Copper Alloy Stamping for Automotive Electrical: Reliability & Performance

TL;DR

Copper alloy stamping for automotive electrical systems demands a precise balance between conductivity, mechanical strength, and thermal resilience. While pure copper (C11000) remains the standard for high-current busbars, modern automotive connectors increasingly rely on engineered alloys like C70250 (Cu-Ni-Si) and C17200 (Beryllium Copper) to withstand the high temperatures of EV powertrains without losing contact force. Success in this field requires navigating the trade-off between % IACS (conductivity) and stress relaxation resistance.

For engineers and procurement teams, selecting the right material is only half the battle. Achieving zero-defect production under IATF 16949 standards involves mastering stamping challenges like springback management in high-strength alloys and controlling oxidation during the forming process. This guide breaks down the critical alloy properties, manufacturing nuances, and supplier criteria essential for reliable automotive electrical components.

The Automotive Trinity: Conductivity, Strength, and Formability

In the realm of automotive electrical stamping, no single material is perfect. Engineers must constantly evaluate the "Automotive Trinity" of material properties to match the specific function of a component, whether it’s a high-voltage EV busbar or a miniaturized sensor contact.

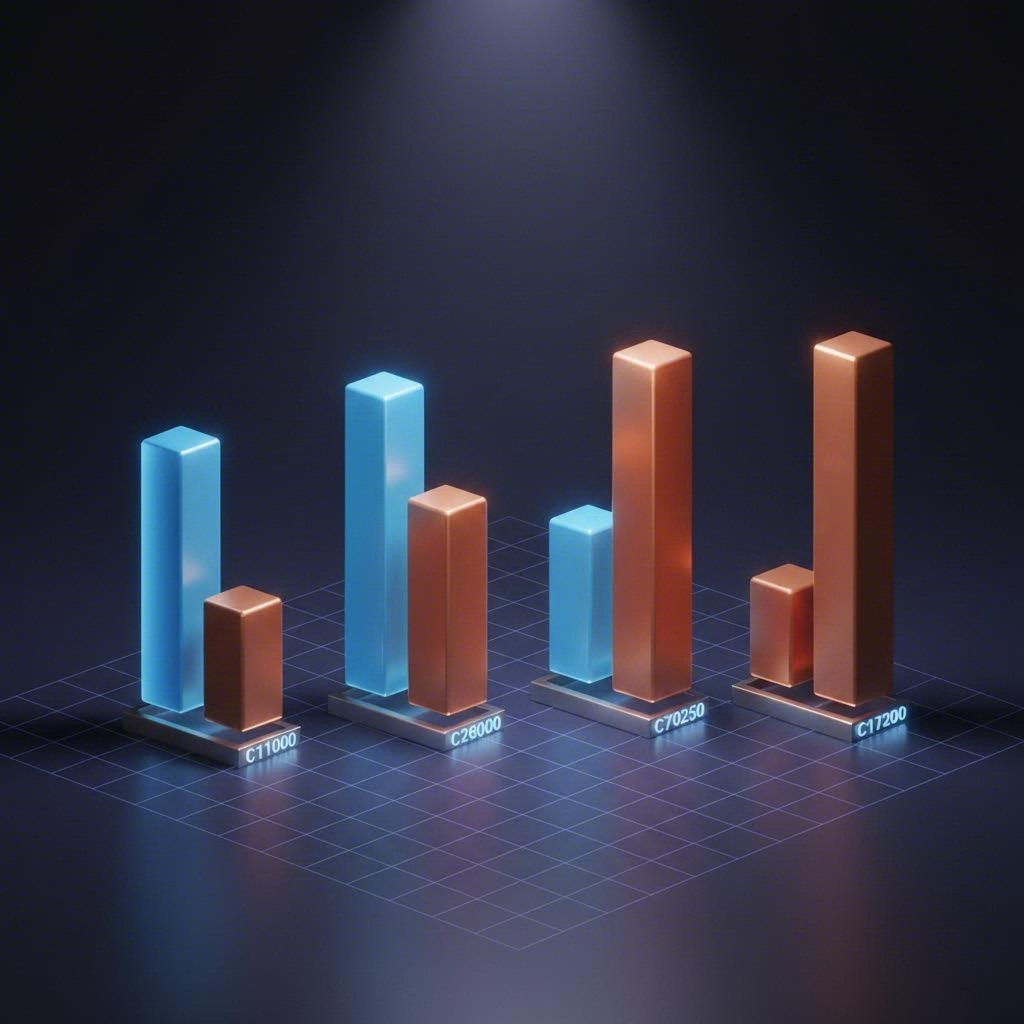

1. Electrical Conductivity (% IACS)

Defined by the International Annealed Copper Standard, this metric dictates how efficiently a material carries current. Pure copper (C11000) sets the benchmark at 101% IACS, making it non-negotiable for power distribution components where resistance generates dangerous heat. However, as you alloy copper to add strength, conductivity typically drops. For example, adding zinc to create Cartridge Brass (C26000) reduces conductivity to roughly 28% IACS, a significant trade-off acceptable only for signal applications rather than power transmission.

2. Stress Relaxation Resistance

Often overlooked but critical for long-term reliability, stress relaxation resistance measures a material's ability to maintain contact force over time, especially under heat. In an engine compartment or EV battery pack reaching 125°C or 150°C, a standard brass terminal may soften and lose its "grip" (spring force), leading to increased resistance and potential failure. High-performance alloys like C70250 are engineered specifically to resist this relaxation, maintaining tight connections for the vehicle's lifespan.

3. Formability (Bend Radius)

Automotive connectors often feature complex geometries with tight 90° or 180° bends. A material’s formability—often expressed as the ratio of minimum bend radius to thickness (R/t)—determines if it will crack during stamping. While soft copper forms easily, high-strength alloys require precise temper selection (e.g., Half Hard vs. Spring Temper) to achieve the necessary shape without structural compromise.

Top Copper Alloys for Automotive Applications: A Selection Guide

Moving beyond generic "copper" or "brass," automotive applications rely on a specific spectrum of alloys. The table below compares the industry standards used in modern vehicle architectures.

| Alloy Grade | Common Name | Conductivity (% IACS) | Tensile Strength (MPa) | Primary Automotive Application |

|---|---|---|---|---|

| C11000 | ETP Copper | 101% | 220–300 | Busbars, battery terminals, fuse links (High Current) |

| C26000 | Cartridge Brass | 28% | 300–600 | Housings, spade terminals, non-critical connectors |

| C51000 | Phosphor Bronze | 15–20% | 310–600 | Contact springs, switches, fatigue-resistant parts |

| C70250 | Corson Alloy (Cu-Ni-Si) | 40–55% | 650–920 | EV connectors, high-temp relays, miniaturized contacts |

| C17200 | Beryllium Copper | 20–25% | 1000–1400+ | Micro-contacts, highest-reliability switches |

The Rise of High-Performance Alloys (C70250)

While C26000 Brass remains a cost-effective workhorse for basic terminals, the industry is shifting toward Cu-Ni-Si alloys like C70250 for EV applications. These "Corson alloys" offer a unique "sweet spot": they provide double the conductivity of brass and nearly triple the strength of pure copper, all while remaining stable at temperatures up to 150°C. This makes them ideal for the high-density interconnects found in modern ADAS and electric powertrain modules.

Specialized Use Cases: Beryllium Copper

For applications demanding the absolute highest strength and fatigue life, such as C17200 Beryllium Copper components, manufacturers use a process called age hardening. This allows the material to be stamped in a softer state and then heat-treated to achieve steel-like strength, though the cost and beryllium dust management make it a premium choice reserved for critical safety systems.

Precision Stamping Processes and Manufacturing Challenges

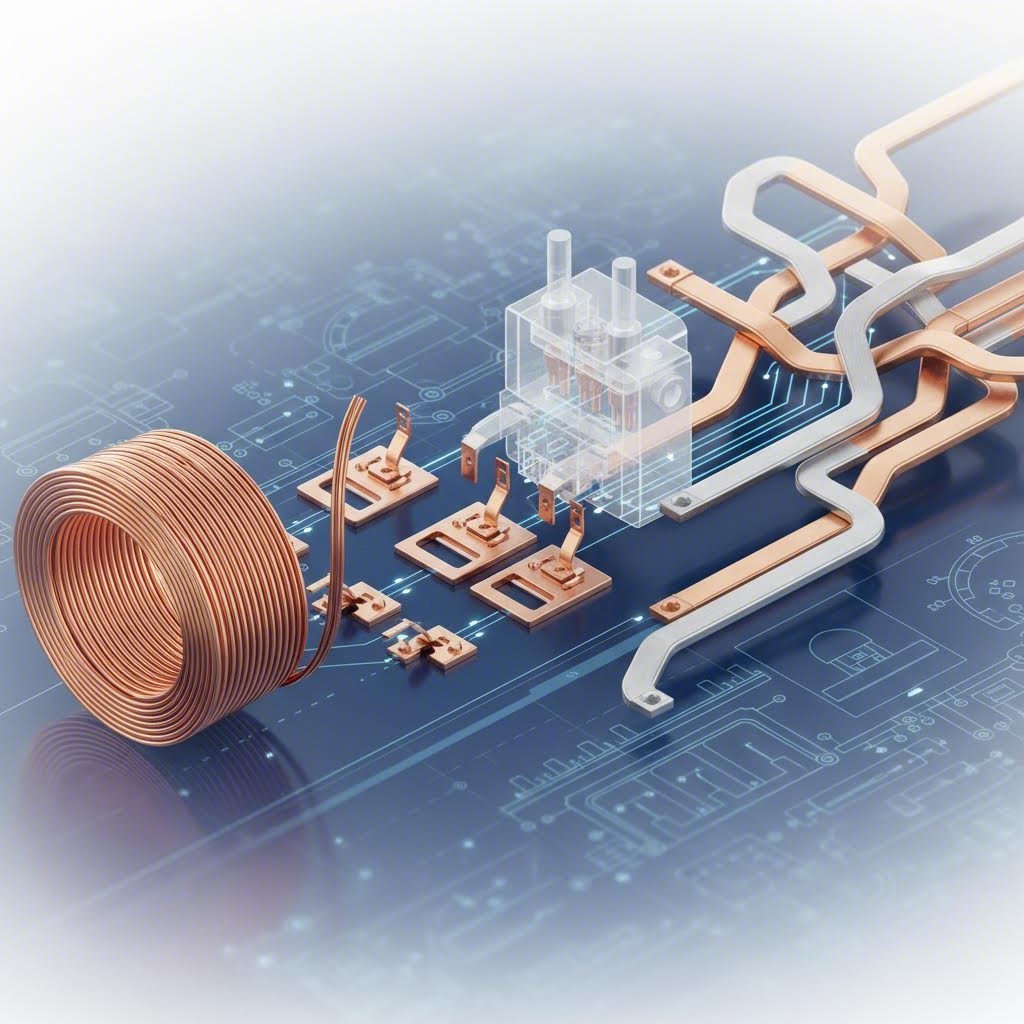

Transforming raw coil into a finished terminal involves more than just brute force. Progressive die stamping is the dominant method for high-volume automotive production, but it introduces specific technical challenges that manufacturers must overcome.

Managing Springback in High-Strength Alloys

As automotive designs favor stronger materials like C70250 or stainless steel-copper composites, "springback" becomes a major hurdle. Springback occurs when the metal tries to return to its original shape after bending, distorting critical tolerances. Experienced stampers counter this by over-bending the material (bending past 90° so it relaxes back to 90°) or using "coining" techniques to relieve internal stresses at the bend radius. The harder the alloy, the more unpredictable the springback, requiring sophisticated tool design and simulation.

Plating and Oxidation Control

Copper is naturally reactive. A fresh oxide layer (patina) can form quickly, interfering with conductivity. For automotive reliability, components are often plated with tin, silver, or gold. The dilemma is when to plate: pre-plating (plating the coil before stamping) is cost-effective but leaves bare metal edges on cut sides, which can corrode. Post-plating (plating loose parts after stamping) offers 100% coverage but is more expensive and risks part entanglement. The choice depends on the component's exposure to elements—under-hood parts typically require the full protection of post-plating.

EV Trends: High Voltage and Miniaturization

The electrification of vehicles has fundamentally altered stamping requirements. Traditional 12V systems allowed for generous tolerances and standard brass terminals. However, 400V and 800V EV architectures demand substantial upgrades in material performance.

Thermal Management & Busbars

High-voltage systems generate significant heat. Stamped busbars made from C11000 or C10200 (Oxygen-Free) copper are replacing round cables because they dissipate heat more efficiently and can be stamped into complex 3D shapes to navigate tight battery packs. These components must often be thick (2mm–6mm), requiring heavy-tonnage presses (300+ tons) that standard connector stampers may not possess.

Miniaturization of Signal Contacts

Conversely, the explosion of sensors for autonomous driving requires microscopic connectors. Stamping these micro-miniature parts requires high-speed presses capable of 1,000+ strokes per minute and vision systems that inspect 100% of parts inline. Alloys must be stronger to hold contact force with less material mass, driving the adoption of high-strength Cu-Ni-Si and Cu-Cr-Zr alloys.

Supplier Selection: IATF 16949 and Engineering Capability

In the automotive supply chain, the ability to stamp a part is secondary to the ability to guarantee it won't fail. The baseline requirement is IATF 16949 certification, a rigorous quality management standard specifically for the automotive sector. It mandates not just error detection, but error prevention through tools like PFMEA (Process Failure Mode and Effects Analysis).

When vetting suppliers, look beyond the certification certificate. Assess their vertically integrated capabilities. Can they design the progressive die in-house? Do they offer prototyping to validate material selection before cutting hard tooling? Manufacturers like Shaoyi Metal Technology exemplify this integrated approach, leveraging heavy-tonnage press capabilities (up to 600 tons) and IATF 16949 protocols to bridge the gap from rapid prototyping to high-volume mass production of critical safety components.

Key questions for your potential partner include:

- Traceability: Can they trace a specific batch of C70250 coil to a specific production lot of finished terminals?

- Tool Maintenance: Do they have in-house EDM and grinding to maintain die sharpness, preventing burrs that could cause electrical shorts?

- Capacity: Can they scale from 10,000 prototype parts to 5 million annual units without redesigning the tooling?

Conclusion: Securing the Connection

The reliability of an automotive electrical system is defined by its weakest link—often a stamped metal clip buried deep within a connector housing. By moving beyond default material choices and aligning alloy properties with specific environmental stressors (heat, vibration, current), engineers can eliminate failure modes before they occur. Whether leveraging the conductivity of C11000 for busbars or the relaxation resistance of C70250 for EV sensors, the successful application of copper alloy stamping relies on a deep understanding of the material science and a partnership with a capable, certified manufacturer.

Frequently Asked Questions

1. Why is C70250 preferred over Brass for EV connectors?

C70250 (Cu-Ni-Si) offers a superior balance of properties for Electric Vehicles compared to standard brass. While brass loses its spring force (stress relaxation) at temperatures above 100°C, C70250 remains stable up to 150°C. Additionally, it provides roughly 40–50% IACS conductivity compared to brass's ~28%, making it more efficient for higher-current signal applications and reducing heat generation.

2. What is the difference between Pre-plating and Post-plating in stamping?

Pre-plating involves stamping parts from a metal coil that is already plated (e.g., with tin). This is cheaper but leaves the stamped edges (where the metal was cut) unplated and exposed to oxidation. Post-plating involves stamping the raw metal first, then plating the loose parts in a barrel or rack. Post-plating covers 100% of the surface, offering superior corrosion resistance, but is generally more expensive.

3. Can C11000 copper be used for spring contacts?

Generally, no. C11000 (pure copper) has excellent conductivity but very poor mechanical strength and yield properties. If used as a spring, it will plastically deform (bend and stay bent) rather than springing back to maintain contact force. Alloys like Phosphor Bronze (C51000) or Beryllium Copper (C17200) are used for springs because they possess the high yield strength elasticity required to maintain connection pressure.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —