Squeeze Casting Process for High Integrity Parts Explained

TL;DR

The squeeze casting process for high integrity parts is an advanced manufacturing method that combines the benefits of casting and forging. By solidifying molten metal under intense, sustained pressure, it produces near-net-shape components with a refined grain structure and virtually no porosity. This technique is ideal for creating safety-critical parts that demand superior mechanical properties, excellent dimensional accuracy, and pressure tightness.

Understanding Squeeze Casting: A High-Integrity Hybrid Process

Squeeze casting, often referred to as liquid metal forging, is a specialized manufacturing process that bridges the gap between conventional casting and forging. It involves introducing molten metal into a preheated die and solidifying it under high pressure. Unlike traditional casting, this pressure is applied slowly and maintained throughout the entire solidification phase. This critical step is what gives the process its unique ability to produce high-integrity parts with exceptional density and strength.

The science behind its effectiveness lies in the metallurgical benefits derived from the high-pressure environment. The sustained pressure forces the molten metal into every detail of the die cavity, ensuring complete filling and preventing the formation of shrinkage voids. More importantly, it suppresses the formation and growth of gas pores, a common defect in other casting methods. This results in a final product that is virtually free of porosity, making it suitable for applications requiring pressure tightness, such as hydraulic and pneumatic components.

Furthermore, the pressure refines the grain structure of the metal as it solidifies. This fine-grain crystal structure leads to significantly improved mechanical properties, including higher tensile strength, impact toughness, and fatigue life. According to manufacturing experts at CastAlum, this unique combination of properties makes squeeze casting the ideal choice for safety-critical components in industries like automotive and aerospace. Parts like suspension knuckles and engine brackets, where failure is not an option, benefit immensely from this enhanced structural integrity.

As a result, squeeze casting has emerged as a powerful alternative to both gravity permanent mold casting and forging. It offers the design freedom and complexity of casting—allowing for intricate shapes and internal cavities—while delivering mechanical performance that approaches that of forged parts. This hybrid nature allows engineers to design components that are not only strong and reliable but also optimized for weight and cost, reducing the need for extensive post-process machining.

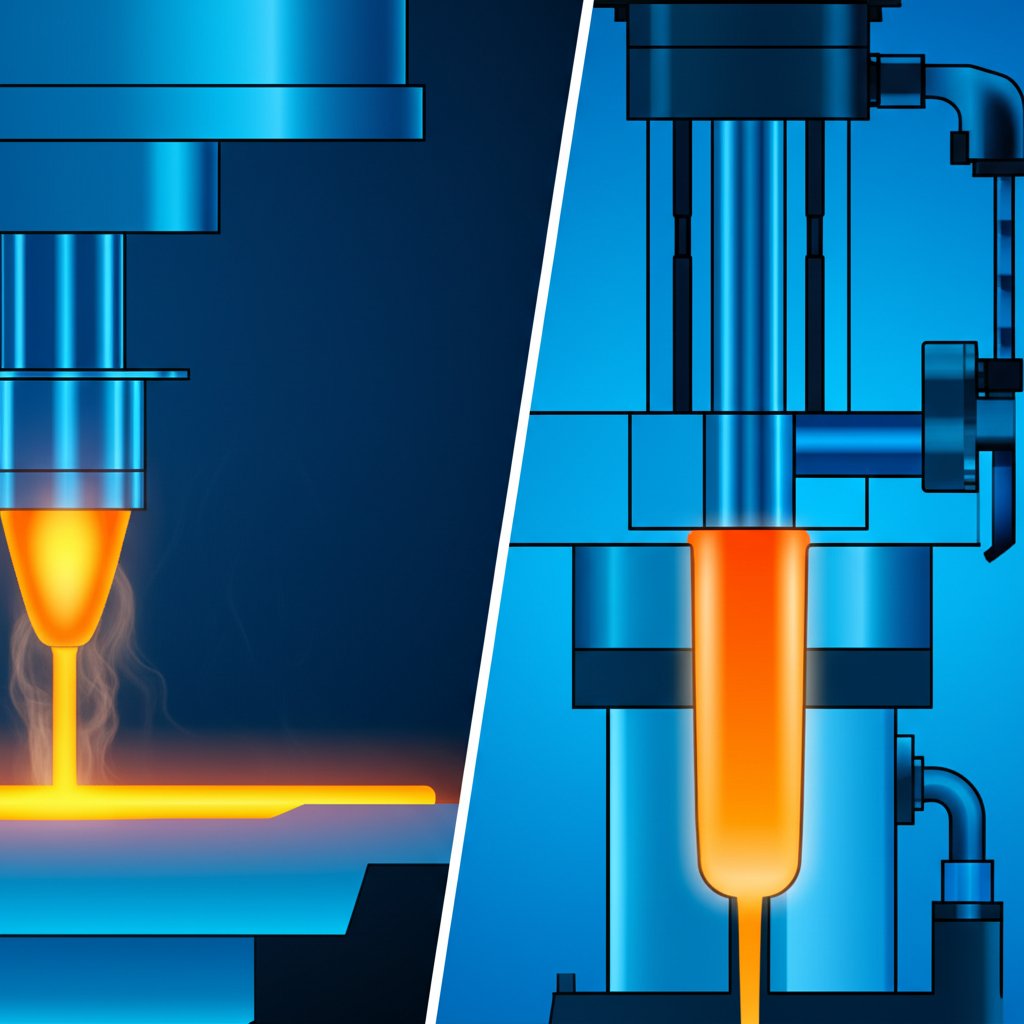

The Core Methodologies: Direct vs. Indirect Squeeze Casting

The squeeze casting process is primarily executed through two distinct methodologies: direct and indirect. The fundamental difference lies in how the molten metal is introduced into the die and how pressure is applied. Understanding this distinction is crucial for selecting the right approach for a specific component's geometry and performance requirements.

Direct squeeze casting is the more straightforward of the two methods. In this process, a precisely measured amount of molten metal is poured directly into the bottom half of a preheated die cavity. The upper half of the die, acting as a punch, then descends, sealing the cavity and applying direct, high pressure to the metal. This pressure is maintained until the part has completely solidified. This method is effective for producing relatively simple, often flat or symmetrical parts, where direct pressure application ensures a dense, uniform structure.

Indirect squeeze casting, in contrast, is a more controlled and versatile technique. Here, the molten metal is first poured into a shot sleeve or secondary pressure chamber connected to the die cavity. A hydraulic ram then injects the metal into the mold under controlled speed and pressure. As detailed by the specialists at CEX Casting, this method minimizes turbulence as the metal enters the die, which significantly reduces the risk of entrapping air and forming oxides. After the cavity is filled, the pressure is intensified and held during solidification. This approach is superior for producing parts with complex geometries, thin walls, and intricate details.

The choice between direct and indirect methods has significant implications for the final product and the manufacturing process itself. The indirect method offers greater control over metal flow, leads to a more uniform pressure distribution across complex shapes, and provides more flexibility in mold design. These advantages often result in components with superior mechanical properties and fewer internal defects.

Key Differences at a Glance

| Feature | Direct Squeeze Casting | Indirect Squeeze Casting |

|---|---|---|

| Metal Introduction | Poured directly into the die cavity. | Injected from a secondary shot sleeve/chamber via a ram. |

| Pressure Application | Applied by a punch that is part of the die itself. | Applied by a ram pushing metal into the cavity. |

| Metal Flow | Can be more turbulent if not carefully controlled. | Laminar (smooth) flow, reducing air entrapment. |

| Best For | Simpler, symmetrical, or flat components. | Complex geometries, thin walls, and high-detail parts. |

| Key Advantage | Simpler tooling and process setup. | Superior process control and part quality. |

Squeeze Casting vs. Conventional Manufacturing: A Technical Showdown

Choosing the right manufacturing process is a critical decision that balances cost, performance, and design complexity. Squeeze casting occupies a unique position, offering a compelling blend of benefits that often outperform traditional methods like High-Pressure Die Casting (HPDC) and forging, especially for high-integrity applications.

Versus High-Pressure Die Casting (HPDC)

The primary advantage of squeeze casting over HPDC lies in the quality of the final part. HPDC involves injecting molten metal into a die at extremely high speeds, which creates turbulence and often traps air and gas within the casting. This leads to porosity, a critical flaw that compromises structural integrity and prevents heat treatment. In contrast, squeeze casting fills the die slowly and applies pressure during solidification, effectively eliminating gas and shrinkage porosity. As explained in a detailed guide by Yichou, this results in a dense, pressure-tight component with a superior microstructure that can be heat-treated and welded.

Versus Forging

Forging is renowned for producing parts with exceptional strength and fatigue resistance. However, it is generally limited to simpler geometries and involves significant material waste and post-process machining to achieve the final shape. Squeeze casting provides a cost-effective alternative for complex components that require high strength. It creates near-net-shape parts, drastically reducing machining costs and material scrap. While forging may still offer superior strength in a single direction for simple shapes, squeeze casting delivers excellent, more isotropic (multi-directional) mechanical properties in complex, three-dimensional designs that are impossible or prohibitively expensive to forge. For applications requiring the ultimate strength of forged parts, especially in the automotive sector, specialized providers are essential. For instance, Shaoyi (Ningbo) Metal Technology offers precision-engineered automotive forging parts, demonstrating the distinct expertise required for that high-performance process.

Process Comparison Overview

| Parameter | Squeeze Casting | High-Pressure Die Casting (HPDC) | Forging |

|---|---|---|---|

| Porosity Level | Virtually zero | Moderate to high (gas and shrinkage) | None (solid-state process) |

| Mechanical Properties | Excellent; heat-treatable | Good; not typically heat-treatable | Superior (directional strength) |

| Geometric Complexity | High (complex shapes, internal cores) | High (thin walls, high detail) | Low to moderate |

| Cost-Effectiveness | Excellent for complex, high-performance parts | Excellent for high-volume, less critical parts | High due to machining and material waste |

Materials and Achievable Mechanical Properties

The squeeze casting process is particularly well-suited for non-ferrous alloys, most notably aluminum and magnesium. The combination of high pressure and controlled solidification allows these materials to reach their maximum performance potential, often exceeding the properties achievable through other casting methods. The ability to produce sound, dense microstructures makes it possible to use high-performance alloys that can be further enhanced through heat treatment.

Common aluminum alloys used in squeeze casting include A356, A380, AlSi9Mg, and AlSi10Mg. Each of these alloys offers a different balance of strength, ductility, and castability. For example, A356 and its variants are known for their excellent strength and ductility after heat treatment, making them a prime choice for structural components that require high reliability. A380 is a more common die-casting alloy, but when used in squeeze casting, its properties are significantly improved due to the reduction in porosity.

For engineers and designers, having access to reliable mechanical property data is essential for material selection. The data below, based on information provided by CEX Casting for their indirect squeeze casting process, illustrates the typical performance that can be expected from various alloys. This quantitative data demonstrates the tangible benefits of the process and allows for precise engineering calculations when designing critical components.

Mechanical Properties of Common Squeeze Cast Alloys

| Alloy Type | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

|---|---|---|---|---|

| A356 | 270 | 240 | 7-10 | 95-105 |

| A356.2 | 280 | 250 | 8-12 | 100-110 |

| A380 | 310 | 290 | 2-4 | 90-100 |

| AlSi9Mg | 250 | 220 | 10-12 | 85-95 |

| AlSi10Mg | 280 | 240 | 8-10 | 90-100 |

| AlSi9Cu3 | 290 | 250 | 7-9 | 95-105 |

Data sourced from CEX Casting for the indirect squeeze casting process.

Choosing the Right Process for Critical Components

The squeeze casting process represents a significant advancement in metal forming, offering a powerful solution for engineers facing the challenge of designing lightweight, complex, and highly reliable components. By combining the most desirable attributes of casting and forging, it delivers a unique value proposition: near-net-shape parts with superior mechanical integrity and virtually no porosity.

The key takeaway is that squeeze casting is not a universal replacement for all other methods but rather a premium, high-performance option for specific applications. It excels where traditional die casting fails to provide the required strength and integrity, and where forging is too costly or geometrically restrictive. Its ability to produce heat-treatable, weldable, and pressure-tight parts makes it indispensable for safety-critical components in the automotive, aerospace, and defense industries.

Ultimately, the decision to use squeeze casting—and whether to opt for the direct or indirect method—depends on a thorough analysis of the part's design, performance requirements, and economic constraints. By understanding its fundamental principles and comparing its capabilities against other manufacturing techniques, designers and engineers can leverage this process to push the boundaries of component performance and innovation.

Frequently Asked Questions

1. What are the main applications of squeeze casting?

Squeeze casting is primarily used for safety-critical and high-performance components where structural integrity is paramount. Common applications include automotive parts like suspension knuckles, control arms, and brake calipers; aerospace structural fittings and housings; and high-performance industrial equipment that requires pressure tightness and high strength.

2. Is squeeze casting more expensive than die casting?

The initial tooling and cycle times for squeeze casting can be higher than for conventional high-pressure die casting, which may result in a higher piece price. However, for complex, high-strength parts, it is often more cost-effective than forging due to its near-net-shape capabilities, which drastically reduce material waste and expensive machining operations. The total cost depends on the component's complexity, volume, and performance requirements.

3. Can steel be used in squeeze casting?

While theoretically possible, squeeze casting is predominantly used for non-ferrous alloys with lower melting points, such as aluminum, magnesium, and copper. The high temperatures and pressures required for ferrous metals like steel pose significant challenges for die life and process control, making it generally impractical and uneconomical compared to other methods like forging or investment casting for steel components.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —