Precision Unlocked: Real-Time Control in Die Casting

TL;DR

Real-time control in die casting is an advanced manufacturing process utilizing a closed-loop system of sensors, controllers, and actuators to continuously monitor and adjust critical variables during metal injection. This system precisely manages molten metal pressure, flow, and die temperature throughout the casting cycle. The primary goal is to ensure the mold cavity is filled completely and uniformly, which directly produces higher-quality parts with minimal defects, consistent density, and superior mechanical strength.

The Fundamentals of Real-Time Process Control in Die Casting

In modern manufacturing, precision and consistency are paramount. Real-time process control represents a significant technological leap in die casting, moving beyond traditional, less precise methods. At its core, it is a dynamic feedback system designed to manage the injection process with sub-microsecond precision. Unlike open-loop or manual systems that are prone to inconsistency and higher defect rates, a real-time system actively corrects deviations as they occur, ensuring every cycle adheres to optimal parameters.

This level of control is necessary to meet the stringent quality demands of industries like automotive and aerospace. The fundamental importance of this technology lies in its ability to transform die casting from a reactive to a proactive process. Instead of inspecting parts for defects after production, real-time control aims to prevent those defects from forming in the first place. This data-driven approach not only enhances part quality but also provides valuable insights for continuous process optimization.

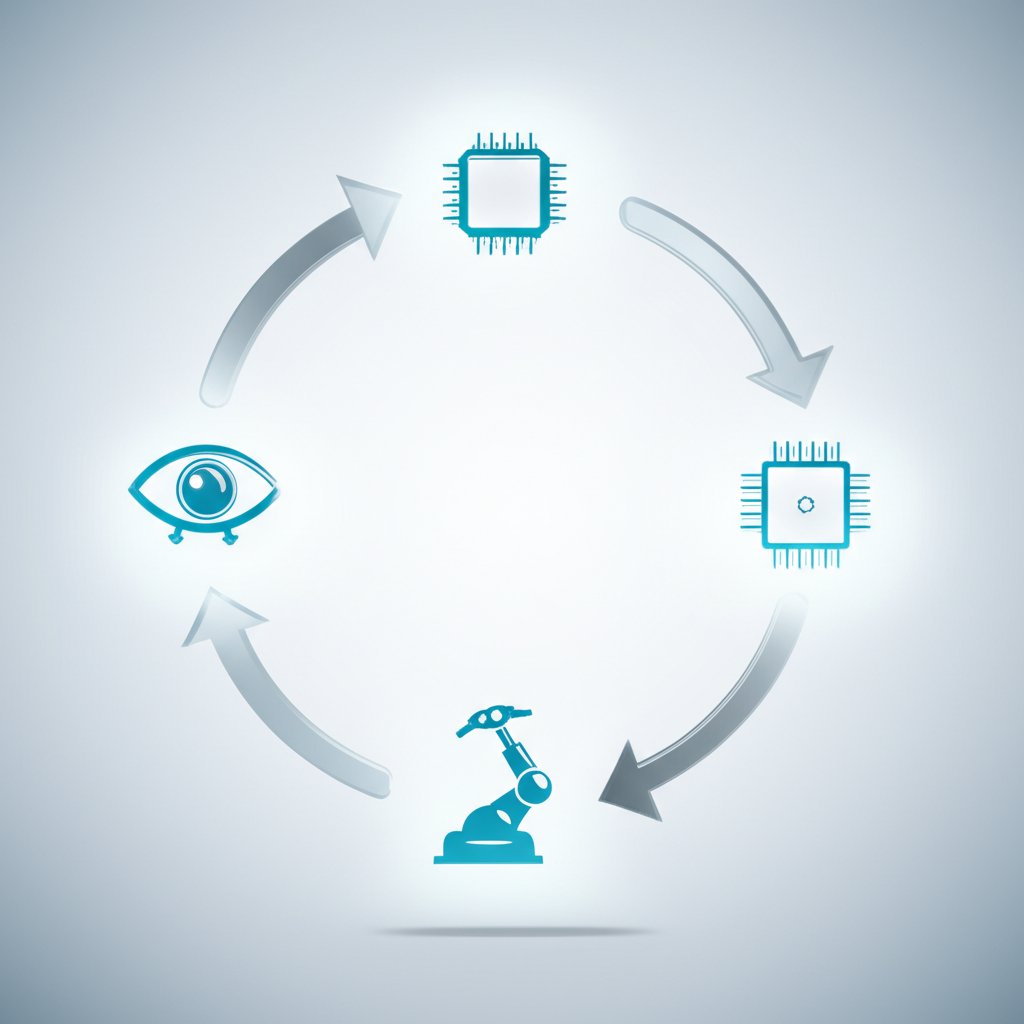

A typical real-time control loop consists of three core components working in synergy:

- Sensors: These devices are placed at critical points to monitor variables such as pressure, temperature, plunger speed, and displacement. They are the system's eyes and ears, gathering raw data from the physical process.

- Controller: This is the brain of the operation, often a specialized unit like the TOSCAST controller or a high-speed data acquisition (DAQ) system like the ADwin. It processes sensor data, compares it to pre-programmed setpoints, and calculates the necessary adjustments.

- Actuators: These are the mechanisms (e.g., hydraulic valves) that execute the controller's commands, physically adjusting the process variables. For instance, an actuator might modify valve openings to regulate injection pressure or alter water flow to manage die temperature.

This continuous cycle of monitoring, processing, and adjusting happens thousands of times per second, a speed that standard PLCs often cannot match. For example, by ensuring accurate molten metal flow during injection, the system guarantees that the mold cavity is filled completely and evenly. This results in parts with uniform density and high mechanical strength, directly addressing the core challenges of complex part production. As described by Techmire, this closed-loop control leads to stable system performance and premium part quality.

Key Monitored Variables: Pressure, Temperature, and Flow

The success of real-time control hinges on its ability to precisely manage the most influential variables in the die casting process. While many parameters are monitored, pressure, temperature, and flow are the most critical for achieving defect-free castings. Each variable presents unique challenges and requires a dedicated control strategy to optimize outcomes.

Pressure control is fundamental to ensuring the molten metal completely fills the intricate details of the die cavity. The process is typically broken into phases: a velocity-controlled filling phase and a pressure-controlled compaction phase. During filling, the system modulates injection speed to prevent turbulence and air entrapment. Once the cavity is filled, the system switches to the compaction phase, applying immense pressure to minimize porosity and ensure the final part has a dense, uniform structure. Poor pressure control can lead to defects like porosity, cold shuts, and incomplete filling.

Equally critical is thermal control, which directly impacts the solidification of the metal and the longevity of the die itself. A significant temperature difference between the molten metal and the mold can cause surface stresses, leading to premature mold wear and compromising part quality. Systems like the REALTIME control from Die Pro provide fully automatic control of die cooling by adjusting the water flow rate in each cooling channel based on outlet temperature readings. This maintains a consistent die temperature in every cycle, preventing defects such as warping, cracks, and dimensional instability. Effective thermal management is crucial for achieving a good surface finish and optimal mold filling.

The table below summarizes the function of each key variable and the benefits derived from its precise real-time control.

| Variable | Primary Function | Benefits of Real-Time Control |

|---|---|---|

| Pressure | Ensures complete mold filling and compresses metal to reduce porosity. | Uniform density, high mechanical strength, minimal porosity, and sharp surface details. |

| Temperature (Thermal) | Manages the rate of solidification and protects the die from thermal shock. | Improved dimensional stability, reduced warping, extended mold lifespan, and prevention of surface defects. |

| Flow/Velocity | Controls the speed at which molten metal enters the die cavity. | Reduced turbulence, prevention of air entrapment (gas porosity), and consistent fill patterns. |

Core Technologies and Systems Enabling Real-Time Control

The implementation of real-time control in die casting is made possible by an integrated architecture of advanced hardware and software. These systems are designed to acquire, process, and act on data with extremely low latency. The primary components include high-fidelity sensors, rapid data acquisition (DAQ) systems, sophisticated controllers, and intuitive monitoring software.

At the forefront are specialized controllers and DAQ systems that serve as the central nervous system. For instance, the ADwin-Gold system provides real-time data acquisition with a deterministic response time of one microsecond or less, offering a level of precision that traditional PLCs cannot achieve. Similarly, Shibaura Machine's TOSCAST controller is designed to integrate data from the entire die casting cell, including auxiliary equipment, to make more intelligent, holistic control decisions. These controllers process vast amounts of data to manage complex injection profiles, such as programming multiple velocity and pressure stages to optimize filling and compaction.

The software component provides the human-machine interface (HMI) for operators and process engineers. Systems like Techmire's Process Parameters and Shot Monitoring System (PPCS) allow operators to set specific values and control limits for dozens of critical parameters. This software often includes powerful diagnostic tools, displaying graphs of shot profiles in real time. If an out-of-tolerance condition is detected, the system can automatically trigger an alarm, stop the machine, or divert the faulty part for inspection. This capability for immediate feedback and action is a hallmark of modern control systems.

When evaluating a real-time die casting control system, manufacturers should look for a combination of key features that ensure performance, flexibility, and data utility. Based on capabilities mentioned by industry leaders, essential features include:

- High-Speed Data Acquisition: The ability to sample data from multiple sensors at high frequencies to capture the entire injection event accurately.

- Deterministic Processing: A dedicated real-time processor that operates independently of a PC's operating system to guarantee consistent response times.

- Advanced Profile Programming: The capability to define multi-stage velocity and pressure profiles for precise control over the filling and compaction phases.

- Real-Time Monitoring and Diagnostics: An intuitive interface that displays live data, shot profiles, and process parameters with graphical analysis tools.

- Automated Alarms and Sorting: The functionality to automatically detect out-of-spec cycles and take corrective action, such as alerting an operator or physically separating suspect parts.

- Data Logging and Network Integration: The ability to store historical process data for quality control, analysis, and integration with factory-wide MES (Manufacturing Execution System) platforms.

Impact and Benefits: Enhancing Quality, Efficiency, and Decision-Making

The adoption of real-time control systems has a transformative impact on die casting operations, delivering substantial benefits across part quality, process efficiency, and strategic decision-making. By moving from a reactive to a proactive control model, manufacturers can achieve a higher level of performance and gain a significant competitive advantage. The primary benefit is a dramatic improvement in part quality, as the system works continuously to prevent defects before they occur, resulting in premium, flash-free castings.

On the factory floor, this translates to greater process efficiency. Real-time adjustments minimize the production of scrap, reducing material waste and the energy consumed in re-melting defective parts. Furthermore, by maintaining stable and optimal process parameters, these systems reduce the variability that often leads to machine downtime. According to Marposs, intelligent die casting systems also enable predictive maintenance. By analyzing trends in process data, the system can alert maintenance teams to potential issues with the machine or die before a catastrophic failure occurs, maximizing uptime.

Beyond immediate production gains, the vast amount of data collected by these systems is a valuable strategic asset. This data provides deep insights into the manufacturing process, allowing engineers to optimize parameters, refine die designs, and troubleshoot issues with empirical evidence. This fosters a culture of data-driven operations where decisions are based on objective analysis rather than operator intuition alone. This collection of real-time insights ultimately leads to smarter, more effective management of the entire production ecosystem.

The key benefits of implementing real-time control in die casting include:

- Superior Part Quality: Achieves minimal defects, uniform density, high mechanical strength, and excellent dimensional accuracy.

- Increased Process Efficiency: Significantly reduces scrap rates, lowers material and energy consumption, and shortens cycle times.

- Enhanced System Stability: Ensures consistent performance shot after shot, leading to more predictable and reliable production output.

- Extended Die Lifespan: Minimizes thermal shock and mechanical stress (like the 'hammer effect'), which helps prevent premature mold wear and damage.

- Data-Driven Optimization: Provides comprehensive data for process analysis, quality control documentation, and continuous improvement initiatives.

- Predictive Maintenance Capabilities: Allows for the early detection of equipment abnormalities, reducing unplanned downtime and maintenance costs.

Frequently Asked Questions

1. How precise is die casting?

Die casting is known for its excellent dimensional accuracy. While dependent on the specific material being cast, a typical precision tolerance is around 0.05 mm for the first 2.5 cm (0.002 inches for the first inch) and an additional 0.025 mm for each additional 2.5 cm (0.001 inches for each additional inch). Real-time control systems are implemented to consistently achieve and even improve upon this high level of precision by minimizing process variability.

2. What are the two basic methods of die casting called?

The two primary methods of die casting are hot-chamber die casting and cold-chamber die casting. In the hot-chamber process, the injection mechanism is immersed in the molten metal bath. This method is typically used for alloys with low melting points, such as zinc and magnesium. In the cold-chamber process, molten metal is ladled into the injection system separately for each cycle, which is necessary for high-melting-point alloys like aluminum that would damage an immersed injection system.

3. What is PDC and GDC?

PDC stands for Pressure Die Casting, and GDC stands for Gravity Die Casting. In GDC, molten metal is simply poured into the mold and fills the cavity under the force of gravity. In PDC, which includes both hot- and cold-chamber methods, the molten metal is injected into the mold under high pressure. This pressure is essential for creating parts with thin walls, intricate details, and a smooth surface finish.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —