Shot Sleeve Lubrication: Your Key to Fewer Casting Defects

TL;DR

Effective shot sleeve lubrication in cold chamber die casting is a critical process for ensuring manufacturing quality and efficiency. Proper lubrication protects the plunger tip and sleeve from premature wear, creates an essential seal for the molten metal, and is fundamental to preventing costly casting defects. The process involves the precise application of specialized lubricants before each injection cycle to reduce friction, manage extreme thermal stress, and ultimately maximize production uptime and the quality of finished parts.

The Critical Role of the Shot Sleeve System in Cold Chamber Casting

In high-pressure die casting (HPDC), the shot sleeve is a hardened steel cylinder that acts as the chamber where molten metal, such as an aluminum or magnesium alloy, is held just before being injected into the die cavity. According to industry resource Haichen, its primary function is to serve as a precise conduit, working in tandem with a plunger (or piston) to generate immense pressure and ensure a controlled, rapid fill of the mold. The integrity of this system is paramount for producing sound, high-quality castings.

Lubrication is not merely a maintenance task in this system; it is an active process variable that directly influences outcomes. The primary purpose of piston lubricants is to protect the piston tip from wear and ensure an adequate seal with the shot sleeve. Without a proper lubricating film, the extreme friction and thermal shock from the molten metal would cause catastrophic wear on both the plunger tip and the sleeve's inner wall. This leads to a loss of dimensional tolerance, compromising the seal required to inject the metal at high pressure.

The consequences of insufficient or improper lubrication are severe and costly. As detailed in a technical paper from Castool Tooling Systems, inadequate lubrication directly results in inconsistent shot velocity, premature component failure, and a significant increase in scrap rates. When the clearance between the plunger and sleeve is compromised by wear, molten alloy can penetrate the gap, a phenomenon known as "flash" or "blow-by," which accelerates further degradation. Furthermore, uneven heating can cause the sleeve to distort, becoming oval and bowed, which guarantees premature failure.

Ultimately, the function of shot sleeve lubrication can be summarized by several key objectives:

- Wear Prevention: Creating a protective barrier between the moving plunger tip and the stationary shot sleeve to minimize abrasive and adhesive wear.

- Pressure Sealing: Maintaining a tight seal to allow the plunger to build the necessary hydraulic pressure to fill the die cavity completely.

- Friction Reduction: Ensuring smooth, consistent plunger movement for predictable shot velocity and uniform mold filling.

- Thermal Management: Assisting in the management of heat transfer between the molten metal, the plunger tip, and the sleeve.

- Defect Minimization: Preventing issues like metal soldering (adhesion) and reducing the generation of scrap parts.

Types of Shot Sleeve Lubricants and Their Properties

The selection of a shot sleeve lubricant depends on numerous factors, including the casting alloy, machine size, cycle time, and specific production goals. Lubricants are broadly categorized into two main types: liquid lubricants and solid lubricants. Each type has distinct properties and application methods tailored to different operational needs. Understanding these differences is crucial for optimizing the die casting process and ensuring the longevity of tooling.

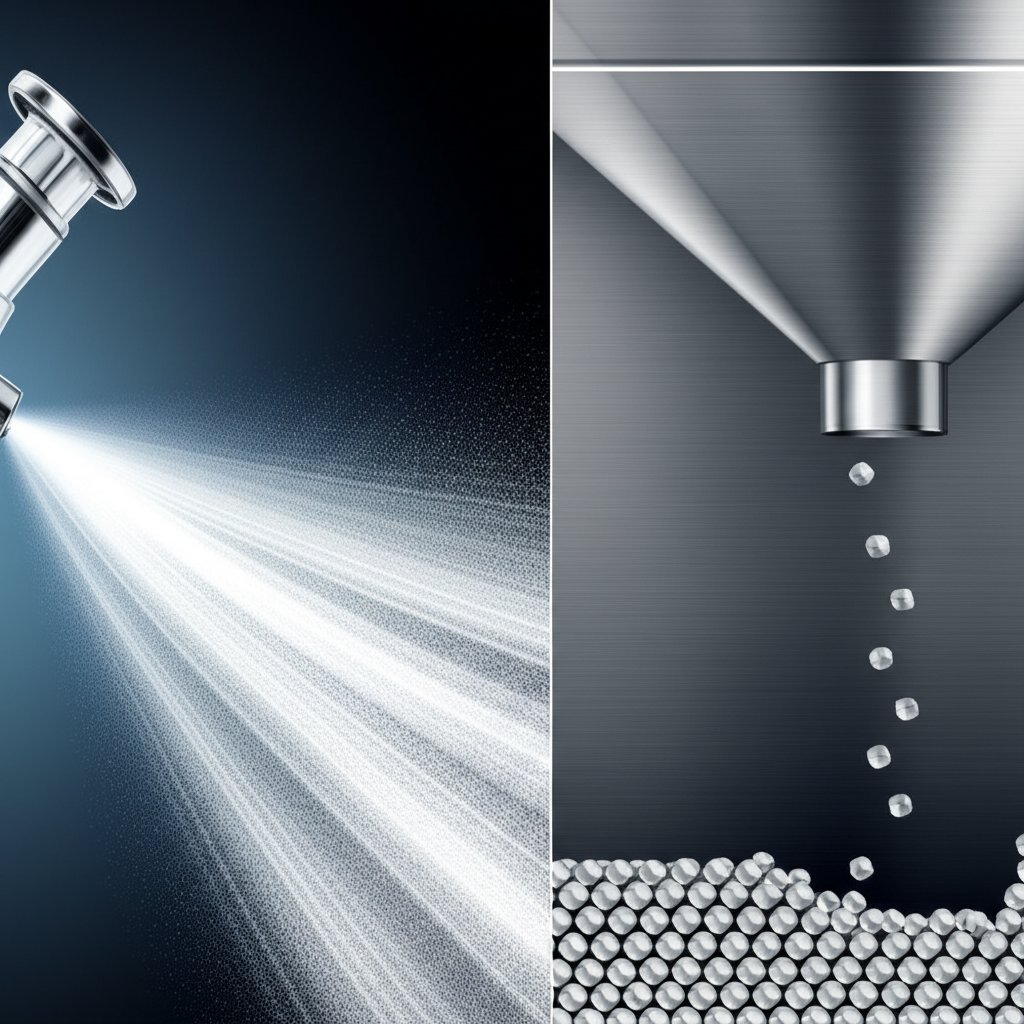

Liquid lubricants are typically high-performance, oil-based fluids. According to industrial supplier HA-International, these oils are designed for universal use across many piston and sleeve pairings and can be applied via a high-pressure spray as an oil mist. This method is particularly effective for large, long shot sleeves, ensuring the entire bore is coated. The chemical composition of these lubricants is critical; research published in MDPI's Lubricants journal notes that many contain extreme pressure (EP) additives with sulfur or chlorine compounds that react at high temperatures to form a protective solid layer on metal surfaces.

Solid lubricants, often wax-based pellets or powders, offer an alternative approach. These are dosed directly into the shot sleeve in front of the plunger tip. The high temperature of the sleeve (a minimum of 180°C / 356°F) melts the pellets, and the resulting liquid is drawn into the gap between the components by capillary action. A major advantage of this method is a cleaner operating environment, as it avoids the overspray associated with liquid lubricants. Many modern solid lubricants are formulated to be graphite-free to prevent the greasy, dark residue that graphite can leave on equipment.

The choice between these types involves clear trade-offs. The precision required in these high-stakes manufacturing environments is immense, as even minor variations can lead to component failure. This principle extends to other advanced metal forming sectors. For instance, producers of high-performance components, such as the automotive forging parts from Shaoyi (Ningbo) Metal Technology, rely on meticulously controlled processes from die design to mass production to ensure every part meets stringent IATF16949 standards. Just as in die casting, the control of friction and temperature is fundamental to achieving superior mechanical properties.

| Property | Liquid Lubricants (Oil-Based) | Solid Lubricants (Wax-Based Pellets) |

|---|---|---|

| Application Method | Sprayed as a fine mist into the sleeve | Dosed as pellets, which melt inside the sleeve |

| Coverage | Excellent for long and large-diameter sleeves | Relies on capillary action for distribution |

| Work Environment | Can create overspray and a misty environment | Significantly cleaner, with less ambient residue |

| Key Advantage | Ensures complete and uniform coating | Efficiency and cleanliness |

| Potential Issue | Can burn and create gas/inclusions if over-applied | May not distribute as evenly in very large sleeves |

Common Lubrication-Related Defects and System Failures

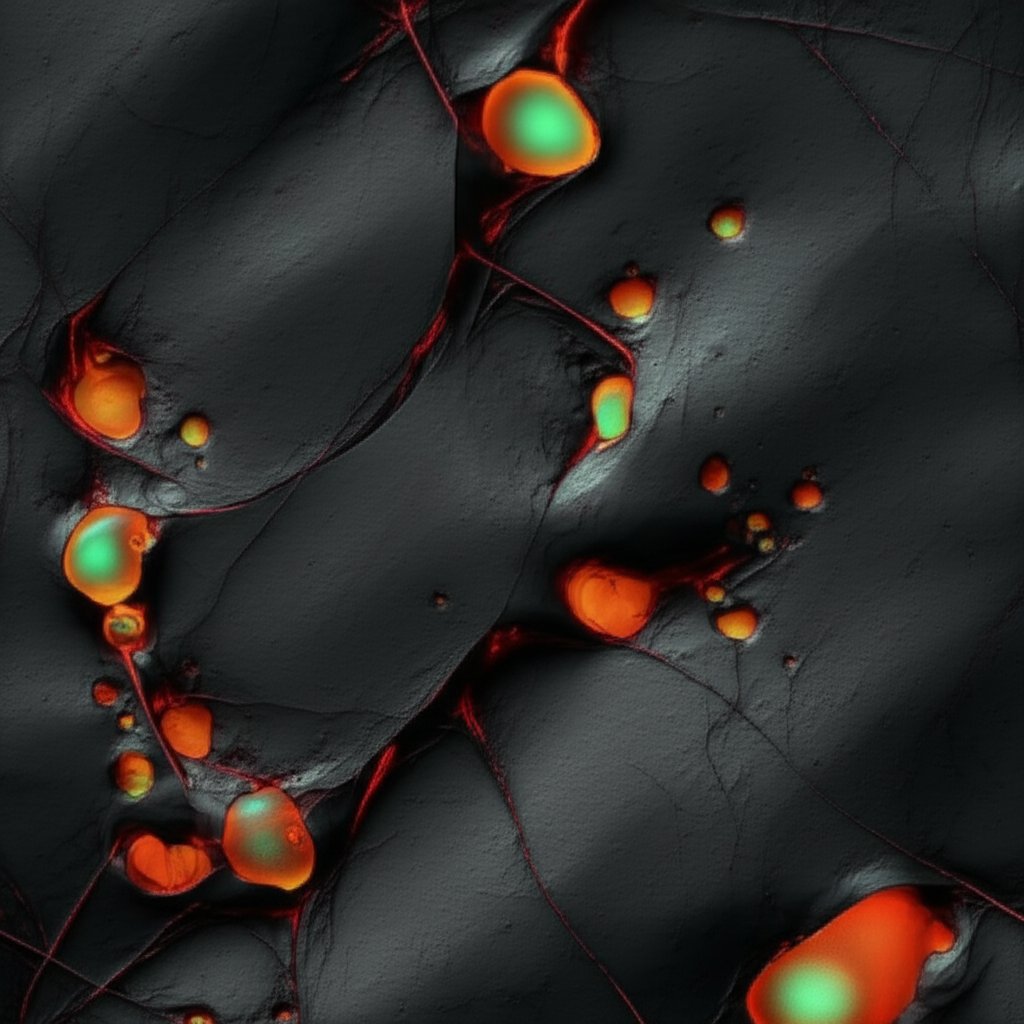

Improper shot sleeve lubrication is a primary contributor to both casting defects and premature equipment failure. When the lubrication strategy fails, it sets off a chain reaction of mechanical and chemical problems that degrade part quality. The most significant issue is the combustion of the lubricant itself. When overheated molten aluminum comes into contact with the lubricant, it can evaporate and burn, creating gas and non-metallic inclusions that become trapped in the final casting. This directly leads to porosity, one of the most detrimental defects in die-cast components, which severely compromises mechanical strength.

Beyond combustion, insufficient lubrication leads to direct physical damage. The immense pressure and movement of the plunger without an adequate protective film cause galling and scoring on the inner surface of the shot sleeve. This wear increases the clearance between the plunger and the sleeve, reducing the efficiency of the injection shot and allowing molten metal to squeeze past the plunger tip. This blow-by not only damages the tooling but also introduces variability into the process, making it difficult to maintain consistent quality.

Conversely, the excessive use of lubricant is also problematic. Over-application, especially with liquid lubricants, increases the likelihood of burning, which generates smoke and gas. This entrapped gas is a major source of porosity. It's a delicate balance: too little lubricant causes wear, while too much causes gas defects. While lubricants are essential for reducing wear, they have limitations. Research on shot sleeve distortion indicates that even with proper lubrication, thermal stresses can still cause the sleeve to deform, and lubricants do not have an appreciable effect on preventing this core issue.

Operators and engineers should watch for key indicators of lubrication problems. A diagnostic checklist can help identify issues before they lead to major production losses:

- Visible Scoring or Streaks: Check the inner wall of the shot sleeve and the surface of the plunger tip for signs of physical wear.

- Inconsistent Shot Velocity: If the plunger speed varies between shots despite consistent machine settings, it often points to friction issues.

- Increased Scrap Rate for Porosity: A sudden spike in parts rejected for gas or shrinkage porosity often links back to lubricant application.

- Visible Smoke or Soot: Excessive smoke during the pouring or injection phase is a clear sign that the lubricant is burning.

- Metal Adhesion (Soldering): Finding solidified bits of the casting alloy stuck to the plunger tip or sleeve wall indicates a breakdown of the lubricating film.

Best Practices for Lubricant Application and System Maintenance

Achieving optimal shot sleeve lubrication requires a systematic approach that combines correct application techniques with a rigorous maintenance schedule. The goal is to apply the minimum amount of lubricant necessary to achieve a consistent, protective film before every shot. This minimizes waste, reduces the risk of combustion-related defects, and extends the life of critical tooling components.

The application process itself is a key area for optimization. For liquid lubricants, a high-pressure oil mist is often the most effective method, ensuring full coverage along the entire length of the sleeve. For solid lubricants, automated pellet feeders provide precise, repeatable dosing. A critical finding from extensive process modeling is the role of the plunger's speed profile. Research has shown that a slow-shot velocity in the range of 0.2–0.4 m/s is most effective at reducing air entrainment and the formation of oxide inclusions. This controlled initial movement prevents the molten metal from folding over on itself and trapping air and burned lubricant byproducts.

A structured lubrication and maintenance cycle is essential for consistent results. The following steps provide a practical framework for operations:

- Pre-Shot Application: The lubricant must be applied before every single shot without exception. Automated systems are highly recommended to ensure this consistency.

- Controlled Plunger Profile: Implement a two-phase shot profile. Start with a slow shot phase (0.4–0.6 m/s) to gently push the molten metal past the pour hole, expelling air forward. Then, transition to the fast shot phase to rapidly fill the die.

- Minimum Quantity Principle: Calibrate the application system (sprayer or doser) to use the least amount of lubricant that still provides complete protection. This can be verified by inspecting the plunger tip for wear after a production run.

- Regular Cleaning: Periodically clean the shot sleeve and plunger tip to remove any buildup of lubricant residue, oxides, or solidified metal.

- Component Inspection: Regularly inspect the shot sleeve for signs of wear, distortion, or cracking. Some operations use advanced reconditioning services to hone and rework sleeves, extending their operational life.

Adherence to these best practices transforms lubrication from a routine task into a strategic tool for quality control. By controlling the application method, plunger velocity, and maintenance schedule, die casters can significantly reduce lubrication-related defects, improve machine uptime, and produce higher quality parts with greater consistency.

Frequently Asked Questions

1. What is a shot sleeve?

A shot sleeve is a critical component in a cold chamber die casting machine. It is a hardened steel cylinder that serves as a temporary reservoir for molten metal after it's ladled from the furnace. A plunger moves within the sleeve to inject the metal under high pressure into the die mold.

2. Which material is used in the cold chamber process?

The cold chamber process is used for metals with high melting points. Common materials include aluminum alloys, magnesium alloys, copper, and brass. These metals are too corrosive or have too high a melting point to be used in hot chamber machines where the injection mechanism is submerged in the molten metal.

3. Why would you choose cold chamber die casting over hot chamber die casting?

Cold chamber die casting is chosen for its ability to handle high-melting-point and corrosive alloys like aluminum. While the cycle times are typically slower than the hot chamber process, it is more versatile and capable of producing large, structurally complex parts, such as engine blocks and transmission housings for the automotive industry.

4. What is HPDC vs LPDC vs GDC?

These are acronyms for different casting processes. HPDC stands for High-Pressure Die Casting, which uses high pressure to inject molten metal for fast, precise production. LPDC is Low-Pressure Die Casting, ideal for large, thin-walled parts requiring high structural integrity. GDC refers to Gravity Die Casting, which relies on gravity to fill the mold and is used to produce strong parts with minimal porosity.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —