Cast Iron for Automotive Dies: The Science of Strength

TL;DR

Cast iron, particularly gray and ductile (nodular) grades, is the preferred material for large automotive stamping dies. This is due to its exceptional combination of high compressive strength, excellent vibration damping, superior wear resistance, and overall cost-effectiveness. To achieve the durability and flawless surface finish required for stamping modern automotive body panels, specialized manufacturing processes and advanced surface treatments like ion nitriding are essential.

Why Cast Iron Is the Material of Choice for Automotive Dies

In the high-pressure world of automotive manufacturing, the tools used to shape vehicle bodies must withstand immense and repetitive forces. Large stamping dies, which press sheet metal into complex forms like doors and hoods, require a material that is both incredibly strong and exceptionally stable. Cast iron has long been the industry standard for this demanding application, offering a unique blend of properties that are difficult to match with other metals, including many steels. Its suitability stems from fundamental characteristics that translate directly into higher-quality parts and a more efficient production line.

The primary advantage of cast iron is its remarkable compressive strength, which allows it to bear heavy loads without deforming. As detailed by industry analyses from sources like Sinoway Industry, this property is critical in stamping operations where millions of cycles are expected over a die's lifetime. Furthermore, cast iron possesses superior vibration damping capabilities. During the violent impact of a stamping press, it absorbs energy and reduces chatter, which is crucial for maintaining dimensional accuracy and achieving a smooth surface finish on the final automotive part. This inherent stability minimizes tool wear and helps prevent defects in the stamped panels.

Beyond its mechanical performance, cast iron provides significant economic and manufacturing advantages. It is generally more cost-effective to produce than forged steel billets of a comparable size, a key consideration for the massive dies used in auto manufacturing. The material also exhibits excellent castability, meaning it can be poured into complex mold shapes to create near-net-shape dies, reducing the amount of subsequent machining required. This combination of performance and value makes it an indispensable material in the automotive sector.

- High Compressive Strength: Withstands extreme stamping forces without losing its shape, ensuring consistent part quality.

- Superior Vibration Damping: Absorbs operational vibrations, leading to greater stability, reduced tool wear, and a better surface finish.

- Excellent Wear Resistance: The material's hardness provides a long service life, even in abrasive conditions with high metal-on-metal friction.

- Cost-Effectiveness: Offers a highly competitive balance of performance and affordability compared to materials like forged steel.

- Good Machinability: Can be machined efficiently to achieve the precise final dimensions and intricate features required for modern vehicle designs.

Key Types of Cast Iron Used in Die Manufacturing

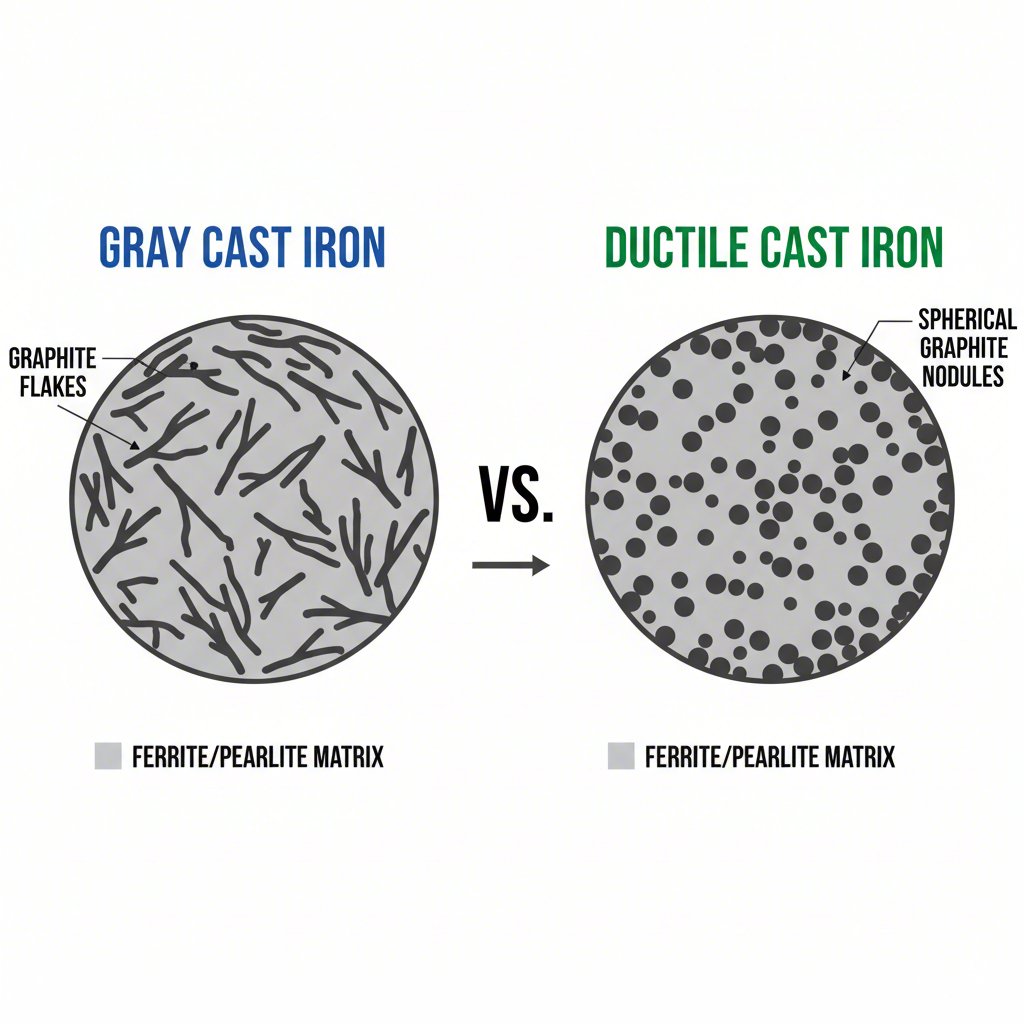

Not all cast iron is created equal. The specific properties of a cast iron alloy are determined by its microstructure, particularly the form that the free carbon (graphite) takes within the iron matrix. For large automotive dies, two main types dominate: gray cast iron and ductile cast iron (also known as nodular or spheroidal graphite iron). The choice between them depends on the specific application, the stresses involved, and the desired balance between performance and cost.

Gray cast iron is the most traditional and widely used type. Its name comes from the gray appearance of a fractured surface, which is caused by the presence of graphite flakes. According to an in-depth comparison by MAT Foundry Group, these flakes give gray iron excellent machinability and unmatched vibration damping capacity. However, these same sharp-edged flakes act as internal stress concentration points, making gray iron brittle and giving it relatively low tensile strength and impact resistance. It is best suited for die components that are under high compressive loads but do not experience significant tensile stress or sharp impacts, such as the main body or base of a die set.

Ductile iron, a more modern innovation, transforms the graphite into small, spherical nodules through the addition of inoculants like magnesium. This seemingly small change has a profound effect on its mechanical properties. The rounded shape of the nodules eliminates the internal stress points found in gray iron, making the material far stronger, tougher, and, as its name suggests, more ductile. It can bend and deform significantly before fracturing, giving it superior tensile strength and impact resistance. This makes ductile iron the ideal choice for critical die components that face higher stresses, such as punches, binders, and inserts that perform the primary shaping and cutting operations.

Gray Iron vs. Ductile Iron: A Technical Comparison

| Property | Gray Cast Iron | Ductile (Nodular) Cast Iron |

|---|---|---|

| Graphite Structure | Flakes | Spheres (Nodules) |

| Tensile Strength | Low (e.g., up to 276 N/mm²) | High (e.g., up to 827 N/mm²) |

| Ductility & Elongation | Very Low (Brittle) | High (Can deform without fracturing) |

| Impact Resistance | Poor | Excellent |

| Vibration Damping | Excellent | Good |

| Common Applications | Die shoes, machinery bases, engine blocks | Die punches, gears, high-pressure pipes |

The Manufacturing and Surface Treatment Process

Creating a large automotive die from cast iron is a multi-stage process that demands considerable expertise in metallurgy, casting, machining, and surface engineering. The journey from raw material to a finished, press-ready tool involves several critical steps, each contributing to the die's final performance and longevity. The initial phase is casting, where molten iron is poured into a sand mold created from a pattern of the die. This process, often sand casting for large components as described by casting specialists at Metco, forms the rough, oversized shape of the die.

Once the casting has cooled and solidified, it moves to the machining stage. As noted by tooling experts at Sandvik Coromant, this requires advanced metalworking skills to cut the rough casting down to its precise final dimensions. Multi-axis CNC milling machines are used to create the complex, curved surfaces that will form the vehicle's body panels. This is a time-consuming and meticulous process, as the final surface must be perfectly smooth and accurate to within fractions of a millimeter. Finding a manufacturing partner with proven expertise is crucial. For instance, providers like Shaoyi (Ningbo) Metal Technology Co., Ltd. specialize in custom automotive stamping dies, leveraging advanced simulations and project management to deliver high-quality tools for OEMs and Tier 1 suppliers.

The final and perhaps most critical step for ensuring performance is surface treatment. An untreated cast iron surface, while hard, is susceptible to adhesion (galling) and wear when stamping coated or high-strength steels. To combat this, the working surfaces of the die undergo a hardening process. According to Advanced Heat Treat Corp., a leading method is ion nitriding, a thermochemical treatment that diffuses nitrogen into the surface. This creates an extremely hard, wear-resistant, and lubricious case layer that prevents metal-on-metal friction, reduces scratching, and allows the die to maintain a superior A-class finish throughout high-volume production runs.

- Casting: Molten gray or ductile iron is poured into a sand mold to create the initial, near-net shape of the die.

- Stress Relieving: The raw casting is heat-treated to relieve internal stresses created during cooling, ensuring dimensional stability.

- Precision Machining: The casting is milled, drilled, and ground using CNC machinery to achieve the exact final geometry and surface contours.

- Surface Hardening: The finished surfaces undergo ion nitriding or a similar treatment to create a durable, low-friction case that resists wear and galling.

- Final Polishing & Assembly: The treated surfaces are polished to a mirror-like finish, and the various components of the die set are assembled and tested.

Making the Right Material Choice for Longevity

In conclusion, the selection of cast iron for large automotive stamping dies is a deliberate engineering choice rooted in a deep understanding of material science and manufacturing economics. The material's inherent compressive strength, ability to dampen vibration, and excellent wear resistance provide a robust foundation for tools that must perform reliably under extreme conditions. By choosing between gray iron for its stability and cost-effectiveness and ductile iron for its superior strength and impact resistance, engineers can optimize the performance and lifespan of each component within a die set.

However, the raw material is only part of the equation. The sophisticated processes of precision machining and advanced surface treatments like ion nitriding are what unlock cast iron's full potential. These steps transform a rough casting into a high-performance tool capable of producing millions of flawless automotive parts. Ultimately, the continued dominance of cast iron in this application is a testament to its unparalleled combination of performance, manufacturability, and value.

Frequently Asked Questions

1. What is the most suitable material for large stamping dies?

For large automotive stamping dies, cast iron, specifically gray cast iron for bases and ductile (nodular) cast iron for high-stress components, is the most suitable and widely used material. This is due to its excellent compressive strength, vibration damping, wear resistance, and cost-effectiveness for producing such large tools.

2. Why is surface treatment necessary for cast iron dies?

Surface treatment, such as ion nitriding, is necessary to significantly increase the surface hardness and reduce friction. This prevents common issues like galling (adhesion) and scoring when stamping modern coated or high-strength steels. It ensures the die maintains a superior surface finish and extends its operational life.

3. Is cast iron still relevant in modern automotive manufacturing?

Absolutely. Despite the availability of advanced steels and other alloys, cast iron remains highly relevant for applications like large stamping dies and engine blocks. Its unique combination of mechanical properties, excellent castability into complex shapes, and overall economic advantages make it an ideal choice for many high-volume automotive components.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —