Single-Stage vs. Progressive Die: A Technical Comparison

TL;DR

Single-stage dies perform one distinct metal stamping operation per press stroke, making them a cost-effective choice for simple parts, prototypes, and low-volume production runs. In contrast, progressive dies utilize a fully automated system that feeds a continuous metal coil through multiple stations, performing a sequence of operations in a single press stroke. This method is exceptionally efficient and ideal for producing complex parts in high volumes with high repeatability.

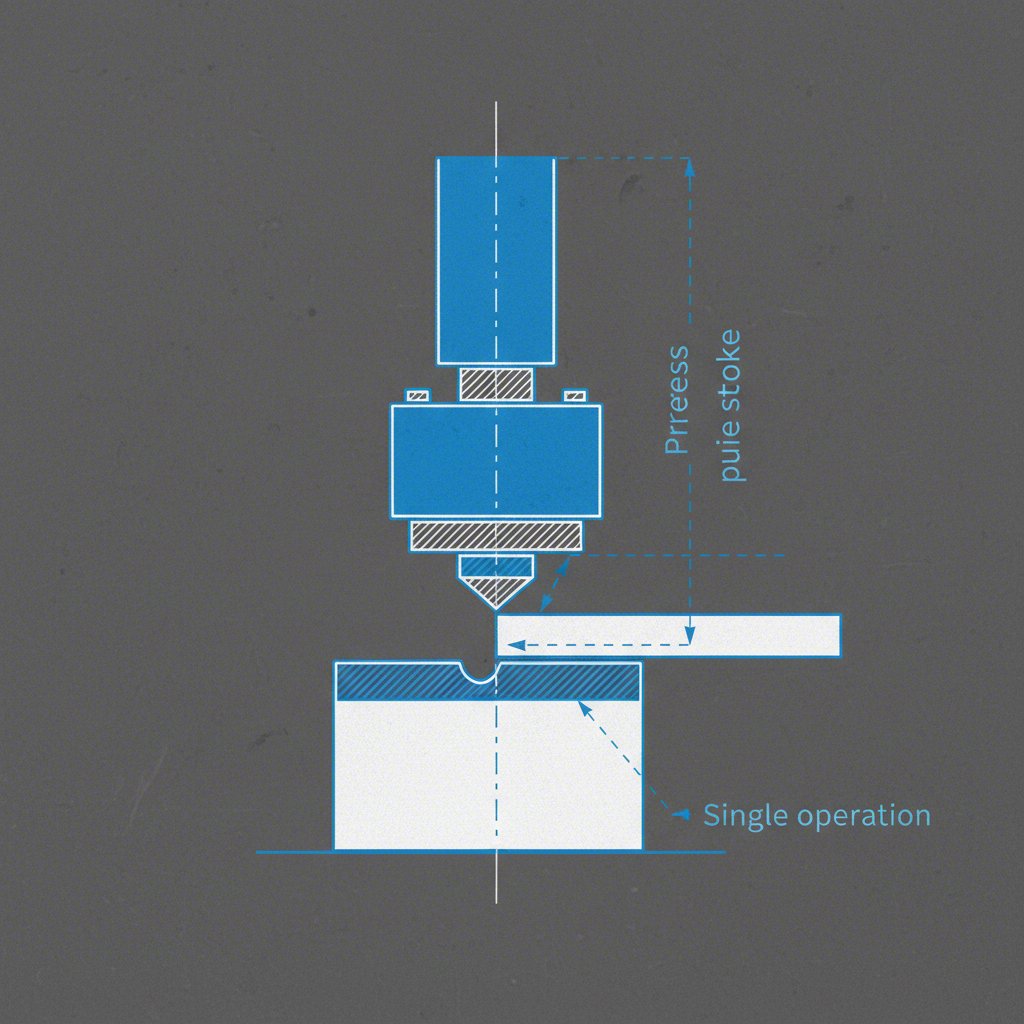

Understanding the Fundamentals: What Is a Single-Stage Die?

A single-stage die, often referred to as a manual or single-operation die, represents a foundational approach in metal stamping. Its core principle is simplicity: the die is designed to perform one specific operation with each stroke of the press. This could be a straightforward task like punching a hole, making a single bend, or blanking a part from a larger sheet of metal. The process typically involves an operator manually feeding the material or part into the press for each operation, although semi-automatic loading is also possible.

The design of single-stage tooling is uncomplicated, which translates to significant advantages in certain manufacturing scenarios. Because the tool only needs to accomplish one task, its design, fabrication, and setup are relatively quick and inexpensive. This makes it an excellent choice for projects where speed to market is critical, such as creating prototypes or executing pilot runs to test a new design. The flexibility to quickly change tooling for different operations also accommodates design iterations with minimal downtime and cost.

However, the simplicity of single-stage dies also comes with limitations, primarily related to production speed and labor intensity. Since each operation requires a separate press cycle and often manual handling, the overall throughput is significantly lower than automated alternatives. For complex parts requiring multiple steps—like a series of bends, holes, and cuts—the process becomes a sequence of separate operations, increasing both time and the potential for error. This makes it less suitable for high-volume production where efficiency and per-unit cost are primary drivers.

Key characteristics of single-stage dies include:

- Pros: Low initial tooling cost, fast lead times for tool creation, simple and easy-to-set-up structure, and high flexibility for design changes.

- Cons: Slower production rates, higher labor costs due to manual part handling, and inefficiency for complex parts requiring multiple operations.

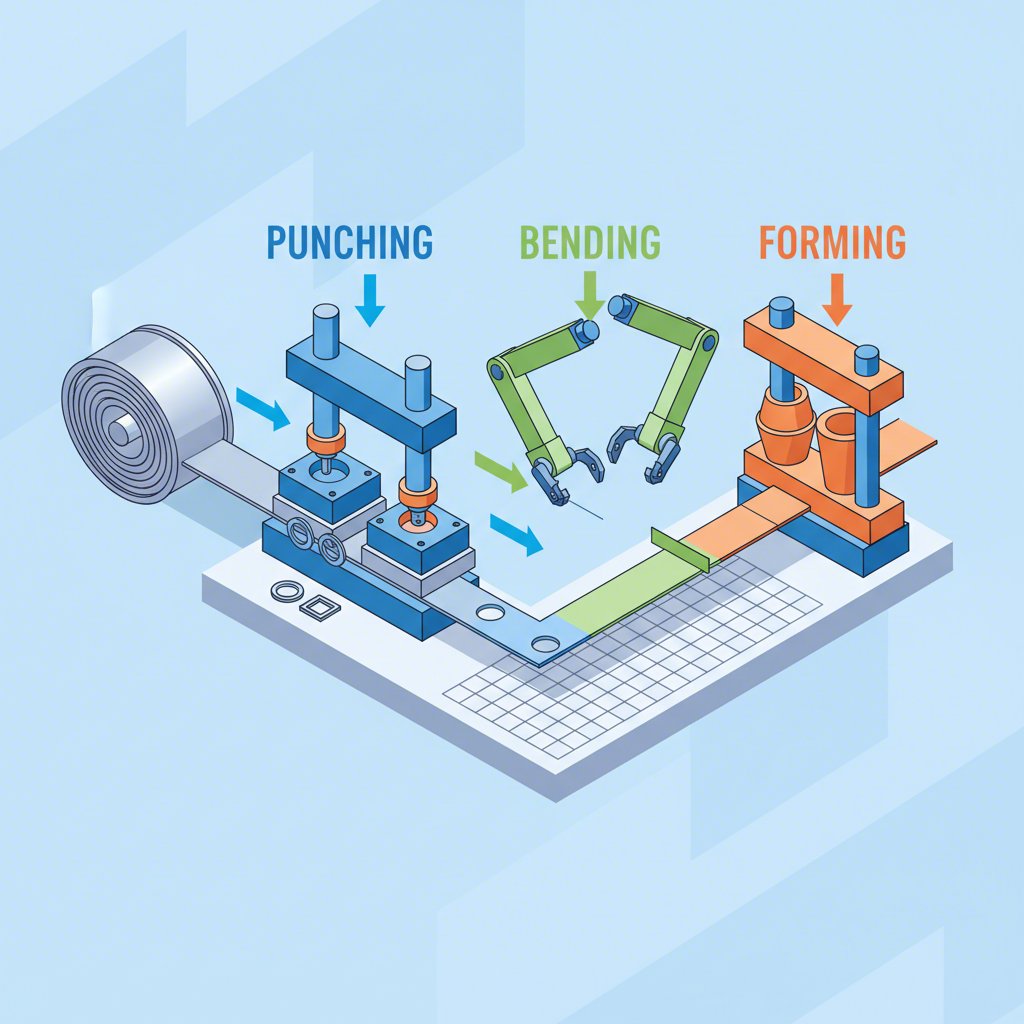

The High-Volume Powerhouse: What Is a Progressive Die?

Progressive die stamping is a highly efficient, automated manufacturing process designed for mass production. Unlike its single-stage counterpart, a progressive die performs multiple operations simultaneously across several stations integrated into a single tool. The process begins with a continuous coil of sheet metal being automatically fed into the press. As this metal strip 'progresses' through the die, each station performs a distinct operation—such as cutting, punching, bending, or coining—in a precise sequence.

The ingenuity of this process lies in its automation and precision. The metal strip remains connected throughout the sequence, held in place by pilot holes that ensure perfect alignment as it moves from one station to the next. By the time the strip reaches the final station, a completed part is cut from it. This continuous, uninterrupted operation allows for extremely high production rates, making it possible to manufacture thousands or even millions of identical parts with exceptional consistency and tight tolerances. This level of repeatability is critical in industries like automotive, electronics, and aerospace.

The primary trade-off for this incredible efficiency is the complexity and cost of the tooling. Progressive dies are intricate, requiring expert design and precision engineering, which leads to a higher upfront investment and longer lead times for die manufacturing. Any damage to a single station can necessitate removing the entire die set for repairs, potentially causing significant downtime. Because of these factors, progressive die stamping is best suited for high-volume orders where the initial tooling cost can be amortized over a large number of parts, resulting in a very low per-unit cost in the long run.

Key characteristics of progressive dies include:

- Pros: Extremely high production rates, reduced labor costs due to automation, high repeatability and consistency, and minimal material waste.

- Cons: High upfront tooling investment, longer lead times for die manufacturing, and greater complexity in design and maintenance.

Head-to-Head Comparison: Single-Stage vs. Progressive Die

Choosing between a single-stage and a progressive die depends entirely on the specific requirements of a project. While both shape metal, they serve different ends of the manufacturing spectrum. A direct comparison across key factors highlights their distinct advantages and ideal use cases. The fundamental difference, as noted by experts at Chia Chang, is that single-stage dies perform one operation per stroke, while progressive dies use multiple stations for continuous, automated production. This core distinction drives all other differences in cost, speed, and application.

The following table breaks down the critical differences between the two processes:

| Factor | Single-Stage Die | Progressive Die |

|---|---|---|

| Process | Performs one operation per press stroke. Typically requires manual or semi-automatic part feeding. | Performs multiple sequential operations in a single press stroke using an automated coil feeding system. |

| Production Volume | Ideal for low-volume runs, prototypes, and pilot projects. | Best suited for high-volume, mass production (thousands to millions of parts). |

| Speed | Slower overall throughput due to separate operations and part handling. | Extremely high production rates due to continuous, automated operation. |

| Part Complexity | Best for simple parts with one or two features. Complex parts require multiple setups. | Excellent for complex parts requiring multiple bends, cuts, and forms in a single cycle. |

| Tooling Cost & Lead Time | Low initial cost and short lead time (typically 3-4 weeks). | High initial investment and longer lead time (typically 4-6 weeks or more). |

| Labor Costs | Higher per-part labor costs due to manual handling and multiple setups. | Very low labor costs due to unattended, automated machine operation. |

| Material Waste | Can be higher if multiple setups are required for a complex part. | Generally lower due to optimized strip layout, though a carrier strip is required. |

| Ideal Applications | Prototypes, small-batch orders, simple brackets, and single-bend components. | Automotive components, electrical connectors, appliance parts, and other high-volume, complex parts. |

In essence, the decision is a classic trade-off between upfront investment and long-term operating costs. A single-stage die offers a low barrier to entry for manufacturing, making it perfect for testing a design or fulfilling a small order. In contrast, a progressive die is a long-term investment in efficiency, designed to produce parts at a scale and speed that single-stage tooling cannot match, ultimately driving down the per-part cost significantly on large runs.

How to Choose the Right Stamping Process for Your Project

Selecting the correct stamping die is a critical decision that directly impacts production efficiency, part quality, and overall project cost. The choice is not merely about which process is 'better,' but which is best aligned with your specific needs. Key considerations, as outlined by manufacturing experts at JV Manufacturing Co., include production volume, part complexity, and budget. By carefully evaluating these factors, you can make an informed decision that optimizes your manufacturing outcome.

Production Volume and Project Lifespan

The first and most important question to ask is: how many parts do you need? For prototypes, pilot runs, or low-volume production (typically in the hundreds or low thousands), a single-stage die is almost always the most cost-effective solution. Its low tooling cost provides a quick return on investment. Conversely, for high-volume runs stretching into the tens of thousands or millions, the high-speed, automated nature of a progressive die will deliver a far lower cost-per-part, easily justifying the significant initial tooling investment.

Part Complexity and Geometry

How intricate is your part design? Single-stage dies are well-suited for simple geometries—flat parts, components with a single bend, or parts requiring basic piercing. If your design involves multiple bends, intricate cuts, and complex forms, a progressive die is superior. It can perform all these operations in a single, highly controlled sequence, ensuring tight tolerances and consistency that would be difficult and time-consuming to achieve with multiple single-stage setups.

Budget and Return on Investment (ROI)

Your budget will heavily influence your choice. If you have limited upfront capital, the low initial cost of single-stage tooling is highly attractive. However, you must also consider the total cost of ownership. For a long-term, high-volume project, the higher per-part labor costs of single-stage stamping can eventually exceed the initial savings. A progressive die, while expensive upfront, offers a much better long-term ROI for sustained mass production through automation and speed. For industries with stringent requirements like automotive, partnering with a specialist in custom stamping dies is crucial. For instance, Shaoyi (Ningbo) Metal Technology Co., Ltd. provides comprehensive solutions from prototyping to mass production for OEMs, leveraging advanced simulations to optimize die design for efficiency and quality.

Material Type and Thickness

Finally, consider the material you are working with. While both processes can handle a variety of metals, the properties of the material can influence the die design. Harsher materials like stainless steel may require more robust and wear-resistant dies, which can increase the cost and complexity of both tooling types. Thicker materials also demand more force, which could favor a simpler, more robust single-stage setup for certain applications or necessitate a more powerful and expensive progressive die system.

Frequently Asked Questions

1. What is the difference between a single die and a progressive die?

A single die, or single-stage die, performs only one stamping process (like cutting or bending) per press stroke. In contrast, a progressive die completes multiple stamping processes across several different stations within a single tool as a continuous strip of metal is fed through it.

2. What are the different types of stamping dies?

Besides single-stage and progressive dies, other common types include compound dies, which perform multiple cutting operations in a single station, and transfer dies, which move an individual part from one station to another for sequential operations. Each type is suited for different levels of part complexity and production volume.

3. What is the difference between stage tooling and progressive tooling?

Stage tooling is another term for single-stage tooling. The primary difference is in speed and volume. Stage tooling is slower and better for small, low-volume production runs, whereas progressive tooling (or progressive die stamping) is very fast and designed for large-scale production.

4. How much does a progressive die cost?

The cost of a progressive die varies significantly based on the part's size and complexity. Tooling costs can range from under $10,000 for small, simple parts to well over $100,000 for large, intricate designs. The high cost reflects the complex engineering required to ensure all stations work in perfect synchronization.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —