HPDC vs LPDC: Choosing Die Casting for Auto Parts

TL;DR

Choosing between high-pressure die casting (HPDC) and low-pressure die casting (LPDC) for auto parts depends on a trade-off between speed and strength. HPDC is a rapid process ideal for high-volume production of smaller, thin-walled components like housings. In contrast, LPDC is slower but produces larger, more complex structural parts such as engine blocks with superior mechanical properties and minimal porosity.

Understanding the Core Processes: How HPDC and LPDC Work

Die casting is a cornerstone of modern automotive manufacturing, but not all die casting methods are created equal. High-pressure and low-pressure die casting represent two distinct approaches to forming metal parts, each with unique mechanics that dictate its best applications. Understanding these foundational differences is crucial for selecting the optimal process for any given automotive component.

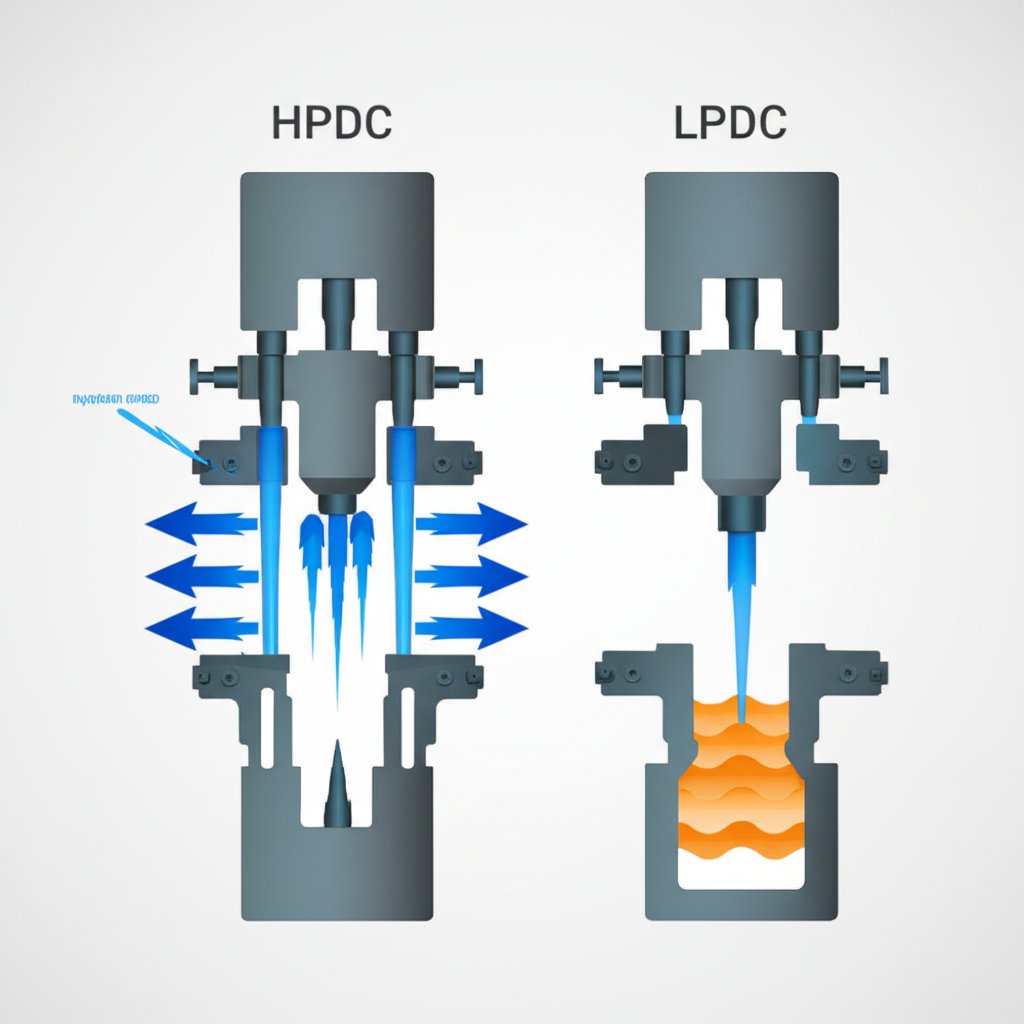

High-pressure die casting (HPDC) is defined by its speed and force. In this process, molten metal is injected into a steel mold, known as a die, under immense pressure—ranging from 150 to 1,200 bar (2,175 to 17,400 psi). As described by manufacturing experts at Dongrun Casting, the metal fills the mold cavity at extremely high speeds, often in less than a second. This rapid injection allows for the production of parts with very thin walls and complex geometries. The machine is typically horizontal, with one half of the die fixed and the other movable. Once the metal solidifies, the die opens, and the part is ejected. The entire cycle is incredibly fast, making HPDC highly efficient for mass production.

Low-pressure die casting (LPDC), on the other hand, is a more controlled and gentle process. Here, the pressure applied is significantly lower, typically between 0.7 and 1.4 bar. In an LPDC machine, which is usually oriented vertically, the holding furnace containing the molten metal is situated below the die. The metal is slowly pushed upward into the mold cavity through a riser tube, working against gravity. This slow, laminar flow minimizes turbulence and reduces the risk of entrapped air, which leads to porosity. The pressure is maintained during solidification, allowing the casting to be continuously fed with molten metal to compensate for shrinkage, ensuring a dense and solid part. This method is ideal for producing parts with excellent mechanical properties.

Head-to-Head Comparison: Key Differentiators for Automotive Applications

When evaluating high-pressure versus low-pressure die casting for automotive parts, engineers must weigh several critical factors. The choice directly impacts production speed, cost, part quality, and design possibilities. While HPDC excels in volume and speed, LPDC offers superior integrity for structural components. The following table and detailed breakdown highlight the essential differences to guide your decision-making process.

| Factor | High-Pressure Die Casting (HPDC) | Low-Pressure Die Casting (LPDC) |

|---|---|---|

| Injection Pressure | Very high (150 - 1,200 bar) | Low (0.7 - 1.4 bar) |

| Cycle Time | Very fast; ideal for high-volume production | Slower; better for lower to mid-volume runs |

| Tooling Cost | High, as dies must withstand extreme pressure | Lower, as pressure requirements are less demanding |

| Part Size & Complexity | Best for small to medium-sized parts with thin walls | Excellent for large, thick-walled, and complex parts |

| Mechanical Properties | Good, but prone to porosity which can limit strength | Excellent; low porosity results in superior strength and ductility |

| Surface Finish | Very smooth and precise | Good, but generally less smooth than HPDC |

| Heat Treatment | Generally not suitable due to internal porosity | Can be heat treated to enhance mechanical properties |

Pressure and Porosity

The most significant differentiator is pressure. The high-speed, turbulent filling in HPDC can trap air, leading to porosity within the casting. While manageable, this can be a critical weakness in components that require high structural integrity or are subject to pressure. In contrast, the gentle, upward fill of LPDC minimizes turbulence, resulting in castings with very low porosity. This makes LPDC parts stronger, more reliable, and suitable for heat treatment, which further enhances their mechanical properties.

Cycle Time and Production Volume

HPDC is built for speed. Its rapid cycles make it far more efficient for high-volume production runs, significantly lowering the per-unit cost for large quantities. According to an analysis by Kurtz Ersa, HPDC cycle times can be 4 to 6 times faster than LPDC. LPDC's slower, more deliberate process results in longer cycle times, making it better suited for prototypes, lower-volume series, or applications where part quality justifies the longer production time.

Part Design and Complexity

HPDC excels at producing parts with thin walls and intricate details, making it perfect for components like electronic enclosures or gearbox housings. However, its inability to use sand cores limits its ability to create complex internal geometries. LPDC, as Kurtz Ersa also notes, can use sand cores. This capability allows for the creation of hollow sections and complex internal channels, which is essential for parts like 'closed deck' engine blocks and sophisticated chassis components that require high rigidity and reduced weight.

Choosing the Right Process for Automotive Parts: From Engine Blocks to Housings

Applying these principles to automotive manufacturing reveals clear use cases for each process. The decision hinges on the part's function, structural requirements, and production volume. The general rule is to use LPDC for large, safety-critical components and HPDC for smaller, high-volume parts where structural demands are less extreme.

Low-pressure die casting is the preferred method for components that form the backbone of a vehicle's performance and safety. Its ability to produce dense, strong, and heat-treatable parts makes it ideal for:

- Engine Blocks and Cylinder Heads: The use of sand cores allows for complex cooling jackets and internal structures, critical for modern, efficient engines.

- Suspension Components: Parts like control arms and knuckles require high strength and fatigue resistance, which the low-porosity nature of LPDC provides.

- Structural Frame and Chassis Parts: Large, hollow-cast components can be produced to be both lightweight and extremely rigid.

- Automotive Wheels: LPDC is commonly used for high-quality aluminum alloy wheels that need to be both strong and cosmetically appealing.

High-pressure die casting, with its emphasis on speed and efficiency, is the workhorse for producing a vast number of other essential automotive parts. It is best suited for:

- Housings and Casings: Gearbox, transmission, and electronic housings are classic examples where thin walls and complex external shapes are needed in high volumes.

- Brackets and Mounts: Numerous small- to medium-sized brackets that hold various components in place are economically produced via HPDC.

- Interior Components: Parts for steering columns, seat frames, and dashboard structures often benefit from the precision of HPDC.

- Oil Pans and Valve Covers: These components require good dimensional accuracy and a smooth surface finish, which HPDC delivers efficiently.

While die casting offers excellent versatility for complex shapes, some automotive applications demand the ultimate in strength and durability, particularly for critical drivetrain and suspension parts. In these cases, alternative manufacturing methods like forging are often considered. For instance, Shaoyi (Ningbo) Metal Technology specializes in automotive forging parts, a process that kneads metal under extreme pressure to create components with superior grain structure and fatigue resistance. This highlights that the optimal manufacturing choice always depends on a deep analysis of the component's specific performance requirements.

Cost and Production Volume Analysis: A Financial Perspective

The financial considerations of choosing between HPDC and LPDC are just as critical as the technical ones. The primary trade-off revolves around initial investment versus per-unit production cost. HPDC involves a high upfront investment in robust machinery and durable tooling capable of withstanding immense pressures. However, its rapid cycle times mean that once production is underway, the cost per part is very low, especially at high volumes.

Conversely, LPDC machines and tooling are generally less expensive, resulting in a lower initial investment. As noted by Sinoway Industry, this makes LPDC a more accessible option for lower to mid-volume production runs. However, the slower cycle times translate to higher machine and labor costs per unit, making it less economical for mass production. The break-even point is a key calculation; for production runs exceeding tens of thousands of units, the high initial cost of HPDC is often amortized, making it the more cost-effective choice in the long run. For prototyping, specialized parts, or smaller production series, LPDC's lower barrier to entry and superior quality can provide better overall value.

Frequently Asked Questions

1. When to use high pressure die casting?

High-pressure die casting should be used for high-volume production of small to medium-sized automotive parts that require intricate designs, thin walls, and a smooth surface finish. It is ideal for components like housings, brackets, and interior parts where production speed and cost-efficiency are top priorities.

2. What are the disadvantages of low pressure die casting?

The main disadvantages of low-pressure die casting are its slower cycle times, which lead to higher per-unit production costs, and its unsuitability for producing very thin-walled parts (typically requiring a minimum wall thickness of around 3 mm). The slower process makes it less economical for mass production compared to HPDC.

3. What are the advantages of low pressure die casting?

The primary advantages of low-pressure die casting are superior mechanical properties due to minimal porosity, the ability to produce large and complex parts using sand cores, and the fact that its castings can be heat-treated to further improve strength. This results in highly reliable components suitable for structural and safety-critical applications.

4. What is the difference between high pressure die casting and low pressure die casting?

The fundamental difference lies in the pressure and speed of molten metal injection. High-pressure die casting uses extremely high pressure (up to 1200 bar) for a very fast, turbulent fill, ideal for high-volume, thin-walled parts. Low-pressure die casting uses very low pressure (around 1 bar) for a slow, controlled fill, producing dense, strong parts ideal for larger structural components.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —