Essential Strategies for High Strength Steel Die Design

TL;DR

Designing dies for high-strength steel (HSS) stamping requires a fundamentally different approach than for mild steels. The unique properties of HSS, such as high tensile strength and reduced formability, lead to significant challenges like increased springback and higher stamping forces. Success depends on creating exceptionally robust die structures, selecting advanced wear-resistant tool materials and coatings, and leveraging forming simulation software to predict and mitigate issues before manufacturing begins.

Fundamental Challenges: Why HSS Stamping Requires Specialized Die Design

High-Strength Steels (HSS) and Advanced High-Strength Steels (AHSS) are cornerstones of modern manufacturing, particularly in the automotive industry, for creating lightweight yet safe vehicle structures. However, their superior mechanical properties introduce complexities that make conventional die design inadequate. Unlike mild steels, HSS exhibits significantly higher tensile strengths, with some grades exceeding 1200 MPa, coupled with reduced elongation or stretchability. This combination is the primary driver behind the unique challenges in HSS stamping.

The most prominent issue is springback, or the elastic recovery of the material after forming. Due to its high yield strength, HSS has a greater tendency to return to its original shape, making it difficult to achieve dimensional accuracy in the final part. This necessitates specialized die processes that incorporate overbending or post-stretching to compensate. Furthermore, the immense force required to form HSS places extreme stress on the die structure, leading to accelerated wear and a higher risk of premature failure if the die is not built to withstand these loads. According to the High Strength Steel Stamping Design Manual, a process that works for mild steel will not always produce acceptable results for HSS, often leading to defects like splits, cracks, or severe dimensional instability.

These material property differences demand a complete re-evaluation of the die design process. The higher tonnage required not only impacts the press selection but also dictates a more robust die construction. The lower formability of HSS means that part designers must work closely with die engineers to create geometries with more gradual transitions and appropriate radii to avoid material failure during stamping. Without a specialized approach, manufacturers face costly trial-and-error cycles, poor part quality, and damaged tooling.

| Design Aspect | Mild Steel | High-Strength Steel (HSS/AHSS) |

|---|---|---|

| Stamping Force (Tonnage) | Lower, predictable forces. | Significantly higher forces, requiring more powerful presses and robust die structures. |

| Springback Compensation | Minimal; often negligible or easily compensated. | High; a primary design challenge requiring overbending, post-stretching, and simulation. |

| Die Wear Resistance | Standard tool steels are often sufficient. | Requires premium tool steels, surface coatings, and hardened components to prevent premature wear. |

| Structural Rigidity | Standard die set construction is adequate. | Requires heavier, reinforced die sets and guiding systems to prevent deflection under load. |

| Formability Considerations | High elongation allows for deep draws and complex shapes. | Lower elongation limits draw depth and requires careful management of material flow to prevent splits. |

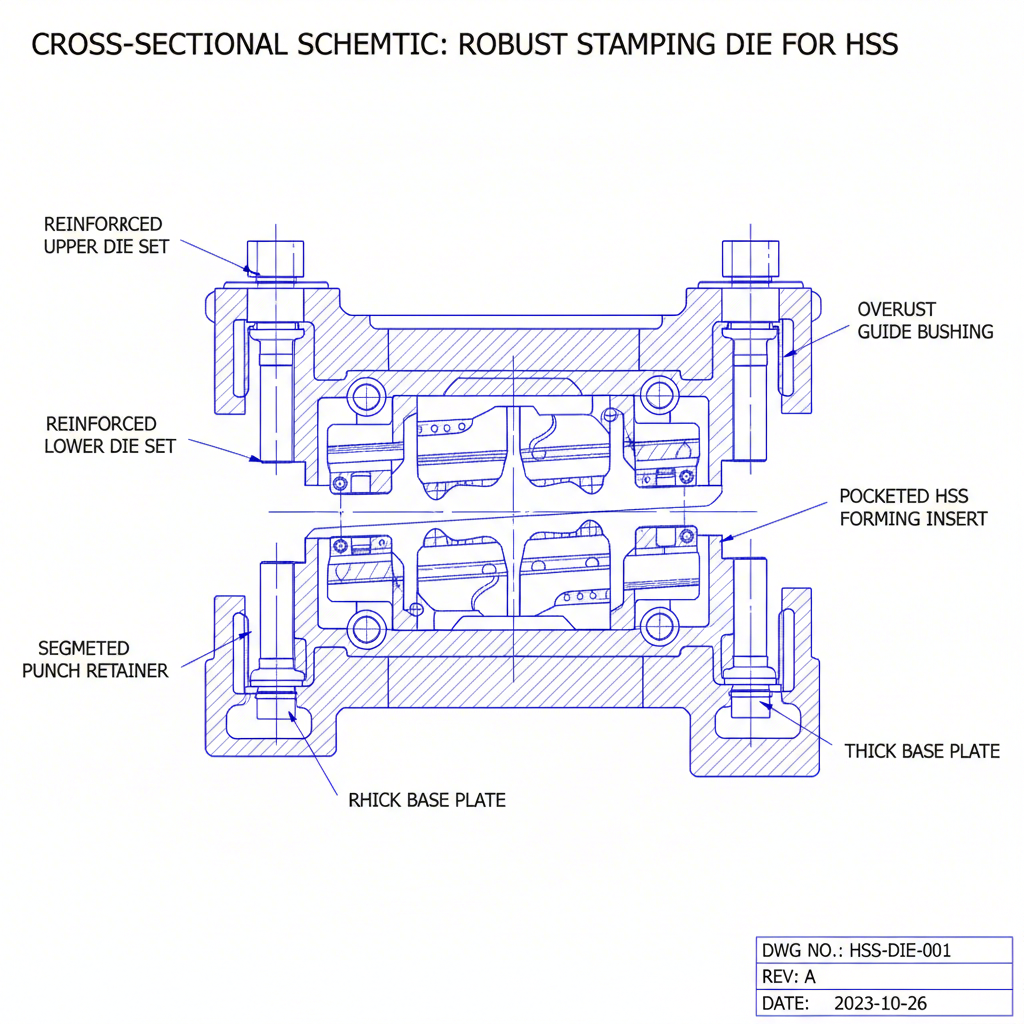

Core Principles of Structural Die Design for HSS/AHSS

To counteract the immense forces and manage the unique behavior of HSS, the structural design of the die must be exceptionally robust. This goes beyond simply using more material; it involves a strategic approach to rigidity, force distribution, and material flow control. The primary goal is to build a die that resists deflection under load, as even minor flexing can lead to dimensional inaccuracies and inconsistent part quality. This often translates to heavier die sets, thicker plates, and reinforced guiding systems to ensure precise alignment between the punch and cavity throughout the press stroke.

Effective management of material flow is another critical aspect of structural design. Features that are optional or less critical for mild steel become essential for HSS. Drawbeads, for example, must be carefully designed and placed to provide precise restraining force, preventing uncontrolled material movement that can cause wrinkles or splits. In some advanced processes, features like a "lockstep" are added to the die to intentionally induce a stretch in the part's sidewalls near the end of the press stroke. This technique, known as post-stretching or "shape-setting," helps to minimize residual stresses and significantly reduce springback.

Designing and building these complex tools requires deep expertise. For instance, leaders in the field like Shaoyi Metal Technology specialize in custom automotive stamping dies, leveraging advanced CAE simulations and project management to deliver high-precision solutions for OEMs. Their work in progressive die design for HSS, which involves multiple forming stations, must be meticulously planned to account for work hardening and springback at each stage. The structure of a multi-station progressive die for HSS is far more complex and must be engineered to handle cumulative stresses across all operations.

Key Structural Design Checklist for HSS Dies

- Reinforced Die Sets: Utilize thicker, higher-grade steel plates for the die shoe and punch holder to prevent flexing.

- Robust Guiding System: Employ larger guide pins and bushings, and consider pressure-lubricated systems for high-load applications.

- Pocketed and Keyed Components: Securely pocket and key all forming steels and inserts into the die shoe to prevent any movement or shifting under pressure.

- Optimized Drawbead Design: Use simulation to determine the ideal shape, height, and placement of drawbeads to control material flow without causing fracture.

- Springback Compensation Features: Design forming surfaces with calculated overbend angles to account for material springback.

- Hardened Wear Plates: Incorporate hardened wear plates in high-friction areas, such as under cam slides or on binder surfaces.

- Sufficient Press Tonnage: Ensure the die is designed for a press with adequate tonnage and bed size to handle the high forming loads without compromising the machine.

Die Material Selection and Component Specifications

The performance and longevity of a die used for stamping high-strength steel are directly tied to the materials used in its construction. The extreme pressures and abrasive forces generated during HSS forming will quickly destroy dies made from conventional tool steels. Therefore, selecting the right materials for critical components like punches, dies, and forming inserts is not an enhancement but a fundamental requirement for a durable and reliable process. The choice depends on the specific HSS grade, production volume, and the severity of the forming operation.

High-performance cold-work tool steels, such as D2 or powdered metal (PM) grades, are often the starting point. These materials offer a superior combination of hardness, toughness, and compressive strength compared to common tool steels. For even greater performance, especially in high-wear areas, advanced surface coatings are applied. Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) coatings create an extremely hard, lubricious surface layer that reduces friction, prevents galling (material transfer from the sheet to the die), and dramatically extends the life of the tool.

Beyond the primary forming surfaces, specialized components are essential for precision and durability. Punches must be specially designed with the right material, geometry, and coating to withstand the high impact and piercing forces. The guiding and locating components, such as nest guides and locating pilot pins, also require hardening and precision grinding to maintain accurate blank positioning, which is critical for part quality in progressive dies. Every component must be specified to handle the elevated demands of HSS stamping.

| Material / Coating | Pros | Cons | Best For |

|---|---|---|---|

| D2 Tool Steel | Good wear resistance, high compressive strength, widely available. | Can be brittle; may not be sufficient for the most extreme AHSS grades. | Forming sections, cutting edges, and general-purpose HSS applications. |

| Powdered Metal (PM) Steels | Excellent toughness and wear resistance, uniform microstructure. | Higher material cost. | High-wear areas, complex forming inserts, and stamping ultra-high-strength steels. |

| PVD Coatings (e.g., TiN, TiCN) | Very high surface hardness, reduces friction, prevents galling. | Thin layer can be damaged by severe impact or abrasive wear. | Punches, forming radii, and areas with high friction and risk of material pickup. |

| Carbide Inserts | Exceptional hardness and wear resistance, very long life. | Brittle, sensitive to shock, and high cost. | Cutting edges, trim steels, and small, high-wear inserts in high-volume production. |

The Role of Simulation in Modern HSS Die Design

In the past, die design for challenging materials relied heavily on the experience and intuition of seasoned designers. This often involved a lengthy and expensive process of physical trial and error. Today, forming simulation software has become an indispensable tool for mastering the complexities of high-strength steel stamping. As highlighted by solution providers like AutoForm Engineering, simulation enables engineers to accurately predict and resolve potential manufacturing issues in a virtual environment, long before any steel is cut for the die.

Stamping simulation software, using Finite Element Analysis (FEA), creates a digital twin of the entire forming process. By inputting the part geometry, HSS material properties, and die process parameters, the software can forecast critical outcomes. It visualizes material flow, identifies areas prone to excessive thinning or splitting, and most importantly, predicts the magnitude and direction of springback. This foresight allows designers to iteratively modify the die design—adjusting drawbeads, modifying radii, or optimizing the blank shape—to develop a stable and capable process from the outset.

The return on investment for simulation is significant. It drastically reduces the need for physical die tryouts, which shortens lead times and lowers development costs. By optimizing the process digitally, manufacturers can improve part quality, reduce material scrap, and ensure a more robust production run. For HSS, where the margin for error is slim, simulation transforms die design from a reactive art into a predictive science, ensuring that complex parts meet the most stringent requirements for safety and performance.

A Typical Simulation Workflow for Die Optimization

- Initial Feasibility Analysis: The process begins by importing the 3D model of the part. A quick simulation is run to assess the general formability of the design with the selected HSS grade, identifying any immediate problem areas.

- Process and Die Face Design: Engineers design the virtual die process, including the number of operations, binder surfaces, and initial drawbead layouts. This forms the basis for the detailed simulation.

- Material Property Definition: The specific mechanical properties of the chosen HSS (e.g., yield strength, tensile strength, elongation) are entered into the software's material database. Accuracy here is crucial for reliable results.

- Full Process Simulation: The software simulates the entire stamping sequence, analyzing stresses, strains, and material flow. It generates detailed reports, including formability plots that highlight risks of splits, wrinkles, or excessive thinning.

- Springback Prediction and Compensation: After the forming simulation, a springback analysis is performed. The software calculates the part's final shape after springback and can automatically generate compensated die surfaces to counteract the distortion.

- Final Validation: The compensated die design is re-simulated to verify that the final stamped part will meet all dimensional tolerances, ensuring a robust and capable manufacturing process.

Integrating Advanced Principles for Modern Die Design

The evolution of die design for high-strength steel stamping marks a significant shift from traditional, experience-based practices to a sophisticated, engineering-driven discipline. The fundamental challenges posed by HSS—namely extreme forces, high springback, and increased wear—have made older methods unreliable and inefficient. Success in this demanding field now hinges on the integration of robust structural engineering, advanced material science, and predictive simulation technology.

Mastering HSS die design is no longer just about building a stronger tool; it is about creating a smarter process. By understanding the underlying material behaviors and utilizing digital tools to optimize every aspect of the die, from its overall structure to the coating on a punch, manufacturers can overcome the inherent difficulties of forming these advanced materials. This integrated approach not only enables the production of complex, high-quality parts but also ensures the reliability and longevity of the tooling itself. As the demand for lightweight and safe components continues to grow, these advanced design principles will remain essential for competitive and successful manufacturing.

Frequently Asked Questions About HSS Die Design

1. What is the single biggest challenge in stamping high-strength steel?

The most significant and persistent challenge is managing springback. Because of the high yield strength of HSS, the material has a strong tendency to elastically recover or warp after the forming pressure is released. Predicting and compensating for this movement is critical to achieving the required dimensional accuracy of the final part and often requires sophisticated simulation and die compensation strategies.

2. How does die clearance differ for HSS compared to mild steel?

Die clearance—the gap between the punch and the die cavity—is typically larger and more critical for HSS. While mild steel can be formed with more generous clearances, HSS often requires a clearance that is a precise percentage of the material thickness to ensure a clean shear during trimming and to control the material accurately during forming. An incorrect clearance can lead to excessive burrs, high stress on cutting edges, and premature die wear.

3. Can the same lubricants be used for HSS and mild steel stamping?

No, HSS stamping requires specialized lubricants. The extreme pressures and temperatures generated at the die surface during HSS forming can cause standard lubricants to break down, leading to friction, galling, and tool damage. High-performance, extreme-pressure (EP) lubricants, including synthetic oils, dry-film lubricants, or specialized coatings, are necessary to provide a stable barrier between the die and the workpiece, ensuring smooth material flow and protecting the tooling.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —