Custom Forged Wheel Fitment Guide: From Measurement To Perfect Stance

Why Precision Fitment Transforms Your Custom Forged Wheel Experience

Ever watched someone install a beautiful set of forged wheels only to discover they rub against the fenders at every turn? That frustrating scenario happens more often than you'd think—and it's entirely preventable. When you're investing in custom forged wheels, proper wheel fitment isn't just important; it's everything.

Why Custom Forged Wheels Demand Precision Fitment

Here's the fundamental difference you need to understand: off-the-shelf wheels force you to adapt your expectations to whatever sizes the manufacturer decided to produce. You're essentially settling for "close enough." Custom forged wheels flip this equation entirely. These precision-engineered components are built to your exact specifications—every millimeter of width, every degree of offset, every aspect of the design crafted specifically for your vehicle.

This flexibility is incredibly powerful, but it comes with responsibility. When a manufacturer asks for your specifications, there's no safety net of pre-determined sizes to catch measurement errors. Get the numbers right, and you'll achieve the best fitment possible—that perfect stance where wheels sit exactly where you envisioned. Get them wrong, and you've got expensive custom pieces that don't work as intended.

The Stakes of Getting Fitment Wrong

The consequences of incorrect tire fitment extend far beyond aesthetics. According to Performance Plus Tire, wrong wheel offset creates serious problems affecting virtually every aspect of vehicle performance—from handling instability during emergency maneuvers to premature wear on wheel bearings, suspension components, and steering parts. Even small offset changes of 5-10mm can dramatically affect high-speed stability.

Whether you're building a track-focused machine, perfecting a street cruiser, or upgrading a performance vehicle like a Porsche with chrome wheels GT3RS-style aesthetics, the precision of your measurements determines your success.

Custom forged wheels eliminate compromise entirely—but only when fitment is calculated correctly. The same flexibility that allows perfect specifications also means there's no room for guesswork.

This wheel fitment guide bridges the gap between basic wheel knowledge and the specific workflow you need as a custom forged wheel buyer. You'll move from understanding terminology and measurement techniques to confidently ordering wheels that fit your vehicle perfectly. Think of it as your roadmap from tape measure to installation day—covering every critical step along the way.

Essential Fitment Terminology Every Enthusiast Must Master

Before you grab a tape measure or start calculating specifications, you need to speak the language of wheel fitment fluently. These terms aren't just technical jargon—they're the foundation for every decision you'll make when ordering custom forged wheels. Understanding what does offset mean on wheels, how bolt patterns work, and why hub bore matters will save you from costly mistakes down the road.

Offset Explained in Practical Terms

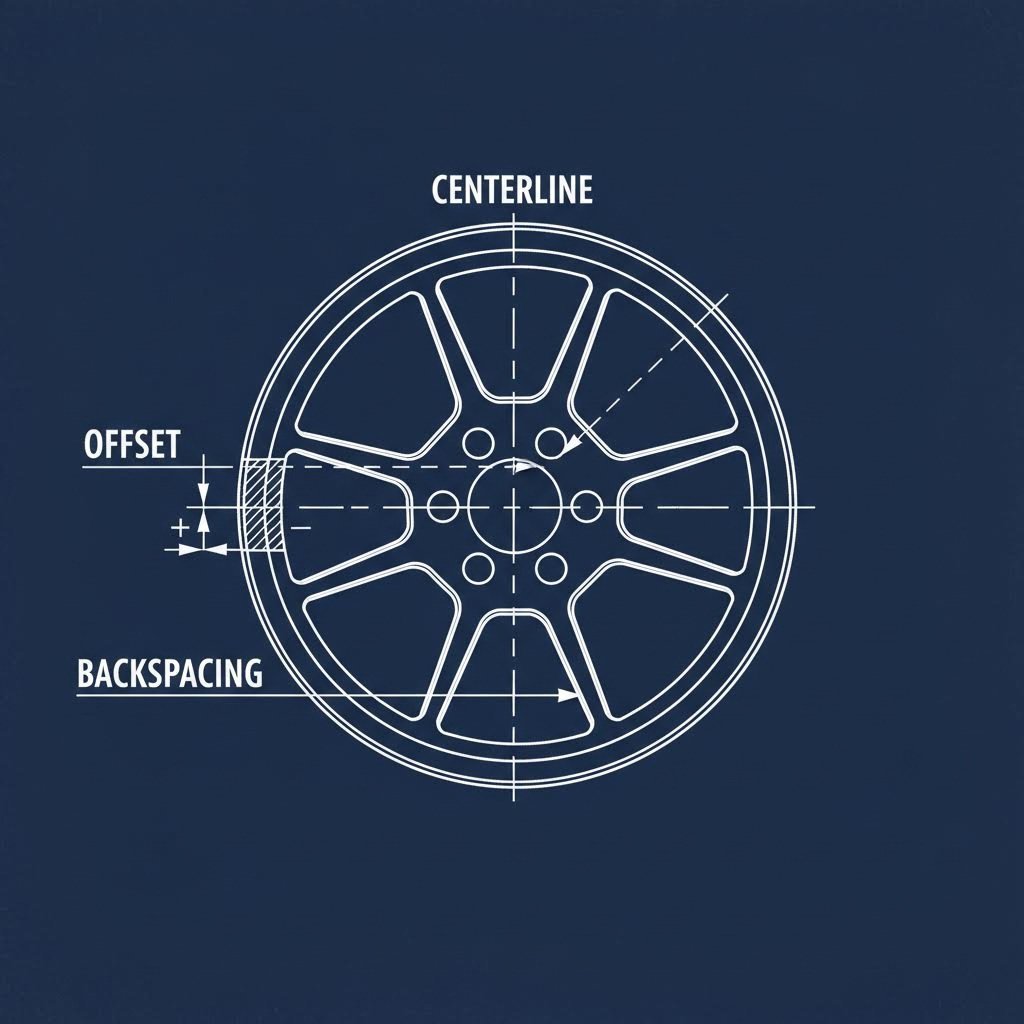

Offset is perhaps the most misunderstood yet critical measurement in wheel fitment. Simply put, it's the distance from the wheel's mounting surface (where the wheel bolts to the hub) to the true centerline of the wheel. This measurement, expressed in millimeters, determines how far inward or outward your wheel sits relative to the suspension and fender.

According to Discount Tire, offset directly impacts your vehicle's stance and ensures wheels don't interfere with fenders, brakes, or suspension components. Here's how the three offset types affect wheel positioning:

- Positive Offset: The mounting surface sits closer to the wheel's outer face, pushing the wheel further under the fender. Most modern vehicles, including European platforms like the e82 and F22 BMW, come equipped with positive offset wheels from the factory. This creates a clean, tucked appearance.

- Zero Offset: The mounting surface aligns exactly with the wheel's centerline. This neutral position is less common but serves as a reference point for understanding offset changes.

- Negative Offset: The mounting surface sits closer to the wheel's inner edge, pushing the wheel outward toward or past the fender. Often called "deep dish" wheels, negative offset creates aggressive stances but requires careful clearance calculations.

The practical implication? Changing offset by just 10mm can mean the difference between perfect fitment and constant rubbing. When upgrading from factory wheels, you'll typically need to calculate how much offset change your vehicle can accommodate before hitting suspension components or fenders.

Bolt Pattern and Hub Bore Fundamentals

Your bolt pattern—also called lug pattern—must match your vehicle exactly. There's no workaround here. This measurement consists of two numbers: the quantity of lug holes and the diameter of the circle they form.

Measuring bolt patterns differs based on whether you have an even or odd number of lugs:

- Even Lug Patterns (4, 6, or 8 lugs): Measure straight across from the center of one bolt hole to the center of the hole directly opposite. For example, the Mustang bolt pattern is 5x114.3mm, while the Dodge Charger bolt pattern measures 5x115mm—seemingly similar but not interchangeable.

- Odd Lug Patterns (5 lugs): Since holes aren't directly opposite each other, Bolt-Pattern.com recommends measuring from the center bore edge to the nearest bolt hole edge, then adding the bolt hole diameter and doubling the measurement for accurate results.

Beyond bolt pattern, hub bore is equally critical. This is the center hole diameter that fits over your vehicle's hub. Velgen Wheels explains the crucial distinction between mounting styles:

- Hub-Centric Wheels: The center bore matches your hub diameter precisely, allowing the hub itself to support the vehicle's weight. This provides superior stability, reduces vibration, and minimizes stress on lug nuts—essential for high-performance applications.

- Lug-Centric Wheels: Feature an oversized center bore, relying on lug nuts alone for centering. While more versatile across vehicle platforms, they require hub-centric rings to eliminate vibration and may need more frequent lug nut retorquing.

For custom forged wheels, hub-centric fitment is the gold standard. Manufacturers can machine the exact center bore diameter for your specific vehicle, ensuring that precision fit you're paying for.

Backspacing and Its Relationship to Offset

While offset measures from the centerline, backspacing measures from the mounting surface to the wheel's inner lip (back edge). These measurements are mathematically related but serve different purposes when checking clearances.

Think of it this way: backspacing tells you exactly how much space the wheel occupies behind the mounting surface—critical for ensuring clearance from suspension arms, brake calipers, and inner fender liners. A wheel with more backspacing sits further inward, while less backspacing pushes the assembly outward.

The relationship works like this: for any given wheel width, increasing positive offset increases backspacing. Conversely, moving toward negative offset reduces backspacing. When comparing wheels of different widths, you'll need to calculate both measurements to understand true fitment implications.

Now that you understand the language, it's time to put these terms into practice with hands-on measurement techniques for your specific vehicle.

Step-by-Step Measurement Methodology for Accurate Specifications

Ready to grab your tools and start measuring? This is where theory meets practice. Whether you're planning upgrades similar to the popular tesla model 3 tire size configurations or working with a completely different platform, the measurement process remains consistent. With a few basic tools and careful technique, you'll gather every specification needed to order custom forged wheels with confidence.

Measuring Your Current Wheel Specs Accurately

Before measuring clearances for new wheels, you need baseline data from your existing setup. According to AutoZone, you'll need just a few common tools: a tape measure or ruler, a straight edge (a level or piece of lumber works perfectly), and a calculator. A caliper is optional but adds precision.

- Remove the Wheel from the Vehicle: Start by safely jacking up your vehicle and removing the wheel completely. While some measurements are possible with wheels mounted, accuracy improves dramatically with full access to the mounting surface and inner lip.

- Measure the Wheel's Total Width: Place your straight edge across the wheel's outer edges—not the tire, but the rim itself. Measure from the outer lip on one side to the outer lip on the opposite side. Important: measure from the mounting flanges, not the bead seats where the tire sits. A wheel marketed as "8 inches wide" should measure approximately 8 inches between these points.

- Determine the Wheel Diameter: Measure from the inner edge of the bead seat on one side straight across to the inner edge on the opposite side. This gives you the true diameter where your tire mounts—typically matching the manufacturer's stated size (17", 18", 19", etc.).

- Calculate the Centerline: Divide your measured width by two. For an 8-inch wheel, the centerline sits at 4 inches from either edge. This reference point is essential for calculating offset.

- Measure the Offset: Place your straight edge across the back of the wheel (the side that faces the vehicle). Measure the distance from the straight edge down to the wheel's mounting surface—the flat machined area where the wheel contacts the hub. Subtract your centerline measurement from this number. If the result is positive, you have positive offset; if negative, you have negative offset.

- Verify the Bolt Pattern: Count the lug holes, then measure the bolt circle diameter using the method appropriate for your lug count. For 4 or 6-lug patterns, measure center-to-center across opposite holes. For 5-lug patterns, measure from the center of one hole to the far edge of the non-adjacent hole.

- Measure the Center Bore: Use a tape measure or caliper to measure the diameter of the center hole. For utmost accuracy, AMMO NYC recommends using a telescopic bore meter on your original wheels for quick, precise readings.

Fender and Suspension Clearance Assessment

Your current wheel measurements establish a baseline, but custom forged wheels often feature different widths and offsets. That means you need to map out your available clearance envelope—the three-dimensional space your new wheel-and-tire combination can occupy without interference.

Start with vertical clearance. Measure from the center of your wheel hub straight up to where you contact the top fender wall. This measurement, combined with your intended tire diameter, determines whether larger wheels will fit without rubbing the fender arch. Keep in mind that many enthusiasts upgrading to configurations like the tesla model y tire size often push these limits—knowing your exact clearance prevents surprises.

Next, assess backspacing clearance. According to AMMO NYC, you need to measure the distance between the innermost fender wall and the wheel contact point of the mounting hub. Note the total depth of the wheel well and the depth from the hub to the closest piece of your wheel assembly—this includes struts, control arms, and tie rods.

Inner fender liner considerations matter too. Many vehicles have plastic liners that extend closer to the wheel than the metal fender itself. Check for any fasteners, reinforcements, or contours that might contact a wider wheel. Sometimes relocating or trimming these liners creates additional clearance, but you need to identify these obstacles during measurement.

Brake Caliper Clearance Measurement

Brake caliper interference is one of the most common fitment failures—and one of the most dangerous. Your wheel fitment calculator can't predict this without accurate input.

Measure the brake caliper clearance in two dimensions. First, determine the diameter at the extremity of your brakes—the outermost point of the caliper or rotor. This establishes your minimum wheel diameter. A wheel smaller than this measurement simply won't fit over your brakes.

Second, measure the distance between the caliper face and the hub mounting surface. This tells you how much backspacing your wheels need before spokes or inner barrel contact the caliper. AMMO NYC emphasizes measuring this distance to ensure no friction occurs with wheel spokes—particularly critical for multi-spoke forged designs with minimal clearance between spokes.

Measuring at Multiple Suspension Positions

Here's what separates thorough measurements from incomplete ones: suspension travel. Your vehicle's suspension compresses over bumps and extends during rebound. A wheel that clears everything at ride height might slam into the fender or inner liner at full compression.

Perform your clearance measurements at three positions:

- Normal Ride Height: The baseline position with the vehicle's weight on the wheels.

- Full Compression (Bump): Jack the vehicle body up while the wheel remains on the ground, or push down firmly on the fender to simulate compression. Check all clearance points in this compressed state.

- Full Extension (Droop): With the wheel hanging freely (vehicle jacked by the frame, not the suspension), check that nothing contacts during maximum droop—particularly important for steering components at full lock.

Also turn the steering wheel fully left and right while checking clearances. A wheel that fits perfectly straight ahead might contact inner fender components or tie rods at full steering lock. This rim fitment calculator approach—checking multiple positions—ensures your measurements account for real-world driving conditions, not just static display.

With your measurements complete and documented, you're ready to translate these numbers into specific fitment styles and the exact specifications they require.

Understanding Flush Poke Tucked and Stretched Fitment Styles

Now that you've gathered your measurements, here's the exciting part—deciding exactly how you want your wheels to sit. Your fitment style determines the entire visual character of your build and directly influences the specifications you'll order. Whether you're chasing a subtle factory-plus appearance or an attention-grabbing show stance, understanding these styles helps you translate vision into precise numbers.

Flush Fitment Specifications and Requirements

Flush fitment represents the sweet spot for most enthusiasts—and for good reason. According to Apex Wheels, a flush fitment occurs when the wheels and tires sit exactly flush with the fenders, maximizing the wheel and tire sizes you can run while dramatically improving both appearance and performance.

What makes flush so popular? You're extracting maximum grip from wider wheels and tires while maintaining a clean, intentional look. The wheel face aligns with the fender's edge—not tucked underneath, not poking out. It's the Goldilocks zone of wheel fitment.

Achieving flush requires careful offset calculations based on your measurements. You'll typically run lower offsets than factory specifications to push the wheel outward. For example, when comparing 17x9 compared to 17x7 rims, that extra two inches of width needs offset compensation to maintain proper positioning. A 17x7 with +45 offset might need to become a 17x9 with +35 offset to stay flush—every width increase demands recalculation.

The tradeoff? Tighter clearances mean you may need supporting modifications. Apex Wheels notes that certain vehicles require fender rolling or additional negative camber to prevent rubbing. These aren't deal-breakers, but factors to consider when planning your build.

Aggressive Stance Considerations

Beyond flush, three distinct styles offer varying levels of visual aggression—each with specific specification implications.

Tucked Fitment: This style positions wheels and tires behind the fender line, creating a "sleeper" aesthetic often seen on air-ride builds. As Apex Wheels explains, tucked fitments don't fully utilize available fender clearance, which leaves some performance potential untapped. However, it's the safest approach for daily drivers who want zero rubbing risk. Tucked specs typically involve higher positive offsets or narrower widths than flush would allow.

Poke Fitment: When wheels extend past the fenders, you've got poke. This aggressive look ranges from subtle (an inch or so) to extreme. Custom Wheel Offset demonstrates this progression clearly: a 20x9 wheel with +1 offset creates roughly one inch of poke on a Ford F-150, while a 20x12 with -44 offset pushes out approximately 5.5 inches. The relationship is predictable—lower (more negative) offsets and wider widths equal more poke.

Poke works well on trucks and lifted vehicles but can look disproportionate on low sports cars. It also exposes your wheels to road debris and may require extended fender flares for legal compliance in some jurisdictions.

Stretched Fitment: This style pairs narrower tires with wider wheels, creating a distinctive sidewall appearance. Wondering what size stretched tire can I fit on 20x9 rims? Generally, a 245mm tire on a 9-inch wheel creates moderate stretch, while a 225mm creates aggressive stretch. Stretched setups often accompany stance builds where extreme camber angles demand this tire-to-wheel relationship.

Keep in mind that stretched tires reduce your contact patch and can affect handling characteristics. It's primarily an aesthetic choice rather than a performance enhancement.

Fitment Style Comparison

Choosing your style depends on your priorities. The following comparison breaks down what each fitment demands in terms of specifications and what you'll gain—or sacrifice—with each approach:

| Fitment Style | Typical Offset Range | Width Considerations | Clearance Requirements | Best For |

|---|---|---|---|---|

| Tucked | Higher positive (factory or above) | Factory width or slightly wider | Minimal—stays within fender envelope | Daily drivers, air-ride builds, zero-rub priority |

| Flush | Lower than factory (+15 to +35 typical) | 1-2 inches wider than factory | May require fender rolling, camber adjustment | Street performance, balanced aesthetics/function |

| Poke | Zero to negative (-12 to -44 common) | 2-4 inches wider than factory | Often needs fender modifications, lift kits on trucks | Show trucks, aggressive builds, lifted vehicles |

| Stretched/Stance | Varies widely based on camber | Wide wheels with narrow tires (285/35 18x9.5 combinations) | Extensive—requires camber, fender work, low suspension | Show cars, aesthetic-focused builds |

Matching Fitment Style to Driving Purpose

Your intended use should guide your fitment choice. Track-focused builds benefit from flush or slightly tucked fitments that maximize tire width without interference during aggressive cornering. The width of c8 z06 back tires—345mm rear steamrollers—demonstrates how track-oriented vehicles prioritize contact patch over stance aesthetics.

Street performance cars typically aim for flush fitment. You'll enjoy improved grip from wider tires while maintaining practical daily drivability. The c8 z06 tires size specifications from the factory represent Chevrolet's engineering balance between grip and clearance—a reference point when planning similar builds.

Show-oriented builds have more flexibility. If your car primarily attends meets and cruises rather than attacks corners, stretched and stance fitments become viable despite their handling compromises. Just understand you're trading performance for visual impact.

For extreme performance applications, consider that the size of tires c8 zr1 uses represents the pinnacle of OEM track-focused engineering—proof that manufacturers prioritize function when lap times matter. Your custom specifications should reflect similar priorities if performance is your goal.

Wheel Width to Tire Width Relationship

Every wheel width has an acceptable tire width range. Going too narrow creates instability; too wide risks bead unseating. Use this rim size chart guideline for common combinations:

- 8.0" wheel width: 215mm to 245mm tire width (ideal: 225-235mm)

- 9.0" wheel width: 235mm to 265mm tire width (ideal: 245-255mm)

- 9.5" wheel width: 245mm to 275mm tire width (ideal: 255-265mm)

- 10.0" wheel width: 255mm to 285mm tire width (ideal: 265-275mm)

- 10.5" wheel width: 265mm to 295mm tire width (ideal: 275-285mm)

- 11.0" wheel width: 275mm to 305mm tire width (ideal: 285-295mm)

These ranges shift when intentionally stretching tires. A 285/35 18x9.5 setup sits on the wider end of acceptable for that wheel width, creating a square sidewall. Pushing to a 265 on the same wheel introduces stretch.

With your fitment style selected and target specifications in mind, the next step involves understanding how different vehicle platforms affect these calculations—because the same specs produce different results across various makes and models.

Vehicle Platform Fitment Considerations for Popular Performance Cars

Here's a reality check that catches many enthusiasts off guard: the same wheel specifications produce completely different results on different vehicles. A 19x10 +40 setup that sits perfectly flush on one platform might tuck excessively on another or rub constantly on a third. Understanding your specific vehicle's fitment characteristics—before ordering custom forged wheels—saves both frustration and money.

Each platform brings unique challenges shaped by factory engineering decisions: suspension geometry, fender design, brake package size, and OEM wheel specifications all influence what fits. Let's break down the most popular performance platforms and their specific fitment considerations.

American Muscle Platform Fitment Nuances

American performance cars offer generous wheel wells and relatively straightforward fitment—but generation-specific details matter enormously.

Chevrolet Corvette Generations: The Corvette platform demonstrates how dramatically fitment parameters shift across generations. According to Fitment Industries, c5 corvette wheels run a 5x120.65mm bolt pattern with diameter ranges spanning 17 to 20 inches, widths from 8.5 to 9.5 inches, and offsets typically between +39 and +56. The C5's relatively compact brake package accommodates 17-inch diameter minimums on base models, though Z06 variants with larger brakes may require 18-inch minimums.

Moving to c6 corvette wheels, you'll find the same bolt pattern but evolved offset ranges to accommodate wider factory fenders. The C6's more aggressive stance from the factory means c6 wheels often run lower offsets than their C5 counterparts for equivalent visual results. Real-world examples show 19x10 +44 setups achieving hellaflush appearances on C5 platforms—specifications that would sit differently on newer generations.

C7 and C8 Corvettes continue this evolution with increasingly aggressive factory fitments. The mid-engine C8's unique architecture requires careful rear clearance calculations due to the engine's positioning.

Chevrolet Camaro Variants: Camaro wheels present their own generation-specific challenges. Fifth and sixth-generation Camaros run 5x120mm bolt patterns with hub bores around 67.1mm. However, the ZL1 variants complicate matters significantly—their massive Brembo brake packages often require minimum 20-inch diameter wheels to clear the front calipers.

Standard SS models typically clear 19-inch wheels, while base V6 and turbo-four variants accommodate 18-inch setups. When shopping for camaro wheels, always verify your specific brake package. A wheel that fits a 2SS might not clear a ZL1's front brakes.

Ford Mustang Platform: The S550 and S650 Mustang generations run 5x114.3mm bolt patterns—a departure from the 5x4.5-inch pattern on older models. Hub bore measures 70.5mm, and factory offsets typically range from +35 to +55 depending on trim level. The mustang wheel upgrade path is well-documented, with most enthusiasts running 19x10 or 19x11 rear fitments for aggressive stances. GT Performance Package brakes require careful diameter verification—some 18-inch wheels won't clear the larger rotors.

European Performance Vehicle Considerations

European platforms demand more precision in specifications, with tighter tolerances and more complex suspension geometries affecting fitment outcomes.

BMW Chassis Codes: BMW's development code system (E-codes and F-codes) provides a reliable framework for understanding fitment parameters. According to Alloy Wheels Direct, BMW's factory options and recognized tuning company specifications establish tested wheel and tire sizes that ensure correct fit and safety.

The BMW F22 (2 Series Coupe) exemplifies typical BMW fitment parameters: 5x120mm bolt pattern, 72.6mm hub bore, and factory-approved wheel sizes ranging from 16x7 to 19x8. Front offsets typically span +40 to +45, while rear fitments on staggered setups run +47 to +52. These specifications reflect BMW's engineering priorities—maintaining proper scrub radius for steering feel while maximizing tire width.

Older E-chassis vehicles like the e82 (1 Series Coupe) share the 5x120mm pattern but often accommodate slightly different offset ranges. Factory-approved specs for the E82 include 18x7.5 +47 front and 18x8.5 +52 rear configurations—numbers that work well as starting points for custom wheel calculations.

One critical BMW consideration: many performance variants come equipped with different brake packages. An M Sport package, M Performance brakes, or full M-car setup each requires different minimum wheel diameters. Always verify your specific brake configuration before finalizing specifications.

Nissan 370Z Platform: The 370z wheels run a 5x114.3mm bolt pattern with a 66.1mm hub bore—specifications shared with many Nissan and Infiniti performance platforms. Factory wheel sizes range from 18 to 19 inches, with staggered widths (wider rear than front) being the norm. Common upgrade paths push to 19x9.5 front and 19x10.5 rear configurations, with offsets in the +15 to +25 range for aggressive fitments.

The 370Z's Akebono brake package on Sport and Nismo trims adds complexity. These four-piston front calipers sit closer to the wheel face than base brakes, requiring careful spoke clearance verification on multi-spoke forged designs.

Tesla Electric Vehicle Fitment

Tesla's electric platforms introduce unique fitment considerations that traditional combustion vehicles don't share.

Tesla model 3 wheels run a 5x114.3mm bolt pattern with a 64.1mm hub bore—smaller than many performance sedans. Factory wheels range from 18 to 20 inches depending on trim, with the Performance variant running staggered 20x8.5 front and 20x9.5 rear setups. Offset ranges typically fall between +35 and +45.

What makes Tesla 3 wheels unique? Weight sensitivity. Electric vehicles' efficiency depends heavily on unsprung mass, making lightweight forged wheels particularly beneficial. Additionally, the Model 3's battery placement creates a low center of gravity that affects suspension geometry—and by extension, optimal offset calculations for handling balance.

Regenerative braking reduces heat buildup in the friction brakes, meaning Tesla owners often don't need as aggressive brake cooling provisions in their wheel designs. However, the Performance variant's track-oriented brake package still requires minimum diameter verification.

Platform Specification Reference Table

Use this reference table as a starting point for your platform's baseline specifications. Remember—these represent typical ranges, and your specific vehicle configuration may differ:

| Vehicle Platform | Bolt Pattern | Hub Bore | Common Diameter Range | Typical Front Offset | Typical Rear Offset | Brake Package Notes |

|---|---|---|---|---|---|---|

| C5 Corvette (1997-2004) | 5x120.65mm | 70.3mm | 17-20" | +40 to +56 | +40 to +56 | Z06 may require 18" minimum |

| C6 Corvette (2005-2013) | 5x120.65mm | 70.3mm | 18-20" | +40 to +58 | +50 to +58 | Z06/ZR1 require 19" minimum |

| 5th/6th Gen Camaro SS | 5x120mm | 67.1mm | 19-20" | +35 to +50 | +35 to +50 | 19" clears standard brakes |

| Camaro ZL1 | 5x120mm | 67.1mm | 20" | +27 to +35 | +27 to +35 | 20" minimum for Brembo package |

| S550/S650 Mustang GT | 5x114.3mm | 70.5mm | 18-20" | +35 to +50 | +35 to +50 | PP brakes may require 19" |

| BMW F22 (2 Series) | 5x120mm | 72.6mm | 16-19" | +40 to +45 | +45 to +52 | M Sport package affects clearance |

| Nissan 370Z | 5x114.3mm | 66.1mm | 18-19" | +15 to +30 | +15 to +30 | Akebono brakes need spoke clearance |

| Tesla Model 3 | 5x114.3mm | 64.1mm | 18-20" | +35 to +45 | +35 to +45 | Performance variant check 20" clearance |

How Factory Brake Packages Affect Wheel Diameter Minimums

Your brake package often dictates your minimum wheel diameter more than any other factor. According to Alcon, common rotor sizes of 343mm, 355mm, and 380mm require minimum wheel diameters of 17", 18", and 19" respectively.

This relationship becomes critical when upgrading brakes and wheels simultaneously—or when purchasing wheels for a vehicle with aftermarket big brake kits. A wheel that cleared factory brakes won't necessarily fit over a 380mm rotor upgrade. Always measure your current brake dimensions before finalizing wheel diameter specifications.

Performance-oriented factory packages present similar challenges. Corvette Z06, Camaro ZL1, and Mustang GT Performance Package vehicles all ship with larger-than-base brake components that restrict wheel diameter options. When in doubt, measure the outermost point of your caliper and add at least 1 inch of clearance to determine your minimum safe wheel diameter.

How Suspension Modifications Change Fitment Parameters

If you've modified—or plan to modify—your suspension, your fitment calculations change significantly. Lowering springs and coilovers reduce fender clearance at the top of the wheel arch, often requiring more positive offset or narrower widths to prevent rubbing.

Camber adjustments create opposite effects. Adding negative camber tilts the top of the wheel inward, creating additional fender clearance that allows wider wheels or lower offsets. Many stance-oriented builds combine lowering with negative camber specifically to accommodate aggressive wheel fitments.

Air suspension offers the most flexibility. As noted in Corvette fitment examples, air ride allows drivers to adjust ride height on demand—running slammed at shows while raising for street driving. If you're planning air suspension, measure clearances at your intended low position, not at ride height.

Upgraded control arms, particularly those offering camber or caster adjustment, may relocate suspension pickup points. This can affect both inner and outer clearances, requiring verification after installation.

Understanding these platform-specific nuances positions you to make informed decisions about specifications. But the real advantage of custom forged wheels lies in their ability to be manufactured to whatever specifications your platform demands—a flexibility that pre-made wheels simply can't match.

Custom Forged Wheel Manufacturing and Fitment Flexibility

So you've measured your vehicle, chosen your fitment style, and understand your platform's specifications. Now comes the critical question: why does custom forged manufacturing matter for achieving that perfect fit? The answer lies in how these wheels are made—and why that process unlocks fitment possibilities that cast alternatives simply cannot match.

How Forging Enables Unlimited Fitment Options

Imagine ordering c7 corvette rims that match your exact vision—19x11 rear wheels with a specific +48 offset designed to sit perfectly flush with your quarter panels. With cast wheels, you're limited to whatever molds the manufacturer decided to produce. With forged wheels, you're starting from a blank canvas.

According to JC Forged Wheels, the forging manufacturing process begins with aerospace-grade 6061-T6 aluminum that's heated and pressed under 8,000 to 10,000 tons of pressure. This creates a "forging"—a solid aluminum block with exceptional grain structure uniformity. From there, CNC machines carve out the profile, width, offset, and spoke design according to your exact specifications.

Here's what makes this revolutionary for fitment: since most forged wheels are individually made, there's virtually no limitation on customization. Flexiforge Wheel confirms that custom forged wheels are fully made-to-order, with every specification—diameter, width, offset, PCD, and center bore—built according to your measurements rather than predetermined production runs.

Think about what this means for your camaro zl1 rims search. Instead of scouring forums for the one offset that "kind of works," you specify exactly what your clearance measurements dictate. Need a +32 offset instead of the +30 or +35 that cast manufacturers offer? No problem. Require a specific center bore machined to 67.1mm for perfect hub-centric fitment? Done.

The Custom Specification Advantage

The difference between custom forged and cast wheel options becomes clear when you compare available specifications:

- Diameter Range: Forged wheels commonly span 17" to 24"+ in single-millimeter increments, while cast production typically limits options to standard sizes (17", 18", 19", 20").

- Width Flexibility: Custom forging accommodates widths from 7" to 14"+ in half-inch increments. Cast wheels usually offer only full-inch widths within a narrow range per design.

- Offset Precision: Forged manufacturing allows any offset specification—positive, zero, or negative—in single-millimeter increments. Cast wheels typically offer 2-3 offset options per size.

- Bolt Pattern Options: Forged wheels can be drilled to any bolt pattern, including uncommon specifications. Cast wheels come pre-drilled for high-volume patterns only.

- Center Bore Matching: Custom forging machines the exact hub bore for your vehicle, ensuring true hub-centric mounting. Cast wheels often use universal bores requiring adapter rings.

- Brake Clearance Engineering: Spoke designs and inner barrel profiles can be modified for specific brake packages—critical for corvette c6 wheels that need to clear Z06 brake calipers.

Cast wheels, by contrast, are formed by pouring molten aluminum into molds. As JC Forged Wheels explains, this process accounts for 90% of OE wheels and offers affordability through mass production—but at the cost of customization. You're choosing from what exists rather than specifying what you need.

Why Manufacturing Quality Certifications Matter

Custom specifications mean nothing if the finished product doesn't match what you ordered. A wheel specified at +45 offset that arrives at +48 throws off your entire fitment calculation. This is where manufacturing quality becomes paramount.

According to Flexiforge Wheel, reliable forged wheel manufacturers should hold certifications including ISO 9001 for quality management systems, JWL and JWL-T for safety compliance, TÜV certification for European markets, and critically—IATF 16949:2016 for automotive industry standards.

IATF 16949 certification deserves special attention. This standard covers the entire production process and focuses on continuous improvement and defect prevention. For custom wheel buyers, it means confidence that your specified dimensions will be met precisely. When working with IATF 16949 certified manufacturers like Shaoyi Metal Technology, you're partnering with facilities that deliver precision hot forging solutions meeting exact specifications for automotive components—the same rigorous standards applied to OEM suspension arms and drive shafts translate directly to wheel manufacturing precision.

In-House Engineering for Complex Fitment Requirements

Sometimes standard specifications aren't enough. Maybe you're running a big brake kit that requires specific spoke geometry. Perhaps your c6 z06 wheels need custom backpad designs to clear aftermarket suspension components. Or you're building a show car where every millimeter matters for that perfect stance.

These complex requirements demand manufacturers with in-house engineering capabilities. Rather than simply inputting numbers, engineering teams can analyze your specific application and optimize the design accordingly. This includes rapid prototyping capabilities—some facilities can produce prototype wheels in as little as 10 days—allowing you to verify fitment before committing to a full production run.

For enthusiasts seeking zl1 wheels or gt500 wheels with specific clearance requirements, this engineering support proves invaluable. The manufacturer becomes a partner in your build rather than just a vendor filling an order.

The forging process eliminates any porosity, shrinkage, and other micro-defects present in raw material, resulting in aluminum with a high degree of uniformity that allows for a very high weight-to-strength ratio.

This material advantage means forged wheels achieve camaro zl1 wheels-level strength with significantly less material—typically 25-30% lighter than equivalent cast wheels. For fitment purposes, thinner spoke profiles and optimized barrel designs become possible without sacrificing structural integrity, expanding clearance options that cast manufacturing simply cannot achieve.

With the manufacturing advantages of custom forged wheels clear, understanding common pitfalls becomes essential. Even perfect specifications can go wrong during measurement or installation—and knowing how to troubleshoot these issues saves both time and money.

Common Fitment Mistakes and Troubleshooting Solutions

You've done the research, placed your order, and your custom forged wheels have arrived. But what happens when something doesn't fit as expected? Even experienced enthusiasts encounter fitment surprises—wheels that rub at full lock, vibrations at highway speeds, or unexpected clearance issues that weren't apparent during measurement. The good news? Most problems have straightforward solutions once you understand what went wrong.

According to Curva Concepts, every common wheel buying mistake is completely preventable with the right knowledge and preparation. Let's break down the most frequent errors and how to fix them.

Critical Fitment Errors and How to Avoid Them

Some mistakes happen before you even place an order. Catching these early saves tremendous headaches—and potentially the cost of reordering wheels.

Measuring Offset Incorrectly: This remains the most common car fitment error. Many enthusiasts measure from the wrong reference point or confuse backspacing with offset entirely. Remember—offset measures from the mounting surface to the wheel's centerline, not to the outer edge. A 10mm measurement error translates to your wheel sitting nearly half an inch further in or out than intended.

The fix? Double-check your measurements using the methodology outlined earlier, and verify your math before ordering. When in doubt, photograph your measurement process and share with the manufacturer for confirmation.

Ignoring Hub Bore Requirements: Curva Concepts emphasizes that incorrect center bore sizing creates vibrations, accelerated wear, and serious safety concerns. Assuming hub rings can solve any center bore mismatch is a common oversight—but these rings have limitations.

For custom forged wheels, always specify your exact hub bore diameter. Unlike cast wheels with universal bores, forged wheels can be machined precisely to your hub. This eliminates the need for hub rings entirely and provides superior hub-centric mounting. If you're shopping for rims for camaro or similar performance platforms, hub-centric fitment should be non-negotiable.

Underestimating Brake Caliper Clearance: Your wheel might clear the caliper at the thickest point—but what about the irregular shapes and protrusions? Calipers aren't perfectly round, and clearance at one spoke position doesn't guarantee clearance at another. This issue becomes particularly problematic with multi-spoke forged designs where spokes pass close to caliper faces at different rotational positions.

Always measure caliper clearance at multiple points, and verify spoke-to-caliper distance specifically. Many c5 corvette rims and c6 corvette rims installations fail this check when enthusiasts assume diameter clearance equals full clearance.

Overlooking Bolt Pattern Precision: Close enough doesn't cut it. Curva Concepts warns that a 5x100 and 5x112 might seem similar, but they create dangerous mounting situations when mixed. The 12mm difference is invisible to the eye but critical for proper lug engagement and wheel centering.

Troubleshooting Unexpected Clearance Issues

So your wheels are installed, but something's rubbing. Before panicking, identify exactly where contact occurs—the solution depends entirely on the contact point.

Rubbing at Full Steering Lock: According to Apex Wheels, tire rubbing is more than an annoying noise—it's a sign that something in your setup isn't dialed-in properly. When rubbing occurs only at full lock, your issue is likely inner fender liner contact or tie rod interference. Solutions include:

- Trimming or relocating inner fender liners—often the simplest fix for minor contact

- Installing steering stops to limit lock-to-lock travel slightly

- Adding camber to tilt the wheel's top edge inward, creating clearance during turn-in

- Reconsidering offset if the wheel sits too far outward

Rubbing Over Bumps: This indicates insufficient suspension travel clearance. Your static measurements looked perfect, but compression brings the tire into fender or suspension arm contact. Apex Wheels notes that what fits perfectly in your garage might rub under hard cornering or over bumps.

Potential solutions include raising ride height slightly on adjustable coilovers, rolling the fender lip professionally with heat guns and proper tools, or adding negative camber to gain fender clearance. In some cases—particularly with aggressive camaro rims setups—you may need to accept that certain wheel and tire combinations require fender modifications to function properly.

Vibration Issues: Vibrations at highway speed typically indicate improper hub-centric fitment. Orion Motor Tech explains that even minor center bore variations—as small as 0.1mm—can cause noticeable vibration at speed.

If your custom wheels have slightly oversized center bores, quality plastic hub-centric rings solve the problem. Avoid metal rings—they tend to corrode and seize to the hub over time. However, the better solution for honda type r wheels and other performance applications is specifying exact hub bore during manufacturing.

Spacer Usage: When Appropriate vs. When to Reorder

Wheel spacers can solve some fitment issues—but they're not a universal fix. Understanding when spacers make sense versus when you should reorder with different specifications prevents both safety issues and wasted money.

Spacers Are Appropriate When:

- Your wheel's offset is slightly too high (sitting too far inward) and you need 5-15mm of additional poke

- You're running OEM wheels that can't be respecified and need minor clearance adjustment

- You're temporarily testing fitment before committing to custom specifications

- Clearance for aftermarket brake upgrades requires pushing the wheel slightly outward

Reorder Instead When:

- Your offset is too low (wheel poking too far out)—spacers cannot fix this

- You need more than 20mm of correction—stacking spacers introduces risk

- Hub bore mismatch exceeds what quality hub rings can accommodate

- The bolt pattern doesn't match—adapters exist but compromise safety

According to Orion Motor Tech, if using bolt-on spacers, you must confirm your studs or bolts are long enough for safe engagement—at least 6-7 complete threads must engage the lug nuts after installation. Never modify studs to make spacers fit.

Pre-Installation Verification Checklist

Before mounting your new wheels, run through this verification process to catch issues before they become problems:

- Verify bolt pattern matches exactly—test-fit the wheel to the hub without tightening

- Check center bore fitment—the wheel should slide onto the hub with minimal play

- Confirm lug seat type compatibility—conical, ball, or shank seats must match your hardware

- Inspect brake caliper clearance—rotate the wheel by hand and verify no spoke contact at any position

- Check TPMS sensor compatibility—verify valve stem type and sensor fit before tire mounting

- Verify offset matches your order—measure the delivered wheel against specifications

- Test-fit before tire mounting—it's far easier to exchange wheels before tires are installed

Post-Installation Problem Solving

Already installed and encountering issues? Here's how to diagnose and resolve common post-installation problems:

Steering Pull or Wandering: Excessive offset change can alter scrub radius, affecting steering feel. If your vehicle now pulls or wanders, the offset deviation from factory specifications may be too extreme for your suspension geometry. Consider specifications closer to OEM for c5 rims and similar performance applications where handling precision matters.

Premature Tire Wear: Uneven wear patterns often indicate alignment issues caused by aggressive offset changes. After installing wheels with significantly different offsets than factory, a professional alignment is essential—not optional.

Persistent Vibration After Balancing: If wheels balance correctly but vibration persists, suspect hub-centric fitment issues. Recheck center bore fit and hub ring seating. Also inspect the hub mounting surface for debris or corrosion that prevents proper wheel seating.

With troubleshooting knowledge in hand, you're prepared to handle whatever fitment challenges arise. The final step in your custom forged wheel journey involves translating all your measurements and decisions into a confident order—ensuring the manufacturer receives exactly what you need.

The Complete Measurement to Order Workflow for Custom Wheels

You've gathered your measurements, selected your fitment style, and understand your platform's requirements. Now comes the moment of truth—translating all that data into a custom wheel order that arrives exactly as envisioned. This final step separates successful builds from frustrating do-overs. Whether you're ordering c7 corvette wheels, c8 corvette wheels, or supra rims, the workflow remains consistent: organize your data, communicate clearly, and verify before committing.

From Measurements to Confident Ordering

Your measurements mean nothing if they're scattered across napkins and phone notes. Creating a comprehensive specification sheet organizes everything manufacturers need—and forces you to double-check each figure before submitting.

According to Forgeline Motorsports, if you're fitting wheels to a vehicle with any combination of custom suspension, brakes, or body modifications, you'll need to submit complete measurements and dimensions. This applies to virtually every custom forged wheel order where you're pushing beyond factory specifications.

Your specification sheet should include:

- Vehicle Information: Year, make, model, trim level, and any relevant chassis codes

- Wheel Specifications: Diameter, width, offset, bolt pattern, and center bore for front and rear

- Brake Package Details: Caliper make/model, rotor diameter, and measured caliper-to-hub distances

- Suspension Configuration: Stock, lowered, air ride, or specific coilover setup with current ride height

- Intended Fitment Style: Flush, poke, tucked, or specific stance goals

- Tire Specifications: Planned tire size and brand for each axle

Working with Manufacturers for Perfect Results

Communicating your intended use matters as much as raw specifications. A mustang wheel destined for weekend track days requires different engineering considerations than one built purely for shows. Quality manufacturers use this context to guide recommendations and catch potential issues before production begins.

As Wheels Mart Rims emphasizes, fitment tools and manufacturer support eliminate guesswork—but only when you provide complete information upfront. Don't assume manufacturers will fill in blanks; explicit communication prevents assumptions that lead to fitment failures.

Quality-focused manufacturers with robust engineering capabilities and rigorous quality control ensure components meet exact specifications. This precision becomes critical for applications like c6 zr1 wheels where brake clearance tolerances are extremely tight. When working with IATF 16949 certified partners like Shaoyi Metal Technology near Ningbo Port, you're accessing streamlined procurement with globally compliant manufacturing—the same precision hot forging solutions that produce OEM-grade suspension components applied to your custom wheel specifications.

The Complete Ordering Workflow

Follow this sequential process to move from measurements to confirmed order with confidence:

- Compile All Measurements: Transfer your recorded data into a single specification document. Include photos of measurement points for reference.

- Verify Critical Dimensions: Re-measure offset, bolt pattern, and center bore. These three specifications cause the most ordering errors when rushed.

- Research Platform-Specific Successes: Check enthusiast forums for your vehicle to see what specifications others have run successfully. This validates your calculations against real-world results.

- Submit Initial Inquiry: Contact the manufacturer with your complete specification sheet and intended use. Request confirmation that your specifications are achievable and appropriate.

- Review Manufacturer Feedback: Quality manufacturers will identify potential issues—clearance concerns, recommended adjustments, or specification optimizations based on their experience.

- Confirm Final Specifications: After incorporating feedback, document the exact specifications you're ordering. Get written confirmation from the manufacturer matching your understanding.

- Request Production Timeline: Confirm lead times and any prototyping options if you're uncertain about fitment. Rapid prototyping capabilities—sometimes available in as little as 10 days—allow verification before full production commitment.

- Verify Before Tire Mounting: When wheels arrive, measure delivered specifications against your order before mounting tires. This remains your last opportunity to catch discrepancies cost-effectively.

This guide wheel workflow transforms the complexity of custom forged wheel ordering into a manageable, repeatable process. Your measurements become specifications, specifications become confirmed orders, and confirmed orders become wheels that fit exactly as intended. The precision that custom forged manufacturing offers only delivers value when matched with equally precise ordering—and now you have the complete roadmap from tape measure to perfect stance.

Frequently Asked Questions About Custom Forged Wheel Fitment

1. What measurements do I need to get for custom forged wheels to fit perfectly?

You need six critical measurements for custom forged wheel fitment: wheel diameter, width, offset, bolt pattern, center bore (hub bore), and brake caliper clearance. Additionally, measure fender clearance at multiple suspension positions including ride height, full compression, and full extension. For precise results, also check clearances at full steering lock to prevent rubbing during turns. Quality manufacturers like those with IATF 16949 certification can machine exact specifications from these measurements.

2. How do I calculate perfect wheel fitment for my car?

Start by measuring your current wheel specifications including width, diameter, and offset using a straight edge and tape measure. Calculate the centerline by dividing wheel width by two, then measure from the mounting surface to determine offset. Map your clearance envelope by measuring from the hub to fender walls, suspension components, and brake calipers. Factor in suspension travel by checking clearances at compressed and extended positions. Finally, choose your fitment style—flush, poke, or tucked—and adjust offset calculations accordingly.

3. What is the difference between hub-centric and lug-centric wheels for custom applications?

Hub-centric wheels have center bores machined to match your vehicle's hub diameter precisely, allowing the hub itself to support the vehicle's weight. This provides superior stability, reduces vibration, and minimizes stress on lug nuts—essential for high-performance driving. Lug-centric wheels feature oversized center bores that rely solely on lug nuts for centering, requiring hub-centric rings to eliminate vibration. For custom forged wheels, hub-centric fitment is the gold standard since manufacturers can machine the exact center bore diameter for your specific vehicle.

4. How does wheel offset affect my vehicle's stance and handling?

Offset determines how far inward or outward your wheel sits relative to the suspension and fender. Positive offset pushes wheels under the fender for a tucked look, while negative offset extends wheels outward for aggressive poke. Changing offset by just 10mm can mean the difference between perfect fitment and constant rubbing. Incorrect offset also affects handling by altering scrub radius, potentially causing steering pull, premature tire wear, and accelerated wear on wheel bearings and suspension components.

5. Why choose custom forged wheels over cast wheels for fitment flexibility?

Custom forged wheels offer unlimited specification options because each wheel is individually manufactured from aerospace-grade aluminum using CNC machining. Unlike cast wheels limited to predetermined mold sizes, forged wheels accommodate any diameter, width in half-inch increments, exact offset specifications in single millimeters, any bolt pattern, and precise center bore matching. The forging process also eliminates porosity and defects, achieving 25-30% weight savings over cast alternatives while enabling optimized spoke profiles for specific brake clearance requirements.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —