Rapid Prototyping for Automotive Dies: A Strategic Overview

TL;DR

Rapid prototyping for automotive dies is a set of advanced manufacturing techniques used to quickly fabricate functional metal components and tooling directly from digital CAD designs. This process is essential for the modern automotive industry because it drastically accelerates product development, allowing engineers to test and validate parts for form, fit, and function in days instead of the months required by traditional methods. The primary benefits include significant cost savings on initial tooling, reduced time-to-market, and the ability to refine designs through multiple iterations before committing to mass production.

What Is Rapid Prototyping for Automotive Dies and Stamping?

Rapid prototyping is a foundational process in modern product development that quickly fabricates a scale model or a fully functional part from an initial design, typically a Computer-Aided Design (CAD) file. In the context of the automotive industry, it serves as a critical bridge between digital design and physical testing before committing to the high costs and long lead times of production tooling for dies and metal stamping. It allows engineers and designers to hold a tangible version of a component, enabling them to evaluate its design, ergonomics, and functionality in a real-world setting.

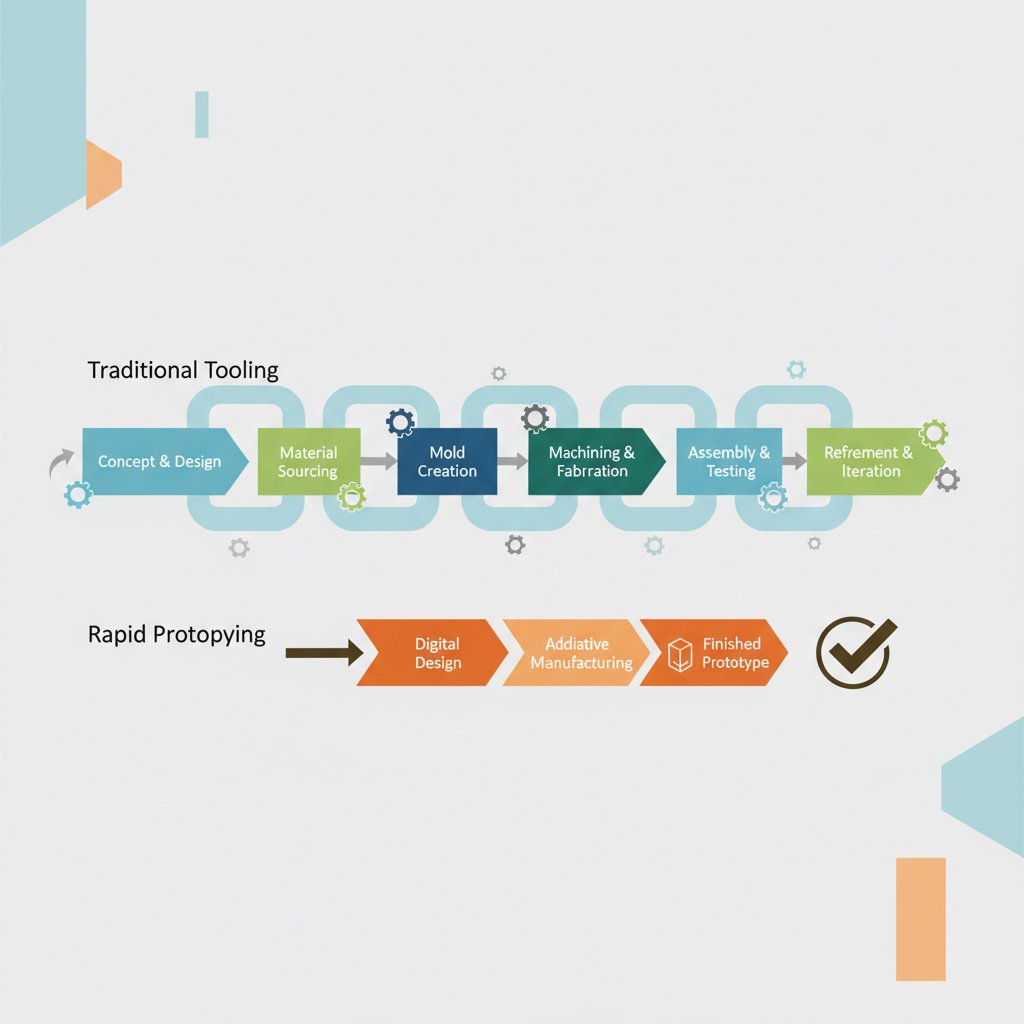

The traditional method of creating automotive dies is a meticulous, time-consuming, and expensive endeavor, often taking months to complete. Rapid prototyping fundamentally disrupts this timeline. As detailed by industry experts, this approach can produce models within days or even hours, transforming ideas into physical parts with incredible speed. This acceleration is not just about speed; it's about agility. It provides engineering teams the opportunity to identify design flaws, test material properties, and make crucial adjustments early in the development cycle, which prevents costly errors from reaching the mass production stage.

Key characteristics of rapid prototyping for automotive components include:

- Speed: Drastically reduces the time from design conception to physical part, enabling faster development cycles.

- Iteration: Facilitates the creation of multiple design versions for testing and evaluation, leading to a more optimized final product.

- Cost-Efficiency: Lowers the initial investment by avoiding the need for expensive and permanent production tooling during the validation phase.

- Material Testing: Allows for the use of various materials, from plastics to production-grade metals like aluminum and steel, to ensure the final part meets performance standards.

This process is applied to a wide range of automotive parts, from small, intricate microstampings and electrical connectors to larger components like brackets and body panels. By leveraging rapid prototyping, manufacturers can validate their designs with confidence, ensuring that the final parts produced by production dies are flawless. For companies specializing in complex components, like DIE-TECH's work with metal microstamping, this early validation is essential for success.

Core Benefits: Accelerating Automotive Innovation

The adoption of rapid prototyping for automotive dies and metal parts offers a suite of compelling advantages that directly impact a company's competitiveness and bottom line. These benefits extend beyond simple speed, influencing everything from design quality to overall project risk. By creating physical parts early and often, automotive manufacturers can make more informed decisions, leading to superior final products and a more efficient path to market.

One of the most significant benefits is the dramatic acceleration of the product development timeline. Traditional tooling processes can take several months, creating a major bottleneck in vehicle development. Rapid prototyping compresses this timeline into a matter of days or weeks. This speed allows for quicker design validation, enabling teams to test form, fit, and function long before committing to final production tooling. This rapid feedback loop means new vehicles and components can reach the market much faster, satisfying consumer demand and providing a crucial competitive edge.

Cost reduction is another primary advantage. While the per-part cost of a prototype may be higher than a mass-produced component, the overall savings are substantial. Prototyping allows for the identification and correction of design flaws at a fraction of the cost of modifying hardened steel production dies. As explained by service providers like Wiegel Tool Works, testing concepts in the early phases prevents mass production issues and saves significant time and money down the line. This risk mitigation is invaluable, as a single flaw in a production die can lead to thousands of faulty parts and expensive retooling.

The core benefits can be summarized as follows:

- Reduced Time-to-Market: Compressing development cycles from months to weeks allows companies to introduce new products faster.

- Significant Cost Savings: Avoids expensive modifications to production tools by validating designs with low-cost prototypes.

- Enhanced Design Verification: Enables tangible, hands-on testing of a part's form, fit, and function, leading to a more reliable and higher-quality final product.

- Greater Design Flexibility: Engineers can experiment with multiple design iterations and materials to optimize performance without the constraints of traditional manufacturing.

- Improved Collaboration: Physical models facilitate clearer communication between design, engineering, and manufacturing teams, ensuring everyone is aligned.

Key Techniques for Prototyping Automotive Metal Parts

The automotive industry employs several distinct rapid prototyping technologies to create metal parts, each with its own strengths and ideal applications. The choice of technique depends on factors like part complexity, required material properties, production volume, and budget. Understanding these methods is crucial for engineers and designers to select the most effective path for their project.

CNC Machining

CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computer-controlled machines to cut and shape blocks of metal into finished parts. It is renowned for its high precision and ability to work with a wide range of production-grade metals, including steel, aluminum, and brass. For automotive applications requiring tight tolerances and excellent surface finish, CNC machining is often the preferred method. It is ideal for creating functional prototypes of engine components, brackets, and fixtures where accuracy is paramount.

Laser Cutting and Custom Forming

For parts that are more two-dimensional, such as brackets, panels, or gaskets, laser cutting offers a fast and cost-effective solution. A high-powered laser cuts sheet metal based on a CAD file, producing clean edges and simple parts very quickly. When more complex three-dimensional shapes are needed from sheet metal, custom stamping and forming techniques are used. These processes use dies to bend, stretch, or shape the metal into its final form. While creating the initial forming tools can be more involved than a simple laser cut, it is essential for prototyping parts that will eventually be mass-produced via stamping.

Metal 3D Printing (DMLS)

Direct Metal Laser Sintering (DMLS), a form of 3D printing, is an additive manufacturing process that builds metal parts layer by layer from a powdered metal. A laser fuses the powder according to the digital design, allowing for the creation of incredibly complex internal geometries that would be impossible to achieve with traditional machining. This technology is perfect for lightweighting initiatives and creating consolidated, highly optimized parts for performance applications like engine components or suspension parts.

To help in selecting the right process, here is a comparison of the key techniques:

| Technique | Speed | Material Options | Cost per Part | Best For... |

|---|---|---|---|---|

| CNC Machining | Moderate to Fast | Wide (Steel, Aluminum, Brass, Titanium) | Moderate | High-precision functional parts with tight tolerances. |

| Laser Cutting | Very Fast | Sheet Metals (Steel, Aluminum) | Low | Simple, flat, or 2D-shaped brackets and panels. |

| Custom Stamping/Forming | Moderate | Sheet Metals | Low to Moderate (after tooling) | Complex sheet metal parts that mimic final production. |

| Metal 3D Printing (DMLS) | Moderate | Good (Titanium, Aluminum, Stainless Steel) | High | Complex geometries, lightweight parts, and consolidated assemblies. |

How to Select the Right Rapid Prototyping Partner

Choosing the right rapid prototyping partner is as critical as the design itself. The quality of the prototype, the speed of delivery, and the engineering insights provided by a vendor can significantly impact a project's success. As the automotive industry demands precision, speed, and expertise, evaluating potential suppliers on a few key criteria is essential for making an informed decision.

First and foremost, consider a partner's experience and specialization. A supplier with a deep history in the automotive sector will understand the industry's stringent standards for quality, materials, and tolerances. For instance, a company that specializes in metal microstamping will have different capabilities than one focused on large body panels. Leading suppliers like Shaoyi (Ningbo) Metal Technology Co., Ltd. demonstrate this by offering comprehensive solutions from rapid prototyping to mass production for OEMs and Tier 1 suppliers, backed by certifications like IATF 16949. This level of specialization ensures they have the right equipment and process controls for your specific needs.

Technical capabilities are another crucial factor. A top-tier partner should offer a range of prototyping technologies, including CNC machining, laser cutting, and progressive die stamping. This allows them to recommend the best-suited process for your part's geometry, material, and functional requirements. Look for suppliers who utilize advanced 3D modeling software and CAE simulations to identify potential manufacturing issues before a single piece of metal is cut. This proactive approach saves time and money by ensuring the design is optimized for manufacturability.

To guide your selection process, consider the following checklist:

- Industry Experience: Do they have a proven track record in the automotive industry with relevant case studies or client testimonials?

- Technical Capabilities: Do they offer a variety of prototyping methods and work with the materials you require?

- Quality Certifications: Are they certified to industry standards like IATF 16949 or ISO 9001?

- Engineering Support: Do they provide design for manufacturability (DFM) feedback to help optimize your part and reduce costs?

- Speed and Agility: Can they meet your project timelines and quickly turn around revisions?

- Scalability: Can they support your project from a single prototype to low-volume and eventually mass production?

By carefully evaluating these factors, you can build a strong partnership with a supplier who not only delivers high-quality prototypes but also acts as a valuable extension of your engineering team, contributing to a smoother and more successful product launch.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —