Progressive Die Vs Transfer Die For Stamping: Your Selection Framework

Choosing Between Progressive and Transfer Dies for Your Next Project

Imagine you're facing a critical decision point. Your engineering team has finalized the part design, production volumes are projected, and now everything hinges on one choice: which stamping die technology will bring your project to life? Select the wrong option, and you're looking at wasted tooling investments, frustrating production delays, and quality issues that ripple through your entire supply chain.

This scenario plays out daily in manufacturing facilities worldwide. The stakes are significant—choosing between a progressive die and a transfer die isn't just a technical preference. It's a strategic decision that directly impacts your bottom line, timeline, and product quality.

Why Your Die Selection Determines Project Success

Your choice of stamping die influences every aspect of your manufacturing operation. When you select the right die type, you'll experience improved part consistency, reduced scrap rates, and optimized cycle times. Get it wrong, and you're facing costly tool modifications, production bottlenecks, and potential quality failures.

Consider this: approximately 25% of project budgets can be lost due to fabrication errors and poor planning decisions. In the world of dies and stamping, that percentage climbs even higher when tooling doesn't match your application requirements. The financial impact extends beyond initial investment—it affects maintenance costs, material utilization, and long-term operational efficiency.

What This Comparison Guide Delivers

This guide goes beyond basic definitions of different types of stamping dies. Instead, you'll find actionable selection criteria that help you match your specific project parameters to the optimal die technology. We've built this framework around real-world decision factors that manufacturing engineers and procurement professionals actually face.

Here are the five critical decision factors this guide addresses:

- Part Geometry and Complexity – Understanding which die type handles your specific forming requirements, from simple blanking to complex three-dimensional shapes

- Production Volume Requirements – Identifying the volume thresholds where each die type becomes cost-effective for your operation

- Material Considerations – Matching die capabilities to your material thickness, hardness, and formability characteristics

- Tooling Investment and Total Cost – Evaluating upfront costs alongside long-term operational expenses for accurate ROI projections

- Lead Time and Flexibility Needs – Balancing speed-to-production against future design change requirements

Whether you're evaluating a progressive die for high-volume electrical components or considering a transfer die for larger automotive stampings, the framework ahead will guide you toward the right decision. Let's dive into the evaluation criteria that separate successful projects from costly missteps.

Evaluation Criteria for Stamping Die Selection

Before diving into the specifics of each die type, you need a reliable measuring stick. How do you objectively compare a progressive stamping setup against a transfer die system when both manufacturers claim their solution is "ideal" for your application? The answer lies in establishing clear, quantifiable evaluation criteria that cut through the marketing noise.

Whether you're a design engineer wrestling with tolerance requirements or a procurement professional balancing capital expenditure against operational costs, you deserve technical depth—not vague generalizations. That's exactly what this framework delivers.

Seven Criteria for Objective Die Comparison

The evaluation framework used throughout this guide centers on seven interconnected performance factors. Each criterion addresses a specific aspect of die and stamping operations, and together they provide a comprehensive picture of how each technology performs under real-world conditions.

- Part Geometry Capabilities – This criterion examines what shapes, features, and forming operations each die type can reliably produce. Progressive dies excel at parts requiring sequential operations on a continuous strip, while transfer dies accommodate more complex three-dimensional geometries. Understanding these boundaries prevents costly redesigns after tooling is already built.

- Production Volume Suitability – Different die technologies hit their economic sweet spots at different volume thresholds. Precision die stamping for millions of identical parts demands different tooling than a 50,000-piece annual run. This criterion establishes where each method delivers optimal cost-per-part efficiency.

- Material Thickness Range – Not every die stamping machine handles all material gauges equally well. Thin materials under 0.5mm present feeding and handling challenges, while thicker stock above 6mm requires significantly higher tonnage and different forming approaches. This factor matches your material specifications to appropriate technology.

- Tolerance Precision – When your application demands tight dimensional control, understanding each die type's inherent precision capabilities becomes critical. Some configurations naturally maintain tighter tolerances than others due to their mechanical operation and part handling methods.

- Tooling Cost Structure – Initial die investment represents just the starting point. This criterion breaks down the complete cost picture: design engineering, die construction, tryout and validation, plus the often-overlooked costs of modifications and spare components.

- Cycle Time Efficiency – Production speed directly impacts your cost-per-part calculations and capacity planning. Progressive tool and die setups typically deliver faster cycle times than transfer systems, but the gap varies significantly based on part complexity and press specifications.

- Maintenance Requirements – Long-term operational costs depend heavily on maintenance intensity. This includes scheduled preventive maintenance, wear component replacement frequency, and the complexity of repairs when issues arise. Some die configurations demand more frequent attention than others.

How We Evaluated Each Stamping Method

These seven criteria aren't arbitrary selections—they represent the factors that consistently determine project success or failure in die stamping operations. Our recommendations throughout this guide consider both initial investment implications and long-term operational costs, giving you a complete financial picture rather than just upfront pricing.

When examining each criterion, we've weighted real-world performance data over theoretical specifications. A die stamping machine might be rated for certain tolerances under ideal conditions, but actual production environments introduce variables that affect outcomes. The assessments ahead reflect what you can realistically expect in your facility.

You'll notice these criteria overlap and influence each other. For instance, tighter tolerance requirements often increase tooling costs and maintenance demands. Higher production volumes can justify greater initial investment but require more robust maintenance programs. Understanding these trade-offs helps you balance competing priorities rather than optimizing for a single factor at the expense of others.

With this evaluation framework established, you're equipped to assess each die type objectively. Let's apply these criteria to progressive die technology first, examining how this high-speed production method performs across all seven dimensions.

Progressive Die Stamping for High-Volume Precision Parts

When production demands call for millions of identical components with consistent quality, progressive die stamping emerges as the workhorse solution. This technology transforms continuous metal strips into finished parts through a carefully orchestrated sequence of operations—all without the material ever leaving the die until the final piece is complete.

But what makes progressive metal stamping so effective for high-volume applications? The answer lies in its ingenious approach to material handling and station sequencing. Let's break down exactly how this process achieves the speed and precision that manufacturers rely on.

How Progressive Dies Achieve High-Speed Production

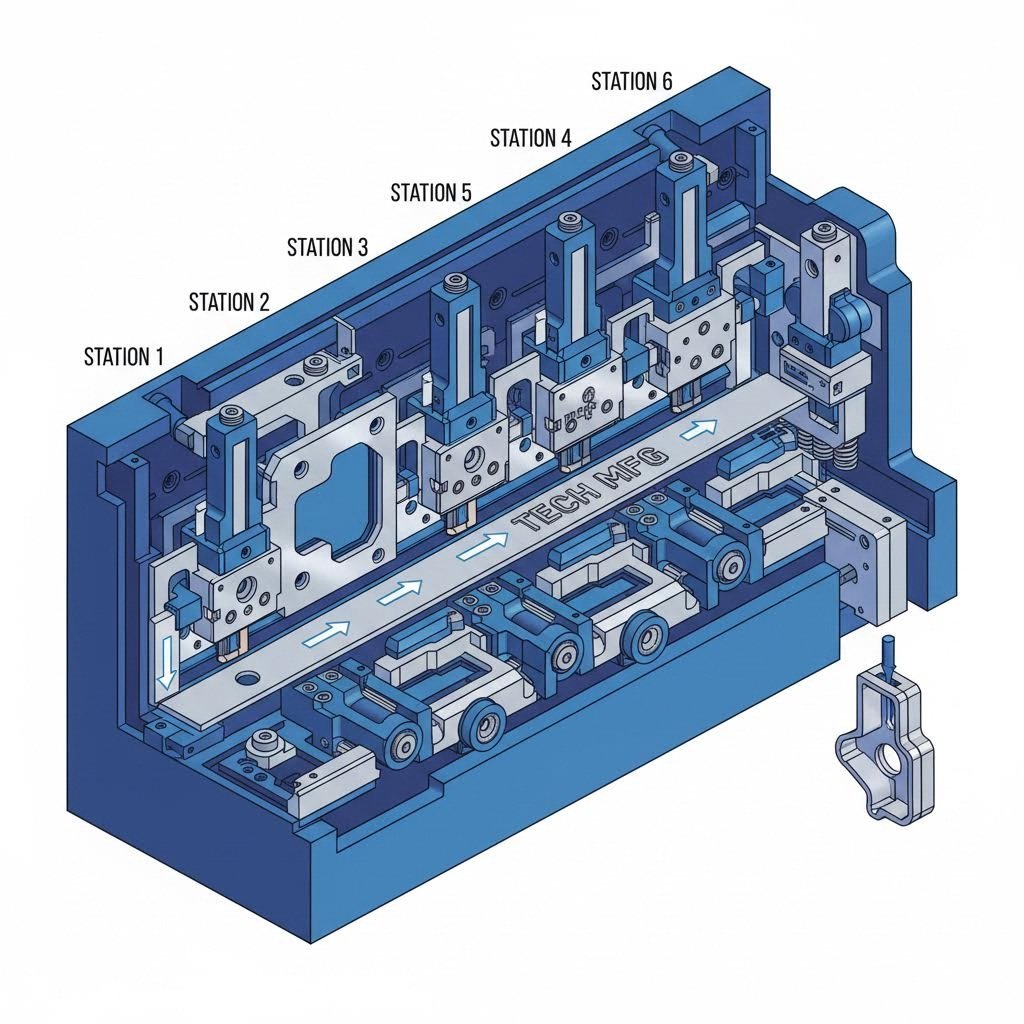

Picture a continuous strip of metal feeding through a die in progressive stamping. Unlike other methods where blanks are cut first and then transferred between stations, the strip remains connected throughout the entire forming process. Each press stroke advances the material to the next station, where a new operation takes place while previous sections undergo their designated tasks simultaneously.

The standard progressive die stamping process follows a carefully designed station sequence:

- Pilot holes – The first stations typically punch pilot holes that serve as precise alignment references. These holes engage with pilot pins at each subsequent station, ensuring accurate positioning throughout the die.

- Piercing operations – Interior holes, slots, and cutouts are created before any forming takes place. Piercing flat material yields cleaner edges and more consistent dimensions than punching formed sections.

- Forming sequences – Bending, drawing, coining, and embossing operations progressively shape the part. Complex geometries often require multiple forming stations to avoid material stress or cracking.

- Cutoff and ejection – The final station separates the completed part from the carrier strip and ejects it from the die. The remaining skeleton material advances out of the press for recycling.

A progressive stamping press can execute this entire sequence at rates exceeding 1,000 strokes per minute for smaller parts. This high speed metal stamping capability, combined with minimal operator intervention, explains why progressive dies dominate high-volume production environments.

Core Strengths of Progressive Die Technology

The die in progressive configurations delivers several distinct advantages that directly address the evaluation criteria established earlier:

- Minimal material handling – Parts remain attached to the carrier strip until completion, eliminating transfer mechanisms and reducing opportunities for damage or misalignment between operations.

- Faster cycle times – Multiple operations occur simultaneously with each press stroke. A ten-station die produces one complete part per stroke while performing ten different operations across the strip.

- Excellent for high-volume runs – The automated nature of progressive stamping makes it extremely cost-effective once volumes exceed 10,000 to 25,000 pieces annually, with cost-per-part advantages increasing dramatically at higher quantities.

- Consistent part quality – Pilot pins ensure precise registration at every station, and the controlled strip progression eliminates the variability that manual or semi-automated handling can introduce.

- Reduced labor requirements – Once set up, progressive dies run with minimal operator involvement. One technician can often monitor multiple presses simultaneously.

- Material efficiency – Careful strip layout and nesting optimization minimize scrap, with material utilization rates often exceeding 75-85% depending on part geometry.

Forming Capabilities Within Progressive Dies

Progressive stamping dies accommodate a surprisingly wide range of forming techniques. Understanding these capabilities helps you determine whether your part geometry fits within progressive technology's sweet spot.

Bending operations form the backbone of most progressive stamped automotive parts and electrical components. V-bends, U-bends, and Z-bends are readily achieved across multiple stations when the bend sequence is properly designed. The key constraint? Each bend must allow the part to continue advancing through subsequent stations without interference.

Coining operations deliver exceptional dimensional control by applying high pressure to compress and flow material into precise die cavities. This technique creates sharp corners, fine details, and tight thickness tolerances that other forming methods struggle to match.

Embossing and shallow draws add three-dimensional features to otherwise flat parts. Ribs, bosses, and shallow cup shapes work well in progressive dies, though draw depth limitations exist based on material properties and strip width constraints.

Material Thickness Considerations

Progressive dies handle an impressive range of material thicknesses, but performance varies significantly across this spectrum. Understanding where progressive dies excel—and where they struggle—prevents costly tool modifications and production headaches.

Optimal thickness range: 0.2mm to 4.0mm

Most progressive stamping die applications fall within this window. Strip feeding mechanisms work reliably, forming operations achieve consistent results, and standard press tonnage accommodates typical part geometries.

Thin material challenges (under 0.2mm)

Very thin materials present feeding difficulties, tend to buckle between stations, and may not register accurately on pilot pins. Specialized feeding equipment and modified die designs can address these issues, but costs increase accordingly.

Thick material limitations (over 4.0mm)

Heavier gauge materials require substantially higher press tonnage and more robust die construction. The increased forming forces can accelerate die wear and may limit the number of operations achievable within a single die.

Ideal Applications for Progressive Stamping

Where does progressive die technology truly shine? Applications combining several favorable characteristics:

- Annual volumes exceeding 25,000 pieces (with optimal efficiency above 100,000 units)

- Part widths that fit within available strip widths (typically under 300mm)

- Moderate forming complexity without deep draws

- Material thickness between 0.3mm and 3.0mm

- Tight tolerance requirements benefiting from consistent registration

Industries leveraging these advantages include automotive (brackets, terminals, connectors), electronics (contacts, shields, frames), appliances (mounting hardware, internal components), and medical devices (precision components requiring high repeatability).

Limitations to Consider

No technology fits every application. Progressive dies encounter constraints that may push certain projects toward transfer die solutions:

- Part size constraints – Strip width limitations restrict maximum part dimensions. Very large parts simply cannot be produced via progressive stamping.

- Deep draw limitations – Parts requiring significant draw depths often exceed what's achievable while maintaining strip connectivity between stations.

- Three-dimensional complexity – Highly complex geometries requiring operations from multiple angles may not be feasible within the linear progression of a progressive die.

- Secondary operations between stations – If your part requires welding, tapping, or other non-stamping operations mid-process, progressive dies cannot accommodate these interruptions.

When your application bumps against these limitations, transfer die technology often provides the solution. Let's examine how transfer stamping addresses the complex, large-format parts that progressive dies cannot efficiently produce.

Transfer Die Stamping for Complex Large-Format Parts

What happens when your part design exceeds progressive die capabilities? When deeper draws, larger dimensions, or complex three-dimensional geometries enter the picture, transfer die stamping becomes your go-to solution. This technology takes a fundamentally different approach—separating the blank from the parent material at the very first operation, then moving it freely through subsequent forming stations.

Think of it this way: while progressive stamping keeps parts tethered to a carrier strip, transfer stamping liberates each blank to be manipulated from any angle. This freedom unlocks manufacturing possibilities that simply aren't achievable otherwise.

Transfer Die Mechanics and Automation Systems

The distinguishing feature of transfer die stamping lies in how workpieces move through the process. Rather than advancing on a continuous strip, individual blanks travel between stations via a sophisticated mechanical transfer system. Understanding this mechanism reveals why transfer dies excel at complex part production.

Here's how the transfer stamping process unfolds:

Stage 1: Blanking Operation

The process begins with a coil of raw metal feeding into the first station. Here, a blanking die cuts the initial part shape—called a blank—from the continuous strip. This is the critical moment where transfer stamping diverges from progressive methods. The blank becomes a free agent, no longer attached to a carrier strip.

Stage 2: Mechanical Transfer Engagement

As the press ram opens, part lifters raise the freshly cut blank off the lower die surface. Simultaneously, the transfer system activates. Two parallel rails running the length of the die move inward, and specialized fingers or grippers mounted on these rails firmly clamp the blank's edges.

Stage 3: Precision Movement

With the blank secured, the entire transfer rail assembly executes a carefully choreographed sequence: lifting the part vertically, moving it horizontally to the next station, and lowering it with extreme precision onto locating pins. The fingers release, rails retract, and all this happens before the press ram begins its downward stroke—often within fractions of a second.

Stage 4: Sequential Forming

The blank progresses through successive stations, each designed for a specific forming operation. Because the part isn't constrained by strip connectivity, die designers enjoy remarkable flexibility in operation sequencing.

Transfer dies rely on either mechanical or pneumatic mechanisms to power this movement. The transfer system consists of fingers resting on transfer bars that move through the X and Y axes—or in more advanced configurations, through X, Y, and Z axes—to grasp blanks and position them with perfect alignment before each operation.

Transfer Press Requirements and Tonnage Considerations

Running transfer dies demands specialized equipment. A transfer stamping press differs significantly from standard progressive presses in several key aspects:

- Larger bed dimensions – Transfer presses feature extended bed areas to accommodate multiple die stations arranged in sequence. The bed must support the weight of the complete die set plus the transfer mechanism hardware.

- Higher tonnage capacity – Deep drawing operations and larger part sizes typically require greater forming forces. Transfer presses commonly range from 400 to 2,500 tons, though applications vary widely.

- Integrated transfer mechanisms – Unlike progressive presses where strip feeding handles material movement, transfer presses incorporate the rail and gripper systems as integral components.

- Slower stroke rates – The mechanical complexity of transferring individual blanks limits cycle speeds compared to progressive operations. However, this trade-off enables forming operations impossible in progressive dies.

When evaluating a die-stamping machine for transfer applications, tonnage selection becomes critical. Undersized presses struggle with deep draws and thick materials, while oversized equipment wastes energy and floor space. Proper matching requires careful analysis of forming forces at each station.

When Transfer Stamping Outperforms Progressive Methods

Transfer die technology delivers decisive advantages for specific application profiles. Understanding these strengths helps you identify when transfer stamping represents your optimal choice.

- Handles larger parts – Without strip width limitations constraining part dimensions, transfer dies produce components that simply won't fit in progressive configurations. Automotive structural panels, large appliance housings, and industrial enclosures often require transfer stamping.

- Accommodates deeper draws – This capability represents transfer stamping's most significant advantage. When the blank is released, material can flow uniformly into the die cavity from all directions. Progressive dies must draw material from the sides connected to the carrier strip, limiting draw depth before tearing occurs. Parts deeper than their diameter almost always require transfer die technology.

- Allows complex three-dimensional forming – With 360-degree access to the part at each station, engineers can incorporate side holes, undercuts, angled flanges, and complex surface contours. Features that would interfere with strip progression become perfectly feasible.

- Enables secondary operations between stations – Transfer dies can integrate tapping heads for threaded holes, welding units for attaching nuts or brackets, and automated systems for inserting plastic or rubber components. This in-die integration dramatically simplifies supply chains.

- Supports multi-axis manipulation – Parts can be rotated, flipped, or repositioned between stations. This flexibility enables forming operations from multiple orientations within a single press cycle.

Material Utilization Advantages

Beyond forming capabilities, transfer dies offer significant material cost benefits that directly impact your bottom line.

Progressive stamping inherently generates scrap in the form of the carrier strip skeleton. This waste represents a substantial percentage of total material cost, especially when working with expensive alloys like stainless steel, aluminum, or brass.

Transfer stamping eliminates this waste stream entirely. Because blanks are cut first and then processed independently, you can optimize blank nesting patterns on the raw coil. Blanks can be arranged in staggered or rotated configurations that maximize the number of parts produced per ton of metal—sometimes using 20% or more less raw material than equivalent progressive die layouts.

For high-volume production runs involving costly materials, these savings often offset the higher tooling investment associated with transfer tool products. The environmental benefits of reduced material consumption add another dimension to this advantage.

Transfer Die Limitations

Every technology involves trade-offs. Transfer stamping's enhanced capabilities come with specific constraints you should factor into your decision:

- Slower cycle times – The mechanical complexity of gripping, transferring, and releasing individual blanks limits production speed. While progressive presses may exceed 1,000 strokes per minute, transfer press stamping typically operates at 10-30 strokes per minute depending on part complexity and transfer distance.

- Higher automation complexity – Transfer mechanisms require precise synchronization between press motion and part movement. The transfer system adds components that must be designed, calibrated, and maintained alongside the die itself.

- Increased maintenance demands – Grippers wear, rails require adjustment, and timing mechanisms need periodic calibration. The transfer system introduces maintenance requirements beyond those of the die stations themselves.

- Greater initial investment – Transfer dies typically cost more than progressive dies for comparable part complexity due to the modular station design and transfer mechanism requirements. Transfer presses also represent larger capital investments than standard progressive press equipment.

- Setup complexity – Achieving perfect synchronization between press stroke timing and transfer mechanism movement requires skilled setup technicians. The testing and installation time to achieve optimal parts movement coordination can be substantial.

Application Sweet Spots for Transfer Dies

Transfer die stamping finds its strongest applications in industries requiring complex, deep-drawn, or large-format components:

Automotive sector – Structural components demanding both strength and light weight, engine oil pans, transmission housings, seat frames, brake calipers, and cylinder heads frequently utilize transfer stamping.

Appliance manufacturing – Deep-drawn stainless steel components requiring excellent surface finishes, such as kitchen sinks, cookware, and washer drums, rely on transfer die capabilities.

Industrial equipment – Pressure vessels, canisters, and housings that must withstand harsh environments benefit from transfer stamping's deep draw and complex forming abilities.

Plumbing and hardware – Fixtures and components requiring the formability and finish quality that transfer stamping provides.

When your project specifications align with these profiles—particularly when deep draws or large part sizes are involved—transfer stamping typically delivers the optimal balance of capability and economy.

But what about simpler parts that don't require either progressive or transfer die complexity? For certain geometries, a third option offers compelling advantages worth exploring.

Compound Die Alternative for Simpler Part Geometries

Not every stamping project demands the complexity of progressive or transfer die technology. Sometimes the smartest engineering decision is recognizing when a simpler solution delivers better results. Enter compound die stamping—the often-overlooked third option that can save you significant tooling investment while achieving exceptional precision for the right applications.

Many competitors mention compound dies in passing but never fully explain when this approach makes strategic sense. That knowledge gap costs manufacturers money. Understanding where compound dies outperform more complex alternatives helps you avoid over-engineering your tooling solution.

Compound Dies for Simple High-Precision Parts

What distinguishes a compound die from its progressive and transfer counterparts? The answer lies in a fundamental operational difference: a compound die performs multiple cuts, punches, and operations in one stroke rather than multiple strokes. Everything happens simultaneously at a single station.

Imagine a washer production scenario. A progressive die would feed a strip through multiple stations—piercing the center hole at one station, blanking the outer diameter at another. A compound die accomplishes both operations in a single press stroke. The punch descends, and the finished washer drops out complete.

This single-stroke efficiency creates remarkable advantages for appropriate applications:

- Superior concentricity and alignment – Because all operations occur simultaneously in the same die cavity, features maintain perfect geometric relationships. The center hole of that washer aligns precisely with the outer diameter every single time.

- Exceptional flatness – Parts exit the metal stamping die without the residual stresses that sequential operations can introduce. This characteristic proves critical for precision flat components.

- Faster per-stroke production – For simple geometries, compound dies produce finished parts faster than progressive dies require to move material through multiple stations.

- Lower tooling complexity – Single-station designs mean fewer components, simpler construction, and reduced points of potential failure.

When Single-Station Stamping Makes Sense

Compound die stamping finds its sweet spot in a specific application profile. Recognizing these characteristics helps you identify projects where this simpler technology delivers optimal results.

Ideal applications for compound die stamping include:

- Flat parts requiring blanking and piercing only – Washers, gaskets, shims, and simple brackets that need precise hole patterns without forming operations represent classic compound die candidates.

- Components demanding extremely tight tolerances – When concentricity, perpendicularity, or positional tolerances must meet stringent specifications, the simultaneous operation of compound dies delivers inherent advantages over sequential processing.

- Lower to medium volume production – Projects in the medium- to high-volume range where progressive die stampings would represent over-investment benefit from compound die economics.

- Parts with simple external profiles – Round, square, rectangular, or simple contoured parts without complex forming requirements.

- Thin material applications – Compound dies handle thin gauge materials effectively, producing clean edges without the feeding complications that thin strips can create in progressive systems.

Comparing Compound Dies to Progressive and Transfer Options

How does compound die technology stack up against the alternatives you've already explored? The comparison reveals clear trade-offs that guide appropriate technology selection.

Compound vs. Progressive Dies:

Compound dies produce finished parts faster on a per-stroke basis for simple geometries. However, progressive dies accommodate far more complex part designs with multiple bends, forms, and features. The custom tooling for compound dies costs less to develop than complex progressive die tooling, making them economically attractive for simpler parts.

Think of it this way: if your part is essentially flat with holes, compound dies likely win. Once you need bends, forms, or sequential operations, progressive technology becomes necessary.

Compound vs. Transfer Dies:

Transfer dies handle the complex three-dimensional geometries and deep draws that compound dies cannot approach. But for simple flat parts, transfer die technology represents massive over-engineering. The transfer mechanism, multiple stations, and specialized press requirements add costs that deliver zero benefit for basic blanking and piercing operations.

Cost Advantages for Appropriate Applications

When your part geometry fits the compound die profile, the economic benefits become compelling:

- Lower initial tooling investment – Simpler die construction translates directly to reduced engineering and manufacturing costs. A compound metal stamping die for a basic washer might cost 40-60% less than a progressive die producing the same part.

- Reduced setup time – Single-station dies require less adjustment and validation than multi-station progressive setups.

- Simplified maintenance – Fewer moving parts and stations mean fewer components requiring inspection, sharpening, and replacement.

- High repeatability – The high degree of repeatability for single-die cases ensures consistent quality throughout production runs.

The key insight? Compound dies eliminate the need for more complex tooling when your part simply doesn't require it. Investing in progressive or transfer capability for a part that could run on a compound die wastes capital that could fund other projects.

With all three major die technologies now on the table, you're ready for a direct comparison that puts concrete numbers and specifications side by side. The next section delivers exactly that—comprehensive comparison matrices that translate these concepts into actionable selection guidance.

Progressive vs Transfer vs Compound Die Comparison Matrix

You've explored each die technology individually—now it's time to see how they stack up head-to-head. This side-by-side comparison cuts through the complexity and gives you the concrete data needed to match your specific project requirements to the optimal stamping solution.

Whether you're evaluating progressive die and stamping options for high-volume electrical components or considering transfer tooling for complex automotive assemblies, these comparison matrices translate technical capabilities into actionable decision criteria.

Head-to-Head Performance Comparison

The following table compares all three die types across the seven evaluation criteria established earlier. Use this as your primary reference when weighing technical capabilities against your project specifications.

| Evaluation Criteria | Progressive Die | Transfer Die | Compound Die |

|---|---|---|---|

| Part Size Range | Small to medium (limited by strip width, typically under 300mm) | Medium to large (no strip width constraints) | Small to medium (single station limits) |

| Complexity Capability | Moderate—sequential bends, piercing, shallow draws; limited 3D forming | High—deep draws, complex 3D shapes, multi-axis operations, secondary processes | Low—flat parts with blanking and piercing only |

| Production Volume Sweet Spot | High volume: 25,000 to millions annually | Medium to high volume: 10,000 to 500,000 annually | Low to medium volume: 5,000 to 100,000 annually |

| Typical Cycle Times | Very fast: 60-1,500+ strokes per minute | Slower: 10-30 strokes per minute | Moderate: 30-100 strokes per minute |

| Tooling Investment Level | Medium to high initial cost; excellent cost-per-part at volume | High initial cost; justified by capability requirements | Lower initial cost; economical for simpler geometries |

| Maintenance Intensity | Moderate—multiple stations require regular inspection | Higher—transfer mechanisms add complexity and wear points | Lower—single station means fewer components |

| Material Utilization | Good (75-85%)—carrier strip creates some scrap | Excellent (85-95%)—optimized blank nesting possible | Good—depends on part geometry and blank layout |

Notice how the die transfer approach sacrifices speed for capability, while progressive die metal stamping trades complexity limits for exceptional throughput. Compound dies occupy a distinct niche where simplicity becomes the primary advantage.

Volume Breakpoints: When Each Method Becomes Cost-Effective

Production volume significantly influences which technology delivers the best return on your tooling investment. Here's where the numbers tell the story:

- Below 5,000 pieces annually—Consider compound dies or even single-station tooling. The lower tooling investment recovers faster at these volumes, and simpler dies meet basic requirements efficiently.

- 5,000 to 25,000 pieces annually—Compound dies often win for flat parts. Progressive dies become viable for complex parts where their capability justifies higher initial cost.

- 25,000 to 100,000 pieces annually—Progressive stamping typically delivers optimal cost-per-part for appropriate geometries. The copper progressive stamping applications common in electrical components often fall within this range.

- 100,000+ pieces annually—Progressive dies dominate for compatible parts. Transfer dies become cost-effective when part complexity demands their capabilities, despite higher per-piece costs.

Remember: these thresholds shift based on part complexity, material costs, and tolerance requirements. A complex part requiring transfer die capabilities might justify the investment at 15,000 annual pieces if no other method can produce it.

Matching Die Type to Your Production Requirements

Beyond raw performance metrics, application suitability matters. Different industries place varying emphasis on the seven evaluation criteria. The following matrix maps die technologies to common application categories.

| Application Category | Progressive Die Suitability | Transfer Die Suitability | Compound Die Suitability |

|---|---|---|---|

| Automotive Components | Excellent for brackets, terminals, connectors, small structural parts | Excellent for deep-drawn panels, housings, structural assemblies | Limited to simple flat brackets and washers |

| Electrical Stampings | Excellent—the electrical stamping process benefits from high-speed production of contacts and terminals | Good for larger enclosures and complex housings | Good for simple flat contacts and shims |

| Appliance Parts | Good for mounting hardware, small internal components, hinges | Excellent for deep-drawn tubs, drums, stainless steel components | Limited to flat hardware components |

| Medical Devices | Excellent for precision components requiring tight tolerances and high repeatability | Good for larger surgical instrument components | Excellent for precision flat components with critical concentricity |

Tolerance and Precision Considerations

When dimensional accuracy drives your decision, understanding each technology's inherent precision capabilities becomes critical:

- Progressive dies achieve typical tolerances of ±0.05mm to ±0.1mm on most features, with tighter control possible through precision tooling and consistent pilot registration.

- Transfer dies match or slightly exceed progressive tolerances for formed features, with ±0.05mm achievable on critical dimensions through careful die design and consistent blank positioning.

- Compound dies deliver the tightest tolerances for flat-part features—±0.025mm concentricity is achievable because all operations occur simultaneously in a single cavity.

For pressing and stamping applications where geometric relationships between features matter more than absolute dimensions, compound dies often outperform more complex alternatives despite their limited forming capability.

Making Your Comparison Work

These matrices provide the framework, but your specific application determines which factors carry the most weight. Consider these priority guidelines:

- Volume-driven projects—Start with cycle time efficiency and tooling cost structure. Progressive dies almost always win for high-volume, compatible geometries.

- Complexity-driven projects—Lead with geometry capabilities. If transfer dies are the only option that works, volume and cost become secondary considerations.

- Tolerance-driven projects—Focus on inherent precision capabilities. Compound dies for flat parts, progressive or transfer for formed features with proper die design.

- Budget-constrained projects—Evaluate compound dies first for simple parts, then progressive dies if complexity requires it. Transfer dies represent the highest investment tier.

With these comparison frameworks in hand, you're equipped to narrow your technology selection. But choosing between progressive, transfer, and compound dies is only half the equation—selecting the right manufacturing partner to execute your tooling project matters equally. Let's examine what separates capable die suppliers from exceptional ones.

Selecting the Right Stamping Die Partner

You've identified whether progressive, transfer, or compound die technology best fits your project. Now comes an equally critical decision: which supplier will design, build, and support your tooling investment? The wrong partner can transform a sound technology choice into months of delays, costly modifications, and quality headaches that undermine your entire production program.

Finding a stamping die partner isn't about locating the lowest quote. It's about identifying a team with the engineering depth, quality systems, and production capabilities to deliver tooling that performs from day one. Let's examine what separates reliable progressive die tooling suppliers from those that leave you troubleshooting problems for months after delivery.

Evaluating Die Suppliers for Your Project Type

The capabilities that matter most depend on your specific project requirements. A supplier excelling at high-volume progressive stamping dies may struggle with complex transfer die applications—and vice versa. Your evaluation should focus on alignment between your needs and their proven strengths.

Engineering Capabilities That Matter

Look beyond impressive equipment lists. The real differentiator lies in engineering expertise that prevents problems before they reach the production floor. When evaluating a potential partner's progressive stamping process capabilities, consider these factors:

- Design for Manufacturability (DFM) analysis—Can they identify part design modifications that improve stampability while maintaining functional requirements? Early DFM input prevents expensive tool changes later.

- Simulation technology investment—Modern die development relies heavily on CAE simulation to optimize forming operations before cutting steel. Suppliers using advanced forming simulation can predict and prevent defects like wrinkling, tearing, and springback during the design phase.

- Material expertise—Different metals behave differently in forming operations. A supplier with deep experience in your specific material—whether high-strength steel, aluminum alloys, or copper—can anticipate challenges that generalists miss.

- Progressive stamping and fabrication integration—Some projects benefit from suppliers offering secondary operations like welding, assembly, or finishing. This integration simplifies your supply chain and reduces quality risks at handoff points.

Quality Certifications That Signal Reliability

Certifications provide third-party validation that a supplier maintains robust quality systems. For automotive applications, IATF 16949 certification represents the gold standard—demonstrating compliance with the rigorous quality management requirements that major OEMs demand. ISO 9001 certification establishes baseline quality system competence across industries.

Beyond certifications, examine their quality infrastructure. Do they maintain in-house metrology capabilities? Can they perform PPAP documentation if your program requires it? These capabilities become critical when you need documented evidence of process capability.

Prototyping Speed and Validation Approach

How quickly can a potential partner validate your die design? Rapid prototyping capabilities reduce the risk of committing to full production tooling before proving out the concept. Some suppliers can deliver prototype parts in as little as 5 days, allowing you to validate fit, form, and function before major tooling investments.

Red Flags When Evaluating Suppliers

Not every supplier advertising progressive tool and manufacturing capabilities can actually deliver. Watch for these warning signs during your evaluation:

- Vague answers about specific experience—When asked about similar projects, capable suppliers provide concrete examples. Evasive responses suggest they're stretching beyond their proven capabilities.

- No simulation or CAE capability—Suppliers still relying solely on trial-and-error die development will cost you time and money during tryout. Modern progressive die stamping process optimization requires simulation technology.

- Resistance to facility visits—Reputable suppliers welcome customer audits. Reluctance to show their operation raises questions about actual capabilities versus marketing claims.

- Unusually low quotes—Tooling quotes significantly below competitors often indicate shortcuts in design, material quality, or validation that create problems during production.

- Poor communication during quoting—If they're unresponsive or unclear during the sales process, expect worse communication when problems arise during tooling development.

- No clear project management process—Complex die projects require structured milestone tracking. Suppliers without defined project management approaches often miss deadlines and deliver surprises.

- Limited material traceability—For critical applications, complete material certification and traceability from mill to finished part is essential. Suppliers unable to provide this documentation may have supply chain gaps.

From Design to Production Timeline Expectations

Understanding realistic lead times helps you plan your production ramp-up accurately. Die complexity, supplier capacity, and your responsiveness during review cycles all influence the schedule.

Typical Timeline Phases:

- Design engineering (2-6 weeks)—Die concept development, simulation analysis, and detailed design. Complex progressive stamping dies with many stations require longer design phases than simpler compound dies.

- Die construction (6-12 weeks)—Machining, assembly, and initial bench fitting. Precision components like die steels and carbide inserts may require additional lead time for specialized suppliers.

- Tryout and validation (1-4 weeks)—Initial press runs, adjustment, and optimization. This phase varies dramatically based on design quality and simulation accuracy. Suppliers achieving high first-pass approval rates minimize this phase significantly.

- Production ramp-up (2-4 weeks)—Process documentation, operator training, and initial production runs at increasing volumes.

Total lead times for progressive dies typically range from 12-20 weeks for moderately complex applications. Transfer dies often require 16-24 weeks due to additional complexity.

The Critical Role of CAE Simulation

Why does simulation capability matter so much? Because the traditional trial-and-error approach to die development wastes time, money, and material. When a die reaches the press for tryout, every modification costs weeks and thousands of dollars.

CAE simulation changes this equation fundamentally. By modeling material flow, forming forces, and springback behavior digitally, engineers can:

- Identify and correct potential defects before cutting die steel

- Optimize blank shape and size for material efficiency

- Predict and compensate for springback to achieve target dimensions

- Validate forming sequences before committing to station layouts

The result? Fewer tryout iterations, faster time-to-production, and tooling that works correctly from the start. Suppliers investing in simulation technology demonstrate commitment to first-pass success rather than fix-it-later approaches.

A Supplier Example: Comprehensive Die Solutions

Consider what comprehensive capability looks like in practice. Shaoyi represents an example of the engineering depth and quality infrastructure discussed above. Their IATF 16949 certification confirms automotive-grade quality systems, while their CAE simulation capabilities enable defect-free tooling development before physical tryout begins.

Their rapid prototyping capabilities—delivering parts in as few as 5 days—allow customers to validate designs quickly. Perhaps most significantly, their 93% first-pass approval rate demonstrates that simulation-driven development delivers real results: tooling that works correctly without extensive modification cycles.

For automotive applications requiring precision stamping with OEM-standard quality, exploring partners with this combination of engineering capability and proven performance reduces project risk significantly. You can learn more about their precision stamping die solutions to see how comprehensive capabilities translate into successful projects.

With supplier evaluation criteria established, you're ready to synthesize everything into a clear decision framework. The final section provides the step-by-step logic for matching your specific project parameters to the optimal die technology and partner selection.

Final Recommendations for Your Stamping Die Decision

You've absorbed the technical details, compared performance metrics, and evaluated supplier considerations. Now it's time to pull everything together into a practical decision framework you can apply to your next project. No more analysis paralysis—just clear logic that guides you from project specifications to confident technology selection.

The truth is, there's no universal winner in the progressive die vs transfer die debate. Each technology excels under specific conditions, and the best choice always depends on your unique project parameters. Let's walk through the decision process step by step.

Your Die Selection Decision Tree

Think of this as a systematic filter. Each question narrows your options until the optimal technology becomes clear. Work through these five decision points in sequence:

-

Part Size Assessment

Start here because size constraints immediately eliminate options. Measure your part's maximum dimensions and compare against technology limits.- If your part fits within 300mm width and doesn't require deep three-dimensional forming, progressive dies remain viable.

- If your part exceeds strip width limitations or requires forming operations from multiple orientations, transfer dies become necessary.

- If your part is relatively small and flat with simple contours, compound dies enter consideration.

-

Geometry Complexity Evaluation

Assess what forming operations your part requires. This step often determines your technology path more than any other factor.- Flat parts with blanking and piercing only? Compound dies likely represent your most economical option.

- Parts requiring sequential bends, shallow draws, and moderate forming? Progressive tooling handles these efficiently.

- Deep draws exceeding 1:1 depth-to-diameter ratios? Complex 3D shapes requiring multi-axis access? Secondary operations like tapping between forming stations? Transfer dies become your only viable path.

-

Volume Requirements

Production quantity dramatically influences cost-effectiveness. Match your annual volumes to each technology's sweet spot.- Below 10,000 pieces annually: Compound dies for simple parts; evaluate progressive only if complexity demands it.

- 10,000 to 100,000 pieces annually: Progressive dies deliver optimal economics for compatible geometries; transfer dies when capability requirements dictate.

- Above 100,000 pieces annually: Progressive dies dominate for appropriate parts; transfer dies justified when necessary for complex geometries despite higher per-piece costs.

-

Material Considerations

Your material specification influences both technology selection and die design requirements.- Material thickness between 0.3mm and 3.0mm with good formability? All three technologies work; choose based on other factors.

- Very thin materials under 0.2mm? Progressive dies may struggle with feeding; compound dies handle thin stock well for flat parts.

- Thick materials over 4.0mm requiring significant forming? Transfer dies provide the tonnage capacity and forming flexibility needed.

- Expensive alloys where material utilization matters? Transfer dies' optimized blank nesting can offset higher tooling costs through material savings.

-

Budget Constraints

Finally, evaluate your investment capacity against expected return.- Limited tooling budget with simple part requirements? Compound dies deliver lowest initial investment.

- Moderate budget with high-volume projections? Progressive dies offer excellent long-term cost-per-part economics.

- Capability-driven project where only transfer dies work? Budget must accommodate higher investment—but you're paying for capability that other methods simply cannot provide.

Making the Right Choice for Your Application

After working through the decision tree, your optimal technology should become clear. Here's the essential guidance for each die type, distilled into rules of thumb you can reference quickly:

Choose progressive dies when your project combines high production volumes (25,000+ annually), smaller part dimensions fitting within strip width limits, and moderate forming complexity without deep draws. Progressive tools deliver unmatched speed and cost efficiency for compatible geometries.

Choose transfer dies when your part requires deep draws, complex three-dimensional forming, large dimensions exceeding strip width limits, or secondary operations between forming stations. Accept slower cycle times and higher investment in exchange for capabilities no other method provides.

Choose compound dies when your part is essentially flat, requires only blanking and piercing operations, and demands tight tolerances between features. The simplicity advantage delivers lower costs and exceptional precision for appropriate applications.

Application-Specific Guidance

Different industries weight these decision factors differently. Consider these tailored recommendations:

Automotive Components

The automotive sector demands both precision and volume. For brackets, terminals, and connectors, prog die technology typically dominates. For structural panels, housings, and deep-drawn components, transfer dies become essential. When evaluating progressive die & stamping solutions for automotive applications, prioritize suppliers with IATF 16949 certification and proven OEM experience.

Electrical and Electronics

High-volume contact and terminal production benefits from progressive tool capabilities and high-speed stamping. The consistent registration and tight tolerances achievable with well-designed progressive tooling meet the demanding specifications of electrical components.

Appliance Manufacturing

This industry spans the full spectrum—from progressive-stamped mounting hardware to transfer-stamped deep-drawn stainless steel components. Match technology to specific part requirements rather than applying a blanket approach across your product line.

Medical Devices

Precision and repeatability often outweigh pure cost considerations. Compound dies excel for flat precision components where concentricity matters. Progressive dies serve high-volume disposable components. Transfer dies handle surgical instrument components requiring complex forming.

Validating Your Decision Before Full Commitment

Even with thorough analysis, uncertainty remains until you've validated your approach with actual parts. This is where prototyping and simulation become invaluable risk-reduction tools.

Before committing to full production tooling investment, consider these validation steps:

- Request simulation analysis—Partners using CAE simulation can predict forming behavior, identify potential defects, and validate your technology selection before cutting die steel.

- Leverage rapid prototyping—Prototype parts, sometimes available in as few as 5 days, allow you to verify fit, form, and function before major tooling investment.

- Conduct pilot production runs—Small initial runs validate process capability and identify optimization opportunities before scaling to full volume.

For automotive applications requiring precision stamping with OEM-standard quality, exploring partners like Shaoyi's precision stamping die solutions provides access to both the engineering capabilities and rapid prototyping infrastructure that de-risks your technology decision. Their 93% first-pass approval rate demonstrates what simulation-driven development achieves: tooling that works correctly from day one.

Your Next Steps

You now have the framework to make confident stamping die technology decisions. Here's how to move forward:

- Document your project parameters—Part dimensions, geometry complexity, volume projections, material specifications, and budget constraints.

- Work through the decision tree—Apply the five-step logic to narrow your technology options.

- Identify qualified suppliers—Use the evaluation criteria from the previous section to build a shortlist of capable partners.

- Request simulation-validated proposals—Suppliers offering CAE analysis reduce your risk significantly compared to trial-and-error approaches.

- Validate through prototyping—Prove out your approach before full production commitment.

The difference between successful stamping projects and costly failures often comes down to these early decisions. Take the time to work through this framework thoroughly, and you'll position your project for efficient production, consistent quality, and optimized costs from the very first production run.

Frequently Asked Questions About Progressive and Transfer Dies

1. What is the difference between progressive dies and transfer dies?

Progressive dies process parts on a continuous metal strip that advances through sequential stations with each press stroke, ideal for high-volume small parts. Transfer dies cut blanks first, then move them independently between stations using mechanical grippers, enabling deep draws and complex 3D forming for larger components. The key distinction lies in material handling—progressive keeps parts attached while transfer liberates them for multi-axis manipulation.

2. What are the disadvantages of progressive die stamping?

Progressive die stamping faces several limitations: part size constraints due to strip width restrictions (typically under 300mm), inability to produce deep draws exceeding certain depth-to-width ratios, limited three-dimensional complexity since parts must advance linearly, and carrier strip waste that reduces material utilization compared to transfer methods. Additionally, punch breakage during manufacturing can halt production and require costly repairs.

3. When should I choose transfer die stamping over progressive stamping?

Choose transfer die stamping when your parts require deep draws with depth exceeding diameter, large dimensions beyond strip width limits, complex three-dimensional forming with multi-axis access, or secondary operations like tapping between forming stations. Transfer dies excel for automotive structural panels, appliance drums, pressure vessels, and any component where the blank needs 360-degree access during forming.

4. What volume thresholds make each die type cost-effective?

Compound dies suit volumes below 25,000 pieces annually for simple flat parts. Progressive dies become optimal between 25,000 and millions of pieces yearly for compatible geometries, delivering excellent cost-per-part efficiency. Transfer dies justify their higher investment at 10,000 to 500,000 annual volumes when part complexity demands their unique capabilities. These thresholds shift based on material costs and tolerance requirements.

5. How do compound dies compare to progressive and transfer dies?

Compound dies perform multiple blanking and piercing operations in a single press stroke at one station, delivering superior concentricity and flatness for simple flat parts like washers and gaskets. They cost less than progressive dies and require minimal maintenance but cannot handle forming operations. Choose compound dies when parts need tight tolerances between features without bends or draws.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —