Die Casting Steering Knuckles: A Process & Materials Guide

TL;DR

Die casting steering knuckles is an advanced manufacturing method that uses processes like low-pressure, squeeze, and semi-solid die casting to create critical automotive suspension parts from lightweight aluminum alloys. This technique allows for the production of complex, high-strength components with superior mechanical properties and surface finishes. Opting for die-cast aluminum over traditional forged steel or cast iron significantly reduces vehicle weight, which in turn improves handling, fuel efficiency, and lowers CO2 emissions.

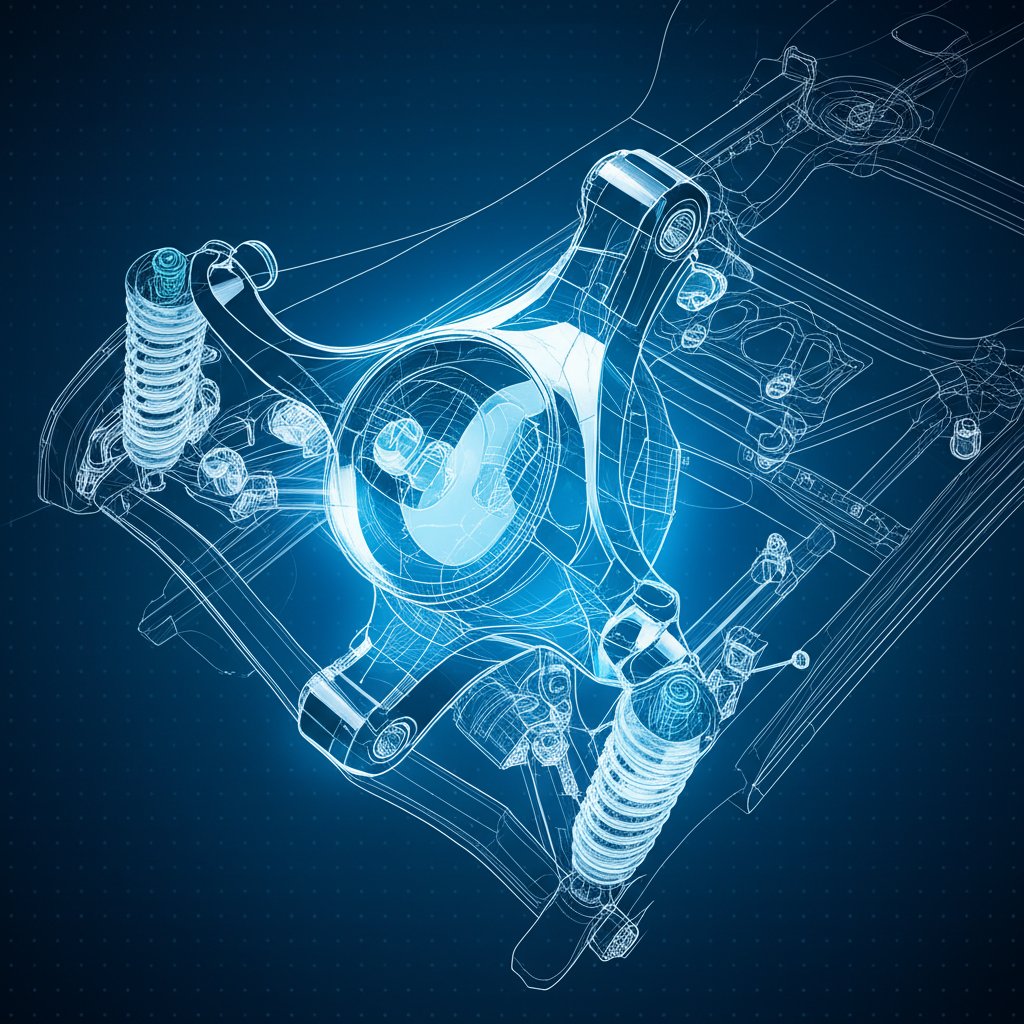

Understanding Steering Knuckles: Function and Materials

The steering knuckle is a vital structural component within a vehicle's suspension system. As the pivot point, it connects the wheel, suspension, and steering linkages, bearing significant loads during acceleration, braking, and turning. As described in a study on semi-solid die casting, these parts require a combination of high strength, high ductility, and the ability to be formed into complex shapes to function safely and effectively. The performance of the steering knuckle directly impacts the vehicle's handling stability and overall safety.

Historically, steering knuckles were predominantly made from robust materials like ductile cast iron or forged steel to ensure durability. However, the automotive industry's relentless pursuit of lightweighting to meet stricter emissions standards and improve fuel economy has driven a shift towards advanced aluminum alloys. Manufacturers like Fagor Ederlan highlight that this transition is key to reducing a vehicle's CO2 footprint and offering significant weight-saving options. Aluminum alloys provide an excellent strength-to-weight ratio, good corrosion resistance, and superior thermal conductivity compared to their ferrous counterparts.

The choice between these materials involves a trade-off between weight, strength, and cost. While steel and iron are known for their sheer strength and lower material cost, aluminum's lower density offers a compelling advantage for modern vehicle design.

- Aluminum Alloys: Offer significant weight reduction, improved vehicle dynamics, and excellent corrosion resistance. They can be cast into highly complex, near-net-shape parts, reducing the need for extensive secondary machining.

- Steel/Iron: Provide exceptional strength and fatigue resistance at a lower cost. However, their high density contributes to greater unsprung mass, which can negatively affect ride quality and handling.

Advanced Die Casting Processes for Steering Knuckles

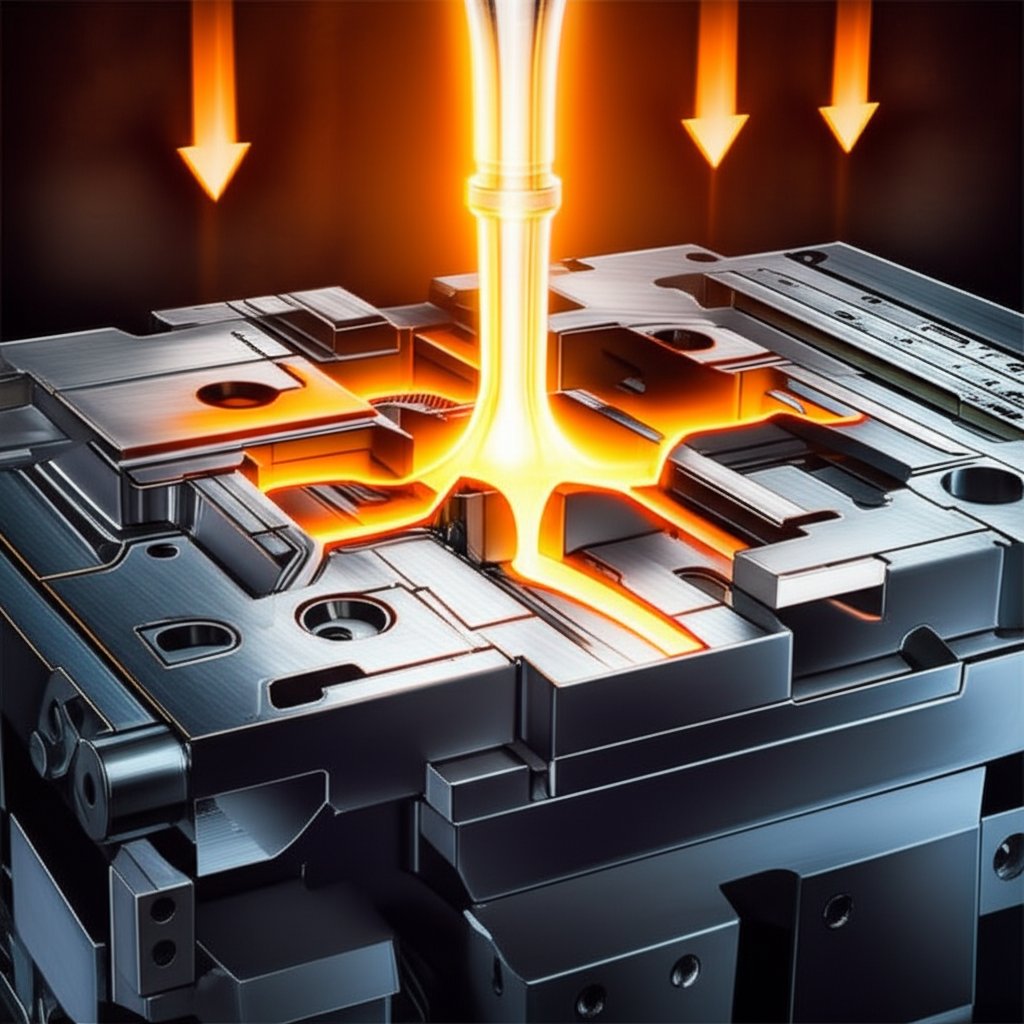

Producing a high-performance aluminum steering knuckle demands more than just a simple casting method. The industry relies on several advanced die casting techniques to ensure the final product is free from defects like porosity and has the required mechanical integrity. These processes are designed to control the flow of molten metal and the solidification process with extreme precision. Leading manufacturers like Saint Jean Industries utilize a range of technologies, including low-pressure and gravity die casting, to achieve optimal results.

Common advanced processes include:

- Low-Pressure Die Casting (LPDC): In this method, molten metal is gently introduced into the mold from below, reducing turbulence and the risk of oxide inclusions. This results in a dense, high-quality casting with excellent mechanical properties.

- Squeeze Casting: This hybrid process combines casting and forging. High pressure is applied to the molten metal as it solidifies, eliminating porosity and refining the grain structure, which leads to superior strength and ductility.

- Semi-Solid Die Casting (SSM): This technique involves injecting a partially solidified metal slurry into the die. The semi-solid state allows for a less turbulent fill, minimizing gas entrapment and producing parts with high integrity and complex geometries, as detailed in research published on Scientific.net.

- Vacuum Die Casting: By creating a vacuum within the die cavity before injection, this process removes trapped gases, leading to castings with very low porosity that can be heat-treated for even greater strength.

While die casting offers numerous advantages, forging remains a prominent manufacturing method for steering knuckles. The choice between casting and forging often depends on the specific performance requirements, production volume, and cost targets. For those exploring robust forged components, specialized providers such as Shaoyi (Ningbo) Metal Technology offer precision-engineered solutions backed by advanced hot forging processes and rigorous quality control.

| Factor | Die Casting (Aluminum) | Forging (Steel/Iron) |

|---|---|---|

| Component Weight | Significantly lighter, reducing unsprung mass. | Heavier, contributing to higher overall vehicle weight. |

| Shape Complexity | Excellent for complex, intricate, near-net-shape designs. | More limited in geometric complexity; often requires more machining. |

| Surface Finish | Generally smoother surface finish out of the mold. | Rougher surface that typically requires post-processing. |

| Production Speed | High cycle times suitable for mass production. | Typically slower and more labor-intensive process. |

| Mechanical Properties | High strength with advanced alloys and processes. | Exceptional strength and fatigue resistance due to grain alignment. |

Benefits and Performance of Die-Cast Aluminum Knuckles

The adoption of die-cast aluminum steering knuckles provides a host of tangible benefits that directly translate to improved vehicle performance and sustainability. The most significant advantage is weight reduction. By replacing heavier steel or iron components, automakers can decrease the vehicle's unsprung mass—the weight of the components not supported by the suspension. This leads to more responsive steering, improved handling, and a smoother ride quality for the occupants.

Beyond performance, die-cast aluminum knuckles contribute to key manufacturing and environmental goals. The ability to cast complex shapes reduces the need for subsequent machining operations, saving time and cost in the production cycle. Furthermore, the lower weight directly impacts fuel efficiency, helping vehicles consume less fuel and, as a result, produce fewer CO2 emissions. This aligns with global sustainability initiatives and stricter environmental regulations facing the automotive industry.

Key advantages of die-cast aluminum steering knuckles include:

- Significant Weight Reduction: Lowers unsprung mass for enhanced vehicle dynamics and fuel economy.

- Design Flexibility: Allows for the creation of intricate and highly optimized geometries that are difficult or impossible to achieve with forging.

- High Mechanical Performance: Advanced casting processes and heat treatments yield components with the high strength and ductility required for safety-critical applications.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, providing excellent resistance to environmental corrosion.

- Sustainability: Contributes to a reduced carbon footprint through vehicle lightweighting and the high recyclability of aluminum.

Design, Tooling, and Optimization Considerations

The journey from a digital concept to a finished steering knuckle is a complex engineering endeavor that relies on sophisticated design tools and manufacturing simulations. The design phase typically begins with Computer-Aided Design (CAD) software, followed by extensive Finite Element Analysis (FEA) using tools like ANSYS. This analysis simulates the various loads the knuckle will experience during its service life to ensure it meets strict stiffness and durability requirements without being over-engineered.

Once the design is finalized, creating the tooling—the die or mold—is the next critical step. The mold's design is paramount for a successful casting. As detailed in a process analysis on gudmould.com, engineers use simulation software like ProCAST to model the flow of molten metal into the mold cavity. This allows them to optimize the gating and runner system, predict potential defects like shrinkage or porosity, and ensure the part solidifies correctly. This simulation-driven approach minimizes costly and time-consuming trial-and-error on the factory floor.

The entire design-to-production workflow is an iterative process focused on optimization. The goal is to produce a lightweight part that meets all performance targets without defects. This involves a clear, structured sequence of steps:

- CAD/CAE Design and Analysis: Creating the initial 3D model and using simulation to verify its structural integrity under real-world forces.

- Mould and Tooling Creation: Designing and manufacturing the high-precision steel dies based on the finalized part geometry and casting process.

- Casting Process Selection and Simulation: Choosing the optimal casting method (e.g., LPDC, Squeeze Casting) and simulating the mold-filling and solidification to prevent defects.

- Production and Machining: Casting the raw parts, followed by precision CNC machining of critical interfaces, such as bearing bores and mounting points.

- Quality Control and Validation: Implementing rigorous inspection methods, including X-ray and dimensional checks, to ensure every part meets safety and quality standards.

Frequently Asked Questions

1. What material is used for steering knuckles?

Traditionally, steering knuckles were made from ductile cast iron or forged steel due to their high strength. However, there is a strong industry trend towards using lightweight aluminum alloys to reduce vehicle weight, improve fuel efficiency, and enhance handling dynamics. Modern vehicles increasingly feature aluminum knuckles produced through advanced casting processes.

2. How to design a steering knuckle?

Designing a steering knuckle is a complex engineering process. It starts with creating a 3D model in CAD software like Creo (Pro/E). This model then undergoes extensive static and dynamic analysis using Finite Element Analysis (FEA) software such as ANSYS. Engineers simulate various loads—from braking, cornering, and vertical impacts—to optimize the knuckle's geometry for maximum strength and stiffness while minimizing its weight.

3. What is the process of steering knuckle forging?

Steering knuckle forging is a manufacturing process where a metal billet is heated and then shaped using compressive forces from a hammer or press. The typical process involves material testing, cutting the raw material to length, heating it to a malleable temperature, and then using a series of dies to pre-form and final-forge the part into its desired shape. This is followed by trimming excess material, heat treatment, and final machining.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —