Precision Die Casting for Transmission Housings: A Technical Overview

TL;DR

Die casting for transmission housings is a high-pressure manufacturing process critical to the automotive industry. It uses specific aluminum alloys, such as A380 and ADC12, to create precise, lightweight, and structurally robust components. This method achieves significant weight reduction compared to traditional materials like cast iron, while ensuring the high performance, thermal management, and durability required for modern vehicle powertrains.

The High-Pressure Die Casting Process Explained

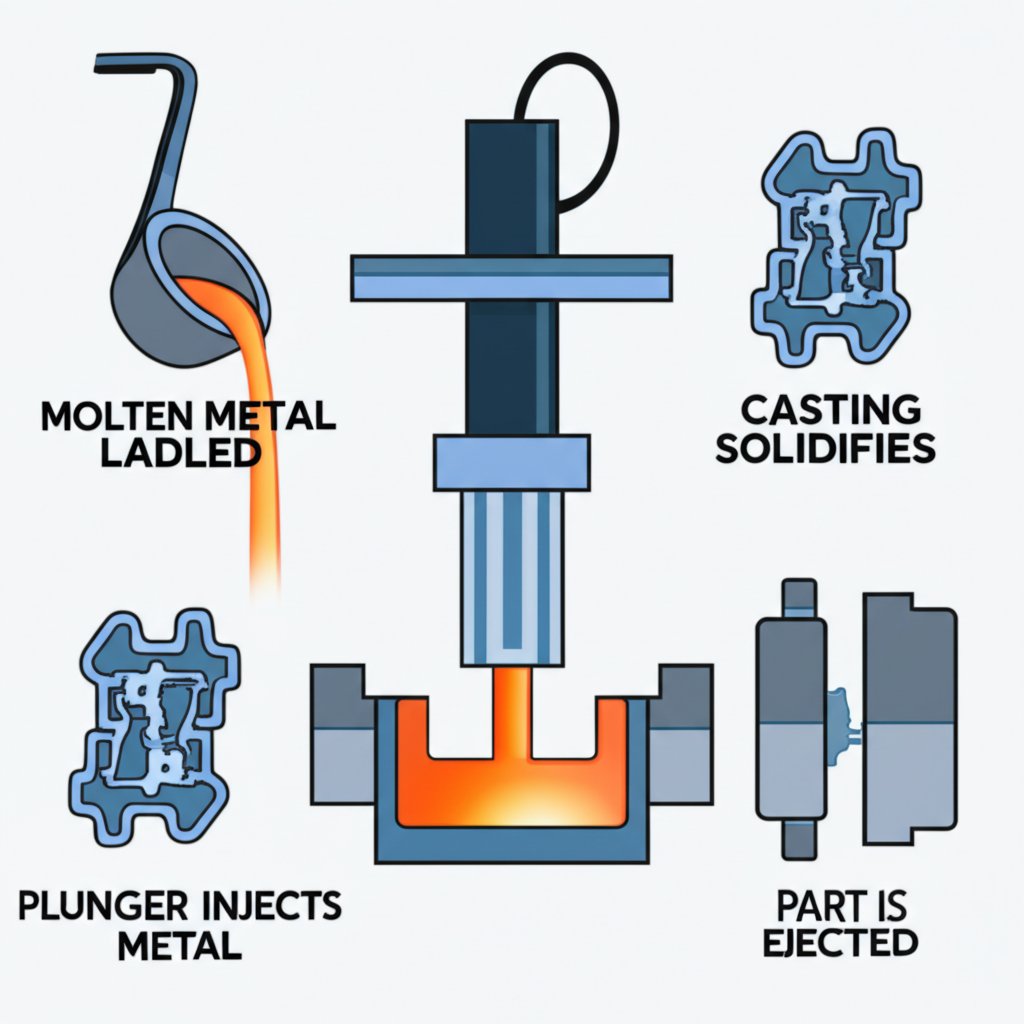

High-pressure die casting is a sophisticated manufacturing technique where molten metal is injected into a steel mold, known as a die, under significant force. This process is ideal for producing the complex geometries of a transmission housing with exceptional speed and precision. The solidified part, or casting, is then ejected, trimmed, and finished. This method is highly valued for its ability to create net-shape or near-net-shape parts, minimizing the need for extensive secondary machining and reducing overall production costs for high-volume runs.

The process can be broadly categorized into two types: hot-chamber and cold-chamber die casting. For aluminum transmission housings, the cold-chamber process is used. In this method, a precise amount of molten aluminum is ladled from a separate furnace into a "cold" shot chamber before being forced into the die by a hydraulic plunger. This separation prevents the molten aluminum from being in constant contact with the injection mechanism, which is crucial for handling metals with higher melting points like aluminum and preventing equipment corrosion.

The production cycle for a transmission housing follows several key stages:

- Die Preparation: The two halves of the steel die are cleaned and lubricated to facilitate part ejection and extend the tool's life.

- Injection: Molten aluminum alloy is injected into the die cavity at high speed and pressure, ensuring the metal fills every intricate detail of the complex housing design.

- Solidification: The metal cools and solidifies rapidly within the water-cooled die. This quick cycle time is a major advantage of die casting.

- Ejection: Once solidified, the die halves open, and the casting is pushed out by ejector pins.

- Finishing: The casting is then moved to a trimming station where excess material (flash, runners, gates) is removed. Subsequent operations may include abrasive blasting, machining of critical surfaces, and cleaning.

However, producing components as complex as transmission valve bodies is considered one of the most difficult challenges in aluminum die casting. These parts require intricate dies with fragile, interlocking components. To ensure the highest quality and minimize defects like porosity, advanced techniques are essential. Manufacturers utilize sophisticated simulation software to optimize metal flow and employ vacuum-assisted systems to remove trapped air from the die cavity, resulting in denser, stronger, and more reliable castings. For more information on complex components, Blue Ridge Pressure Castings provides detailed insights into manufacturing valve bodies and stators.

Critical Material Selection: Aluminum Alloys for Performance

The choice of aluminum alloy is a critical decision that directly impacts the performance, durability, and cost-effectiveness of a die cast transmission housing. Aluminum is the material of choice due to its excellent strength-to-weight ratio, thermal conductivity, and corrosion resistance. Different alloys offer unique properties tailored to specific performance requirements, from withstanding high torque loads to ensuring pressure tightness in hydraulic systems.

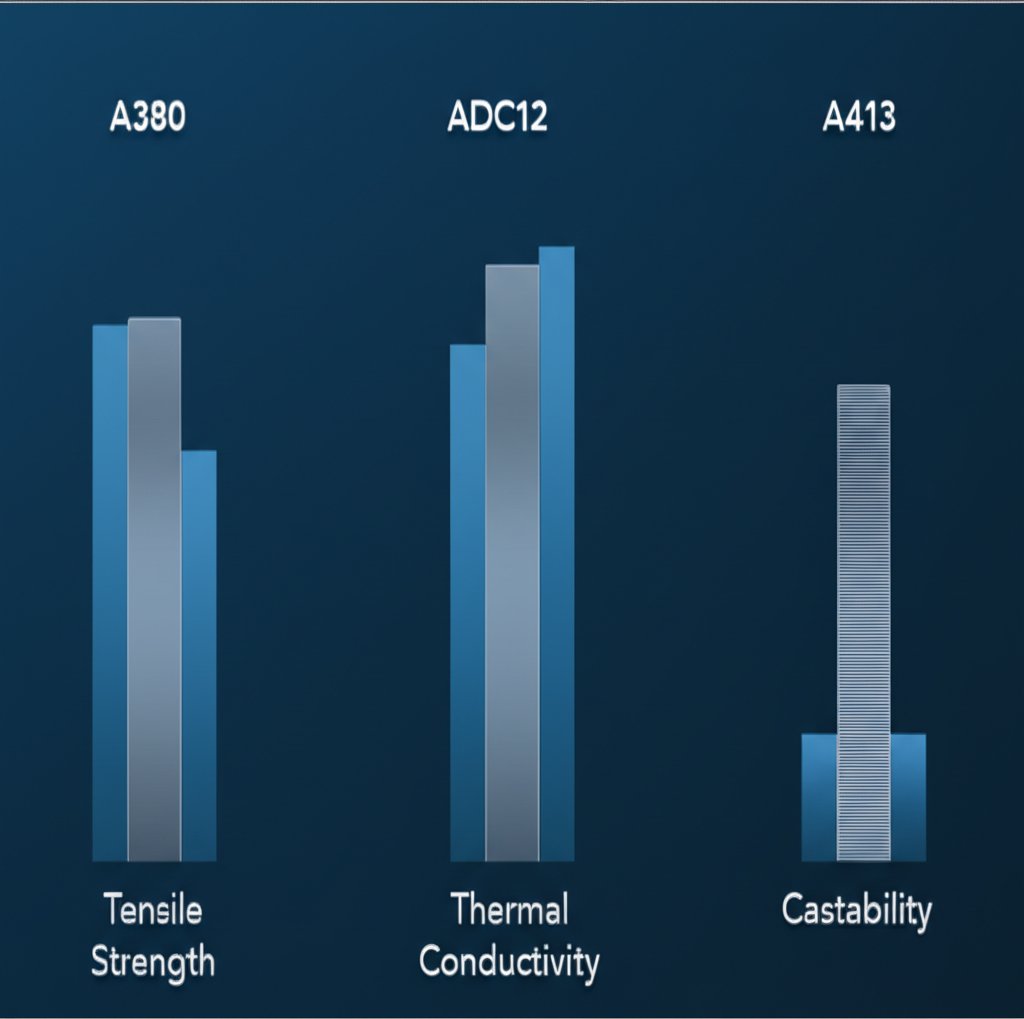

The selection process involves balancing mechanical properties, castability, and application-specific needs. For example, alloys with higher silicon content offer better fluidity, making them suitable for filling thin-walled, intricate sections of a housing. In contrast, alloys with higher copper content provide enhanced strength and wear resistance. According to an analysis by Autocast Inc., several alloys are commonly used for automotive applications, each with distinct advantages.

Here is a comparison of common aluminum alloys used for die casting transmission housings:

| Alloy Designation | Key Characteristics | Primary Applications in Transmissions |

|---|---|---|

| A380 | Excellent balance of castability, mechanical properties, and thermal conductivity. Good dimensional stability. | General transmission cases, engine brackets, and structural components. |

| ADC12 | Exceptional castability and high fluidity. Good strength and impact resistance. | Complex transmission cases and parts requiring high wear resistance. |

| A413 | Superior pressure tightness and fluidity due to high silicon content. Good corrosion resistance. | Intricate, thin-walled components, housings, and parts requiring leak-proof performance. |

| AlSi9Cu3(Fe) | A common European alloy known for its good casting properties and mechanical strength. | Used by major automotive suppliers like GF Casting Solutions for transmission housings. |

Ultimately, the right alloy depends on the specific demands of the powertrain. Engineers must consider factors like operating temperature, mechanical stress, exposure to corrosive fluids, and machining requirements to make an informed decision that ensures the final product meets stringent automotive standards for performance and reliability.

Key Benefits of Die Casting for Transmission Housings

Employing high-pressure die casting for transmission housings offers a host of engineering and economic advantages that are crucial for the competitive automotive market. This manufacturing method is not just about creating a part; it's about optimizing performance, reducing weight, and enabling innovative designs that would be difficult or cost-prohibitive to achieve with other methods.

The primary benefits include:

- Significant Weight Reduction: Aluminum die cast housings can achieve up to a 40% weight reduction compared to traditional cast iron components. This lightweighting is critical for improving vehicle fuel efficiency and handling dynamics.

- Design Complexity and Consolidation: The process allows for the creation of intricate, complex shapes with thin walls. This enables engineers to integrate features like cooling channels, mounting bosses, and stiffening ribs directly into the casting, reducing the need for separate parts and subsequent assembly operations.

- High Precision and Consistency: Die casting delivers exceptional dimensional accuracy and part-to-part consistency. Top manufacturers can achieve tolerances as tight as ±0.05mm, ensuring a precise fit for internal components like gears and bearings.

- Excellent Thermal Management: Aluminum alloys possess high thermal conductivity (around 150 W/m·K), which allows them to efficiently dissipate heat generated by the transmission. This helps maintain optimal operating temperatures, improves lubricant life, and enhances overall powertrain reliability.

- Superior Surface Finish: The process produces a smooth surface finish (often Ra ≤1.6µm), which can reduce or eliminate the need for secondary finishing operations on non-critical surfaces.

When comparing die casting to other manufacturing methods, particularly CNC machining, the key difference lies in scalability and cost per part. While CNC machining offers high precision and is ideal for prototyping or low-volume production, die casting is far more cost-effective for large production runs. The initial investment in tooling for die casting is high, but the low per-part cost and rapid cycle times deliver significant savings at scale.

Achieving Quality: Technical Specifications and Inspection

For a critical component like a transmission housing, quality is non-negotiable. These parts must withstand extreme temperatures, high torque loads, and constant vibration without failure. Therefore, a robust quality control process is essential throughout the die casting manufacturing cycle, from initial design to final inspection. Leading manufacturers adhere to stringent standards to ensure every housing meets exacting specifications.

A key challenge in aluminum die casting is managing porosity, which are tiny voids or gas bubbles trapped within the metal as it solidifies. Excessive porosity can compromise the structural integrity and pressure tightness of the housing. To combat this, manufacturers use advanced techniques like vacuum-assisted casting to evacuate air from the mold cavity before injection. Furthermore, sophisticated die design and thermal analysis help ensure a controlled, directional solidification of the metal, pushing any remaining porosity to non-critical areas.

The manufacturing process for a complete transmission involves more than just the housing. While die casting is ideal for the complex shape of the housing, other high-stress internal components often require different specialized processes. For instance, many gears and shafts rely on high-strength forging to achieve the necessary durability and fatigue resistance. Companies focused on automotive forging parts, such as Shaoyi (Ningbo) Metal Technology, provide these critical internal components, demonstrating how a combination of advanced manufacturing techniques is needed to build a modern powertrain.

To verify that each finished housing meets specifications, a multi-stage inspection process is employed:

- Dimensional Inspection: Coordinate Measuring Machines (CMM) are used to verify that all critical dimensions, such as bearing bores and mounting surfaces, are within the specified tight tolerances (e.g., ±0.05mm).

- Structural Integrity Testing: Non-destructive methods like X-ray inspection are used to detect internal defects such as porosity, ensuring the casting is solid and free of hidden flaws. Some suppliers aim for porosity levels below 0.1%.

- Leak Testing: Housings are often subjected to pressure tests to guarantee they are perfectly sealed, which is vital for containing transmission fluid.

- Material Analysis: Spectrometers are used to confirm the chemical composition of the aluminum alloy, ensuring it meets the required grade.

Finally, a key indicator of a supplier's commitment to quality is certification to automotive industry standards. An IATF 16949 certification, mentioned by suppliers like EMP Tech, demonstrates that the manufacturer has implemented a rigorous quality management system designed to meet the demanding requirements of the automotive sector.

Frequently Asked Questions

1. What alloy should be used for a die cast of a transmission housing?

The most common aluminum alloys for transmission housings are A380 and ADC12. A380 offers a great all-around balance of strength, castability, and thermal properties. ADC12 is known for its excellent fluidity, making it suitable for very complex parts. Other alloys like A413 are used for components requiring superior pressure tightness.

2. Is die casting cheaper than CNC?

For large production volumes, die casting is significantly cheaper per part than CNC machining. Although the initial tooling (the die) is expensive, the high speed of the process and low material waste lead to lower unit costs. CNC is more cost-effective for prototypes and small production runs where tooling costs would be prohibitive.

3. What are the two types of die casting?

The two main types of die casting are hot-chamber and cold-chamber. Hot-chamber is used for metals with low melting points (like zinc), where the injection mechanism is submerged in the molten metal. Cold-chamber is used for metals with high melting points (like aluminum), where the molten metal is ladled into a shot chamber for each cycle, protecting the machinery.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —