The Critical Role of Die Spotting in Precision Tool Making

TL;DR

Die spotting is a critical quality-control process in tool and die making used to ensure the precision alignment and dimensional accuracy of mold or die halves. It involves applying a colorant, like Prussian blue, to one surface and carefully closing the tool in a specialized spotting press under controlled pressure. By inspecting the color transfer, toolmakers can precisely identify and manually correct high spots or imperfections, guaranteeing that the final manufactured parts meet exact specifications and preventing costly production flaws.

The Fundamental Role of Die Spotting in Ensuring Precision

In the world of high-precision manufacturing, the quality of the final product is directly tied to the perfection of the tools used to create it. Die spotting is the indispensable diagnostic step that bridges the gap between a newly machined tool and a production-ready asset. At its core, the process is a meticulous method of verification. Its primary purpose is to ensure that the two halves of a die or mold—the cavity and the core—mate together with near-perfect alignment and contact. This isn't just about fitting pieces together; it's about controlling how raw material, such as sheet metal or plastic, will flow and form under immense pressure.

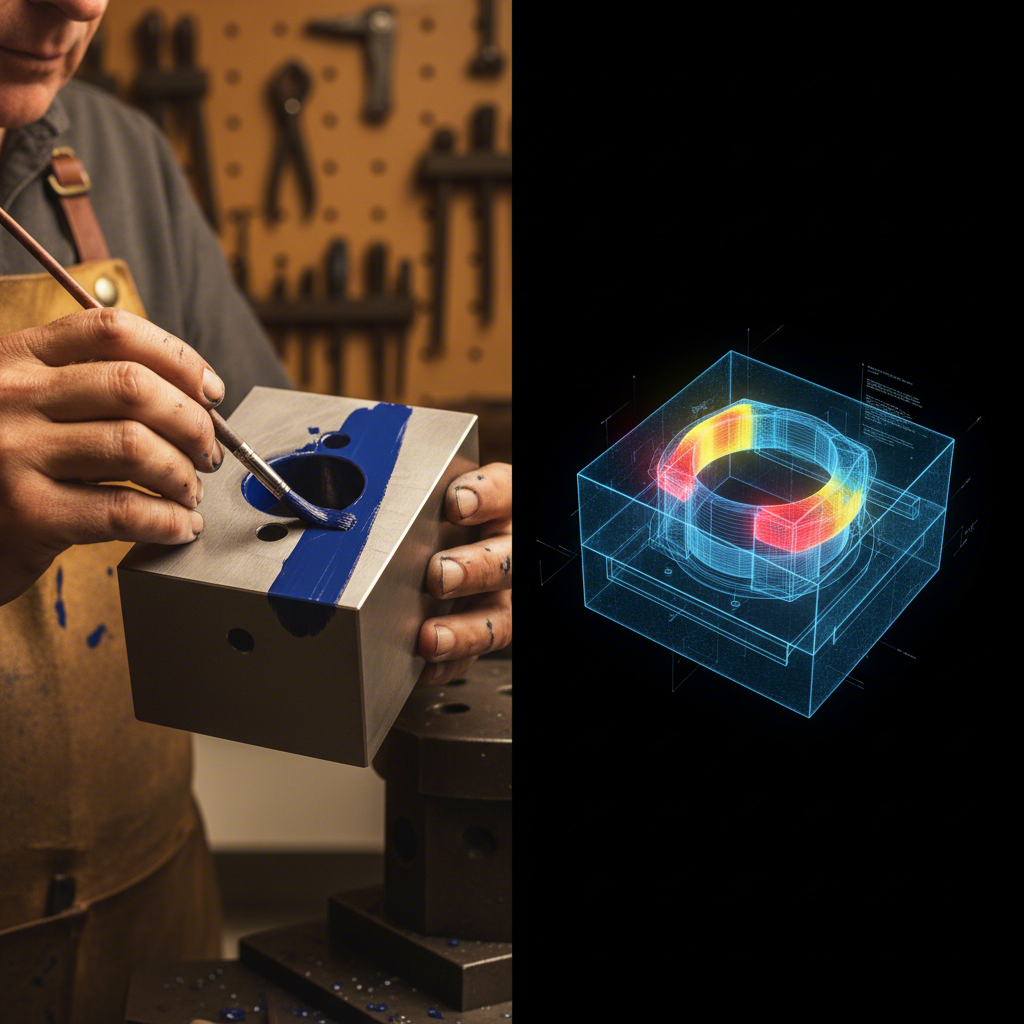

The principle is straightforward yet requires immense skill. A thin, uniform layer of a special, non-drying ink, often called spotting blue, is applied to a master surface of the die. The tool is then placed in a die spotting press and gently closed. When reopened, the ink will have transferred to the opposing surface precisely where contact was made. These marked areas, known as 'high spots,' reveal the exact contact pattern. An incomplete or uneven pattern indicates misalignment or geometric inaccuracies that a toolmaker must painstakingly correct by hand, often by grinding or stoning the surface. This iterative process is repeated until the desired contact percentage—typically 80% or higher—is achieved across the critical surfaces.

Without proper die spotting, manufacturers face significant risks. Even minute inaccuracies in a tool can lead to a host of production defects, such as flashes (excess material leaking from the mold), uneven wall thickness in parts, or surface imperfections. Furthermore, improper alignment can cause extreme, localized pressure on the tool itself, leading to premature wear, chipping, or catastrophic failure. By investing time in spotting, companies ensure not only the quality and consistency of their products but also the longevity and reliability of their multi-million dollar tooling assets.

The key benefits of a thorough die spotting process include:

- Improved Part Quality: Ensures dimensional accuracy and a flawless surface finish on the final product by eliminating tooling imperfections.

- Reduced Tool Wear: Prevents premature damage to the die by distributing clamping and forming forces evenly across the contact surfaces.

- Minimized Production Downtime: Identifies and resolves potential issues before the tool enters mass production, avoiding costly delays and rework on the production line.

- Enhanced Metal Flow Control: In drawing operations, a properly spotted binder surface is essential for controlling the flow of sheet metal, preventing wrinkles or splits.

The Die Spotting Process: A Step-by-Step Breakdown

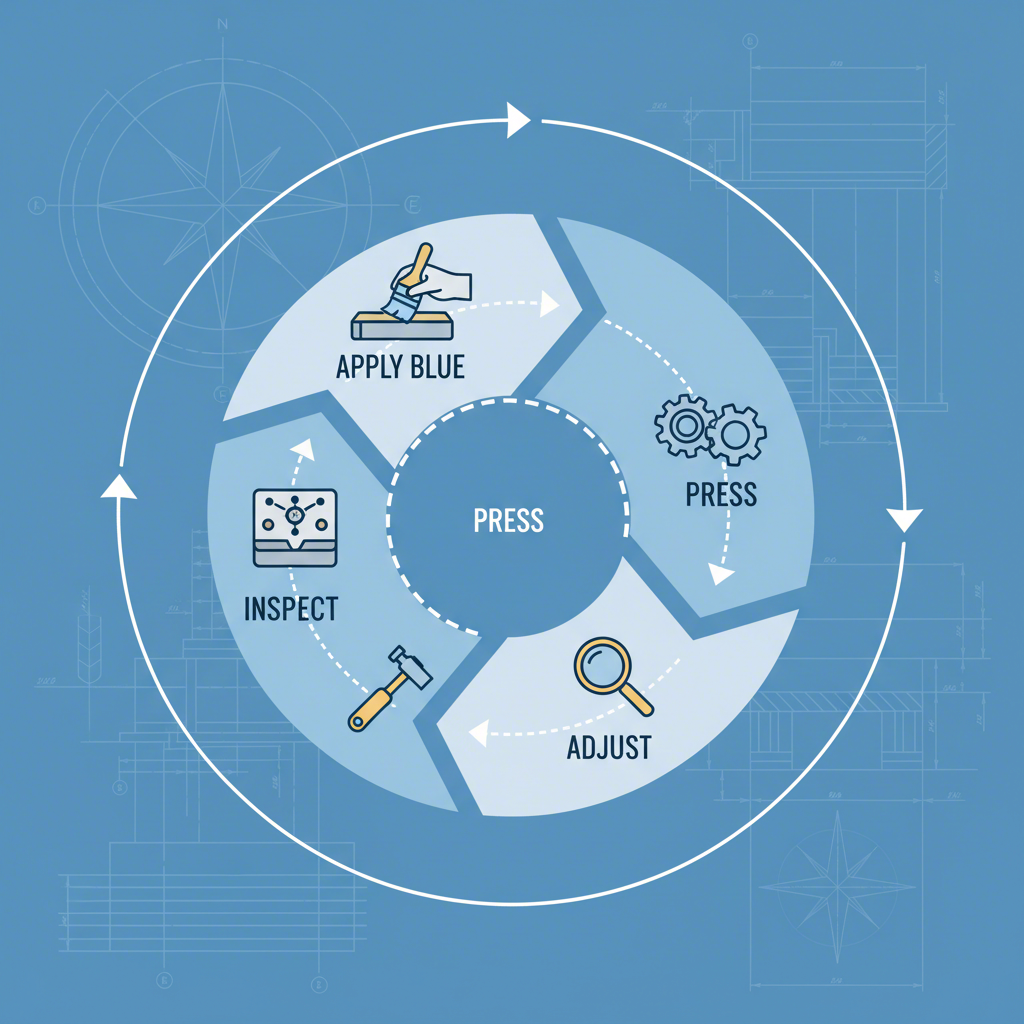

The die spotting process is a methodical and iterative craft that demands patience, precision, and the keen eye of an experienced toolmaker. It is less a single action and more a cycle of testing and refinement. While the specific details can vary based on the tool's complexity and the material being formed, the fundamental procedure follows a structured sequence. This disciplined approach transforms a newly machined tool into a perfectly fitted instrument ready for the rigors of production.

The journey from a rough fit to a production-ready tool can be broken down into the following key steps:

- Preparation and Cleaning: Both halves of the die are meticulously cleaned to remove any oils, debris, or contaminants. The master surface, typically the cavity or the more complex half, is chosen for the initial application of the spotting compound.

- Application of Spotting Compound: A very thin, even layer of spotting blue (or sometimes red) ink is applied to the master surface. The goal is to create a consistent film that will transfer cleanly upon contact, not to pool or obscure the surface details.

- Controlled Closing in the Press: The die is carefully mounted and aligned within a die spotting press. Unlike a production press that operates with high force and speed, a spotting press allows the operator to close the die slowly and apply a specific, controlled amount of pressure. This simulates the clamping force without the violence of a production stroke.

- Inspection of Color Transfer: The press is opened, and the toolmaker carefully inspects both surfaces. The spotting blue will have transferred from the master surface to the opposing side wherever they touched. A perfectly spotted tool will show a uniform, widespread transfer of color.

- Identification and Adjustment: The areas with transferred ink are the 'high spots' that need to be lowered. The toolmaker marks these areas and then manually removes microscopic amounts of material using hand grinders, stones, or polishing tools. This is the most skill-intensive part of the process, as removing too much material can create a low spot, requiring more significant rework.

- Repetition Until Perfection: After the initial adjustments, the die is cleaned, the spotting compound is reapplied, and the entire cycle is repeated. This loop of pressing, inspecting, and adjusting continues until a minimum of 80-90% contact is evenly distributed across all critical faces of the tool.

This meticulous procedure ensures that when the tool is finally put into a production environment, it behaves predictably and produces parts that are dimensionally perfect from the very first cycle. It is a testament to the blend of art and science that defines high-end tool and die making.

Essential Technology: Understanding Die Spotting Presses

While the skill of the toolmaker is paramount, the die spotting process relies heavily on specialized equipment: the die spotting press. This machine is fundamentally different from a production press and is purpose-built for the precision, safety, and control required for fitting tools. Attempting to spot a die in a high-speed production press is not only inaccurate but also extremely dangerous. Spotting presses are designed to bring massive, heavy die halves together with delicate control, allowing for the verification of contact surfaces with micron-level accuracy.

The key features that distinguish a die spotting press are centered on accessibility, precision control, and safety. Many modern presses, like those described by VEM Tooling, feature 180-degree rotating or tilting platens. This allows the upper half of the die to be swiveled out and presented to the toolmaker at a safe and ergonomic working height, eliminating the need for cranes and reducing the risk of accidents. Furthermore, these presses operate at very low pressures and speeds, giving the operator precise control over the closing process to prevent damage to the delicate die surfaces.

This level of precision is why leading manufacturers, including OEMs and Tier 1 suppliers, partner with specialists. For instance, Shaoyi (Ningbo) Metal Technology Co., Ltd. leverages advanced techniques and deep expertise in creating custom automotive stamping dies where such meticulous quality control is non-negotiable. Their commitment to using the right equipment and processes ensures that complex components are manufactured to the highest standards of quality and efficiency.

To fully appreciate their value, it's helpful to compare a dedicated die spotting press with a standard production press for this specific task:

| Feature | Die Spotting Press | Production Press |

|---|---|---|

| Control | Precise, low-pressure, and slow-speed control for delicate adjustments. | High-speed, high-tonnage operation designed for forming parts, not for fine-tuning. |

| Accuracy | Ensures exceptional platen parallelism for true alignment verification. | May lack the fine parallelism control needed for spotting, leading to inaccurate results. |

| Safety & Ergonomics | Features like tilting platens and easy access are designed for operator safety and efficient manual rework. | Lacks features for safe and easy access to die surfaces, making manual adjustments hazardous and inefficient. |

| Efficiency | Dramatically speeds up the iterative spotting process and reduces mold fitting time. | Using it for spotting is slow, cumbersome, and ties up a valuable production machine. |

The Evolution of Die Spotting: From Manual Art to Digital Science

For decades, die spotting has been a revered craft, relying almost entirely on the tactile feedback and experiential knowledge of master toolmakers. This traditional, manual process, while effective, is also incredibly time-consuming and can represent a significant bottleneck in the tool manufacturing timeline. According to industry experts at FormingWorld, the tool tryout phase can account for up to 40% of the total time for tool engineering, with die spotting itself making up 70-80% of that tryout period. This highlights the immense pressure to make this essential step more efficient.

The advent of powerful computing and sophisticated software has begun to revolutionize this age-old practice. The most significant advancement is the use of contact simulation software. Instead of relying solely on physical trial and error, engineers can now create a 'digital twin' of the die set. This virtual model simulates how the die halves will close and what the contact pressure and distribution will look like, even accounting for the slight deflection of the press and tools under load. This allows engineers to predict where high spots will occur before a single piece of steel is cut.

This digital-first approach offers profound advantages. By analyzing the simulation results, toolmakers can pre-emptively adjust the CAD surfaces of the die. For example, they can apply a precise offset to certain areas to compensate for predicted sheet metal thinning or thickening during a forming operation. This means the die is milled to a much closer-to-perfect state from the outset. As a result, the number of physical spotting cycles required is drastically reduced, translating directly into significant savings in both time and cost. The goal is not to eliminate the toolmaker but to empower them with better data, reducing the manual labor from weeks to days.

The future of die spotting lies in a hybrid approach that seamlessly blends digital precision with human expertise. Simulation will handle the heavy lifting of initial analysis and surface compensation, getting the tool 95% of the way there. The final, critical adjustments will still be guided by the skilled hands and discerning eye of the toolmaker, who verifies the digital results with a final physical spotting. This synergy ensures the highest possible quality while meeting the ever-increasing demand for faster production timelines and greater manufacturing efficiency.

Upholding Excellence Through Meticulous Craftsmanship

Die spotting is far more than a simple mechanical check; it is a fundamental pillar of quality assurance in the tool and die industry. It serves as the ultimate validation that a tool, designed in the digital realm and machined from solid steel, will perform flawlessly in the real world. This meticulous, hands-on process ensures that every curve, angle, and surface of a die works in perfect harmony to produce components that meet the strictest standards of dimensional accuracy and aesthetic quality.

From ensuring the precise alignment of mold halves to controlling the intricate flow of material under pressure, the role of die spotting is both critical and irreplaceable. While modern technology like simulation software is streamlining the process and reducing manual effort, it enhances rather than replaces the core principles of this craft. Ultimately, die spotting remains an essential bridge between engineering design and successful mass production, safeguarding against defects, extending the life of valuable tooling, and upholding the promise of manufacturing excellence.

Frequently Asked Questions

1. What is the tool die making process?

The tool and die making process involves the creation of specialized tools, dies, molds, jigs, and fixtures used in manufacturing to mass-produce parts. This highly skilled trade consists of interpreting engineering drawings, setting up and operating machine tools (like lathes, mills, and grinders) to cut and shape metal with high precision, and then assembling, fitting, and repairing these tools. Die spotting is a critical finishing and verification step within this broader process.

2. What is the job description of a tool and die machinist?

A tool and die machinist, or maker, is a skilled artisan who builds and maintains the tooling used in manufacturing. Their responsibilities include reading technical blueprints, setting up and operating a wide range of manual and CNC (Computer Numerical Control) machine tools to produce components with tight tolerances. They then assemble these components, perform fitting processes like die spotting to ensure perfect alignment, and conduct repairs and maintenance on existing tooling to keep production lines running smoothly.

3. Do tool and die makers make good money?

Tool and die making is a highly skilled and valuable trade, and compensation generally reflects this. While salaries can vary significantly based on location, experience, industry, and specific skill set, experienced tool and die makers typically earn a competitive wage. The demand for their precision skills in high-value manufacturing sectors like automotive, aerospace, and medical devices often ensures strong earning potential.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —