Decoding Aluminum Extrusion Tolerances for the Auto Industry

Decoding Aluminum Extrusion Tolerances for the Auto Industry

TL;DR

Aluminum extrusion tolerances for the auto industry are the permissible variations in the dimensions of extruded aluminum parts used in vehicle manufacturing. These precise measurements, governed by the American National Standard ANSI H35.2, are critical for ensuring proper component fit, vehicle performance, structural integrity, and safety. Adherence to these standards, developed by bodies like The Aluminum Association, is essential for lightweighting efforts and producing high-quality automotive components.

Understanding the Fundamentals: What Are Aluminum Extrusion Tolerances?

Aluminum extrusion tolerances refer to the allowable deviation from specified nominal dimensions in an extruded profile. In manufacturing, it's impossible to produce parts with exact dimensions every time; tolerances define an acceptable range of variation. For the automotive industry, where precision is paramount, these tolerances are not just guidelines but critical specifications. They ensure that every component, from a small piece of trim to a large structural frame, fits and functions exactly as designed within a complex assembly.

The importance of these tolerances in automotive applications cannot be overstated. Strict adherence is crucial for vehicle assembly, performance, and safety. For instance, the precise dimensions of a window frame extrusion are vital to creating a perfect weather seal, preventing leaks and reducing wind noise. In electric vehicles (EVs), battery enclosures made from extruded aluminum require extremely tight tolerances to ensure a secure fit, protect sensitive components, and maintain structural rigidity. Even slight deviations can compromise the integrity of the entire system.

Furthermore, as automakers aggressively pursue lightweighting to improve fuel efficiency and EV range, aluminum has become a key material. Extrusions allow for complex, integrated designs that reduce the number of parts and connection points. However, this consolidation of functionality into a single profile means that dimensional accuracy is more critical than ever. A single out-of-tolerance extrusion could affect multiple aspects of the vehicle's build and performance.

The standards governing these critical measurements are developed and published by leading industry authorities. Key organizations include The Aluminum Association, the Aluminum Extruders Council (AEC), and the American National Standards Institute (ANSI). The primary document that engineers and designers rely on is ANSI H35.2: American National Standard Dimensional Tolerances for Aluminum Mill Products, which provides detailed tables and specifications for various tolerance types.

A Deep Dive into Standard Tolerances (ANSI H35.2)

The ANSI H35.2 standard is a comprehensive document that outlines the specific dimensional tolerances for aluminum mill products, including extrusions. It serves as the primary reference for engineers, designers, and manufacturers in the automotive sector. The standard categorizes tolerances into several key types, each controlling a different aspect of an extrusion's geometry to ensure it meets the required form, fit, and function. Understanding these categories is essential for designing parts that are both functional and manufacturable.

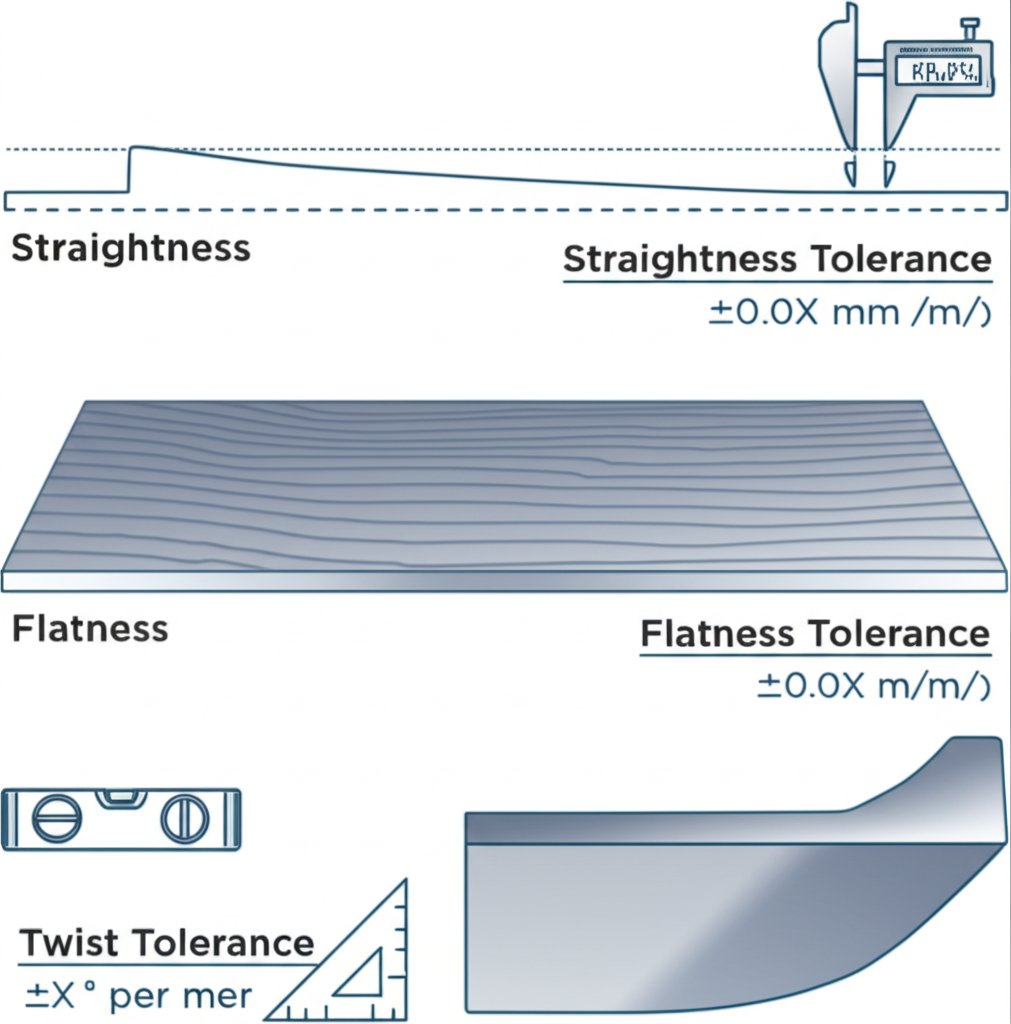

Common types of tolerances specified in ANSI H35.2 include straightness, flatness, twist, and angularity. Straightness refers to the allowable deviation from a straight line along the length of the extrusion. Flatness controls the variation of a surface from a perfect plane. Twist measures the permissible rotation of a profile along its length. Finally, Angularity defines the allowable deviation from a specified angle between two surfaces. Each of these is measured using specific procedures and gauges to ensure consistency across the industry.

These standard tolerances are often sufficient for many applications, but it's important to note that they can vary based on the profile's complexity, alloy, and the size of its circumscribing circle (the smallest circle that the profile's cross-section can fit inside). For particularly demanding applications, tighter "precision tolerances" can be specified, though this may impact production speed and cost. The following table provides a simplified overview of some common standard tolerances for illustrative purposes. For official specifications, consulting the latest edition of ANSI H35.2 is mandatory.

| Tolerance Type | Description | Typical Standard Guideline (Example) |

|---|---|---|

| Straightness | Allowable deviation from a straight line over a given length. | 0.0125 inches per foot of length. |

| Twist | Allowable rotation along the length of the profile. | 0.5 degrees per foot for profiles under 1.5 inches wide. |

| Flatness (Flat Surfaces) | Allowable deviation from a perfect plane on a flat surface. | 0.004 inches per inch of width. |

| Angularity | Allowable deviation from a specified angle. | ±1 to 2 degrees, depending on leg thickness and ratio. |

| Cross-Sectional Dimensions | Allowable variation in the dimensions of the profile's cross-section. | Varies significantly based on dimension, alloy, and shape complexity (e.g., ±0.010" to ±0.050" or more). |

Note: The values in this table are simplified examples based on industry rules of thumb and should not be used for official design specifications. Always refer to the official ANSI H35.2 standard for precise data.

Automotive-Specific Applications and Challenges

In the automotive industry, aluminum extrusion tolerances are not just abstract numbers on a specification sheet; they directly impact the final product's quality, safety, and performance. Specific components rely on different critical tolerances. For structural parts like chassis rails and crash management systems, tolerances for wall thickness and cross-sectional dimensions are vital for ensuring predictable energy absorption during a collision. For battery enclosures in electric vehicles, flatness and angularity are key to ensuring modules fit securely and that seals are effective against moisture and debris.

Other applications highlight the need for precision across various tolerance types. Sunroof tracks, for example, require exceptional straightness to allow for smooth, quiet operation. Decorative trim pieces must have consistent cross-sectional dimensions to ensure seamless alignment with adjacent body panels. Any failure to meet these tolerances can lead to assembly line delays, increased scrap rates, and potential warranty claims down the road. The push for lightweighting adds another layer of complexity, as thinner walls and more intricate profile designs can be more challenging to extrude while maintaining tight tolerances.

For automotive projects demanding components that meet or exceed these tight specifications, partnering with a specialized manufacturer is often necessary. For instance, providers like Shaoyi Metal Technology offer comprehensive services from rapid prototyping to full-scale production under strict IATF 16949 quality systems, delivering custom parts for specific applications. Collaborating with an experienced extruder early in the design process is crucial. They can provide valuable feedback on the manufacturability of a design and help determine the most practical and cost-effective tolerances for a specific application, ensuring the final component meets all functional requirements without being over-engineered.

Frequently Asked Questions

1. What is the primary standard for aluminum extrusion tolerances?

The primary standard is ANSI H35.2, titled "American National Standard Dimensional Tolerances for Aluminum Mill Products." This document is published by The Aluminum Association and provides comprehensive tables and guidelines for various types of tolerances for aluminum products, including extrusions.

2. Why are tolerances so important for electric vehicles (EVs)?

In EVs, tolerances are critical for components like battery enclosures, motor housings, and cooling system elements. These parts require precise fits to ensure safety, thermal management, and protection from the elements. For example, the frame of a battery pack must be manufactured to tight tolerances to ensure all battery modules fit correctly and the entire assembly is sealed against moisture ingress.

3. Can tighter-than-standard tolerances be achieved?

Yes, it is often possible to achieve tolerances that are tighter than the industry standard. These are typically referred to as "precision" or "special" tolerances. However, achieving them may require specialized tooling, slower extrusion speeds, and more rigorous quality control, which can increase the cost of the final part. It is essential to discuss such requirements with the extruder during the design phase.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —