Essential Strategies for Preventing Thermal Fatigue in Dies

TL;DR

Preventing thermal fatigue in dies requires a multi-faceted engineering strategy. The most effective approaches combine selecting materials with high thermal conductivity and strength, such as H-13 tool steel, with advanced surface treatments and disciplined operational controls. Key tactics include applying beneficial surface treatments, implementing periodic stress-relieving cycles, and strictly managing die pre-heating, cooling, and lubrication to minimize the thermal stresses that cause heat checking and premature failure.

Understanding the Core Problem: Mechanisms of Thermal Fatigue in Dies

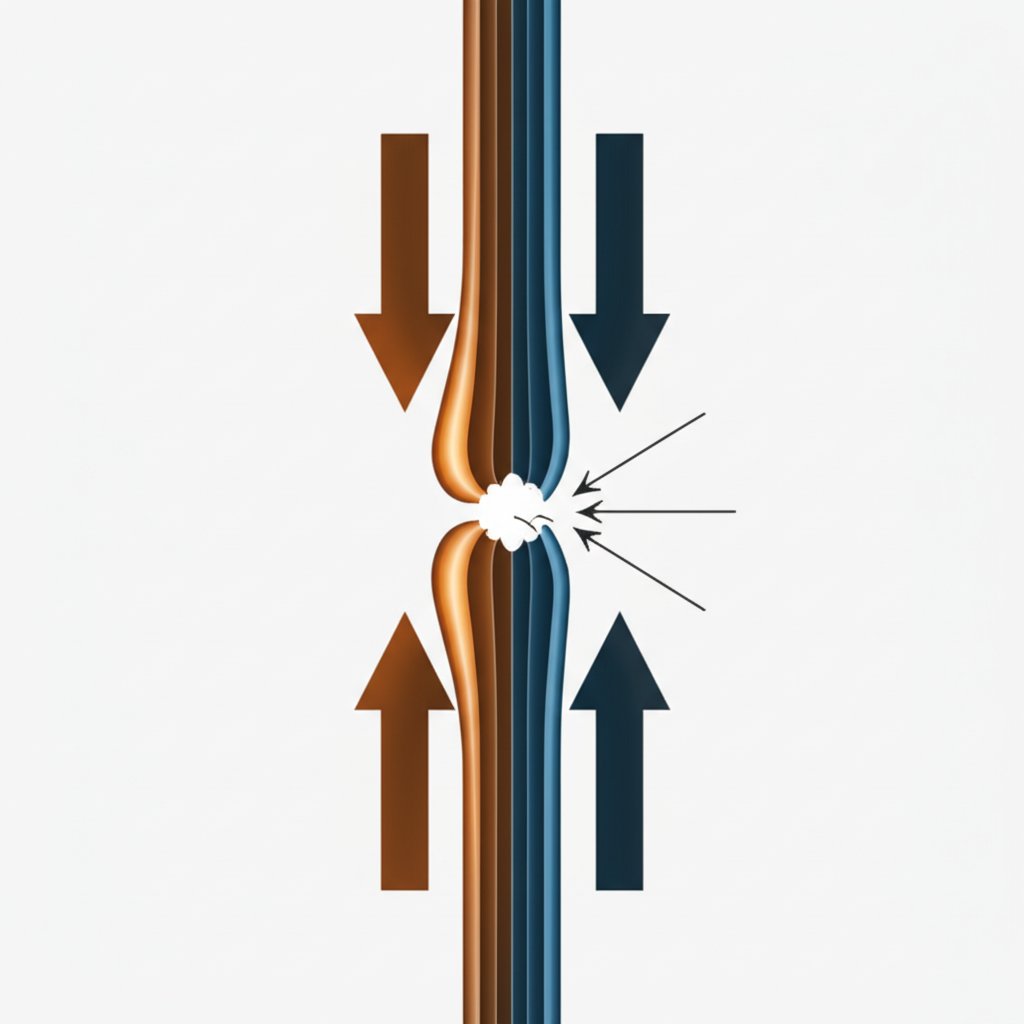

Thermal fatigue, often visible as a network of fine surface cracks known as heat checking or crazing, is a primary cause of failure in casting and forging dies. This phenomenon is not the result of a single event but the cumulative damage from repeated, rapid temperature fluctuations. The process begins when molten metal is injected into the die. The die's surface temperature skyrockets, causing the surface layer to expand rapidly. However, the cooler core of the die resists this expansion, placing the hot surface under immense compressive stress.

As explained by material science experts, if this thermal stress exceeds the material's yield strength at that elevated temperature, the surface layer undergoes plastic deformation. When the casting is ejected and the die cools, the now-deformed surface layer attempts to contract back to its original size. Constrained by the core, it is pulled into a state of high tensile stress. It is this relentless cycle of alternating between compressive and tensile stress that initiates microcracks on the die surface. With each subsequent cycle, these cracks propagate deeper into the die, eventually compromising the surface finish of the cast parts and leading to the die's ultimate failure.

This failure mechanism is distinct from mechanical fatigue because it is driven by thermal gradients within the material. A material with poor thermal diffusivity will experience a steeper temperature gradient between its surface and core, leading to more severe stress and a shorter fatigue life. Understanding this cycle is the critical first step for engineers to effectively diagnose the root cause of die failure and implement targeted, preventative strategies that extend the tool's operational lifespan and maintain production quality.

Material Science Solutions: Alloy Selection and Composition

The first line of defense in preventing thermal fatigue is the selection of an appropriate die material. The ideal material must possess a specific combination of thermophysical properties that allow it to withstand severe temperature swings. According to an in-depth analysis by Materion, a material's resistance to thermal fatigue can be quantified by a parameter that prioritizes high thermal conductivity, high yield strength, a low coefficient of thermal expansion, and a low elastic modulus. High thermal conductivity allows the die to dissipate heat quickly, reducing the temperature gradient between the surface and the core, which in turn lowers thermal stress.

For decades, H-13 tool steel has been the industry standard for aluminum die casting due to its excellent compromise of these properties, offering good toughness, hot hardness, and thermal fatigue resistance. Its performance is enhanced by alloying elements such as chromium, molybdenum, and vanadium, which improve high-temperature strength and durability. However, for even more demanding applications, other advanced alloys may offer superior performance, albeit often at a higher cost or with different machining characteristics. For industries producing high-stress components, such as automotive forging, the initial investment in premium die materials is crucial. Leading suppliers like Shaoyi (Ningbo) Metal Technology emphasize that the quality of mission-critical parts begins with robust tooling, which relies on superior die design and material selection to ensure longevity and precision.

When selecting a die material, engineers must evaluate the trade-offs between thermal performance, mechanical properties, and cost. The following table provides a conceptual comparison of key properties relevant to thermal fatigue resistance for common die materials.

| Material | Key Properties | Application Notes |

|---|---|---|

| H-13 Tool Steel | Good balance of hot hardness, toughness, and thermal shock resistance. Moderate thermal conductivity. | The most common choice for aluminum and zinc die casting. A reliable, cost-effective baseline. |

| Premium H-Series Steels (e.g., H-11, H-10) | Similar to H-13 but can be optimized for higher toughness (H-11) or higher hot strength (H-10). | Used when a specific property needs to be enhanced beyond what H-13 offers. |

| Maraging Steels | Very high strength and toughness at room temperature; can have poor stability at high temperatures. | Can be susceptible to austenite reversion at high temperatures, which is detrimental to thermal fatigue resistance. |

| Copper Alloys (e.g., Beryllium Copper) | Excellent thermal conductivity (5-10x that of steel), but lower hardness and strength. | Often used as inserts in critical, high-heat areas of a steel die to rapidly pull heat away and reduce thermal stress. |

Advanced Surface Engineering and Heat Treatments

Beyond base material selection, various surface and heat treatments can significantly enhance a die's resistance to thermal fatigue. These processes modify the surface properties of the die to better withstand the harsh thermal cycling environment. The goal is typically to increase surface hardness, improve wear resistance, or introduce beneficial compressive stresses that counteract the damaging tensile stresses formed during cooling.

Common surface treatments include nitriding, physical vapor deposition (PVD) coatings, and carbonitriding. Nitriding processes diffuse nitrogen into the steel's surface, forming a very hard outer layer. However, the effectiveness of these treatments can vary dramatically. A detailed study published by NASA on H-13 die steel found that certain ion and gas nitriding processes actually reduced thermal fatigue resistance by creating a brittle surface layer that cracked easily. In contrast, a salt bath treatment that diffused both nitrogen and carbon provided a small improvement. This highlights the importance of selecting a treatment proven for the specific application rather than assuming all hardening treatments are beneficial.

Perhaps the most effective strategy identified in the NASA study was not a surface coating but a procedural heat treatment: periodic stress relieving. By heating the die to a specific temperature (e.g., 1050°F or 565°C) for several hours after a set number of cycles, accumulated internal stresses are alleviated, significantly extending the die's fatigue life. Another effective method is deep cryogenic treatment, where the die is slowly cooled to cryogenic temperatures (below -300°F or -185°C) and then tempered, refining the material's grain structure and improving its durability and wear resistance. The choice of treatment depends on the base material, the severity of the application, and cost considerations.

Operational Best Practices for Die Longevity

Even the most advanced die materials and treatments will fail prematurely without disciplined operational procedures. Managing the thermal conditions during the production cycle is a critical component of preventing thermal fatigue. Best practices focus on minimizing the severity of thermal shock and ensuring that heat is managed uniformly across the die surface. This involves careful control over pre-heating, cooling, and lubrication.

As outlined by industry experts at CEX Casting, optimizing the mold design itself is a crucial first step. This includes using generous radii in corners to avoid stress concentration points and ensuring cooling channels are strategically placed to effectively cool high-temperature areas. Once in production, pre-heating the die to a stable operating temperature before the first shot is essential to prevent the extreme thermal shock of molten metal hitting a cold die. During operation, a consistent cycle time helps maintain thermal stability, while a high-quality die lubricant provides a thermal barrier and aids in part release.

To make these practices actionable, operators can follow a structured maintenance and operational checklist. Implementing these steps consistently can dramatically reduce the rate of heat check formation and extend the functional life of expensive tooling.

- Pre-Production: Ensure the die is properly pre-heated to the recommended temperature for the casting alloy to minimize initial thermal shock.

- During Production: Maintain consistent cycle times to achieve thermal equilibrium. Monitor coolant flow and temperature to ensure efficient and uniform heat extraction. Apply die lubricant consistently and correctly before each cycle.

- Post-Production/Maintenance: Regularly inspect and clean cooling channels to prevent blockages from sediment or scale, which can lead to localized hot spots. Periodically perform stress-relieving heat treatments as recommended for the die material and workload.

- Ongoing Monitoring: Use non-destructive testing (NDT) methods to inspect for early signs of microcracks, allowing for proactive maintenance before they become critical failures.

Frequently Asked Questions

1. How can thermal fatigue be prevented?

Thermal fatigue can be prevented through a combined approach. This includes selecting materials with high thermal conductivity and strength, designing dies to minimize stress concentrators, applying beneficial surface treatments like controlled nitriding or cryogenic treatment, and implementing strict operational controls such as pre-heating dies, ensuring uniform cooling, and using appropriate lubricants.

2. How can fatigue failure in general be prevented?

General fatigue failure, which can be caused by mechanical or thermal loads, is prevented by designing components to operate well below their material's endurance limit. This involves reducing stress concentrations, improving surface finish, selecting materials with high fatigue strength, and implementing maintenance schedules that include regular inspections for crack initiation and periodic treatments like stress relieving to remove accumulated internal stress.

3. How can thermal stress be reduced?

Thermal stress can be reduced by minimizing temperature gradients within a component. This is achieved by using materials with a low coefficient of thermal expansion and high thermal conductivity. Operationally, it involves slowing down heating and cooling rates (e.g., pre-heating dies), designing efficient cooling systems to extract heat uniformly, and using thermal barrier coatings or lubricants to insulate the surface from extreme temperature shocks.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —