Servo Press Technology Automotive Stamping: Mastering AHSS

TL;DR

Servo press technology automotive stamping represents a fundamental shift from fixed-velocity mechanical systems to fully programmable, high-torque forming solutions. By decoupling slide speed from motor rotation, servo presses allow engineers to optimize velocity at Bottom Dead Center (BDC), enabling the precise forming of Advanced High-Strength Steels (AHSS) and aluminum without cracking. This technology delivers 30–50% higher productivity through pendulum motion profiles, extends die life by reducing snap-through shock, and cuts energy consumption by up to 70% compared to hydraulic systems. For automotive manufacturers, it is the definitive solution for balancing lightweighting requirements with mass production efficiency.

The Engineering Core: How Servo Technology Redefines Stamping

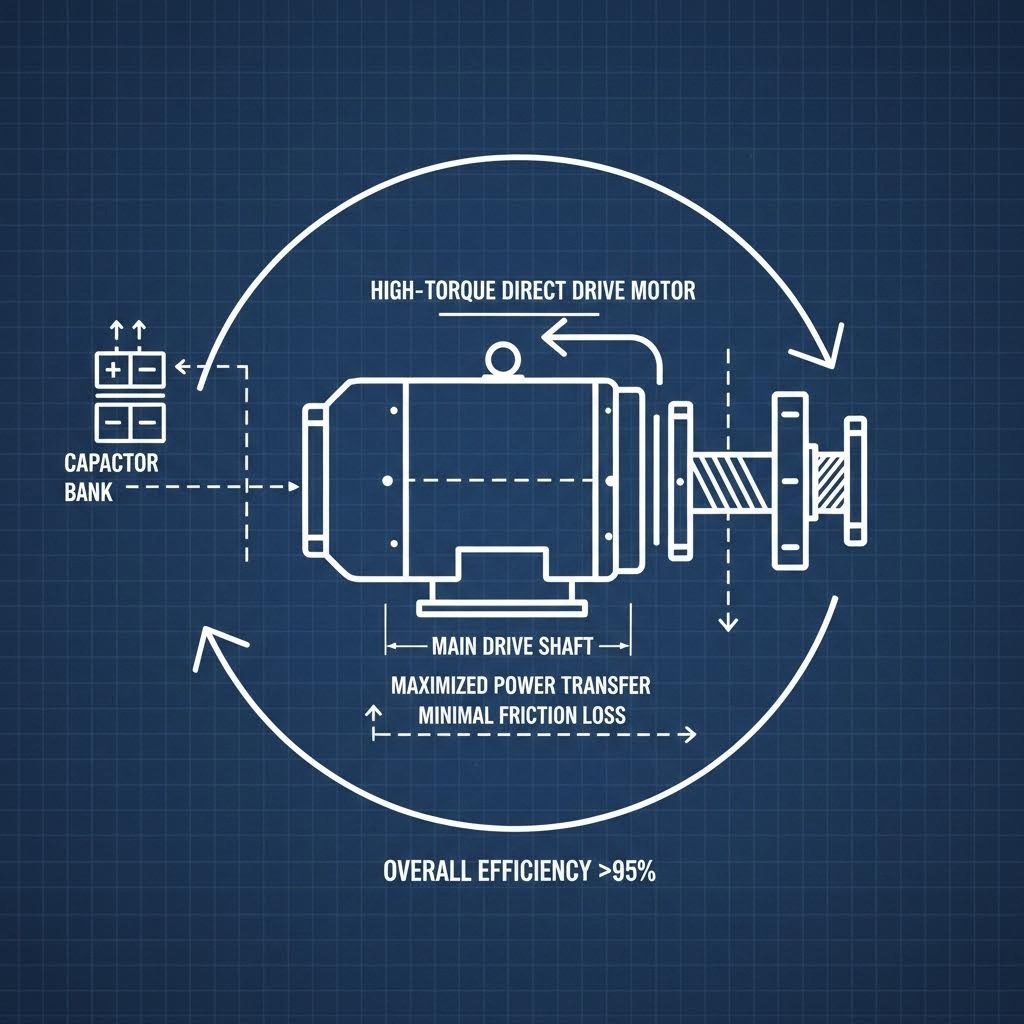

To understand the dominance of servo presses in modern automotive manufacturing, one must distinguish them from traditional flywheel-driven mechanical presses and fluid-power hydraulic systems. The core innovation lies in the Direct Drive mechanism. Unlike mechanical presses that store energy in a continuously rotating flywheel and engage a clutch to transfer force, a servo press utilizes a high-torque, low-RPM servomotor directly coupled to the drive shaft (or via a minimal gear train). This architecture eliminates the clutch and brake assembly—historically the most maintenance-intensive components of a press line—and provides full torque availability at any point in the stroke.

Energy management in these systems is sophisticated. Leading manufacturers like AIDA and Schuler utilize capacitor banks (often termed "Energy Conservation and Optimization" systems) to manage the massive power spikes required during the forming stroke. These capacitors store energy during the non-forming portion of the cycle and release it instantaneously during the hit, leveling the demand on the facility's power grid. This closed-loop feedback system allows for micron-level accuracy, as the motor position is continuously monitored and corrected in real-time, ensuring consistent shut height regardless of thermal expansion or load variation.

For facilities not ready to invest in entirely new press lines, linear servo actuators offer a retrofit pathway. As noted in recent industry analyses, replacing hydraulic cylinders with linear servo actuators can reduce component count by up to 80%, eliminating hydraulic power units (HPUs) and the associated risks of oil leaks and overheating. This modular approach allows stampers to achieve servo-level precision and cleanliness—critical for forming sensitive automotive electronics or interior components—without the capital expenditure of a ground-up installation.

Solving the Lightweighting Challenge: AHSS and Aluminum Applications

The transition to Electric Vehicles (EVs) has accelerated the demand for vehicle lightweighting, pushing stampers to work with materials that are notoriously difficult to form: Advanced High-Strength Steels (AHSS) and aluminum alloys. Traditional mechanical presses, which hit the material at maximum velocity near BDC, often cause cracking or excessive springback in these materials. Servo press technology solves this physics problem by allowing the slide to decelerate just before contact.

By slowing the slide velocity to a crawl at BDC, the material is allowed to flow plastically rather than fracturing under impact. This "dwell" capability significantly reduces springback—the tendency of metal to return to its original shape—ensuring tighter dimensional tolerances. Furthermore, the ability to control the release of tonnage helps mitigate snap-through (reverse tonnage), the violent shock that occurs when the material fractures. Reducing snap-through protects the press frame and significantly extends the life of expensive progressive dies.

Producing these complex, lightweight geometries requires not just advanced machinery but also highly capable manufacturing partners. For automotive entities seeking to bridge the gap from rapid prototyping to high-volume manufacturing, Shaoyi Metal Technology provides comprehensive stamping solutions. Leveraging IATF 16949-certified precision and press capabilities up to 600 tons, they deliver critical components like control arms and subframes that meet global OEM standards, ensuring that the theoretical benefits of servo technology are realized in actual production parts.

Mastering Motion Profiles: The 'Secret Sauce' of Servo

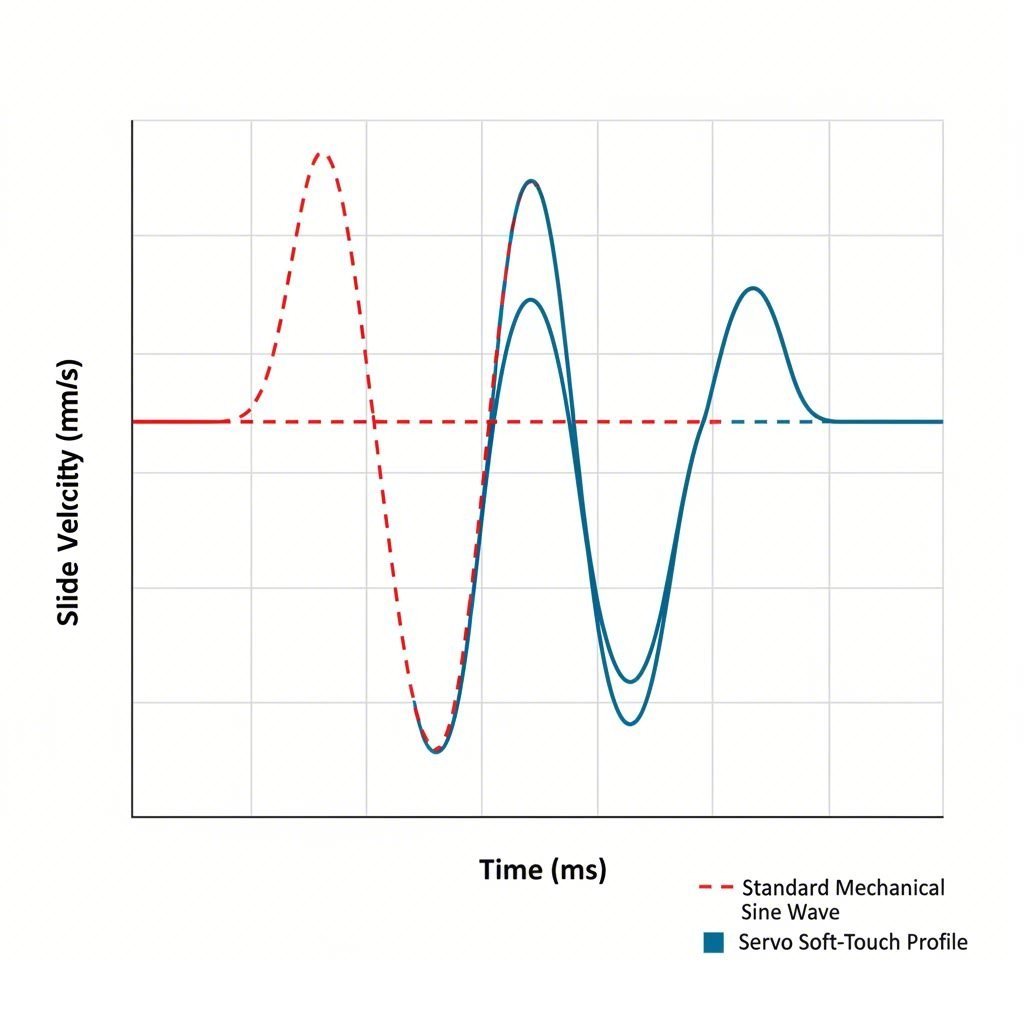

The defining feature of servo press technology is the ability to execute programmable motion profiles. Unlike the fixed sine-wave motion of a crank press, a servo press can modify its velocity and position hundreds of times within a single stroke. Engineers use these profiles to target specific forming defects and optimize cycle times.

- Pendulum Motion: Used primarily to increase Strokes Per Minute (SPM). The ram oscillates back and forth over a short distance without completing a full 360-degree rotation, eliminating wasted motion. This can boost output by 50% or more for shallow parts.

- Link Motion (Soft Touch): Simulates the kinematics of a mechanical link drive but with greater tunability. The slide slows down as it approaches the work, maintains a slow forming speed, and then retracts quickly. This is ideal for drawing applications where maintaining material flow is critical.

- Dwell/Hold Profile: The slide comes to a complete stop at BDC while maintaining full tonnage. This is essential for hot stamping (allowing the part to quench in the die) or in-die processes like tapping or component insertion.

- Restrike/Coining Profile: The ram performs multiple hits at BDC within a single cycle to set the final dimensions and eliminate springback, effectively replacing secondary operations.

Optimizing these curves requires a shift in mindset. Instead of asking "How fast can we run?", engineers must ask "What is the optimal velocity for this specific material grade?" By tailoring the stroke curve to the material's yield characteristics, stampers can eliminate secondary annealing or calibration steps, streamlining the entire manufacturing value stream.

Economic Analysis: Energy, Die Life, and ROI

While the initial capital investment for a servo press is higher than for a mechanical counterpart, the Return on Investment (ROI) is driven by three factors: energy efficiency, die maintenance, and throughput. Energy on Demand is a key differentiator; unlike hydraulic pumps that idle constantly or mechanical flywheels that require continuous energy to maintain momentum, servo motors draw significant power only when moving. Industry data suggests energy consumption can be reduced by 30% to 70%, a critical factor as energy costs rise.

| Metric | Mechanical Press | Hydraulic Press | Servo Press |

|---|---|---|---|

| Energy Usage | High (Flywheel momentum) | High (Pump idling) | Low (On-demand) |

| Slide Velocity | Fixed (Sine wave) | Constant | Fully Programmable |

| Maintenance | High (Clutch/Brake) | High (Seals/Oil) | Low (Minimal moving parts) |

| Forming Precision | Moderate | High | Ultra-High (Micron-level) |

Beyond energy, the impact on tooling life is profound. The reduction of impact shock and vibration means cutting edges stay sharper longer, and die components experience less fatigue. Testimonials from stampers like Small Parts Inc. indicate die maintenance reductions of up to 50% after switching to servo. When combined with the throughput gains from Pendulum motion modes, the total cost per part (CPP) often drops below that of conventional stamping within the first 18–24 months of operation.

Future-Proofing: Industry 4.0 and Smart Stamping

Servo presses are inherently "smart" machines, serving as the anchor for Industry 4.0 initiatives in the press shop. Because the drive system is fully digital, it generates a wealth of data—torque, position, temperature, and vibration—that can be analyzed for predictive maintenance. Load Signature Analysis allows the press to detect subtle variations in material hardness or lubrication before a bad part is made, automatically adjusting the slide position to compensate.

This connectivity enables the creation of Digital Twins, where the entire press line simulation is run virtually before a physical die is ever cut. Engineers can validate motion profiles and interference curves in software, drastically reducing setup times. As the automotive industry moves toward autonomous manufacturing, the servo press's ability to self-correct and integrate with plant-wide ERP systems makes it a future-proof investment for the next generation of vehicle production.

Frequently Asked Questions

1. What is the difference between a mechanical press and a servo press?

The primary difference lies in the drive mechanism and control. A mechanical press uses a flywheel, motor, and clutch-brake system to store and release energy, resulting in a fixed slide speed and stroke length. A servo press uses a high-torque servomotor to drive the slide directly, allowing for fully programmable stroke lengths, variable slide velocities, and the ability to dwell or reverse direction at any point in the cycle.

2. How does servo press technology improve AHSS stamping?

Servo presses improve Advanced High-Strength Steel (AHSS) stamping by allowing the slide to slow down significantly just before impact and during the forming portion of the stroke. This reduces the shock to the material and allows more time for plastic deformation, which minimizes common defects like cracking and springback that occur when AHSS is formed at high speeds on traditional presses.

3. Can a servo press replace a hydraulic press?

Yes, in many applications. Servo presses offer the programmable speed and full-tonnage-throughout-stroke capabilities of hydraulic presses but with significantly higher speeds, better energy efficiency, and greater precision. While hydraulic presses are still used for deep draw applications requiring extremely long strokes, servo presses are increasingly replacing them for automotive structural components due to their superior cycle times and cleanliness.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —