High-Pressure Die Casting (HPDC): Process & Applications

TL;DR

High-Pressure Die Casting (HPDC) is an efficient manufacturing process where molten metal is injected under immense pressure into a hardened steel mold, known as a die. This method is ideal for the high-volume production of complex, thin-walled, and precise components from non-ferrous alloys like aluminum, zinc, and magnesium. HPDC is valued for its speed, ability to produce excellent surface finishes, and its critical role in industries such as automotive and electronics.

The High-Pressure Die Casting Process: A Step-by-Step Breakdown

High-Pressure Die Casting (HPDC) transforms molten metal into a solid, near-net-shape part in a matter of seconds. The process is defined by its use of extreme force—from 1,500 to over 25,000 psi—to inject the liquid metal into a custom-made steel die. This ensures the metal fills every intricate detail of the mold cavity before it solidifies. The entire cycle is highly automated, making it a cornerstone of modern mass production.

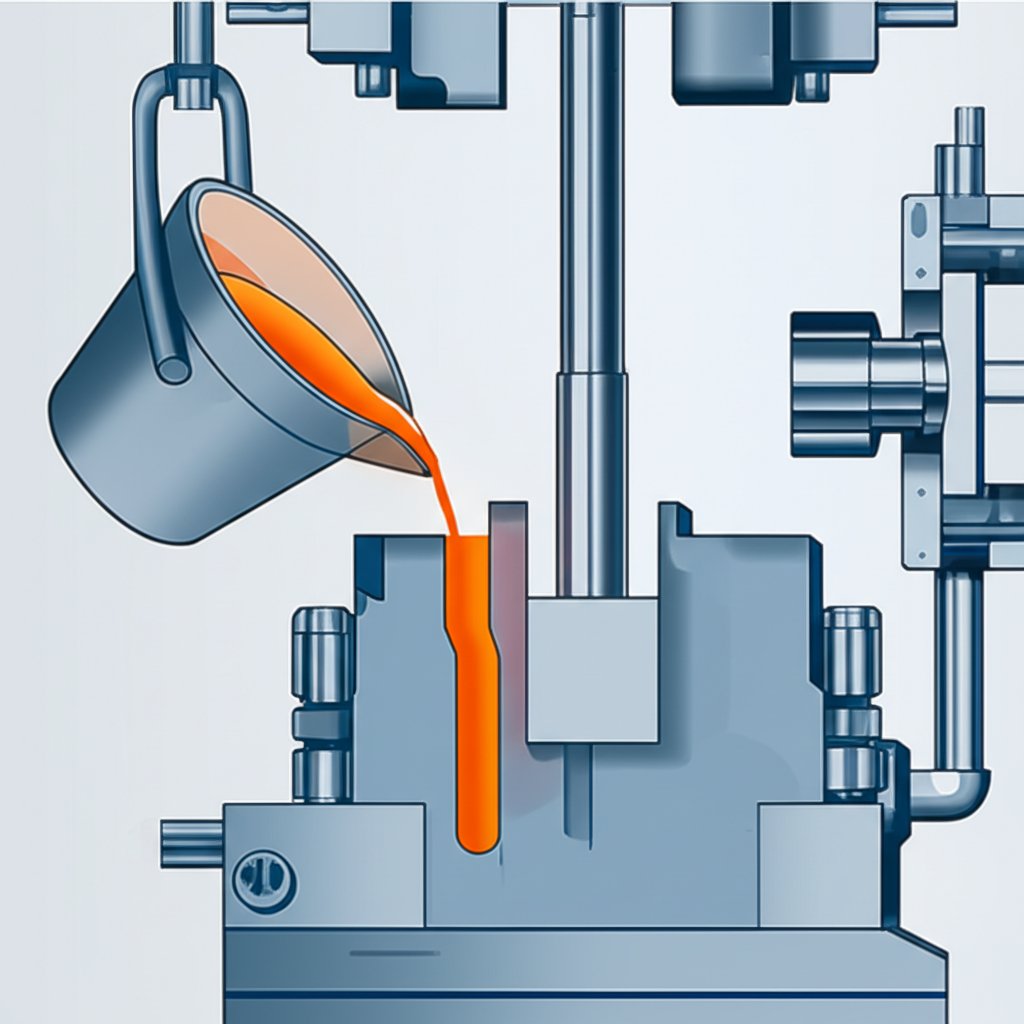

There are two primary methods used in HPDC, distinguished by how the molten metal is introduced into the machine: the hot-chamber and cold-chamber processes. The choice between them largely depends on the melting point of the alloy being used.

- Hot-Chamber Die Casting: This method is suitable for metals with lower melting points, such as zinc and magnesium alloys. In this process, the injection mechanism is submerged in the molten metal bath. This integration allows for faster cycle times because the metal has a shorter distance to travel into the die.

- Cold-Chamber Die Casting: Reserved for alloys with high melting points like aluminum, this method involves ladling the molten metal into a separate "cold chamber" or shot sleeve for each cycle. A hydraulic plunger then forces the metal into the die cavity. While slightly slower, this process prevents the high-temperature metal from damaging the injection components.

Regardless of the method, the core HPDC process follows a consistent sequence of steps to ensure quality and repeatability:

- Mold Preparation: Before injection, the two halves of the steel die are cleaned and lubricated. This coating helps regulate the die's temperature and ensures the finished part can be easily ejected without damage.

- Injection: The molten metal is forced into the sealed die cavity at extremely high speed, often filling the mold in milliseconds. This rapid injection minimizes the risk of the metal solidifying prematurely and ensures complex features are accurately formed.

- Solidification and Cooling: Once the cavity is filled, the molten metal cools and solidifies rapidly under continued pressure. The steel die acts as a heat sink, drawing thermal energy away from the casting.

- Part Ejection: After the part has solidified, the die halves are opened, and ejector pins push the casting out of the mold. This step is carefully controlled to prevent any deformation of the newly formed component.

- Trimming: The final casting often includes excess material, such as runners and flash, where the metal flowed into the die. This material is trimmed off, and the scrap is typically recycled back into the production process, improving material efficiency.

Key Advantages and Disadvantages of HPDC

High-Pressure Die Casting is a preferred manufacturing method in many industries due to its unique balance of speed, precision, and cost-effectiveness for high-volume production. However, it also comes with specific limitations that make it unsuitable for certain applications. Understanding these trade-offs is crucial for making an informed decision about its use.

The primary benefit of HPDC is its efficiency. The highly automated process allows for extremely fast production cycles, which significantly lowers the cost per part when manufacturing in large quantities. This speed, combined with the ability to produce parts with excellent dimensional accuracy and smooth surface finishes directly from the mold, often eliminates the need for costly and time-consuming secondary machining operations. Furthermore, the high injection pressure enables the creation of parts with very thin walls—sometimes less than 1mm—which is ideal for producing lightweight yet strong components.

Despite these strengths, HPDC has notable disadvantages. The most significant is the high initial tooling cost. The hardened steel dies are complex and expensive to manufacture, making the process economically unviable for low-volume production or prototyping. Another common issue is porosity. The turbulent, high-speed injection of molten metal can trap air or gas within the casting, creating tiny voids. As noted by experts at MRT Castings, this porosity can compromise the mechanical strength of the part and limits the effectiveness of heat treatments, which are often used to enhance durability.

| Advantages | Disadvantages |

|---|---|

| High Production Speed: Rapid cycle times make it ideal for mass production. | High Initial Tooling Costs: Expensive steel dies are only cost-effective for high volumes. |

| Excellent Surface Finish: Parts have smooth surfaces, reducing the need for secondary finishing. | Potential for Porosity: Trapped gas can create internal voids, weakening the part. |

| Complex Geometries & Thin Walls: Ability to produce intricate shapes and lightweight designs. | Limited Heat Treatment: Porosity restricts the ability to fully heat-treat components. |

| High Dimensional Accuracy: Produces parts with tight tolerances and excellent repeatability. | Limited to Non-Ferrous Metals: Primarily used for aluminum, zinc, and magnesium alloys. |

Common Materials and Core Industry Applications

High-Pressure Die Casting is predominantly used for non-ferrous metals, as their lower melting points are compatible with the reusable steel dies. The choice of material is dictated by the application's requirements for weight, strength, corrosion resistance, and thermal properties. The most commonly used alloys in HPDC are:

- Aluminum Alloys: Lightweight, strong, and corrosion-resistant, aluminum alloys like A380 are a top choice for the automotive and aerospace industries. They offer an excellent balance of castability and mechanical performance.

- Zinc Alloys: Known for their exceptional fluidity, zinc alloys can fill highly intricate molds with ease. They provide high dimensional stability and are ideal for producing small, precise components with a high-quality surface finish, often used in electronics and decorative hardware.

- Magnesium Alloys: As the lightest of the common structural metals, magnesium is used when minimizing weight is the top priority, such as in portable electronics and high-performance automotive parts.

The capabilities of HPDC have made it indispensable across several major industries. The automotive sector is by far the largest user, employing HPDC to manufacture everything from engine blocks and transmission housings to complex structural components. According to a report by Roland Berger, HPDC is a potential "gamechanger" for manufacturing large, single-piece automotive parts, which can replace assemblies of 70 to 100 individual components. This consolidation simplifies production, reduces costs, and improves vehicle consistency.

The automotive sector's reliance on advanced metal forming is vast. While HPDC is a game-changer for large structural components and housings, other methods like precision forging are critical for components demanding maximum strength and fatigue resistance. For instance, specialists in automotive forging parts like Shaoyi (Ningbo) Metal Technology produce robust components using hot forging processes, complementing the capabilities of casting. Other key applications for HPDC include electronics, where it's used for laptop housings and heat sinks, and the medical field, for producing surgical tools and diagnostic equipment enclosures.

HPDC vs. Low-Pressure Die Casting (LPDC)

While HPDC is known for speed and volume, it's not the only die casting method available. Low-Pressure Die Casting (LPDC) offers a different set of advantages and is chosen for applications where internal integrity is more critical than production speed. The fundamental difference lies in the pressure and velocity at which the molten metal enters the die.

HPDC uses extremely high pressures (10,000+ psi) to inject metal rapidly, which is ideal for thin-walled, complex parts and high-volume runs. In contrast, LPDC uses much lower pressures (typically under 100 psi) to gently fill the mold from below. This slower, more controlled fill minimizes turbulence, resulting in castings with significantly less porosity and higher internal soundness. This makes LPDC better suited for structural parts where mechanical strength and pressure tightness are paramount.

The trade-off is cycle time and surface finish. LPDC is a slower process, making it more appropriate for medium-volume production. Additionally, the surface finish of LPDC parts is generally not as smooth as that achieved with HPDC. The choice between the two processes ultimately depends on the specific requirements of the component being manufactured.

| Feature | High-Pressure Die Casting (HPDC) | Low-Pressure Die Casting (LPDC) |

|---|---|---|

| Injection Pressure | Very High (1,500 - 25,000+ PSI) | Low (2 - 22 PSI) |

| Production Volume | High | Medium |

| Cycle Time | Very Fast (seconds) | Slower (minutes) |

| Internal Quality (Porosity) | Prone to porosity due to turbulence | High integrity, minimal porosity |

| Surface Finish | Excellent | Average to Good |

| Best For | Complex, thin-walled cosmetic parts | Structural parts requiring high integrity |

Frequently Asked Questions About HPDC

1. What is the difference between HPDC and LPDC?

The primary difference is pressure and speed. HPDC uses very high pressure for rapid injection, making it ideal for high-volume production of parts with thin walls and excellent surface finish, though it can lead to porosity. LPDC uses low pressure for a slower, controlled fill, resulting in parts with higher internal integrity and less porosity, making it suitable for medium-volume structural components.

2. What are the disadvantages of HPDC?

The main disadvantages of HPDC include high initial tooling costs, making it unsuitable for small production runs. The process is also prone to porosity, where trapped gases create small voids in the casting, which can weaken the part and limit the effectiveness of subsequent heat treatments. Additionally, it is only suitable for non-ferrous metals like aluminum, zinc, and magnesium.

3. What is a pressure die casting?

Pressure die casting is a manufacturing process where molten metal is forced into a mold cavity under pressure. This category includes both high-pressure and low-pressure die casting. The use of pressure allows for the production of parts with greater detail, better surface finish, and higher dimensional accuracy compared to gravity-fed casting methods.

4. What are the two types of die casting?

The two main types of die casting processes are hot-chamber and cold-chamber die casting. Hot-chamber casting is used for metals with low melting points (like zinc) and has a faster cycle time. Cold-chamber casting is used for metals with high melting points (like aluminum) to prevent damage to the machine's injection components.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —