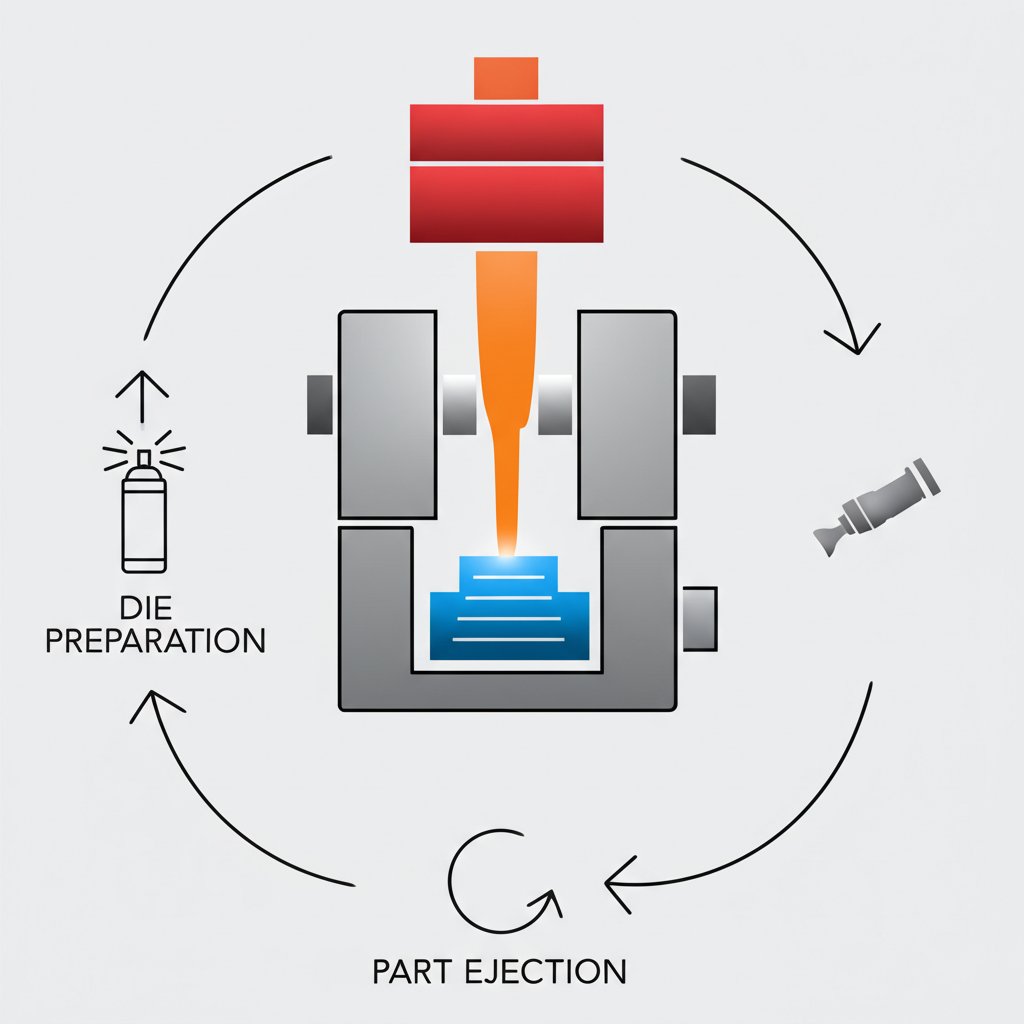

The automotive die casting process is a highly refined, multi-stage operation that transforms molten metal into a finished component with remarkable speed and precision. The entire workflow can be broken down into four primary stages: die preparation, filling (injection), ejection, and shakeout (trimming). Each step is critical to ensuring the final part meets strict quality standards for dimensional accuracy and surface finish.

First, the die must be prepared. The two halves of the hardened steel mold are cleaned and then sprayed with a lubricant. This lubricant serves two purposes: it helps control the temperature of the die and acts as a releasing agent, ensuring the solidified casting can be removed easily without damage. Once lubricated, the two die halves are securely closed and clamped together under immense force to withstand the high-pressure injection that follows.

Next is the filling or injection stage. Molten metal, which has been melted in a separate furnace (for the cold-chamber process) or within the machine itself (for the hot-chamber process), is forced into the die cavity. A plunger injects the metal at high speed and pressure, ensuring it fills every crevice of the mold before it begins to solidify. The pressure is maintained during the cooling phase to minimize shrinkage and porosity. After the metal solidifies, the die halves are opened, and the casting is pushed out by ejector pins. Finally, in the shakeout stage, excess material such as runners, sprues, and flash (thin material that seeps out at the die's parting line) is trimmed from the casting. This scrap material is typically collected and remelted for reuse, making the process highly sustainable.

The two main methods of high-pressure die casting are the hot-chamber and cold-chamber processes, which are suited for different metals and applications.

| Feature | Hot-Chamber Die Casting | Cold-Chamber Die Casting |

|---|---|---|

| Mechanism | The injection mechanism is immersed in the molten metal bath, which is contained within the machine's furnace. | Molten metal is ladled from a separate furnace into a 'cold' shot chamber for each cycle. |

| Suitable Metals | Low-melting-point alloys like zinc, magnesium, and lead. | High-melting-point alloys like aluminum and its alloys. |

| Cycle Speed | Faster, as the metal is fed directly into the injection system. | Slower, due to the extra step of transferring the metal to the machine. |

| Pressure | Typically lower (up to 35 MPa). | Significantly higher (up to 150 MPa) to inject the metal quickly. |

| Common Automotive Applications | Door lock housings, seat belt components, sensor housings. | Engine blocks, gearbox cases, mounting brackets, structural parts. |

Core Materials in Automotive Die Casting: Aluminum, Zinc, and Magnesium

The choice of material in automotive die casting is critical, as it directly influences the final component's weight, strength, corrosion resistance, and cost. The most commonly used materials are non-ferrous alloys of aluminum, zinc, and magnesium, each offering a unique set of properties tailored to specific applications.

Aluminum alloys are the most prevalent in the automotive industry, primarily due to their excellent combination of light weight and strength. As detailed by Fictiv, alloys like A380 are valued for their good mechanical properties, high thermal conductivity, and corrosion resistance, making them ideal for parts that operate under stress and at high temperatures. Common applications include engine blocks, gearbox cases, oil pans, and structural components like chassis parts. The use of aluminum is a key strategy for vehicle lightweighting to improve fuel economy.

Zinc alloys, such as those in the Zamak family, are another popular choice. Zinc is prized for its exceptional casting fluidity, which allows it to fill intricate and thin-walled sections of a mold with high precision. It offers excellent dimensional stability, high impact strength, and is easily plated for decorative or protective finishes. According to Bruschi, zinc is often used for parts requiring a high-quality surface finish and tight tolerances, such as door handles, lock housings, seat belt retractor gears, and electronic sensor housings.

Magnesium alloys are the lightest of the common die casting metals, offering a superior strength-to-weight ratio. Magnesium is approximately 33% lighter than aluminum and 75% lighter than steel. This makes it an ideal material for applications where weight reduction is the highest priority. As explained by 3ERP, magnesium is used for components such as steering wheel frames, seat frames, instrument panels, and transfer cases. Its excellent machinability and damping capacity are also significant advantages in automotive design.

Comparison of Key Die Casting Alloys

- Weight: Magnesium is the lightest, followed by aluminum, with zinc being the heaviest of the three.

- Strength: Zinc alloys generally offer higher tensile strength at room temperature, but aluminum alloys retain their strength better at elevated temperatures.

- Corrosion Resistance: All three offer good corrosion resistance, with specific performance depending on the alloy and surface treatment.

- Cost: Zinc and aluminum are generally more cost-effective for high-volume production, while magnesium can be more expensive.

- Casting Process: Zinc and magnesium can be cast using the faster hot-chamber process, whereas aluminum requires the slower cold-chamber process due to its higher melting point and corrosive effect on steel injection components.

Key Die Casting Techniques and Their Applications

While high-pressure die casting (HPDC) is the most common method, several variations have been developed to meet specific manufacturing needs, particularly for critical automotive components where structural integrity is paramount. These techniques include low-pressure die casting and vacuum-assisted die casting, each offering distinct advantages for different applications.

High-Pressure Die Casting (HPDC) remains the standard for producing a vast majority of automotive parts due to its speed and ability to create complex, net-shape components. It's used for everything from engine components and transmission housings to smaller parts like sensor casings and brackets. However, a common challenge with HPDC is the potential for air entrapment during the rapid injection of molten metal, which can lead to porosity in the final casting. This porosity can compromise the part's mechanical properties and prevent heat treatment.

To address this, Vacuum-Assisted Die Casting is employed. In this process, a vacuum is used to remove air and gases from the die cavity before the metal is injected. This significantly reduces porosity, resulting in denser, stronger parts with an improved surface finish. This technique is ideal for safety-critical components and parts that require subsequent welding or heat treatment, such as structural nodes, engine mounts, and suspension components.

Low-Pressure Die Casting (LPDC) is another alternative, where molten metal is gently introduced into the mold from below using low pressure (typically 7 to 30 psi). This slower, more controlled fill minimizes turbulence and air entrapment, leading to parts with excellent mechanical properties and low porosity. LPDC is often chosen for larger, symmetrical components like wheels and certain engine blocks, where structural integrity is more critical than a fast cycle time.

Advantages and Disadvantages of Die Casting

Like any manufacturing process, die casting has a distinct set of trade-offs that make it suitable for some applications but not others.

Advantages

- High Production Speed: The process is highly automated and can produce parts at a very rapid rate, lowering the cost per part in high-volume runs.

- Excellent Dimensional Accuracy: Die casting produces parts with very tight tolerances, often eliminating the need for post-machining.

- Complex Geometries: The process allows for the creation of intricate shapes and thin walls that are difficult to achieve with other methods.

- Smooth Surface Finish: Castings have a naturally smooth surface, which can be easily plated or finished for aesthetic purposes.

Disadvantages

- High Initial Cost: The tooling (dies) and machinery required for die casting are very expensive, making it cost-prohibitive for low-volume production.

- Material Limitations: The process is generally limited to non-ferrous metals with high fluidity, such as aluminum, zinc, and magnesium.

- Potential for Porosity: In standard HPDC, trapped air can cause internal pores, which can affect the part's strength and prevent heat treatment.

- Long Lead Times for Tooling: Designing and manufacturing a new die is a complex and time-consuming process.

Final Thoughts on the Automotive Die Casting Process

The automotive die casting process is a foundational technology that enables the production of the lightweight, complex, and reliable components essential for modern vehicles. From improving fuel efficiency through weight reduction to enabling sophisticated designs with high-precision parts, its impact is undeniable. By leveraging the unique properties of aluminum, zinc, and magnesium alloys, manufacturers can tailor components to meet specific performance, safety, and cost targets. As the automotive industry continues to evolve toward electric and autonomous vehicles, the demand for advanced die casting techniques that produce even larger and more integrated structural parts will only continue to grow, solidifying its role as a critical manufacturing process for the future.

Frequently Asked Questions

1. What is the main difference between die casting and forging?

The primary difference lies in the state of the metal. In die casting, metal is heated until it becomes molten (liquid) and is then injected into a mold to solidify. In forging, the metal is heated until it is malleable but remains in a solid state. It is then shaped by applying immense pressure with a hammer or a press. Forging typically produces stronger, more durable parts, while die casting is better for creating complex, intricate shapes.

2. Why is porosity a concern in die casting?

Porosity refers to tiny voids or gas bubbles trapped within the cast metal as it solidifies. It is a concern because it can weaken the component, making it susceptible to cracking under stress. Porosity also prevents parts from being safely heat-treated or welded, as the trapped gas expands when heated, which can cause blisters on the surface and internal micro-cracks, compromising the part's structural integrity.

3. Can steel or iron be used in die casting?

While technically possible, die casting ferrous metals like steel and iron is very uncommon. Their extremely high melting temperatures would cause rapid degradation and wear on the steel dies, making the process economically unfeasible due to short tool life. The process is therefore almost exclusively used for non-ferrous metals with lower melting points.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —