Die Cast Parts: Balancing Form, Function, and Finishes

TL;DR

The distinction between aesthetic vs functional die cast parts is not a binary choice but a spectrum of design priorities. Success hinges on balancing visual appeal with performance requirements like durability and corrosion resistance. This balance is primarily achieved through strategic material selection, adherence to design for manufacturability (DFM) principles, and the critical application of specific surface finishes tailored to the part's end use.

Defining the Spectrum: Aesthetic vs. Functional Priorities

In the world of manufacturing, the debate between form and function is a constant. For die cast parts, this isn't a matter of choosing one over the other but rather of navigating a spectrum of priorities. Nearly every component requires a blend of both aesthetic appeal and functional performance. The key is to define the primary intent early in the design process, as this decision cascades through every subsequent choice, from material selection to the final surface treatment.

Aesthetic considerations focus on the visual and tactile qualities of a part. These are paramount for consumer-facing products where the look and feel directly influence perceived value. Factors include surface smoothness, color consistency, texture, and the absence of visual defects like parting lines or sink marks. A sleek laptop chassis, a polished automotive interior trim, or a decorative housing for a high-end appliance are all examples where aesthetics are a driving force. Achieving a superior cosmetic finish often requires meticulous mold design and secondary finishing processes that can increase costs.

Functional requirements, on the other hand, are dictated by the part's operational environment and mechanical purpose. These priorities include structural integrity, wear resistance, corrosion protection, thermal conductivity, and dimensional accuracy. For an internal engine bracket, a gearbox housing, or an aerospace component, function is non-negotiable. The part must perform reliably under stress, temperature variations, and exposure to chemicals or moisture. Surface finishes in this context are less about appearance and more about enhancing durability and longevity, as noted in a guide by Kenwalt Die Casting.

The trade-off between these priorities is often a matter of engineering and economics. For instance, designing a part with complex curves for aesthetic reasons might create challenges for molten metal flow, potentially compromising internal integrity. Conversely, optimizing a part for maximum strength might result in a less visually appealing finish. The goal for any product team is to clearly define the end-use and strike the most effective balance, ensuring the final component is both attractive and dependable without exceeding budget constraints.

The Critical Role of Surface Finishes

Surface finishes are the most powerful tool for elevating both the aesthetic and functional qualities of a die-cast part. A finish is not merely a coating; it is a critical manufacturing step that can transform a raw casting into a high-performance, visually appealing component. As Zetwerk explains, the surface finish goes beyond looks to significantly impact performance. The choice of finish directly addresses the priorities defined in the design phase, whether the goal is a mirror-like shine, rugged corrosion resistance, or enhanced electrical conductivity.

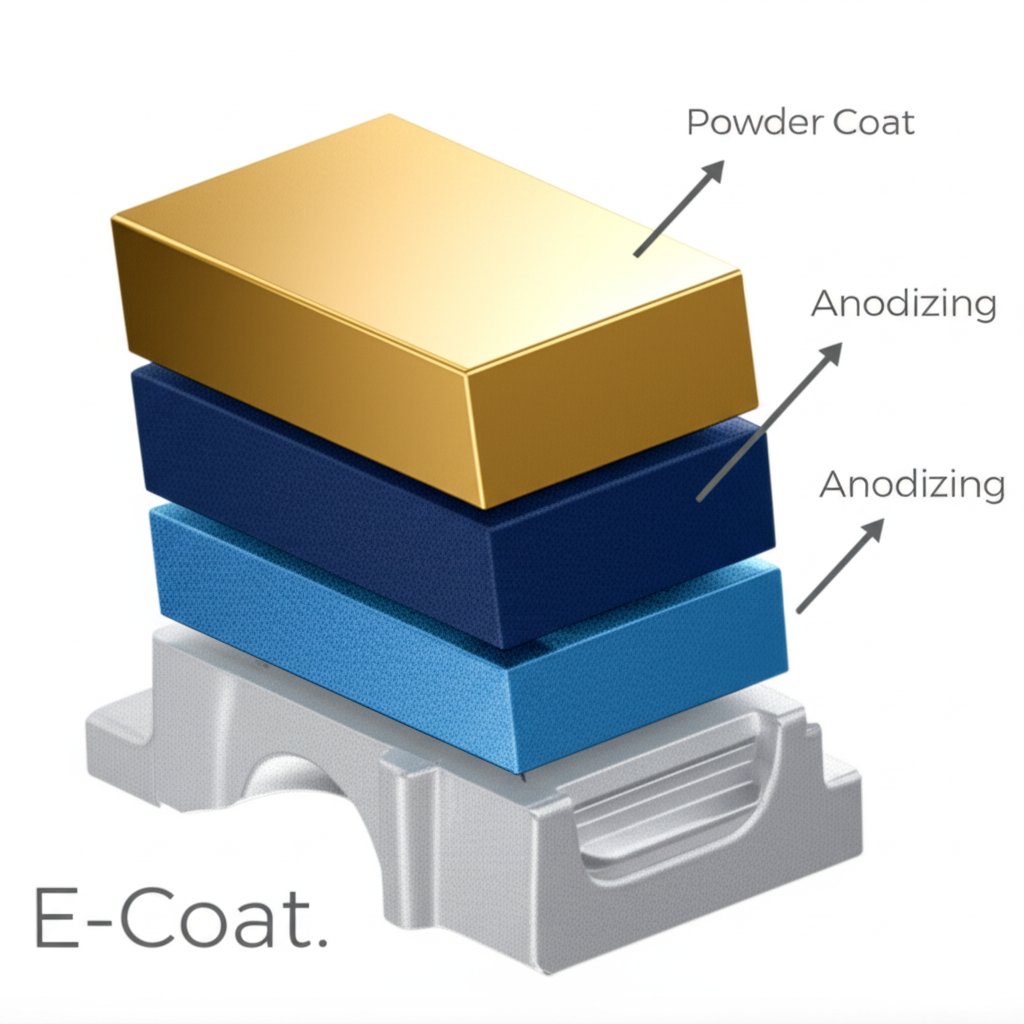

Several common finishing options are available, each offering a unique combination of benefits. Anodizing is an electrochemical process that creates a hard, corrosion-resistant oxide layer on aluminum parts, perfect for consumer electronics that need durability and a premium feel. Powder coating provides a thick, durable, and decorative finish in a vast range of colors, making it ideal for automotive parts and outdoor equipment. For the highest aesthetic demands, polishing creates a smooth, reflective surface, while electroplating adds a thin layer of another metal (like chrome or nickel) for beauty, wear resistance, and conductivity.

For more industrial or functional needs, treatments like chromate conversion coating offer excellent corrosion resistance at a low cost, making them suitable for aerospace and electronics where performance outweighs appearance. Similarly, sand or shot blasting is a cost-effective way to clean a part and create a uniform matte texture, which also serves as an excellent preparatory step for painting or coating.

Selecting the right finish requires a careful analysis of the part's application, environment, and budget. A comprehensive cost and comparison guide can be invaluable for making an informed decision. To simplify this choice, the table below compares common finishes based on their primary benefits and typical applications.

| Finishing Type | Primary Benefit | Corrosion Resistance | Relative Cost | Common Applications |

|---|---|---|---|---|

| Anodizing | Aesthetic & Functional | High | Medium | Consumer electronics, medical devices, architectural trim |

| Powder Coating | Functional & Aesthetic | Very High | Medium | Automotive parts, outdoor furniture, industrial housings |

| Polishing | Aesthetic | Low (unless coated) | High | Premium decorative parts, luxury hardware, reflectors |

| Electroplating (e.g., Chrome) | Aesthetic & Functional | Very High | High | Automotive trim, plumbing fixtures, electrical connectors |

| Chromate Conversion | Functional | Medium | Low | Aerospace parts, electronics, paint primer |

| Shot Blasting | Functional (Preparation) | None | Low | Pre-treatment for coating, industrial components |

Fundamental Design Principles for Optimized Parts

Long before a surface finish is applied, the foundational design of a die-cast part determines its ultimate success. Adhering to Design for Manufacturability (DFM) principles is essential for creating components that are both functionally sound and aesthetically pleasing. These principles ensure the part can be produced efficiently, with minimal defects, and at a lower cost. As detailed in a comprehensive design guide, key variables like wall thickness, fillets, and draft angles are critical.

One of the most important principles is maintaining uniform wall thickness. Abrupt changes in thickness can cause the molten metal to cool unevenly, leading to defects like porosity (internal voids) and sink marks (surface depressions). These not only weaken the part (a functional failure) but also mar its appearance (an aesthetic failure). By keeping walls consistent, designers ensure smooth metal flow and structural integrity.

Fillets and radii—the rounding of sharp internal and external corners—are another crucial element. Sharp internal corners create stress concentrations, making the part prone to cracking under load. By adding a generous fillet, stress is distributed more evenly, dramatically improving the part's strength and fatigue life. From an aesthetic perspective, rounded edges provide a smoother, more finished look. Similarly, draft angles (a slight taper on vertical walls) are necessary to eject the part from the mold without damage, preserving its carefully designed surface finish.

Material selection also plays a pivotal role. Aluminum alloys are popular for their excellent balance of light weight and strength, making them ideal for many automotive and electronic applications. Zinc alloys offer high fluidity, allowing for intricate details and very thin walls, which is great for small, complex components. For applications requiring extreme strength and durability, especially in the automotive sector, alternative processes may be considered. For example, some high-stress components benefit from hot forging. Companies like Shaoyi (Ningbo) Metal Technology specialize in precision-engineered automotive forging parts, offering robust solutions where mechanical performance is the absolute priority.

To ensure a successful design, engineers should review a checklist of these core principles before finalizing a model:

- Wall Thickness: Is it as uniform as possible? Are transitions gradual?

- Draft Angles: Is there sufficient draft (typically 1-3 degrees) on all surfaces parallel to the die opening?

- Fillets and Radii: Are all sharp internal and external corners generously radiused?

- Parting Line: Is the parting line placed in a non-critical or less visible area to minimize its aesthetic impact?

- Ribs & Bosses: Are ribs used to add strength to thin walls instead of increasing overall thickness? Are they properly proportioned (e.g., 50-60% of the wall thickness)?

Striking the Right Balance for Your Project

Ultimately, creating a successful die-cast component is an exercise in strategic compromise and intelligent design. The conversation is not about choosing aesthetics or function, but about defining the ideal blend of both for a specific application. By prioritizing needs early, designers can make informed decisions that guide the entire manufacturing process. A consumer product may lean toward a flawless surface finish, while an industrial part will prioritize material strength and corrosion resistance above all else.

The journey from concept to finished part relies on a holistic approach. It begins with fundamental design principles that prevent defects and ensure manufacturability. It continues with careful material selection aligned with performance and cost targets. Finally, it culminates in the selection of a surface finish that enhances the part's inherent qualities, providing the necessary durability, protection, and visual appeal. By mastering the interplay between these elements, manufacturers can produce die-cast parts that are not only fit for purpose but also exceptional in quality.

Frequently Asked Questions

1. What is the most suitable material for die casting?

Aluminum alloys are among the most popular materials for die casting because they offer a great balance of strength, light weight, and corrosion resistance. This makes them an excellent choice for a wide range of applications, from automotive parts to consumer electronics. Zinc alloys are also common, valued for their ability to form intricate, detailed parts with high precision.

2. What is the difference between die casting and regular casting?

The primary difference lies in the process and materials. Die casting uses high pressure to inject molten metal into a reusable steel mold (a die), making it ideal for high-volume production of non-ferrous metals like aluminum and zinc. Other casting methods, like sand casting or investment casting, use expendable molds and are often better suited for lower volumes or for casting ferrous metals like iron and steel.

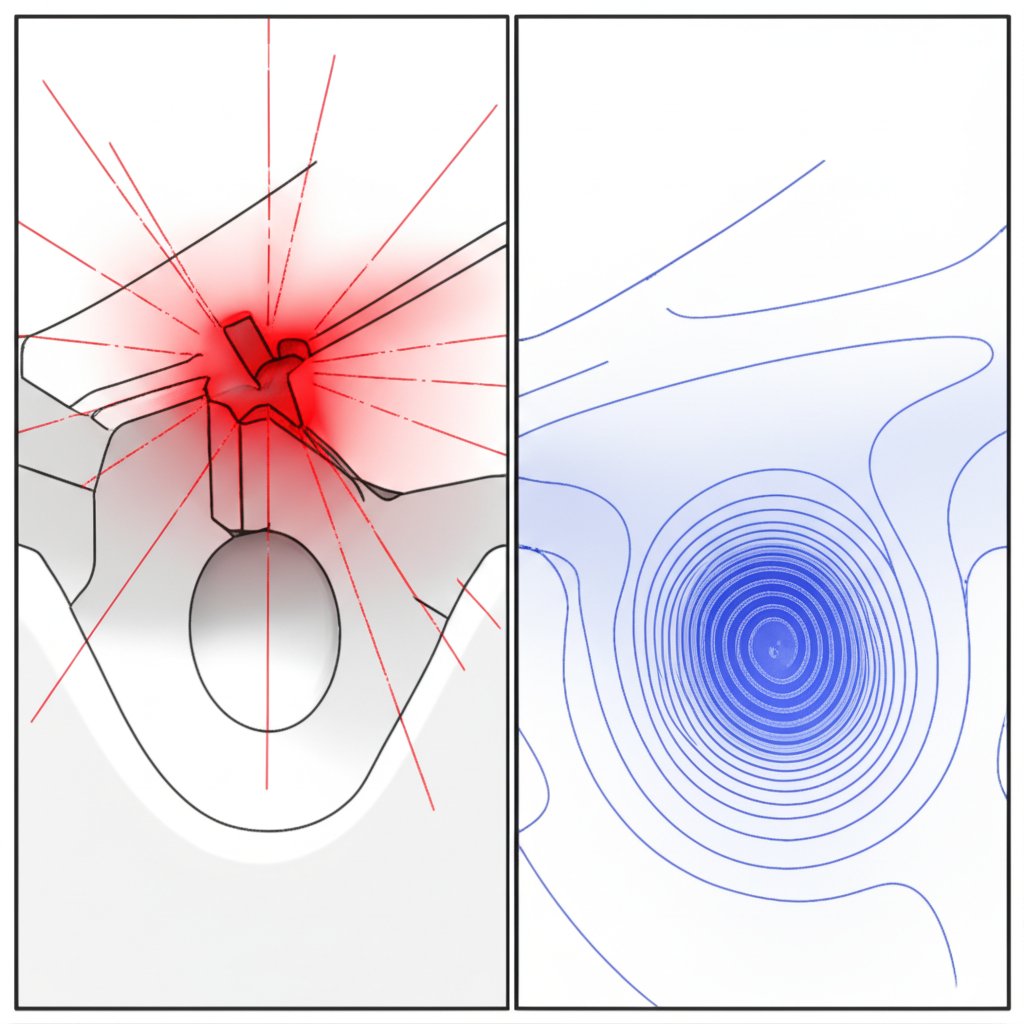

3. What are the disadvantages of High-Pressure Die Casting (HPDC)?

A significant disadvantage of HPDC is the potential for porosity. Because the molten metal is injected so quickly, air can become trapped, creating tiny voids within the part. This porosity can weaken the component's mechanical properties and compromise its structural integrity. The high initial cost of tooling (the steel die) also makes it less economical for small production runs.

4. Is die casting additive manufacturing?

No, die casting is a formative manufacturing process, not an additive one. Additive manufacturing, like 3D printing, builds an object layer by layer from nothing. In contrast, die casting shapes a part by injecting molten material into a pre-existing mold or die to give it its final form.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —